文章编号:1004-0609(2015)-07-1839-07

高体积分数MWCNTs/AZ80复合材料的显微组织

徐卫平1,李蒙江1, 2,柯黎明1,邢 丽1

(1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. 中国航空工业昌河飞机工业有限责任公司 55车间,景德镇 333000)

摘 要:采用搅拌摩擦加工技术制备体积分数为19.5%的多壁碳纳米管(MWCNTs)增强AZ80镁基复合材料,研究经多道次搅拌摩擦加工(FSP)加工后复合材料的显微组织和MWCNTs在基体中的分布和稳定性,分析MWCNTs与基体的界面结构特征。结果表明:多道次FSP能提高MWCNTs在基体中的分散性,并在基体中形成了纳米晶,晶体尺寸仅5 nm左右。经多道次FSP后,MWCNTs在径向上的多壁结构未受到机械损伤,但经7道次加工后,在复合材料中发现有少量Al4C3相;碳纳米管与镁基体以半共格的界面形式相接。

关键词:搅拌摩擦加工;多壁碳纳米管;镁基复合材料;显微组织

中图分类号:TB331 文献标志码:A

Microstructure of high volume fraction MWCNTs/AZ80 composites

XU Wei-ping1, LI Meng-jiang1, 2, KE Li-ming1, XING Li1

(1. School of Aeronautical Manufacturing and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. 55 Workshop, China Aviation Industry Changhe Aircraft Industry Co., Ltd, Jingdezhen 333000, China)

Abstract: The multi-walled carbon nanotubes(MWCNTs) with volume fraction of 19.5% reinforced AZ80 magnesium matrix composites were prepared by friction stir processing(FSP). The microstructures of the composites were investigated. The distribution and stability of MWCNTs in the composites were investigated. The structural feature of the interface between MWCNTs and matrix was analyzed. The results show that the stability of MWCNTs in matrix is enhanced by multi-pass FSP. The nanocrystals with size of about 5 nm form in the composites. The multi-walled structures of MWCNTs along the diameter direction are not damaged by multi-pass FSP. There are a few Al4C3 phase in the composites after 7 passes by FSP. MWCNTs and magnesium matrix are joined in the form of semi-coherent interface.

Key words: friction stir processing; multi-walled carbon nanotube; magnesium matrix composite; microstructure

多壁碳纳米管(Multi-walled carbon nanotubes,MWCNTs)具有长径比大、密度低、热稳定性高及强度和刚度高等独特的物理性能[1-4]和力学性能[3-6],被广泛应用于各种材料的增强试验中。镁合金具有密度低、比强度和比刚度高等优异的特性[7],尤其是其密度仅为1.8×103 g/cm3左右,是当今最轻的金属结构材料[8],以镁合金为基体、MWCNTs为增强体制备的镁基复合材料在航天航空及汽车等结构件上拥有巨大的应用潜力[9-12]。

目前,已开展的关于MWCNTs增强镁基复合材料的研究主要集中在复合材料的制备工艺及性能测定等方面,所制备的复合材料的MWCNTs体积分数不高于10%,未能充分发挥碳纳米管和镁合金固有的轻质高强特性。MORISADA等[13]利用FSP法并采用在试板上开槽的方式制备了成形良好的MWCNTs/AZ31复合材料,且MWCNTs分布均匀,显微硬度较母材有显著的提高。MORISADA等[13]还采用了开槽法制备复合材料,开槽的槽宽为1 mm、槽深为2 mm,但采用这样的凹槽尺寸只能用于材料的表面改性,无法获得大体积的复合材料。

为此,本文作者在MORISADA等[13]研究的基础上采用大尺寸凹槽添加MWCNTs粉末,运用FSP技术制备了体积分数为19.5%的MWCNTs/Mg复合材料,用以降低复合材料的密度,并在此基础上研究了经不同道次加工后复合材料的显微组织及MWCNTs与基体的界面结构特征,为大体积块体复合材料的制备提供一定的实践与理论依据。

