DOI: 10.11817/j.ysxb.1004.0609.2020-35762

焊后热处理对钛/铝FSB接头组织及性能的影响

张忠科1,武靖伟1,赵华夏2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 中国航空制造技术研究院 航空焊接与连接技术航空科技重点实验室,北京 100024)

摘 要:研究了6082铝合金和TC4钛合金分别添加钎料锌和镍下的搅拌摩擦钎焊(FSB)搭接接头微观组织及焊后热处理后接头界面金属间化合物(IMC)的生成种类和先后顺序以及生长动力学模型。研究表明:添加钎料锌时,界面金属间化合物主要由AlZn、TiAl、TiAl2、TiAl3组成,先后顺序为TiAl2→TiAl3→TiAl→AlZn,并获得了界面IMC层的生长动力学模型为;添加钎料镍时,界面金属间化合物层主要由TiNi、Al3Ni2、Ti3Al和TiAl组成,先后顺序为776 K以下,Ti-Ni-Al焊接界面金属间化合物形成的顺序是Al3Ni2→TiNi→TiAl→Ti3Al,776 K以上时生成顺序为Al3Ni2→TiNi→Ti3Al→TiAl,并获得了界面IMC层的生长动力学模型。界面IMC层的厚度均随着温度的提高或保温时间的延长而增加。添加锌的接头的剪切强度由未热处理时的154 MPa提高到194 MPa,而添加钎料镍的接头由142 MPa提高至166 MPa。

关键词:钛/铝异种金属;搅拌摩擦钎焊;钎料;金属间化合物;热力学与动力学

文章编号:1004-0609(2020)-04-0739-11 中图分类号:TG146.2;TG453.9 文献标志码:A

近年来,随着钛/铝焊接构件在航空航天、高速铁路以及汽车船舶等行业中的应用越来越广泛[1-3],但是钛、铝两种金属物理性能上的较大差异,导致钛/铝异种金属在焊接过程中产生不同的金属间化合物(IMC),致使钛/铝异种金属连接成了广大学者所研究的热门话题[4-6]。

越来越多的学者就钛/铝异种金属的连接方式进行了实验和讨论,并从中找到了钎焊、熔焊以及搅拌摩擦焊等焊接方式,其中研究搅拌摩擦焊接(FSW)的较多。如陈玉华等[7]研究了钛/铝异种金属FSW搭接接头的显微组织,从而获得焊缝成形良好,无孔洞和裂纹等缺陷的搭接接头的最佳工艺参数。SONG等[8-9]研究了偏移量对TC4钛合金和6061铝合金接头组织及力学性能的影响,发现选择合适的偏移量可获得强度超过母材的焊接接头。经过搅拌摩擦焊接形成的接头中会存在一些脆性IMC,为了减少脆性IMC的产生,一些学者提出了钎焊和搅拌摩擦焊的复合焊接-搅拌摩擦钎焊(FSB)进行焊接。张贵峰等[10]开发了搅拌摩擦钎焊技术(FSB),并采用锌作钎料,但是大部分的锌熔化后从焊缝中流出,由此得到的铝/钢焊接接头的组织主要为脆性的Al-Fe IMC,需要通过控制其主要参数(如搅拌头转速、焊接速度)来降低IMC的厚度。张鑫[11]通过在3 mm的TC4和2Al14中间添加0.05 mm的锌箔和镍箔下完成搅拌摩擦钎焊,并通过焊缝表面以及微观组织的观察,并结合各种力学实验以找到最合适的焊接工艺参数。

通常情况下,在焊接过程中,由于母材性能之间的差异,热量的输入使焊接接头各个区域的剪切强度出现差异,为研究该问题并提高其强度,故采用焊后热处理的方式以提高接头力学性能。已有研究者就焊后热处理对接头性能的影响做了研究。朱东晖等[12]的研究表明,与刚焊完的接头相比,经过焊后热处理的接头的力学性能得到一定提升。李国伟等[13]对10 mm厚的7075铝合金进行了等离子弧焊焊接,并对焊后的接头进行了固溶+水淬时效热处理,发现热处理后接头的抗拉强度从热处理前的397.9 MPa提高到545.1 MPa,焊缝的显微硬度也有所改善,力学性能显著提高。杜春平等[14]对Al-Zn-Mg合金焊接接头进行了焊后热处理,研究表明接头固溶区的硬度和耐腐蚀性能均随焊后热处理时效时间的延长和温度的升高而提升。上述研究结果均表明了焊后热处理可使接头力学性能得到一定的改善。也有学者采用热力学与动力学的手段分析了焊接界面IMC的热力学和动力学规律。王星星等[15]通过熔炼合金的方法制备了AgCuZnSn钎料,并利用热分析动力学方法获得了钎焊工艺熵和接头性能熵的表达式从而表征了AgCuZnSn钎料的钎焊性能。金玉花等[16]利用动力学的手段研究了6061铝合金和AZ31B镁合金搅拌摩擦搭接焊接头界面IMC的生长行为,结果发现整个IMC层的生长厚度与退火时间的平方根成线性关系,即其生长受扩散机制的影响。韩丽青等[17]利用热力学和动力学的手段研究了TA2/316L焊接接头真空热处理后界面IMC层的生长规律,结果表明界面IMC呈线性增长。

