文章编号:1004-0609(2007)01-0014-10

熔体处理和双向电磁搅拌复合快速制浆技术

冯鹏发1, 2,唐靖林1,李双寿1,曾大本1

(1. 清华大学 机械工程系,北京 100084;

2. 金堆城钼业集团有限公司,西安 710075)

摘 要:分析了中间合金微细粉末熔体处理工艺和双向电磁搅拌工艺中,Al-5Ti-B合金粉末粒度、粉末加入 量、加入温度、静置时间、中间合金加入顺序、单向旋转时间、电源频率、浇注温度和搅拌时间等工艺参数对A356合金半固态浆料的组织和制备效率的影响规律及其原因,开发出适合于铝合金的熔体处理+双向电磁搅拌半固态浆料复合制备技术。结果表明:该技术可在20~25 s内制备出α(Al)的形状因子约为0.85、晶粒尺寸为70~ 80 μm(空冷尺寸)的A356合金半固态浆料。

关键词:Al-5Ti-B微细粉末;A356合金;浆料快速制备;熔体处理;双向电磁搅拌

中图分类号:TG 146.2; TG 115.9 文献标识码:A

Rapid multiple slurry-preparation technology of melt treatment and reversible electromagnetic stirring

FENG Peng-fa1,2, TANG Jing-lin1, LI Shuang-shou1, ZENG Da-ben1

(1. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

2. Jinduicheng Molybdenum Group Co. Ltd., Xi’an 710075, China)

Abstract: The influences and reasons of the processing parameters of melt treatment and electromagnetic stirring, namely particle size of Al-5Ti-B alloy powder, addition level, addition temperature, holding time, addition sequence of master alloys, one-way rotation time, power frequency, pouring temperature, on the microstructure of semi-solid A356 alloy slurry and the preparation efficiency were systematically studied. Based on the results, a multiple semi-solid Al alloy slurry preparation technology of melt treatment and reversible electromagnetic stirring was explored. The results show that by this technology, semi-solid A356 alloy slurry with α(Al) shape factor of about 0.85 and particle size of 70-80 μm (in air-cooling state) could be prepared in 20-25 s.

Key words: Al-5Ti-B alloy powder; A356 alloy; rapid slurry preparation technology; melt treatment; reversible electromagnetic stirring

非枝晶半固态合金浆料的制备效率一直是制约流变成形技术发展的困难之一[1-2],为此国内外出现了很多台制浆设备对应一台成形设备的生产设计[3-6],但其设备利用率较低。本文作者旨在前期研究[7]的基础上,开发出一种可实现制浆设备-成形设备一对一配套的半固态合金浆料快速制备技术。

按照熔体处理+双向电磁搅拌复合制备技术[7]的思路,首先选择粒度呈高斯分布的微米级Al-5Ti-B粉末作为细化剂,并采用Al-10Sr挤压杆作为变质 剂,优化出最佳熔体处理技术,然后在最佳熔体处理技术的基础上,对电磁搅拌技术进行优化分析,最后得出制备效率最大、浆料组织最佳的A356合金半固态浆料制备技术。

1 实验

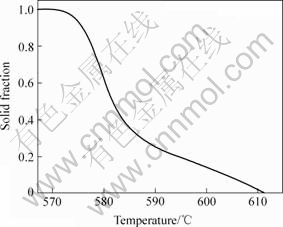

实验材料为A356铝合金。通过差热分析确定其固相率与温度对应关系如图1所示。为保证合金熔 体在不同制备方法和制备工艺下受到的搅拌过程具有可比性,本实验中所有搅拌过程的结束温度相同,为 607 ℃(即5 %固相率对应温度),并以此来控制搅拌时间。熔体处理和电磁搅拌过程的温度变化,采用热电偶和温度采集系统进行记录。采用空冷取样。试样的显微组织采用经OMNICON-5000图像分析仪改进的铸造金相分析系统测量。

图1 实验用A356合金锭温度—固相率曲线

Fig.1 Temperature—solid fraction curve of A356 alloy

初生α(Al)相的形貌采用形状系数Fc描 述[3],Fc=4πS/P2,晶粒的大小采用当量直径Dc表示, ,其中,S,P分别为α(Al)相晶粒的截面积和截面周长。Fc值介于0~1之间,Fc值越趋近1,表明α(Al)相晶粒越圆整。

