Al2O3/WC-10Co/ZrO2/Ni金属陶瓷的微波烧结

史晓亮,杨 华,邵刚勤,段兴龙,熊 震

(武汉理工大学 材料复合新技术国家重点实验室,湖北 武汉,430070)

摘 要:以纳米WC-10Co复合粉末、YSZ纳米粉末、Al2O3亚微粉末与工业Ni粉为原料,采用微波烧结+热等静压处理制备性能优良的Al2O3/WC-10Co/ZrO2/Ni金属陶瓷,研究微波烧结、微波烧结+热等静压处理对Al2O3/WC-10Co/ZrO2/Ni金属陶瓷的组织结构和力学性能的影响。研究结果表明:WC-10Co(10%,质量分数),YSZ(30%),Al2O3(55%)与Ni(5%)复合粉末高能球磨后,经过微波烧结+热等静压处理,可以得到平均晶粒度小于1.5 ?m的整体性能较好的亚微Al2O3/WC-10Co/ZrO2/Ni金属陶瓷,其相对密度为98.4%,洛氏硬度为HRA 94.0;微波烧结+热等静压可以有效地消除微波烧结造成Al2O3/WC-10Co/ZrO2/Ni金属陶瓷中的孔隙,提高复合材料的密实度和力学性能,而且金属陶瓷的晶粒基本没有异常长大。

关键词:WC-10Co纳米复合粉末;亚微Al2O3粉末;纳米ZrO2粉末;微波烧结;热等静压处理

中图分类号:TF125.3 文献标识码:A 文章编号:1672-7207(2007)04-0623-06

Microwave sintering of Al2O3/WC-10Co/ZrO2/Ni cermets

SHI Xiao-liang, YANG Hua, SHAO Gang-qin, DUAN Xing-long, XIONG Zhen

(State Key Laboratory of Advanced Technology for Materials Synthesis & Processing,

Wuhan University of Technology, Wuhan 430070, China)

Abstract: Using the microwave sintering and hot isostatic pressing (HIP) technology, the sintering properties of nanocrystalline WC-10Co(10%, mass fraction), Y2O3 stabilized nanocrystalline ZrO2(30%), submicron Al2O3(55%) and nickel(5%) composite powder in microwave sintering were studied. The results show that after Al2O3/WC-10Co/ZrO2/Ni cermets are sintered by microwave sintering and hot isostatic pressing, the relative density and Rockwell hardness of cermets with average grain size of less than 1.5 ?m are 98.4% and 94.0, respectively. Submicron Al2O3/WC- 10Co/ZrO2/Ni cermets have excellent properties. The sintering body sintered by using microwave sintering and HIP can not only increase the density of specimen and lower the porosity, but also avoid discontinuous grain growth.

Key words: WC-10Co nanocomposite powder; submicron Al2O3 powder; Y2O3 stabilized nanocrystalline ZrO2 powder; microwave sintering; hot isostatic pressing

纳米/超细材料相对于传统粗晶材料,其硬度、强度、柔性、韧性、弹性模量与磁性等明显提高。陶瓷材料具有许多优越的特性,如高温力学性能好,抗化学侵蚀性能、电绝缘性强,硬度和耐磨性较高等。但陶瓷材料缺乏像金属在受力状态下发生滑移引起塑性变形的能力,容易产生缺陷和裂纹,且易于导致应力高度集中。金属-陶瓷复合材料是由一种或多种陶瓷相与金属或合金组成的多相复合材料。它既保留原组分材料的特性,又具有原单一组分材料所无法获得的或更优异的特性。性能优良的金属陶瓷可以广泛地用于木工刀具、牙医工具、金属加工、精密工模具、航天材料以及耐磨材料等领域[1-2]。