由于利用热力学和动力学的分析了钛/铝FSB界面IMC生长[18]的研究较少,因此本文针对焊后钛/铝FSB接头经退火热处理来提高接头的力学性能,研究了热处理温度和保温时间对接头组织和力学性能的影响、不同热处理温度下钛/铝界面IMC在热处理过程中的生长动力学模型和界面IMC的影响规律,为提高接头性能提供理论和实验依据。

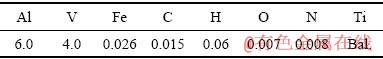

1 实验

试验装置示意图如图1所示。试验材料为6082铝合金和TC4钛合金,其化学成分表分别如表1和2所示,其中铝合金的规格为100 mm×100 mm×2 mm,而钛合金的厚度为100 mm×100 mm×1 mm。锌与铝在任何温度下都不生成Al-Zn IMC,而生成Al-Zn固溶体,且与钛在各温度下的反应均很单一;镍箔可以优先与铝反应生成塑性好的Al-Ni IMC,从而阻止脆性的Ti-Al IMC生成。因此,选用锌箔和镍箔作为钎料[7],其厚度[19]均为0.05 mm。

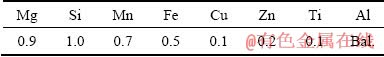

表1 6082铝合金化学成分

Table 1 Chemical compositions of Al6082 (mass fraction, %)

表2 TC4钛合金化学成分

Table 2 Chemical compositions of TC4 (mass fraction, %)

焊接设备为FSW-3LM-015型数控搅拌摩擦焊机,搅拌头材料为镍基高温合金,其轴肩直径19 mm,搅拌针直径为5 mm,搅拌针长度为2 mm。焊前将待焊的铝合金和钛合金表面用砂纸进行打磨以去除其表面的氧化膜,然后再按铝合金-钎料-钛合金自上而下的顺序构建搭接试验。经多次优化工艺参数,该试验所选参数为:添加钎料锌时搅拌头转速n=1600 r/min,焊接速度v=60 mm/min;添加钎料镍时n=1400 r/min,v=60 mm/min,下压量均为0.2 mm,焊接开始搅拌头在铝母材上摩擦10 s,焊后再电阻炉中进行退火热处理。由于钛、铝、锌和镍的熔点分别为1678、660、419和1495 ℃,在热处理实验中,选择所有材料的最低熔点为界线,合理选择热处理温度,因此添加钎料锌时的热处理温度选为300、350和400 ℃,添加钎料镍时选为400、500和600 ℃,保温时间均为30、60和90 min,退火后样品随炉冷至室温。在WDW-100D型万能材料试验机进行拉剪实验,加载速率为0.5 mm/min,试验试样每组3个。借助扫描电镜(SEM)对界面焊核区的IMC形貌和分布进行观察和分析,通过能谱(EDS)对钛/铝接头界面显微组织及元素分布进行观察和分析,并利用X射线衍射(XRD)进一步来确定界面IMC层的相。

图1 搅拌摩擦焊接实验示意图

Fig. 1 Schematic diagrams of friction stir brazing(Unit: mm)