,其中,S,P分别为α(Al)相晶粒的截面积和截面周长。Fc值介于0~1之间,Fc值越趋近1,表明α(Al)相晶粒越圆整。

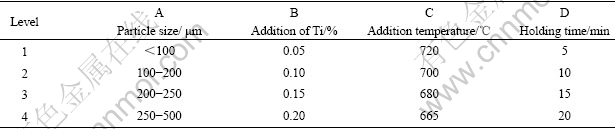

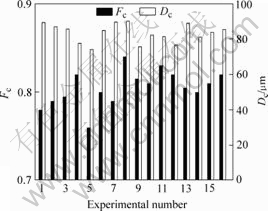

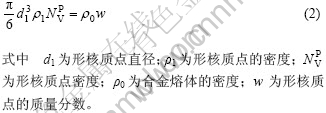

为获得采用Al-5Ti-B微细粉末进行晶粒细化的最佳工艺,按照正交实验规则,参照L16(45)正交实验表,设计L16(44)正交实验因素水平列于表1,实验次数为16,以Fc和Dc为实验指标。熔体处理过程如下:熔体在720~750 ℃保温后,加入0.4 %Al-10Sr并静置5 min,接着在t1内降温至因素C所示温度,在该温度下加入Al-5Ti-B粉末并在t2内降温至640 ℃进行电磁搅拌,浆料温度到达607 ℃时结束搅拌并空冷取样。t1+t2=25 min,即保证Al-10Sr的孕育时间均为30 min,具有相同的变质效果,使细化结果具有可比性。其中的电磁搅拌采用如下工艺[7],即正-反无间歇双向搅拌、电源频率f=30 Hz、输出电压U=220 V、单向搅拌时间?τ=5 s、搅拌时间τ=67 s。

表1 正交实验因素与水平表

Table 1 Orthogonal experimental factors and their levels

在获得最佳熔体处理工艺后,把采用最佳熔体处理工艺处理后的合金熔体转移至双向电磁搅拌装置中,采用涂覆特殊涂料的网孔不锈钢制坩埚,依次对单向旋转时间(1~5 s)、电源频率(20~30 Hz)、浇注温度(640~615 ℃)和搅拌时间等搅拌参数进行实验分析。

2 结果与讨论

2.1 Al-5Ti-B微细粉末熔体处理工艺分析

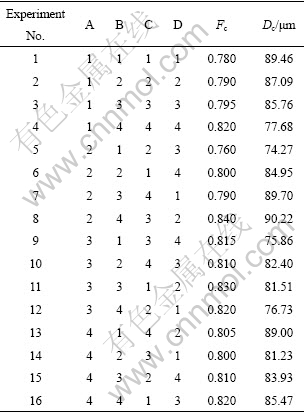

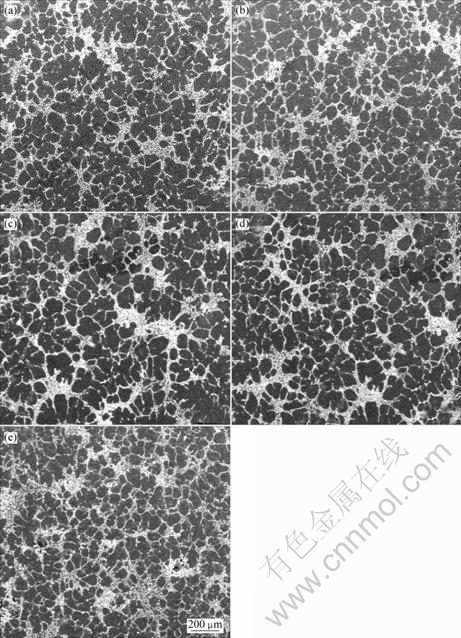

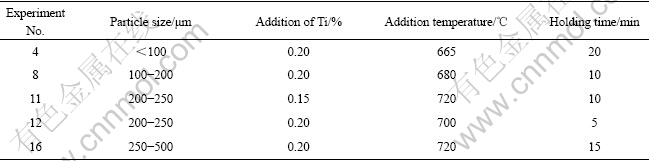

表2和图2给出Al-5Ti-B微细粉末晶粒细化的正交实验结果。可以看出,Al-5Ti-B合金微细粉末熔体处理工艺的变化对α(Al)相晶粒尺寸的影响较小,而对晶粒形状因子影响明显,其中4、8、11、12和16号实验的形状因子明显优于其它几组实验。4、8、11、12和16号实验获得的A356合金浆料组织见图3,其工艺参数见表3。分析这5个实验的工艺参数可以看出,在采用Al-5Ti-B微细粉末进行晶粒细化的较佳工艺中,粉末的加入量为0.15 %~0.2 %Ti,而粉末粒 度、加入温度和静置时间等3个工艺参数选择4种水平都有可能。