ZrO2陶瓷耐火度高,比热容和导热系数小,是理想的高温绝缘材料。化学稳定性强,高温时仍能抗酸性和中性物质的腐蚀。ZrO2的四方相向单斜相的转化在Al2O3基体中产生应力场,在Al2O3/ZrO2界面产生微裂纹。这些应力场和微裂纹导致晶间断裂的裂纹偏转,能有效地降低裂纹扩展的驱动力。另外,当穿晶断裂在单斜相ZrO2中扩展时,裂纹扩展的驱动力会由于单斜相ZrO2的塑性变形而降低[3]。超细WC-Co硬质合金具有高强度、高硬度的“双高”性能,在制作集成电路板微型钻头、点阵打印机针头、精密工模具、难加工材料刀具等方面具有广阔的应用前景[4-7],而Al2O3因硬度高,密度低,刚性强,化学稳定性好及耐高温等优良特性,成为应用最广泛的结构材料之一[8-9]。

微波烧结依靠材料本身吸收微波能转化为材料内部分子的动能和势能,材料内外同时均匀加热,这样,材料内部热应力可以减少到最小程度;其次,在微波电磁能作用下,材料内部分子或离子的动能增加,使烧结活化能降低,扩散系数提高,可以进行低温快速烧结,使细粉来不及长大就被烧结[10-14]。

本文作者以喷雾热解-连续还原碳化方法制备的纳米WC-10Co复合粉末、络合-凝胶法制备的YSZ纳米陶瓷粉末、硫酸铝铵热分解法自制的α-Al2O3亚微粉末和工业Ni粉为原料,采用微波烧结、微波烧 结+热等静压制备Al2O3/WC-10Co/ZrO2/Ni金属陶瓷。

1 实 验

实验原料有:采用喷雾热解-连续还原碳化方法制备的纳米WC-10Co复合粉末;以络合-凝胶法制备的YSZ纳米陶瓷粉末、工业Ni粉;以硫酸铝铵热分解法自制的α-Al2O3亚微粉末。

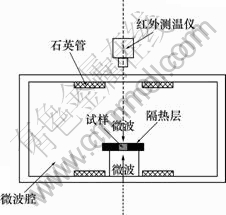

将亚微Al2O3粉末、WC-10Co纳米复合粉末、YSZ纳米陶瓷粉末和Ni粉按质量比为55?10?30?5进行混合,同时加入适量的晶粒生长抑制剂VC和Cr3C2,在行星球磨机上球磨,加入适量的无水乙醇和WC-10Co硬质合金球(球料质量比8?1),装入硬质合金球磨罐中,密封好后在球磨机上以400 r/min的转速球磨48 h,高能球磨后的Al2O3/WC-10Co/ZrO2/Ni复合粉末在真空干燥箱中干燥,然后研磨、过筛、称量、成型、脱脂,试样在南京杰全微波设备有限公司生产的NJZ04-1型微波高温烧结炉(见图1)中烧结。微波快速烧结制度如下:温度为1 300 ℃,保温10 min,升温速率为130 ℃/min,高纯Ar气保护。烧结试样的长×宽×高为15 mm×5 mm×5 mm。热等静压制度:高纯Ar气介质,压力为120 MPa,烧结温度为1 320 ℃,保温保压60 min。为了对比实验,试样高温微波烧结制度如下:温度为1 500 ℃,保温10 min,升温速率为130 ℃/min,高纯Ar气保护。

图1 微波烧结设备示意图

Fig.1 Schematic diagram of apparatus for continuous microwave sintering

用日本Rigaka公司生产的D/MAX-RB型X射线衍射仪(XRD)对混合后的粉末和烧结块体进行物相分析,用日本电子株式会社生产的JSM-5610LV型扫描电镜(SEM)对粉末和烧结块断口进行显微形貌分析。按GB3849—83标准测定洛氏硬度,根据阿基米德定律,利用排水法,采用GB3850—83标准测定密度。

2 结果与讨论

图2所示为高能球磨后的WC-10Co/ZrO2/Al2O3/ Ni复合粉末TEM照片。可见,粉末由100~200 nm的团聚体组成。高能球磨制备WC-10Co/ZrO2/Al2O3/Ni纳米复合粉末,为制备组织结构均匀的金属陶瓷材料打下了有利的基础。图3所示为WC-10Co(10%)/ ZrO2(30%)/Al2O3(55%)/Ni(5%)复合粉末经过高能球磨机球磨48 h后的XRD谱。可见,混合粉末由Al2O3,Al(OH)3,m-ZrO2和t-ZrO2组成。Al(OH)3相可能是硫酸铝铵热分解法时热解温度偏低或热解时间过短造成的,在烧结过程中可能会影响烧结体的性能。