2 结果与讨论

2.1 界面IMC的生长

2.1.1 添加钎料锌时界面IMC的生长

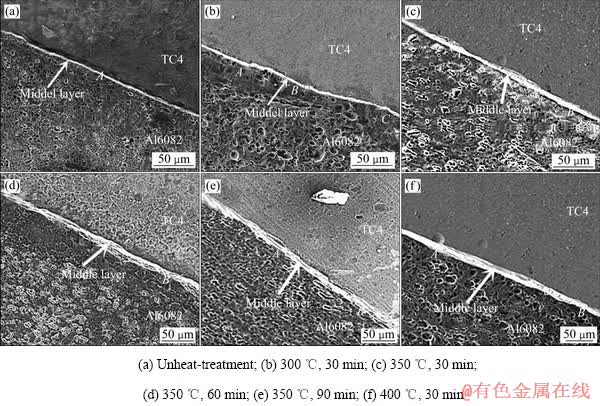

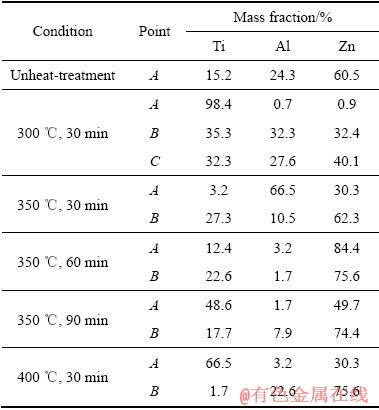

图3所示为添加钎料锌时钛/铝界面IMC在不同热处理条件下的微观形貌,该图反映了界面金属间化合物的动态生长过程。由图3可以看出,界面IMC的厚度随热处理温度和保温时间的增加而增厚。反应初期:未经热处理时界面只形成一层连续的IMC,厚度仅有1.9 μm,如图3(a)所示,这说明在较低温度下界面的相互作用较低。随着热处理温度的升高,如图3(b)、(c)和(f)所示,界面IMC层的厚度由300 ℃时的4.3 μm增加至400 ℃时的8.6 μm。随着保温时间的延长,如图3(c)~(e)所示,界面IMC层的厚度由30 min时的4.3 μm增加至90 min的5.3 μm。对不同参数下的A、B层进行能谱点扫分析,其IMCs中的主要元素的成分分析结果见表3,并将图3(c)对应的试样横截面进行XRD分析,结果见图4。由图4可知,在该参数下的FSB搭接接头的IMC层主要由AlZn、TiAl、TiAl2、TiAl3组成。结合EDS与XRD分析结果,可以确定靠近钛侧的IMC为Ti-Al IMC,靠近铝侧的为AlZn固溶体。

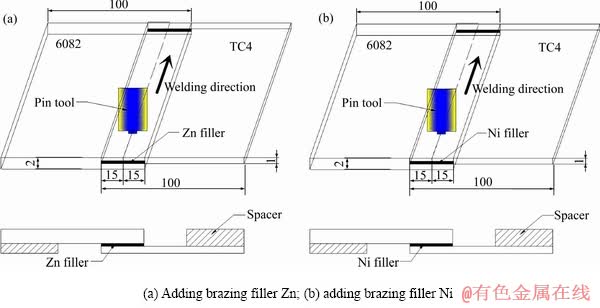

图2 焊接接头横截面

Fig. 2 Cross section of Ti/Al FSB joints

图3 不同温度及保温时间下添加钎料锌时Ti/Al界面的微观形貌

Fig. 3 Microstructure morphologies of Ti/Al interface annealing at different temperatures and holding time by adding filler Zn

在退火过程中,外界为钛、锌和铝基体界面IMC的形成、界面原子的扩散和重新组合提供了能量,界面IMC的厚度及形貌会发生变化。在长时间的退火过程中,AlZn固溶体与Ti-Al IMC之间保持平衡状态,共同作用使界面IMC层厚度增加。

表3 添加钎料锌时不同退火条件下的特殊位置的化学成分

Table 3 Compositions measured at special location for different annealing conditions by adding filler Zn

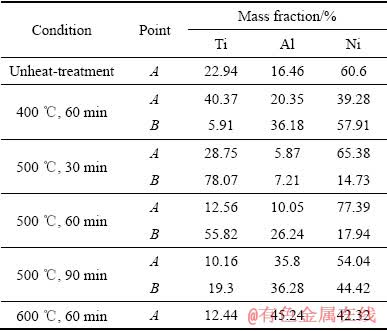

2.1.2 添加钎料镍时界面金属间化合物的生长

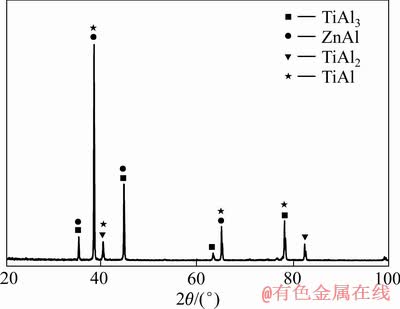

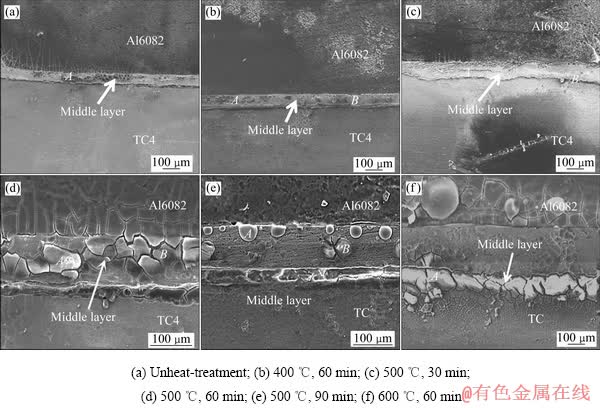

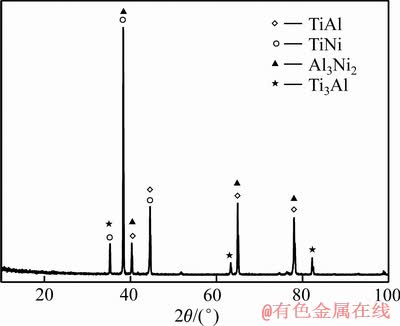

图5所示为添加钎料镍时钛/铝界面IMC在不同热处理条件下的微观形貌。从图5中可以看出,未热处理时界面形成了厚度为5.5 μm的IMC层,随着热处理温度和保温时间的增长,界面IMC层的厚度逐渐增加,从400℃时的6.4 μm增加到600 ℃的8.8 μm和从由30 min时的7.0 μm增加到90 min时的7.9 μm,这说明在界面处形成了不同的IMC。对不同热处理条件下的A、B层进行EDS点扫分析,其主要元素及含量见表4,并对图5(d)搭接接头的横截面进行XRD分析,如图6所示,其结果显示在该参数下接头的IMC层主要由TiNi、Al3Ni2、Ti3Al和TiAl组成。结合EDS与XRD分析结果,可以确定靠近钛侧的IMC为TiNi、Ti3Al和TiAl相,靠近铝侧的为Al3Ni2 IMC。