表2 Al-5Ti-B微细粉末晶粒细化正交实验结果

Table 2 Orthogonal experimental results of melt treatment by Al-5Ti-B micron powder

图2 正交实验结果定量分析

Fig.2 Values of quantitative analysis of orthogonal experiments

图3 部分正交实验制得的A356合金浆料显微组织

Fig.3 Microstructures of A356 alloy slurries obtained by following orthogonal experiment No.: (a) 4; (b) 8; (c) 11; (d) 12; (e) 16

表3 部分正交实验的工艺参数

Table 3 Processing parameters of some orthogonal experiments

由于显微组织的绝对定量化存在一定误差,因此仅从最小Dc值和最大Fc值的角度来确定最佳熔体处理工艺是不可行的。下面分析4、8、11、12和16号实验中,粉末粒度、粉末加入量、加入温度和静置时间等4个工艺参数对半固态合金浆料组织的影响,以确定这些工艺参数的主次顺序,进而确定Al-5Ti-B微细粉末熔体处理的最佳工艺。

2.1.1 粉末加入量的影响

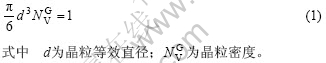

粉末的加入量直接决定异质形核质点的数量,进而决定最终浆料的组织,因此是4个工艺参数中最重要的参数。如果将晶粒按照等效球体计算,则其晶粒密度可用下式估算:

本组实验获得晶粒尺寸为80~90 μm,由此可得到 大致为(2.6~3.7)×1012 m-3。

大致为(2.6~3.7)×1012 m-3。

单位体积合金熔体内的形核质点数可计算为

TiB2质点的直径d1取为5 μm(文献[8]认为,TiB2质点的直径一般不超过5 μm,大部分不超过 2 μm)。TiB2质点的密度ρ1为3.8×103 kg/m3。当Al-5Ti-B粉末加入量为3 %(即0.15 %Ti)时,TiB2质点的加入量w为0.096 %。根据式(2)可得出, =1.04×1013 m-3。

=1.04×1013 m-3。

比较可知,当Al-5Ti-B微细粉末加入量为0.15%Ti时,即使选用最大尺寸的TiB2质点, 也远大于

也远大于 。文献[9-11]研究表明,当形核质点较少时,晶粒数随着形核质点数的增加而线性增加,当形核质点数超过晶粒数的2~3倍后,形核质点的增多对晶粒数影响甚微。因此,粉末的加入量在0.15%~0.2%Ti之间变化,对A356合金浆料组织的影响差别不大。

。文献[9-11]研究表明,当形核质点较少时,晶粒数随着形核质点数的增加而线性增加,当形核质点数超过晶粒数的2~3倍后,形核质点的增多对晶粒数影响甚微。因此,粉末的加入量在0.15%~0.2%Ti之间变化,对A356合金浆料组织的影响差别不大。

2.1.2 粉末粒度的影响

由于本组实验所用Al-5Ti-B粉末均为微米级,尺寸差别不明显,加之筛分后的粒度呈高斯分布,不同平均粒度的粉末中尚有大量相同直径的粉末颗粒,因此将粉末分为<100、100~200、200~250、250~500 μm,对熔体处理效果影响较小。Kaneko等[12]利用机械合金化法将Al、Ti、B微米粉末混合,然后压制、热挤压,制备出直径为7 mm的Al-Ti合金块和Al-Ti-B合金块,其晶粒细化效果与图3(b)相当,也验证了这一点。