图2 WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)复合粉末TEM照片

Fig.2 TEM image of WC-10Co(10%)/ZrO2(30%)/Al2O3 (55%)/Ni(5%) composite powder

图3 WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)复合粉末的XRD谱

Fig.3 XRD pattern of WC-10Co(10%)/ZrO2(30%)/ Al2O3(55%)/Ni(5%) composite powders

图4所示为1 300 ℃、保温10 min条件下微波烧结制备的WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶瓷的断口形貌。可见,试样组织结构比较均匀,晶粒不存在着明显的异常长大现象,晶粒分布范围较窄,平均晶粒尺寸约为1.0 ?m,但密实程度较差,组织结构中明显存在大量的孔隙。故复合材料的力学性能得不到保证。

放大倍数:(a) 2 000倍; (b) 5 000倍; (c) 10 000倍; (d) 10 000倍

图4 1 300 ℃微波烧结10 min的WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶瓷的断口形貌

Fig.4 SEM images of fractured surface of specimen prepared by using microwave sintering at 1 300 ℃ for 10 min

在微波烧结过程中,升温速率比较快,虽然可以有效地控制晶粒的长大,但由于微波烧结是无压烧结,同时相对于常规的液相烧结过程,烧结时间大大缩短,不利于通过充分的液相烧结来消除气孔间的连通,进而提高烧结体的密实度和力学性能。为了提高烧结体性能,应该适当降低升温速率和延长烧结时间。

图5所示为在1 300 ℃,保温10 min微波烧结并同时在1 320 ℃,120 MPa,保温60 min热等静压处理条件下制备的WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/ Ni(5%)金属陶瓷的断口形貌,图中黑色和灰色颗粒为Al2O3晶粒,白色小颗粒为WC,Co,Al2O3,Ni及抑制剂的混合物(如图5(c)与5(d)箭头与文字所示)。由图可见,试样组织结构比较均匀,晶粒不存在着明显的异常长大现象,晶粒分布范围较窄,平均晶粒尺寸约为1.5 ?m,但密实程度与单纯的微波烧结制备的烧结体的密度程度相比得到提高,组织结构中的孔隙得到明显消除。故复合材料应该在宏观上具有好的力学性能。体系由于存在大量的颗粒表面及孔隙,故处于非平衡状态,具有向平衡稳定状态转变的趋势,以降低过剩的表面能,这是微波烧结致密化的主要驱动力。在外压存在的条件下,引起致密化的驱动力是外压与表面能降低所致,因此,经过微波烧结+热等静压后的试样的密度有所提高,但同时为晶粒粒度粗化提高了条件,故微波烧结+热等静压得到的烧结体的平均晶粒粒径(1.5 ?m)大于微波烧结体的平均晶粒粒径(1.0 ?m)。

放大倍数:(a) 2 000倍; (b) 5 000倍; (c) 10 000倍; (d) 20 000倍

图5 1 300 ℃微波烧结+热等静压处理10 min制备WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%) 金属陶瓷的断口形貌

Fig.5 SEM images of fractured surface of specimens prepared by using microwave sintering and hot isostatic pressing at 1 300 ℃ for 10 min

图6所示为微波烧结+热等静压处理制备的WC-10Co(10%)/ZrO2(30%)/ Al2O3(55%)/Ni(5%)金属陶瓷烧结试样的XRD谱。与图3所示的WC-10Co(10%)/ ZrO2(30%)/Al2O3(55%)/Ni(5%)复合粉末的XRD谱相比,经过微波烧结+热等静压处理的金属陶瓷中存在大量单斜相的m-ZrO2的峰,这说明复合材料经过高温烧结后,部分四方相t-ZrO2向单斜相m-ZrO2转变,可在Al2O3/ZrO2和WC/ZrO2界面产生微裂纹。这些应力场和微裂纹导致了晶间断裂的裂纹偏转,从而有效地降低裂纹扩展的驱动力。另外,当穿晶断裂在单斜相ZrO2中扩展时,裂纹扩展的驱动力会由于单斜相ZrO2的塑性变形而降低,从而在一定程度上提高WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶瓷复合材料的断裂韧性。同时复合粉末中Al(OH)3相经过微波烧结+热等静压处理后,在烧结试样的中基本得到了消除。