图4 添加钎料锌时Ti/Al接头界面扩散层的XRD谱

Fig. 4 XRD pattern of diffusion layer of Ti/Al interface by adding filler Zn

图5 不同温度及保温时间下添加钎料镍时Ti/Al界面的微观形貌

Fig. 5 Microstructure morphologies of Ti/Al interface annealing at different temperatures and holding time by adding filler Ni

表4 添加钎料Ni时不同退火条件下特殊位置的化学成分

Table 4 Compositions measured at special location for different annealing conditions by adding filler Ni

图6 添加钎料Ni时Ti/Al 接头界面扩散层的XRD谱

Fig. 6 XRD pattern of diffusion layer of Ti/Al interface by adding filler Ni

与添加钎料锌时的情形相似,在退火过程中,外界为钛、镍和铝基体界面IMC的形成、界面原子的扩散和重新组合提供了能量,使得钛、镍和铝基体界面IMC的厚度及形貌发生了变化。在长时间的退火过程中,各种IMCs之间保持平衡状态,共同作用使界面IMC层厚度增加。另外,加入镍后接头的剪切强度比不加镍时高,其原因主要是在铝侧中间层形成致密的结合,而在钛侧接头存在较多缺陷,即未完全形成冶金结合,此处生成的IMC较均匀,但比较脆,在文献[7]中也发现有相似现象。

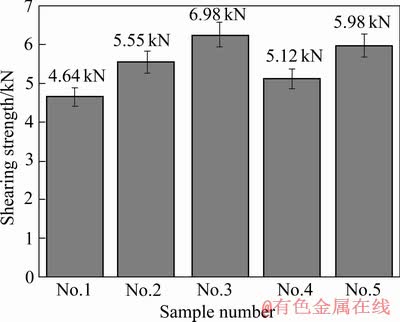

2.2 焊后热处理对接头剪切强度的影响

图7所示为不加钎料和添加钎料锌和镍以及热处理后接头的剪切强度分布情况。No.1表示不添加钎料下接头的剪切强度,No.2和No.4分别是添加钎料锌和镍在最佳焊接工艺参数(Zn,n=1600 r/min;Ni,n=1200 r/min;v=60 mm/min)下接头的剪切强度,而No.3和No.5分别是No.2和No.4经热处理后(Zn,热处理温度为350 ℃,保温30 min;Ni,热处理温度为500 ℃,保温60 min)接头的剪切强度。

图7 各参数下接头的剪切强度

Fig. 7 Shearing strength of joints at different parameters

从图7可以看出,添加钎料锌和镍时接头的剪切强度均高于不添加钎料时接头的剪切强度,而添加钎料锌时接头的剪切强度高于添加钎料镍时接头的剪切强度。在钛/铝FSB搭接实验中,添加钎料锌时的接头强度最高,为5.55 kN。从图6可以看到,经热处理后接头的剪切强度均得以提高。其原因是:在焊接过程中,熔化的锌对实现锌与铝合金和钛合金的冶金结合起到了至关重要的作用;而加入钎料镍时,由于Ni-Al IMC比脆性的Ti-Al IMC先生成,故钎料镍的添加同样起到了重要的作用。

虽然IMC和固溶体层厚度明显增加,但由于IMC种类改变,同时界面边沿区域填充了缝隙,界面边沿区域通过热处理增加了扩散等作用,使接合强度进一步提高[20]。

2.3 界面热力学

2.3.1 添加钎料锌时界面热力学结果

在热处理过程中,TC4/6082 FSB界面反应较为简单,具体过程如下。从Al-Zn二元相图可以看出,在382 ℃时发生共晶反应:L γ+β,生成γ+β共晶体;在275 ℃时发生共析反应:γ

γ+β,生成γ+β共晶体;在275 ℃时发生共析反应:γ α(Al)+β(Zn),生成α(Al)+β(Zn)共析体,冷至室温析出AlZn固溶体。从Ti-Al二元相图可以看出,在焊接过程中,TiAl、TiAl2、TiAl3、Ti3Al等Ti-Al IMCs都会生成,但是经过热处理后这些Al-Ti IMCs均会变化,因此在Ti-Zn-Al FSB界面可能会生成Al-Zn固溶体相和Ti-Zn、Al-Ti IMCs。从热力学来看,生成的化合物及生成顺序与其标准生成自由能有关。采用热力学第一近似计算方程[21],在热力学温度下计算反应的标准生成自由能,由此判断 TC4/6082在Zn作钎料下的焊接接头中各组元之间在一定的温度下是否发生化学反应以及反应程度。根据相关热力学数据[21-22],估算Ti-Zn-Al界面可能发生的反应所形成的IMCs的标准生成自由能如表5所示。