2.1.3 加入温度和静置时间的影响

从4、8、11、12和16号实验的工艺参数(表3)可看出,粉末粒度越小,则加入温度越低,而静置时间与粉末粒度不存在明显的关联。从在熔体处理过程中的作用来看,加入温度和静置时间只是提供晶粒形核和生长的热力学及动力学条件,即保证中间合金的熔解、形核质点的分离、形核质点的弥散、初晶晶核的形成。粉末颗粒越细,表面活性越大,所需熔化温度越低,因此加入温度随粉末粒度大小而变化,粒度较大时加入温度较高,粒度较小时加入温度较低。无论粉末粒度大小如何,分离出的TiB2质点尺寸是比较一致的,因此,静置时间在5~20 min之间变化对其效果影响甚微,静置时间可缩短(例如,12号实验只有5 min),但考虑到Al-10Sr合金的孕育时间要求和工艺操作,静置时间选用20 min。

正交实验没有考虑Al-5Ti-B合金与Al-10Sr合金之间的交互作用,下面通过实验来分析这两种中间合金加入顺序对熔体处理效果的影响。为此设计如下3组实验:1) 先加Sr后加Ti:720 ℃加入Al-10Sr,10 min内降温至665 ℃,加入Al-5Ti-B,静置20 min后进行电磁搅拌;2) Ti、Sr同时加:665 ℃同时加入Al-5Ti-B和Al-10Sr,静置20 min后进行电磁搅 拌;3) 先加Ti后加Sr:665 ℃加入Al-5Ti-B,静置10 min后加入Al-10Sr,再静置10 min后进行电磁搅拌。从实验结果可看出(图4),在其它条件(粉末粒 度、加入量、加入温度、静置时间、电磁搅拌参数等)相同的情况下,“先加Ti后加Sr”工艺与“先加Sr后加Ti”工艺得到的组织形貌相近,二者均优于 “Ti、Sr同时加”工艺。其原因在于:一般地,Al-5Ti-B合金采用氟盐法制备。K2TiF6、KBF4和纯Al加入熔炉中后,可能发生的化学反应有[13]:

图4 中间合金加入顺序对α(Al)相形貌的影响

Fig.4 Influences of adding sequence of master alloys on microstructures of α(Al): (a) Adding Al-10Sr firstly, then Al-5Ti-B; (b) Adding Al-10Sr and Al-5Ti-B together; (c) Adding Al-5Ti-B firstly, then Al-10Sr

2KBF4+3Al→AlB2+2KAlF4

3K2TiF6+13Al→3TiAl3+3KAlF4+K3AlF6

6KBF4+3K2TiF6+10Al→3TiB2+9KAlF4+K3AlF6

2KBF4+Ti+2Al→TiB2+2KAlF4

AlB2+xTi→(Al1-x,Tix)B2+xAl

分析这些反应可看出,Al-5Ti-B合金中的相组成有Al、AlB2、TiAl3和(Al1-x,Tix)B2,其中(Al1-x,Tix)B2为介稳态化合物。当Al-5Ti-B和Al-10Sr同时作用于Al-Si合金熔体中时,在保温温度下,Al-5Ti-B合金中的(Al1-x,Tix)B2相将分离出部分B原子,与Al-10Sr中Al4Sr相分离出的Sr原子生成SrB6(李建国等[14]通过 X射线衍射分析证实了SrB6的存在),此化合物的熔点约为2 500 ℃,在熔体中非常稳定,因此同时添加 Ti、Sr工艺将带来B、Sr的消耗,造成晶粒细化效果和共晶硅变质效果共同减弱。如果Al-5Ti-B和Al-10Sr相隔一段时间分别加入,无论先加Ti后加Sr工艺还是先加Sr后加Ti工艺,当Al-5Ti-B中(Al1-x,Tix)B2相分离出B原子时,熔体中不存在游离态Sr原子,分离出的B原子将与Ti原子形成稳定的TiB2质点,起到形核质点的作用。

总结以上实验,得到Al-5Ti-B微细粉末熔体处理最佳工艺为:1) 粉末加入量为0.15~0.20 %Ti;2) 粉末粒度要求≤500 μm;3) 加入温度为:粗粉采用高温,细粉采用低温,即粒度<100 μm:665 ℃;100~200 μm:680 ℃;200~250 μm:700~720 ℃;250~500 μm:720 ℃;4) 静置时间为20 min;5) 中间合金加入顺序为Sr、Ti间隔10 min加入,Al-5Ti-B粉末加入温度低于720 ℃时,采用先加Sr后加Ti工艺,否则采用先加Ti后加Sr工艺。