1 实验

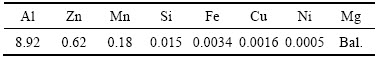

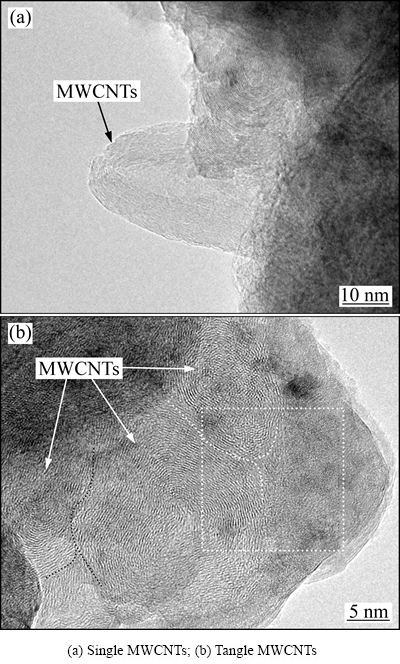

以T6态AZ80变形镁合金为基体材料,其主要化学成分如表1所列,以MWCNTs为增强体,其外径为20~50 nm、长度为5~20 μm。图1所示为透射电镜下MWCNTs的原始形貌。

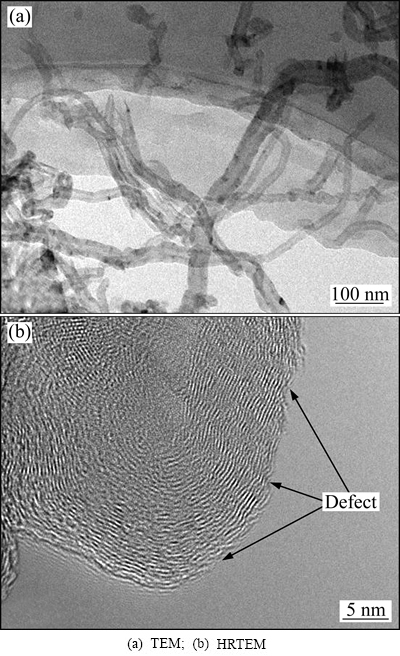

表1 AZ80镁合金的化学成分

Table 1 Chemical composition of AZ80 magnesium alloy (mass fraction,%)

图1 MWCNTs的原始形貌

Fig. 1 Original morphologies of MWCNTs

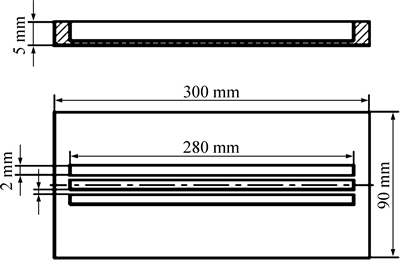

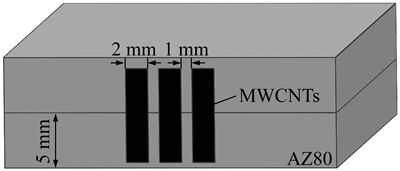

试验在自制的FSP设备上进行。截取两块尺寸为300 mm×90 mm×5 mm的试板,在试板中心开槽,上板槽深为4 mm,下板槽深为4.5 mm,槽长均为280 mm,如图2 所示, MWCNTs的添加方式如图3所示。搅拌针为左旋粗牙螺纹,大径12 mm,长度7.5 mm,轴肩直径为30 mm。沿垂直于复合材料加工方向截取横截面并制备成金相试样,在4XB-TV型倒置光学显微镜上进行金相组织观察。在FEI Tecnai G2 F30型场发射透射电子显微镜上进行透射电镜分析,加速电压为50~300 kV,点分辨率≤0.2 nm,线分辨率≤0.102 nm,最小束斑≤0.3 nm。

图2 试板开槽尺寸

Fig. 2 Slot size of test plate (Unit: mm)