α(Al)+β(Zn),生成α(Al)+β(Zn)共析体,冷至室温析出AlZn固溶体。从Ti-Al二元相图可以看出,在焊接过程中,TiAl、TiAl2、TiAl3、Ti3Al等Ti-Al IMCs都会生成,但是经过热处理后这些Al-Ti IMCs均会变化,因此在Ti-Zn-Al FSB界面可能会生成Al-Zn固溶体相和Ti-Zn、Al-Ti IMCs。从热力学来看,生成的化合物及生成顺序与其标准生成自由能有关。采用热力学第一近似计算方程[21],在热力学温度下计算反应的标准生成自由能,由此判断 TC4/6082在Zn作钎料下的焊接接头中各组元之间在一定的温度下是否发生化学反应以及反应程度。根据相关热力学数据[21-22],估算Ti-Zn-Al界面可能发生的反应所形成的IMCs的标准生成自由能如表5所示。

表5 Ti-Zn-Al界面可能发生的反应及所形成的IMCs的标准生成自由能

Table 5 All possible chemical reactions occurring at Ti-Zn-Al interface and Gibbs free energy of IMCs

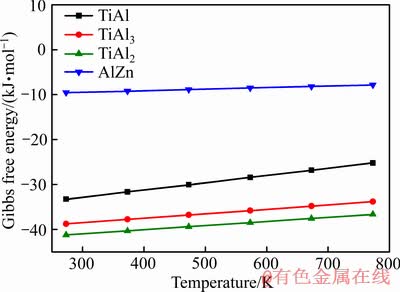

根据上述反应产物的标准生成自由能与温度之间的关系,再通过Origin软件绘出反应自由能随时间的变化曲线,如图8所示。

图8 Ti-Zn-Al界面各种IMCs的标准生成自由能与温度的关系

Fig. 8 Relationship between Gibbs free energy and temperature for different IMCs at Ti-Zn-Al interface

选择最小自由能为基本判据,也就是说一个化学反应或过程能否在等温等压的条件下发生,取决于该反应的自由焓是负值还是正值。当为负值时,反应可以进行,负值越大,该反应越容易发生,趋势越大。两个相同类型的反应,其反应顺序取决于其自由焓负值的大小,负值越大,越优先反应。从图8中可以看出,生成AlZn相的摩尔吉布斯自由能远大于TiAl2、TiAl3和TiAl相的摩尔吉布斯自由能[23-24],说明AlZn相是在TiAl2、TiAl3和TiAl等相形成后才形成。故当温度低于600 ℃时,自由能由低到高依次是TiAl2、TiAl3、TiAl和AlZn;自由能越低,说明此IMC越稳定,也越容易形成。故在673 K以下,Ti-Zn-Al焊接界面IMC形成的顺序为TiAl2→TiAl3→TiAl→ AlZn,并发现各种IMCs的吉布斯自由能均随着温度的升高而升高。

根据XU等[25]的研究发现,TiAl2是一种亚稳相,因而在焊接过程中,这种IMC不可能生成,而其他IMCs的吉布斯自由能在温度低于800 K时均小于0,说明在该温度范围内,这些IMCs可能在Ti-Al界面上生成。通过上面热力学计算并分析可知,在Ti-Zn-Al焊接接头界面处可以生成TiAl3、TiAl相和AlZn固溶体,而图4所示的Ti-Zn-Al焊接接头界面的XRD分析结果也表明,在Ti-Zn-Al焊接接头界面处较易生成TiAl3、TiAl和AlZn这三种IMCs或固溶体,与上述热力学计算的结果相一致。这表明所建立的热力学计算模型能够反映IMCs的生成可能性以及生成顺序。

2.3.2 添加钎料镍时界面热力学结果

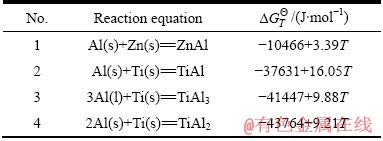

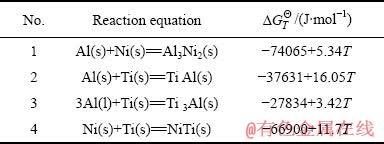

在热处理过程中,TC4/6082 FSB界面反应较为复杂,再结合Al-Ti二元相图和Al-Ni二元相图及Ti-Ni二元相图,可以知道在Ti-Ni-Al界面可能生成Ti-Al、Ti-Ni和Al-Ni这三种IMCs。判断TC4/6082在镍作钎料时的FSB焊接接头中各组元之间在一定的温度下是否发生化学反应、反应所形成的IMC以及生成顺序均与其生成吉布斯自由能有关。根据热力学第一近似计算方程[21-22],可以估算出Ti-Ni-Al界面可能发生的反应形成的IMCs标准生成自由能,如表6所示。