2.2 双向电磁搅拌工艺分析

下面在电磁搅拌规律分析[7]的基础上,优化出Al-5Ti-B微细粉末熔体处理+双向电磁搅拌复合技术中的最佳电磁搅拌工艺。

非枝晶合金浆料的形成过程中,搅拌工艺主要起两个作用:一是保证晶核分布少或无偏析,使熔体处于整体形核状态;二是保证晶粒生长过程中按照形核之初的球状形态,在各个方向均衡稳定地生长。这两个作用的实现都依赖于磁场对熔体产生足够的搅拌强度。影响合金熔体搅拌强度的因素包括合金熔体的电导率、磁场的磁感应强度、磁场与合金熔体之间的相对速度。在实验材料选定后,熔体的电导率随之固定不变。旋转磁场的磁感应强度主要与通电线圈的输入功率和电源频率有关。磁场与合金熔体之间的相对速度取决于磁场与合金浆料的转差率、合金浆料的单向转动速度。另外,熔体的浇注温度也对半固态合金浆料的组织和制备效率具有重要影响。目前尚无法严格定量地分析这些工艺参数的影响规律,因此下面采用实验法对其进行优化。

2.2.1 单向旋转时间的影响

图5所示为旋转磁场的不同单向旋转时间下,α(Al)相形貌照片及定量分析结果。可以看出,在熔体处理工艺和其它电磁搅拌参数一定的情况(0.15%Ti;Al-5Ti-B粉末粒度<100 μm、正-反无间歇双向搅拌;浇注温度t0=640 ℃;搅拌频率f=30 Hz;电源电压U=220 V;搅拌时间τ=67 s)下,当单向旋转时间较短时,随着单向旋转时间的增加,晶粒的形状因子增大,晶粒圆整度提高,晶粒尺寸减小;当单向旋转时间超过3 s时,情况相反。

图5 单向旋转时间对α(Al)相形貌的影响

Fig.5 Influences of one-way rotation times on microstructures of α(Al) (Addition level of Al-5Ti-B: 0.15 %Ti; particle size: <100 μm; reversible stirring without interval; t0=640 ℃;f=30 Hz;U=220 V;τ=67 s): (a) 1 s; (b) 2 s; (c) 3 s; (d) 4 s; (e) 5 s

单向旋转时间的变化直接影响合金熔体与磁场之间的相对运动速度和合金熔体受到的惯性冲击次 数,进而影响合金熔体受到的搅拌强度和非枝晶组织形貌。下面对单向旋转时间与搅拌强度之间的关系进行定量分析。

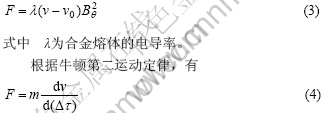

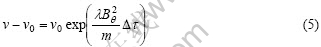

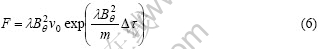

计合金熔体的质量为m,合金熔体的旋转速度为v,磁场的旋转速度为v0,磁场的切向磁感应强度为 Bθ,磁场的单向旋转时间为?τ,则可得到熔体受到的电磁力F为

联立式(3)和式(4),求解并结合初始条件?τ=0, v=0得到合金熔体与磁场之间的相对速度为

进而得到:

从式(6)可以看出,在磁场参数一定的情况下,合金熔体受到的电磁力与单向旋转时间?τ成指数关系。而磁场的转向次数,即合金熔体受到反向冲击惯性力的次数,与单向旋转时间成反比。当单向旋转时间较小时,搅拌强度主要取决于搅拌力的大小,而当单向旋转时间较大时,搅拌强度主要取决于熔体受到的反向冲击次数。因此,当单向旋转时间超过3 s时,合金熔体与磁场之间的相对速度增加带来的电磁力增加量,远不及磁场转向次数减少带来的惯性冲击损失,即在本实验条件下,单向旋转时间宜选3 s。