图3 MWCNTs添加方式的示意图

Fig. 3 Schematic diagram of MWCNTs adding method

2 结果与讨论

2.1 复合材料的晶粒尺寸

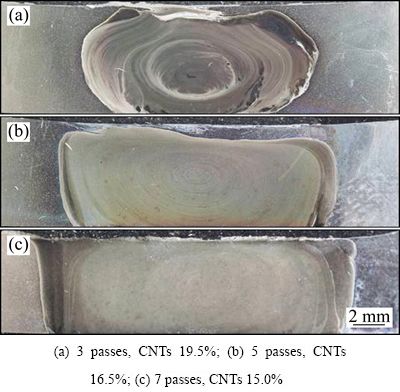

图4所示为经3、5、7道次FSP后复合材料的横截面宏观形貌。用Image-plus软件测试并计算得所制备的复合材料中MWCNTs体积分数分别为19.5%、16.5%和15.0%。由图4可见,随着加工道次的增加,复合区面积依次增大,MWCNTs体积分数随之减小,搅拌区组织逐渐均匀。

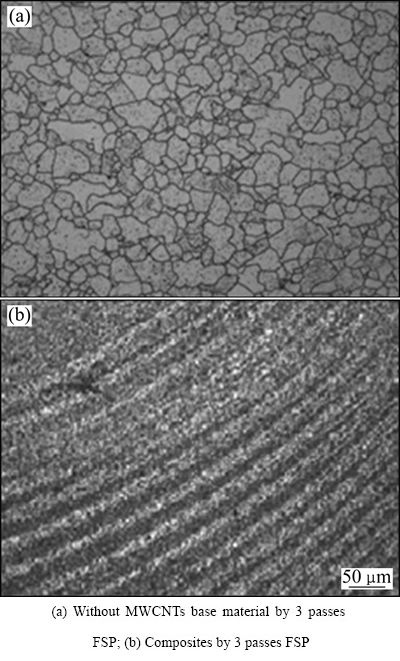

图5(a)所示为未添加MWCNTs 3道次FSP母材的显微组织形貌。由图5(a)可见,组织是较大晶粒和细小的动态再结晶晶粒混合组成,且分布不均匀。图5(b)所示为添加了MWCNTs 3道次FSP复合材料中心区形貌。由图5(b)可见,在同样的观察倍数下,无法看清晶粒的形貌,结合后面的分析可知,由于大量MWCNTs弥散分布于基体中阻碍了晶粒的生长,从而形成了更为细小的纳米晶。

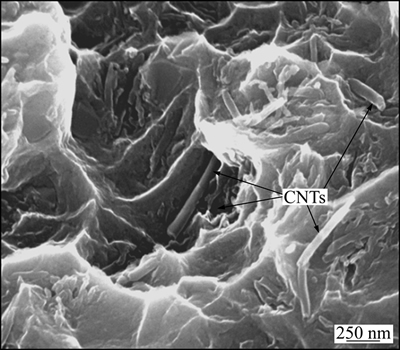

图6所示为经7道次FSP后复合材料的断口表面形貌。由图6可见,在复合材料的韧窝内和撕裂棱上存在MWCNTs的拔出或拔断的现象(见图6中箭头),经7道次加工后,MWCNTs与基体混合充分,MWCNTs在基体中的分散性均匀,其复合材料中的MWCNTs与基体界面结合最为紧密。