图6 微波烧结+热等静压处理制备WC-10Co(10%)/ ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶瓷的XRD谱

Fig.6 XRD pattern of WC-10Co(10%)/ZrO2(30%)/ Al2O3(55%)/Ni(5%) cermets prepared by using microwave sintering and hot isostatic pressing

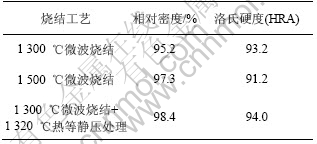

表1所示为不同烧结工艺下烧结体的力学性能。可见,微波烧结+热等静压处理制备的试样与微波烧结制备的试样相比,洛氏硬度与密实度都有较大幅度的提高,洛氏硬度为94.0,相对密度为98.4%。

表1 不同烧结工艺下的烧结体的力学性能

Table 1 Mechanical properties of samples with different sintering techniques

图7所示为微波烧结+热等静压处理制备试样中不同颜色颗粒(见图5(c)与5(d))的能谱分析结果,其中烧结试样中黑色和灰色颗粒为Al2O3晶粒,白色小颗粒为WC,Co,Al2O3,Ni及抑制剂的混合物。

(a) 界面间的白色小颗粒;(b) 灰色颗粒;(c) 黑色颗粒

图7 微波烧结+热等静压处理制备的烧结试样中不同颜色颗粒的表面能谱分析

Fig.7 Analysis of energy dispersive spectroscopy (EDS) of grain in specimen prepared by microwave sintering and hot isostatic pressing

在烧结体产生裂纹或缺陷过程中,晶粒之间的接触面上会产生阻力来阻止裂纹或缺陷的产生。在烧结体的断裂过程中,晶粒越小,其断裂的路径就会越曲折,路径加长,阻止其发生断裂。断裂强度主要取决于晶粒的大小和晶粒之间的接触。WC弥散在Al2O3晶粒晶界中,在一定程度上可以抑制Al2O3晶粒长大,同时还可以阻碍、屏蔽或偏转裂纹的蔓延;金属相Co和Ni弥散在Al2O3晶粒晶界中,在金属陶瓷材料断裂过程中可以通过相界面的张(压)应力消除裂纹扩展,从而提高材料的断裂韧性。

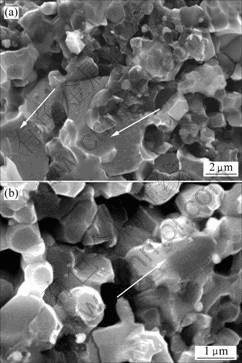

图8所示为1 500 ℃微波烧结10 min制备的WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶

瓷的断口形貌。可见,断口中明显存在异常长大的晶粒,个别晶粒尺寸甚至超过6 ?m,且存在大量的孔洞,组织结构不均匀,因此,其力学性能很难得到很大提 高。虽然1 500 ℃微波烧结试样的相对密度相对于1 300 ℃微波烧结试样(见图4)的相对密度得到了一定的提高,但洛氏硬度由于晶粒的变粗和异常长大而减小(见表1)。因此,制备性能优良、组织结构均匀的WC-10Co(10%)/ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶瓷,低温微波快速烧结+热等静压处理工艺要优于简单的高温微波烧结。

放大倍数:(a) 8 000倍; (b) 20 000倍

图8 1 500 ℃微波烧结10 min制备WC-10Co(10%)/ ZrO2(30%)/Al2O3(55%)/Ni(5%)金属陶瓷的断口形貌

Fig.8 SEM images of fractured surface of specimens prepared by using microwave sintering at 1 500 ℃ for 10 min