2.2.2 电源频率的影响

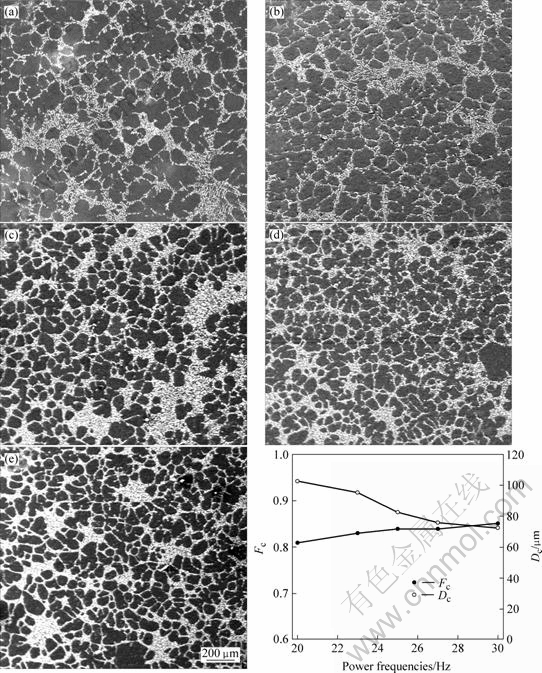

图6所示为不同电源频率下,α(Al)相形貌照片及定量分析结果。可以看出,在熔体处理和其它电磁搅拌参数一定的情况下,晶粒的形状因子随着电源频率增大而略有增加,当电源频率稍大于20 Hz时,随着电源频率增大,晶粒尺寸减小幅度较大,当电源频率达到27 Hz以上时,晶粒尺寸趋于平稳。

图6 电源频率对α(Al)相形貌的影响

Fig.6 Influences of power frequencies on the microstructures of α(Al) (Addition level of Al-5Ti-B: 0.15 %Ti; particle size <100 μm; reversible stirring without interval; t0=640 ℃; ?τ=3 s; U is at maximum permissive voltages of power frequencies; τ=67 s): (a) 20 Hz; (b) 23 Hz; (c) 25 Hz; (d) 27 Hz; (e) 30 Hz

目前,关于电源频率对晶粒形貌的影响及其规律存在一定争议。邢书明[15]通过冷却速度为2.6 K/s的机械搅拌实验表明,搅拌速度低于3 000 r/min时,搅拌速度的提高有助于晶粒细化。文献[16]指出,电磁力随着电源频率的提高并不是单调变化,而是存在一个最大值,即电源频率为20 Hz时电磁力最大。由于电磁搅拌装置结构不同,合金熔体的物性不同,这种说法不具有普适性。另外,电源频率越高,旋转磁场的透入强度越弱[17]。因此,目前尚无法定量地分析电源频率对晶粒形貌的影响。

搅拌作用对晶粒的生长过程会产生两种相互矛盾的作用。一方面,搅拌使固-液界面前沿的速度边界层、温度边界层和溶质边界层变薄,界面稳定性降低,不但有利于提高晶粒生长速度,而且易于界面失稳,使非枝晶生长方式变为枝晶生长方式。另一方面,搅拌可加剧液相中溶质扩散速度和结晶潜热排泄速度,降低固-液界面前沿的溶质浓度梯度和温度梯度,使晶粒生长速度减缓,界面稳定性增加。如果第一种作用占主导地位,则搅拌频率越大,晶粒尺寸越大,形状因子越小。如果第二种作用占主导地位,则情况正好相反。邢书明[15]认为,缓冷条件下的搅拌主要起第一种作用,快冷条件下的搅拌主要起第二种作用。在本实验装置下,浆料制备过程的冷却速度(0.5~0.7 K/s)属于快冷条件,因此,搅拌频率越高,晶粒尺寸越小,晶粒的形状因子越大。