图4 复合材料横截面宏观形貌

Fig. 4 Cross-section macroscopic morphologies of composites

图5 母材和复合材料中心区形貌

Fig. 5 Morphologies of base material and composites in center area

图6 经7道次FSP后复合材料的断口表面形貌

Fig. 6 Fracture surface morphology of composites by 7 passes FSP

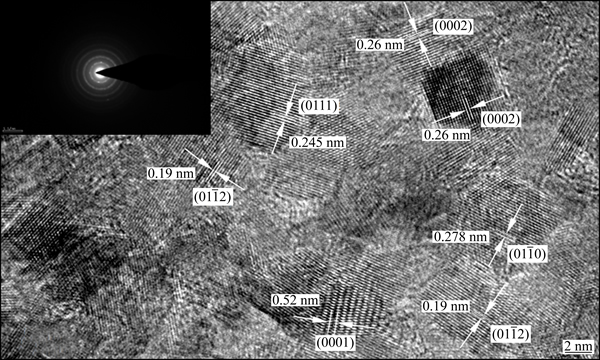

由于在光学显微镜下无法观察到复合材料的晶粒尺寸以及有代表性的组织结构,因此,取横截面中心位置的复合材料在TEM下进行显微组织观察。图7所示为经7道次加工后复合材料的HRTEM像。从衍射图像可知,组织为多晶结构。由图7可见,该区域分布着大量取向不同的晶体结构,且这些晶体结构的取向差较大(大于15°),为大角度晶界;对其进行标定后可以断定其为基体中的晶粒,且晶粒取向分明,晶界轮廓清晰。这里值得一提的是,这些晶粒的大小仅为5 nm左右,这个尺寸在金属基复合材料中是极为细小的。这是由于复合材料中MWCNTs的体积分数比以往报道过的都高,且在搅拌摩擦加工过程中,搅拌头的剧烈搅拌作用使基体中的晶粒破碎并发生动态再结晶。此时,由于大量MWCNTs被弥散分布于基体中,其钉扎作用有效地阻碍了晶粒边界的生长,极大地限制了晶粒尺寸的增大,所制备的复合材料的晶粒尺寸仅为5 nm的超细纳米晶粒,这说明FSP可以成为制备纳米材料的一种可能的工艺。

2.2 碳纳米管的分散性和稳定性

图8所示为经5道次FSP后分布在基体中的MWCNTs。IEADI等[14]发现经多道次FSP后,MWCNTs会受到一定程度的损伤,其多壁结构转变为具有球型外壳的碳结构。图8 (a)所示为单根MWCNTs穿插在镁基体中,MWCNTs端头及侧身的多壁结构清晰可见,且保持完好。这说明经5道次FSP后,MWCNTs在径向上的多壁结构并未受到机械损伤,能够稳定地存在于基体中。图8(b)所示为相互缠结在基体中的MWCNTs,其形成原因主要有以下两个方面:一方面,由于原始态的MWCNTs纯度只有98%,其中2%的杂质包括非晶碳、无定性碳、碳纳米粒子和催化剂粒子等。这些杂质粒子的存在,容易引起MWCNTs的团聚,使碳纳米管不易分散;另一方面,由于添加的MWCNTs体积分数较高,在FSP过程中MWCNTs未能得到充分分散,这在搅拌摩擦加工过程中是无法避免的。此外,从图8 (b)中可见,MWCNTs在长度方向上垂直纸面排列,其结构为界面分明且完整的多壁结构,由此证明MWCNTs在微区内具有一定的定向排列,这能够提高CNTs对基体的强化作用。

图7 经7道次加工后复合材料的HRTEM像

Fig. 7 HRTEM image of composites by 7 passes FSP (inset is corresponding SAED pattern)