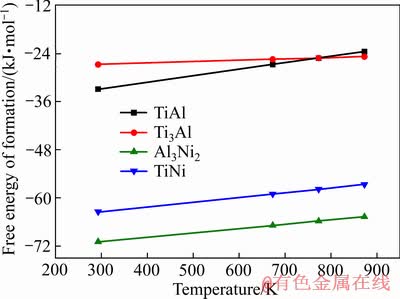

根据上述反应产物的标准生成自由能与温度之间的关系,再通过Origin软件绘出反应吉布斯自由能随时间的变化曲线,如图9所示。从图9中可以看出,生成TiNi和Al3Ni2的吉布斯自由能远低于Ti-Al金属间化合物的,根据最小自由能基本判据,可以得知在Ti-Ni-Al焊接界面最先生成Al3Ni2相,其次是TiNi相,最后是TiAl相和Ti3Al相,但当温度约在776 K时Ti3Al和TiAl吉布斯自由能相等[23-24],故在776 K以下,Ti-Ni-Al焊接界面IMC形成的顺序是Al3Ni2→ TiNi→TiAl→Ti3Al,776K以上,其生成顺序Al3Ni2→ TiNi→Ti3Al→TiAl。自由能越低,金属间化合物越稳定,并发现各种IMCs的吉布斯自由能均随着温度的升高而升高。图5所示的Ti-Zn-Al焊接接头界面的XRD谱也表明,在Ti-Zn-Al焊接接头界面处较易生成Al3Ni2、TiNi和TiAl这三种IMCs,与上述热力学计算结果相一致,表明所建立的热力学计算模型能够反映IMCs的生成可能性以及生成顺序。

表6 Ti-Ni-Al界面可能发生的反应及所形成的IMCs的标准生成自由能

Table 6 All possible chemical reactions occurring at Ti-Ni-Al interface and Gibbs free energy of IMCs

图9 Ti-Ni-Al界面各种IMCs的标准生成自由能与温度的关系

Fig. 9 Relationship between Gibbs free energy and temperature for different IMCs at Ti-Ni-Al interface

2.4 界面动力学

Ti-Zn-Al界面IMC及固溶体的生长主要受钛、铝、锌等原子的扩散所控制,Ti-Ni-Al界面IMC的生长主要受钛、铝、镍等原子扩散的控制。而扩散系数又受焊接过程中焊缝处的温度所控制,即受焊接工艺参数的控制。一般固态IMC的增长符合线性或抛物线式的增长动力学,线性增长意味着增长处的增长率受限于反应速度,而抛物线增长意味着增长受体扩散的限制。如果增长过程受体扩散的控制,那么再结晶退火后IMC的增长应符合抛物线规律[26],此时n=0.5。

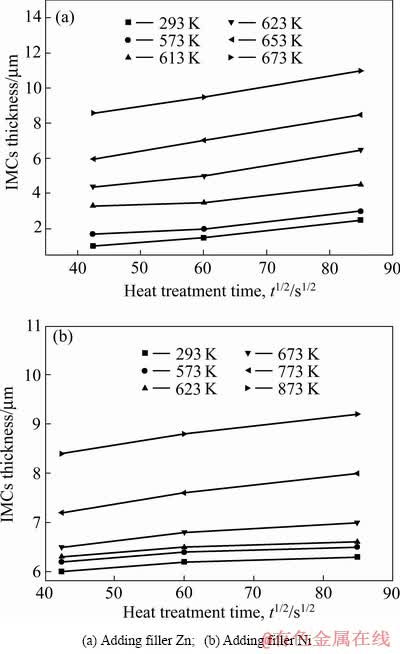

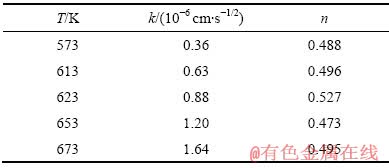

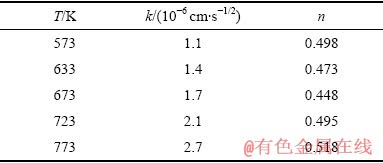

图10所示为添加钎料锌和镍时Ti/Al FSB接头中间IMC层的厚度与退火温度及保温时间的关系。从图10中可以看出,添加锌和镍时Ti/Al FSB接头界面IMC的增长均符合抛物线规律,意味着IMC层在再结晶退火时受体扩散的控制,增长率常数可以从线性回归分析计算得到,即W-t曲线中的斜率k。

表7和8所示分别为添加钎料锌和镍时焊接界面IMC的生长率常数。从表中可以看出,在这些温度下的时间指数n均在0.5上下浮动,这意味着在添加钎料锌和镍时的Ti/Al FSB焊接过程中,界面IMC及固溶体的生长呈抛物线规律,即界面IMC和固溶体的形成在一定程度上受到体扩散的影响。

再根据Arrhenius公式确定界面IMC增长的激活能Q:

(1)

(1)

式中:k为增长率常数,cm2/s;k0为频率因子,cm2/s;Q为激活能,kJ/mol;R为摩尔气体常数,8.314 J/(mol·K)。

图10 中间IMC层的厚度与退火温度及保温时间的关系

Fig. 10 Relationship between thickness of intermetallic compound (IMC) layer and annealing time

表7 添加钎料锌时焊接界面IMC在不同退火温度下的生长率常数

Table 7 Calculated growth rate constants of interface IMCs at different annealing temperatures by adding filler Zn