根据这组实验可确定,在冷却速度为0.5~0.7 K/s的情况下,最佳电源频率为27~30 Hz。

2.2.3 浇注温度和搅拌时间的影响

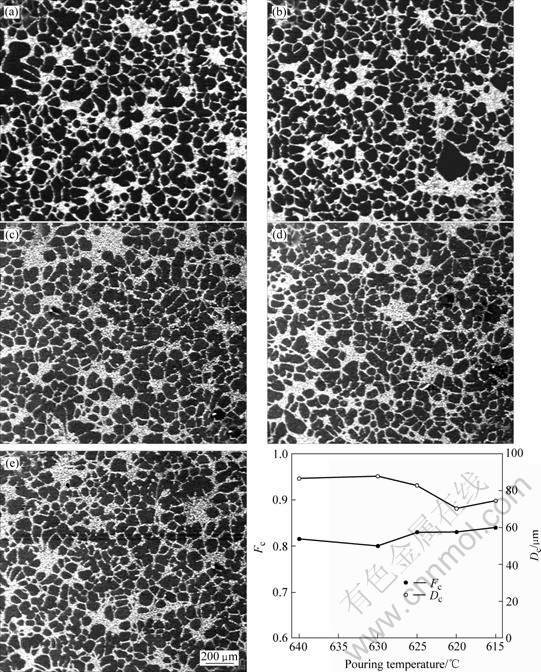

图7所示为不同浇注温度下,α(Al)相形貌照片及定量分析结果。在本实验条件下,当搅拌过程从640、630、625、620、615 ℃进行到607 ℃时,所需搅拌时间依次为67、50、35、25、20 s。从图7可看 出,在熔体处理和其它电磁搅拌参数一定的情况 下,当浇注温度从640 ℃开始下降时,形状因子随之增大,而晶粒尺寸逐渐减小并在620 ℃达到最低点(~75 μm),之后晶粒有所粗化。其原因分析如下:在665 ℃下,Al与TiB2颗粒上的TiAl3富集层通过包晶反应形成α(Al)晶核后,在合金熔体到达液相线 (611.5 ℃)之前,α(Al)晶核将出现两种不利于晶粒细化的现象:沉淀和重熔;要减少因沉淀而导致有效晶核减少的机会,可缩短合金熔体在液相区的停留时 间,也可通过加强电磁搅拌使其处于不断运动中;而要减少晶核重熔的机会只有通过缩短熔体在液相区的停留时间。缩短液相区停留时间的途径有两种:加快熔体的冷却速度和降低浇注温度,或将这两种方法综合。当半固态合金浆料制备坩埚直径较大时,四周的强冷作用会使靠近坩埚壁的浆料因为受到激冷而呈枝晶生长,因此,本文实验采用降低浇注温度的方 法,即:浇注温度越低,晶核重熔和偏聚的机会越 小,有利于晶粒细化。但当浇注温过低时,加入的中间合金粉末无法充分熔解,不利于形核质点从粉末颗粒中分离,同样导致有效晶核损失。本组实验表 明,对A356合金而言,选择浇注温度为615~620 ℃(相应的制备时间为20~25 s)可取得最佳的晶粒细化效果。

图7 浇注温度对α(Al)相形貌的影响

Fig.7 Influences of pouring temperatures on microstructures of α(Al) (Addition level of Al-5Ti-B: 0.15 %Ti; particle size <100 μm; reversible stirring without interval; t0=640 ℃; f=30 Hz; U=220 V; ?τ=3 s; τ=67 s): (a) 640 ℃; (b) 630 ℃; (c) 625 ℃; (d) 620 ℃; (e) 615 ℃

总结以上实验,得到电磁搅拌的最佳工艺为:正-反无间歇双向搅拌、单向旋转时间为3 s、电源频率为27~30 Hz、浇注温度为615~620 ℃。

3 结论

1) 获得Al-5Ti-B微细粉末熔体处理+双向电磁搅拌复合技术制备A356合金半固态浆料的工艺如下:在适当的温度(粗粉采用高温,细粉采用低温,即粉末粒度<100 μm:665 ℃;100~200 μm:680 ℃;200~250 μm:700~720 ℃;250~500 μm:720 ℃)下,与Al-10Sr合金间隔10min加入0.15%~0.20% Ti的微米级Al-5Ti-B合金粉末,并选用正-反无间歇双向搅拌、单向旋转时间为3 s、电源频率为27~30 Hz、浇注温度为615~620 ℃的电磁搅拌工艺。采用这组工艺,可在20~25 s内制备出形状因子为0.85左右,晶粒尺寸为70~80 μm(空冷尺寸)的A356合金半固态浆料。

2) 晶粒细化剂无论采用变形合金还是微细粉 末,都存在一个最大加入量,超过最大加入量后,加入量的增加不再对α(Al)相的大小产生影响或影响甚微。

3) 当Al-5Ti-B和Al-10Sr同时作用于Al-Si合金熔体时,SrB6的生成将造成晶粒细化效果和变质效果共同减弱。无论变形合金还是微细粉末,在熔体处理过程中,应分别加入。

REFERENCES

[1] Flemings M C, Martinez R A, de Figueredo A M. Metal alloy compositions and process [P]. US 20020096231, 2002-07-25.

[2] 赵大志,路贵民,崔建忠. 半固态铸造技术的发展状况及前景[J]. 铸造, 2005, 54(10): 943-947.