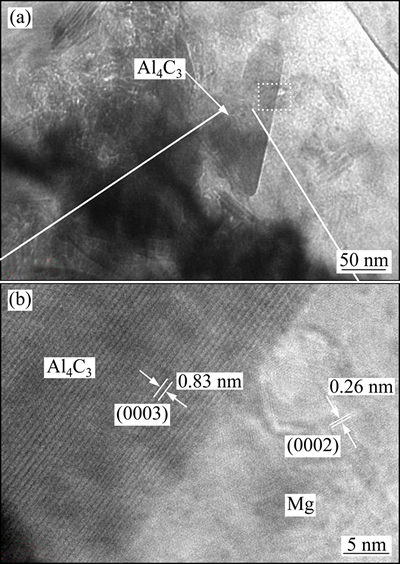

图9所示为经7道次FSP后复合材料的HRTEM像。从图9 (a)中可见,在基体中穿插着一根直径与MWCNTs直径相仿但长度相差甚远的“棒状”相,为了确定该相是否为MWCNTs,对其微区进行了放大,如图9(b)所示。图9(b)中左侧晶格条纹呈现平行排列,这与高分辨透射电镜下MWCNTs逐层卷曲排列的结构不符,由于MWCNTs在侧壁方向不会受到机械损伤.因此,可以断定该直纹相不是MWCNTs。通过测量图中直条纹间的原子间距可知,图9(b)中左侧晶面间距为0.83 nm,晶面指数为(0 0 0 3),成分为Al4C3化合物;右侧晶面间距为0.26 nm,晶面指数为(0 0 0 2),成分为基体镁。在整个界面区域没发现非晶层的存在,Al4C3相与镁基体之间为直接原子结合,且两相之间的界面光滑、平直,在二者的界面处没有发现其它杂质相。

图8 经5道次FSP后复合材料中MWCNTs的HRTEM像

Fig. 8 HRTEM images of MWCNTs in composites by 5 passes FSP

分析Al4C3相形成原因主要有以下两个方面:一方面,由于AZ80基体中含有8.92%(质量分数)的铝元素,经7道次加工后,复合材料内部具有很高的热输入量,达到了C-Al反应开动的临界温度(500 ℃),使得MWCNTs和铝发生了界面反应。另一方面,试验选用的商用MWCNTs是用化学气相沉积法生产的碳纳米管,由于该方法制备的碳纳米管并非完美的石墨烯低能面曲卷而成的碳纳米管,相比电弧放电方法生成的碳纳米管在外壁上存在更多的缺陷,如图1(b)箭头所示。这就意味着对于化学气相沉积法制备的碳纳米管将有更多的缺陷暴露在Al元素中,同时,在化学气相沉积法生产的碳纳米管上存在一些无定性碳、非晶碳和碳纳米粒子等杂质,在FSP制备复合材料的过程中,易与基体中的Al发生化学反应,促进Al4C3相的生成。此外,经7道次加工后,由于受到剧烈的机械搅拌作用,MWCNTs在长度方向受到严重的损伤,长径比大幅减小,MWCNTs端头由原始的封闭状态(见图1(b))转变为开口状态,使MWCNTs与Al在内外壁上均能发生反应,加剧了Al4C3相的形成。因此,当温度达到一定程度时,碳壁缺陷处碳原子的能量较高,扩散激活能降低,在高温和机械搅拌的双重作用下,使得Al原子不断扩散进入MWCNTs的石墨烯碳壁结构并与其逐层反应生成Al4C3相,如图9(b)所示。据CI等[15]报道,Al4C3相能够改善界面结合强度,而在基体中少量的Al4C3相存在能够起到强化基体的作用。