表8 添加钎料镍时焊接界面IMC在不同退火温度下的生长率常数

Table 8 Calculated growth rate constants of interface IMCs at different annealing temperatures by adding filler Ni

对Arrhenius公式两边取对数得

(2)

(2)

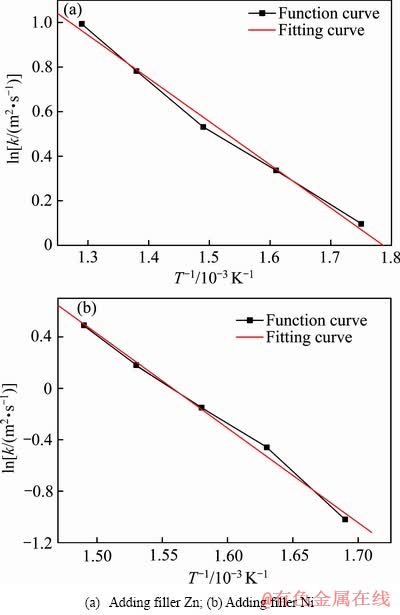

通过式(2)可分别画出添加钎料锌和镍时的 -1/T的函数曲线,得出曲线的斜率为m=-Q/R,再通过线性回归就可以计算出激活能Q=mR。图11所示为Ti-Zn-Al和Ti-Ni-Al焊接界面的IMC层生长速度的Arrhenius图。从图11中可以看出,尽管有2至3个点偏离了曲线,但其他点仍然满足Arrhenius公式。经回归方法计算得出,添加钎料锌时的动力学参数为激活能Q=62.98 kJ/mol、k0=1.82×10-6 m2/s;添加镍时的动力学参数为激活能Q=72.09 kJ/mol、k0=3.26× 10-6 m2/s。

-1/T的函数曲线,得出曲线的斜率为m=-Q/R,再通过线性回归就可以计算出激活能Q=mR。图11所示为Ti-Zn-Al和Ti-Ni-Al焊接界面的IMC层生长速度的Arrhenius图。从图11中可以看出,尽管有2至3个点偏离了曲线,但其他点仍然满足Arrhenius公式。经回归方法计算得出,添加钎料锌时的动力学参数为激活能Q=62.98 kJ/mol、k0=1.82×10-6 m2/s;添加镍时的动力学参数为激活能Q=72.09 kJ/mol、k0=3.26× 10-6 m2/s。

最后将上面所得到的k0和Q值代入到经验公式[27],可得到TC4/Al6082在添加钎料锌和镍时FSB焊接界面的IMC厚度W分别为:

W=1.82×10-6m2·s-1·exp[-62.98(kJ/mol)/(RT)]·t1/2 (3)

W=3.26×10-6 m2·s-1·exp[-72.09(kJ/mol)/(RT)]·t1/2 (4)

图11 焊接界面IMC层生长速度的Arrhenius图

Fig. 11 Arrhenius graph of growth rate of IMC layer

3 结论

1) 添加钎料锌时,6082铝合金和TC4钛合金的FSB搭接接头中,界面IMC层的厚度仅有1.9 μm;而添加钎料镍时,界面IMC层的厚度为5.5 μm。无论添加钎料锌还是添加钎料镍,随着热处理温度的增加,接头的剪切强度均先增大后减小,但是总体较未热处理的接头的剪切强度提高了很多。添加钎料锌时接头的剪切强度由154 MPa提高到194 MPa;添加钎料镍时接头的剪切强度由142 MPa提高至166 MPa。

2) 在退火过程中,界面IMC层的厚度随着热处理温度和保温时间的增加而增大。添加钎料锌时,IMC层主要由AlZn、TiAl、TiAl2、TiAl3组成;添加钎料镍时,IMC层主要由TiNi、Al3Ni2、Ti3Al和TiAl组成。随着温度的升高,其生长均遵循抛物线规律,生长动力学与退火时间的平方根呈正比关系,生长受扩散机制影响。

3) 在Ti-Zn-Al焊接界面最先生成ZnAl固溶体,先后反应的顺序为TiAl2→TiAl3→TiAl→AlZn。在Ti-Ni-Al焊接界面最先生成Al3Ni2 IMC,因为当温度在776 K(503 ℃)时Ti3Al和TiAl吉布斯自由能相等,故在673~873 K之间IMCs生成的顺序不一样,即在776 K以下,Ti-Ni-Al焊接界面IMCs形成的顺序是Al3Ni2→TiNi→TiAl→Ti3Al;在776K以上,其生成顺序为Al3Ni2→TiNi→Ti3Al→TiAl。

4) Ti-Zn-Al和Ti-Ni-Al焊接界面上的IMCs增长符合抛物线增长规律,通过试验和回归计算,得到了焊接界面金属间化合物和固溶体的动力学模型分别为W=1.82×10-6 m2·s-1·exp[-62.98(kJ/mol)/(RT)]·t1/2和W=3.26×10-6 m2·s-1·exp[-72.09(kJ/mol)/(RT)]·t1/2。

REFERENCES

[1] LI Cui, LI Bin, WU Ze-feng, QI Xiao-yong, YE Bin, WANG Ai-hua. Stitch welding of Ti-6Al-4V titanium alloy by fiber laser[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 91-93.