ZHAO Da-zhi, LU Gui-min, CUI Jian-zhong. Development and prospects for semi-solid metal casting [J]. Foundry, 2005, 54(10): 943-947.

[3] Fan Z. Semisolid metal processing [J]. International Materials Reviews, 2002, 47(2): 49-85.

[4] Flemings M C. Behavior of metal alloys in the semisolid state [J]. Metallurgical Transactions A, 1991, 22(5): 957-981.

[5] Kirkwood D H. Semisolid metal processing [J]. International Materials Reviews, 1994, 39(5): 173-189.

[6] Uchida M. Feature of UBE squeeze process and UNRC process (semi-solid casting) [A]. 李荣德. 第三届中国国际压铸会议论文集[C]. 沈阳: 东北大学出版社, 2002: 207-219.

Uchida M. Feature of UBE squeeze process and UNRC process (semi-solid casting) [A]. LI Rong-de. Proceedings of the 3rd China International Conference on Die Casting [C]. Shenyang: Northeastern University Press, 2002. 207-219.

[7] 冯鹏发,唐靖林,李双寿,等. A356.2合金半固态浆料在线制备技术研究[J]. 中国有色金属学报, 2006, 16(1): 13-21.

FENG Peng-fa, TANG Jing-lin, LI Shuang-shou, et al. On-line preparation technology of semi-solid slurry of A356.2 alloy [J]. The Chinese Journal of Nonferrous Metals, 16(1): 13-21.

[8] 李建国,王 亮. AlTiC中间合金细化剂研究的最新进展[J]. 轻合金加工技术, 2003, 31(3): 7-11.

LI Jian-guo, WANG Liang. Recent development in research of AlTiC master alloy [J]. Light Alloy Fabrication Technology, 2003, 31(3): 7-11.

[9] McCartney D G. Grain refining of aluminium and its alloys using inoculants [J]. International Materials Reviews, 1989, 34(5): 247-260.

[10] Murty B S, Kori S A, Chakraborty M. Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying [J]. International Materials Reviews, 2002, 47(1): 3-29.

[11] Maxwell I, Hellawell A. A simple model for grain refinement during solidification [J]. Acta Metallurgica, 1975, 23: 229-237.

[12] Kaneko J K, Sugamata M, Schimamune R, et al. Al-Ti and Al-Ti-B grain refiners processed by mechanical alloying for aluminum castings [J]. Transactions of the Japan Foundrymen's Society, 1991, 10: 72-75.

[13] 边秀房,刘相法,马家骥. 铸造金属遗传学[M]. 济南: 山东科学技术出版社, 1999: 76-111.

BIAN Xiu-fang, LIU Xiang-fa, MA Jia-ji. Heredity of Cast Metals[M]. Ji’nan: Shandong Science & Technology Press, 1999: 110-118.

[14] 李建国,马洪涛,张柏清,等. Al-3Ti-4B细化剂和Al-10Sr变质剂对ZL104合金的联合作用[J]. 金属学报, 2000, 36(6): 579-583.

LI Jian-guo, MA Hong-tao, ZHANG Bai-qing, et al. The combination effect of Al-3Ti-4B and Al-10Sr master alloy on ZL104 alloy [J]. Acta Metallurgica Sinica, 2000, 36(6): 579-583.

[15] 邢书明.铝合金半固态连铸技术与理论[D]. 北京:清华大学,2001: 63-66.

XING Shu-ming. Technology and Theory of Continuous Casting Processing of Semi-Solid Aluminum Alloy [D]. Beijing: Tsinghua University, 2001: 63-66.

[16] 曹广畴. 现代板坯连铸[M]. 北京: 冶金工业出版社, 1994: 413-419.

CAO Guang-chou. Modern Slab Continuous Casting [M]. Beijing: Metallurgical Industry Press, 1994: 413-419.

[17] 谢水生,黄声宏. 半固态金属加工技术及其应用[M]. 北京: 冶金工业出版社, 1999: 25-30.

XIE Shui-sheng, HUANG Sheng-hong. Semi-solid Metal Process and its Application [M]. Beijing: Metallurgical Industry Press, 1999: 25-30.

收稿日期:2006-05-31;修订日期:2006-11-28

通讯作者:唐靖林,副教授;电话:010-62772502,E-mail:tangjl@mail.tsinghua.edu.cn

(编辑 陈爱华)