图9 经7道次FSP后复合材料的TEM像和HRTEM像

Fig. 9 TEM (a) and HRTEM (b) images of composites by 7 passes FSP

2.3 碳纳米管与基体的界面结构特征

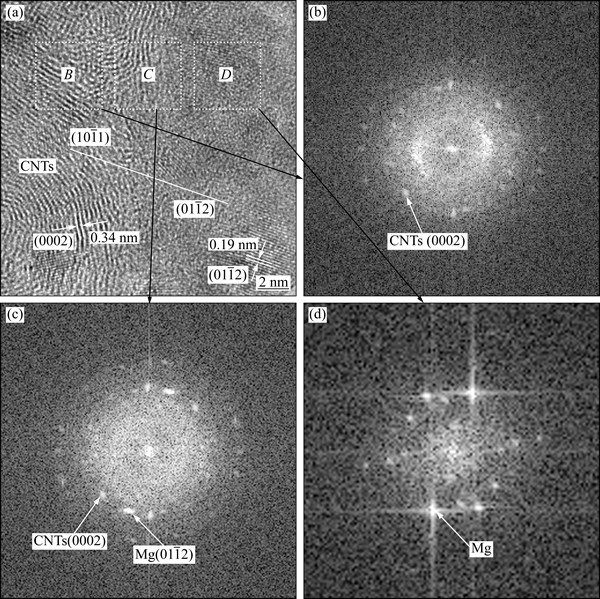

图10(a)所示为图8(b)方框中MWCNTs与镁基体界面处的HRTEM像。由于MWCNTs与Mg很难同时满足晶体衍射条件,因此,MWCNTs-Mg界面处的晶格条纹不清淅。由图10(a)可见,左侧面间距为0.34 nm,成分为MWCNTs,并非其它碳的结构或其它物质;而右侧面间距为0.190 nm,为Mg( )的面间距。两相界面基本上是直接原子结合,界面结合较为紧密,部分镁基体已扩散进MWCNTs内部。为了确定两者之间是否存在位向关系,分别在MWCNTs、镁基体和两者的界面处进行傅里叶变换,其结果如图10(b)~(d)所示。由傅里叶变换可知,MWCNTs与镁基体之间存在位向关系,位向关系如式(1)所示。镁(

)的面间距。两相界面基本上是直接原子结合,界面结合较为紧密,部分镁基体已扩散进MWCNTs内部。为了确定两者之间是否存在位向关系,分别在MWCNTs、镁基体和两者的界面处进行傅里叶变换,其结果如图10(b)~(d)所示。由傅里叶变换可知,MWCNTs与镁基体之间存在位向关系,位向关系如式(1)所示。镁( )晶面的面间距为0.190 nm,MWCNTs中(

)晶面的面间距为0.190 nm,MWCNTs中( )晶面的面间距为0.203 nm,通过式(2)计算可知[16],两者点阵错配度为16.5%,错配度较大,为半共格相界。因此,为了缓解镁基体与MWCNTs之间的晶格错配,在镁基体与MWCNTs之间的界面处,镁基体的晶面间距将发生变化。

)晶面的面间距为0.203 nm,通过式(2)计算可知[16],两者点阵错配度为16.5%,错配度较大,为半共格相界。因此,为了缓解镁基体与MWCNTs之间的晶格错配,在镁基体与MWCNTs之间的界面处,镁基体的晶面间距将发生变化。

(1)

(1)

(2)

(2)

式中:δ为晶格错配度;am为镁的晶格常数;ac为碳纳米管的晶格常数。

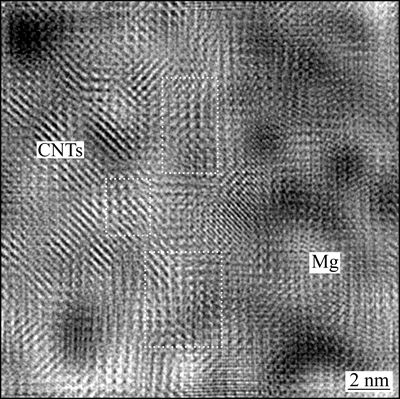

图11所示为图10(a)的傅里叶逆变换图像,由图11可以清楚地观察到,在虚线框区域内,MWCNTs与镁基体界面处的原子为直接结合,错配度较小,两者界面为半共格晶面,而在其他区域为非共格晶面,总体上呈现半共格相界,界面结合较为紧密。

3 结论

1) 运用FSP技术可制备MWCNTs体积分数高达19.5%的镁基复合材料,晶粒尺寸仅为5 nm左右。

2) 经5道次FSP后,MWCNTs在径向上的多壁结构没有受到机械损伤,能够稳定地存在于基体中;经7道次FSP后,MWCNTs在长度方向发生断裂,其长度大幅减小,并有少量断裂的MWCNTs与基体中的Al反应生成Al4C3化合物。

图10 MWCNTs-Mg界面的HRTEM像和傅里叶变换像

Fig. 10 HRTEM image of MWCNTs-Mg interface in Fig. 8(b) (a) and Fourier transform image of area B, C and D in Fig. 10(a), (b), (c), (d)

图11 图10(a)的傅里叶逆变换

Fig. 11 Inverse Fourier transform of Fig. 10(a)

3) 碳纳米管与镁基体之间存在位向关系: ,两者以半共格的界面形式相接,界面结合稳定。

,两者以半共格的界面形式相接,界面结合稳定。

REFERENCES

[1] INAGAKI M. The formation of carbon nanotubes[J]. Carbon, 2012, 50(10): 3966.