3 结 论

a. Al2O3/WC-10Co/ZrO2/Ni纳米复合粉末经微波烧结+热等静压处理后能获得具有较好组织结构和力学性能的金属陶瓷材料。

b. 相对于陶瓷与陶瓷的复合,金属相Co和Ni作为粘结相能在不过分降低硬度的前提下提高材料的断裂韧性。

c. WC-10Co/ZrO2/Al2O3/Ni金属陶瓷复合材料中经过微波烧结+热等静压处理后部分四方相的t-ZrO2向单斜相m-ZrO2的转变,在一定程度上提高了金属陶瓷复合材料的断裂韧性。

参考文献:

[1] Cha S I, Hong S H, Ha G H, et al. Mechanical properties of WC-10.21Co cemented carbides sintered from nanocrystalline spray conversion processed powders[J]. International Journal of Refractory Metals and Hard Materials, 2001, 19(4/6): 397-403.

[2] Gille G, Szesny B, Dreyer K, et al. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts[J]. International Journal of Refractory Metals and Hard Materials, 2002, 20(1): 3-22.

[3] Lee B T, Lee K H, Hiraga K J. Stress-induced phase transformation of ZrO2 in ZrO2 (3mol%Y2O3)-25vol%Al2O3 composite studied by transmission electron microscopy[J]. Scripta Materialia, 1998, 38(7): 1101-1107.

[4] Shao G Q, Duan X L, Xie J R, et al. Sintering of nanocrystalline WC-Co composite powder[J]. Reviews on Advanced Materials Science, 2003, 5(4): 281-286.

[5] Allibert C H. Sintering features of cemented carbides WC-Co processed from fine powders[J]. International Journal of Refractory Metals and Hard Materials, 2001, 19(1): 53-61.

[6] Andrén H O. Microstructure development during sintering and heat-treatment of cemented carbides and cermets[J]. Materials Chemistry and Physics, 2001, 67(1/3): 209-213.

[7] Upadhyaya G S. Materials science of cemented carbides-an overview[J]. Materials and Design, 2001, 22(6): 483-489.

[8] Han B Q, Li N. Synthesis of Al2O3/WC powder by aluminothermic reduction and carbonization method[J]. Trans Nonferrous Met Soc China, 2004, 14(2): 246-250.

[9] Borsa C E, Jones N M R, Todd R I. Influence of processing on the microstructure development and flexture strength of Al2O3/SiC nanocomposites[J]. Journal of the European Ceramic Society, 1997, 17(3): 865-872.

[10] Agrawal D K. Microwave processing of ceramics[J]. Solid State & Materials Science, 1998, 3(5): 480-485.

[11] R?diger K, Dreyer K, Gerdes T, et al. Microwave sintering of hardmetals[J]. International Journal of Refractory Metals & Hard Materials, 1998, 16: 409-416.

[12] Cheng J P, Agrawal D, Zhang Y H, et al. Fabricating transparent ceramics by microwave sintering[J]. Amer Cera Soc Bull, 2000, 79(9): 71-74.

[13] Fang Y, Roy R, Agrawal D, et al. Transparent mullite ceramics from disphasic aerogels by microwave and conventional processing[J]. Mater Let, 1996, 28(1/3): 11-15.

[14] 史晓亮, 杨 华, 邵刚勤, 等. 微波烧结法制备WC-10Co硬质合金[J]. 中南大学学报: 自然科学版, 2006, 37(4): 666-669.

SHI Xiao-liang, YANG Hua, SHAO Gang-qin, et al. Preparation of WC-10Co cemented carbide by microwave sintering[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 666-669.

收稿日期:2006-10-28

基金项目:教育部科学技术重点研究项目(105123);武汉理工大学基金资助项目(xjj2005166)

作者简介:史晓亮(1974-),男,黑龙江佳木斯人,博士,副研究员,从事纳米金属陶瓷和高密度合金研究

通讯作者:史晓亮,男,副研究员;电话:027-87216912; E-mail: sxl@mail.whut.edu.cn