[2] DUONG B, GANGOPADHYAY P, SERAPHIN S, THOMAS J. Multiwall carbon nanotubes grown by thermocatalytic carbonization of polyacrylonitrile[J]. Carbon, 2012, 50(12): 4754-4757.

[3] THOSTENSON E T, REN Zhi-feng, CHOU Tsu-wei. Advances in the science and technology of carbon nanotubes and their composites: A review[J]. Composites Science and Technology, 2001, 61(13): 1899-1912.

[4] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354(6348): 56-58.

[5] SRIVASTAVA D, WEI Chen-yu, CHO Kyeongjae. Nanomechanics of carbon nanotubes and composites[J]. Applied Mechanics Reviews, 2003, 56(2): 215-230.

[6] LI Chun-yu, CHOU Tsu-wei. Elastic moduli of multi-walled carbon nanotubes and the effect of van der Waals forces[J]. Composites Science and Technology, 2003, 63(11): 1517-1524.

[7] LIMA D K, SHIBAYANAGIB T, GERLICH A P. Synthesis of multi-walled CNT reinforced aluminum alloy composite via friction stir processing[J]. Materials Science and Engineering A, 2009, 507(1/2): 194-199.

[8] 王立军. 航空工程材料与成形工艺基础[M]. 北京: 北京航空航天大学出版社, 2010.

WANG Li-jun. Aeronautical engineering material and forming technology[M]. Beijing: Beijing University of Aeronautics and Astronautics Press, 2010.

[9] DIERINGA H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review[J]. Journal of Materials Science, 2011, 46(2): 289-306.

[10] HIROYUKI F, JERZY A S, KATSUYOSHI K, RICHARD C. The influence of carbon nanotubes on the corrosion behaviour of AZ31B magnesium alloy[J]. Corrosion Science, 2010, 52(12): 3917-3923.

[11] LI Qi-zhen, TIAN Bing. Compression behavior ofmagnesium/ carbonnanotubecomposites[J]. Journal of Materials Research, 2013, 28(14): 1877-1884.

[12] RASHAD M, PAN F S, TANG A, ASIF M, AAMIR M. Synergetic effect of graphene nanoplatelets (GNPs) and multi-walled carbon nanotube (MW-CNTs) on mechanical properties of pure magnesium[J]. Journal of Alloys and Compounds, 2014, 603: 111-118.

[13] MORISADA Y, FUJII H, NAGAOKA T, FUKUSUMI M. MWCNTs/AZ31 surface composites fabricated by friction stir processing[J]. Materials Science and Engineering A, 2006, 419(1/2): 344-348.

[14] IZADI H, GERLICH A P. Distribution and stability of carbon nanotubes during multi-pass friction stir processing of carbon nanotube/aluminum composites[J]. Carbon, 2012, 50(12): 4744-4749.

[15] CI Li-jie, RYU Zhen-yu, JIN-PHILLIPP Neng Yun, R HLE Manfred. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum[J]. Acta Materialia, 2006, 54(20): 5367-5375.

HLE Manfred. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum[J]. Acta Materialia, 2006, 54(20): 5367-5375.

[16] 何菊生, 张萌肖, 祁 陵. 半导体外延层晶格失配度的计算[J]. 南昌大学学报(理科版), 2006, 30(1): 63-67, 102.

HE Ju-sheng, ZHANG Meng-xiao, QI Ling. Calculation of the lattice mismatch between semiconductor epitaxy and substrate[J]. Journal of Nanchang University (Natural Science), 2006, 30(1): 63-67, 102.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51364037);航空科学基金资助项目(20140956003)

收稿日期:2014-10-27;修订日期:2015-05-04

通信作者:徐卫平,副教授;电话:18070026937;E-mail:xuweiping1203@126.com