[2] CHEN Jun, ZHANG Qing. Effect of electrochemical state on corrosion-wear behaviors of TC4 alloy in artificial seawater[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(4): 1011-1012.

[3] 朱政强, 曾 纯, 张义福, 熊志林. 铝/钛异质材料超声波焊接研究[J]. 热加工工艺, 2011, 40(7): 118-120.

ZHU Zheng-qiang, ZENG Chun, ZHANG Yi-fu, XIONG Zhi-lin. Study on ultrasonic welding of Al/Ti dissimilar alloys[J]. Journal of Thermal Processing Technology, 2011, 40(7): 118-120.

[4] 吴新勇, 廖 娟, 薛 鑫, 詹艳然. 钛/铝异种合金脉冲激光焊接接头裂纹产生机理[J]. 精密成型工程, 2018, 10(6): 95-97.

WU Xing-yong, LIAO Juan, XUE Xin, ZHAN Yan-ran. Mechanism of joint crack in pulse laser welding of titanium/aluminum alloy[J]. Precision Molding Engineering, 2018, 10(6): 95-97.

[5] 潘春晓. 异种钢及异种金属焊接[M]. 北京: 人民交通出版社, 2000: 13-15.

PAN Chun-xiao. The welding of dissimilar metal and steel[M]. Beijing: Renmin and Jiaotong Press, 2000: 13-15.

[6] 陈玉华, 倪 泉, 黄春平, 柯黎明. 钛/铝异种金属搅拌摩擦焊搭接接头的组织结构[J]. 焊接学报, 2011, 32(9): 116-117.

CHEN Yu-hua, NI Quan, HUANG Chu-ping, KE Li-ming. Structure of friction stir welded lap joints of different titanium/aluminum metals[J]. Transactions of the China Welding Institution, 2011, 32(9): 116-117.

[7] 张 鑫, 陈玉华, 王善林. 中间层材料对Ti/Al搅拌摩擦焊接组织和性能的影响[J]. 稀有金属材料与工程, 2016, 45(5): 1290-1295.

ZHANG Xin, CHEN Yu-hua, WANG Shan-lin. Effect of Intermediate layer on microstructure and mechanical properties of Ti/Al Joint welded by friction stir welding[J]. Rare Metal Materials and Engineering, 2016, 45(5): 1290-1295.

[8] SONG Zhi-hua, NAKATA Kazuhiro, WU Ai-ping. Influence of probe offset distance on interfacial microstructure and mechanical properties of friction stir butt welded joint of Ti6A14V and A6061 dissimilar alloys[J]. Materials and Design, 2014, 57(5): 269-278.

[9] WU Ai-ping, SONG Zhi-hua, NAKATA Kazuhiro. Interface and properties of the friction stir welded joints of titanium alloy Ti6A14V with aluminum alloy 6061[J]. Materials and Design, 2015, 71(4): 85-92.

[10] 张贵锋, 苏 伟, 韦中新, 郭文亮, 张建勋. 搅拌摩擦钎焊制备铝/钢防腐双金属复合板新技术[J]. 焊管, 2010, 33(3): 18-24.

ZHANG Gui-feng, SU Wei, WEI Zhong-xin, GUO Wen-liang, ZHANG Jian-xun. The new technology of aluminum/steel antiseptic bimetal composite plate by friction stir brazing[J]. Welding Pipe, 2010, 33(3): 18-24.

[11] 张 鑫. 中间层材料对Ti/A1异种金属搅拌摩擦焊接头组织及性能的影响[D]. 南昌: 南昌航空大学, 2015.

ZHANG Xin. Effect on intermediate layer on microstructure and mechanical properties of friction stir welded joint of Ti/Al dissimilar metals[D]. Nanchang: Nanchang Hangkong University, 2015.

[12] 朱东晖, 陈江华, 刘春晖, 孟立春. 焊后热处理对Al-Mg-Si-Cu合金激光焊焊接接头微观结构和力学性能的影响[J]. 中国有色金属学报, 2015, 25(9): 2343-2349.

ZHU Dong-hui, CHEN Jiang-hua, LIU Chun-hui, MENG Li-chun. Effects of post-weld heat treatment on microstructure and mechanical properties of laser-beam welded Al-Mg-Si-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2343-2349.

[13] 李国伟, 陈芙蓉, 韩永全, 梁亚红. 焊后热处理对7075铝合金PVPPA焊接接头组织及性能的影响[J]. 焊接学报, 2018. 39(2): 58-60.

LI Guo-wei, CHEN Fu-rong, HAN Yong-quan, LIANG Ya-hong. Influence of post-weld heat treatment on microstructure and mechanical properties of 7075 aluminum alloy P-VPPA welded joint[J]. Transactions of the China Welding Institution, 2018, 39(2): 58-60.

[14] 杜春平, 王培吉. 焊后热处理对Al-Zn-Mg合金焊接接头组织及性能的影响[J]. 中国有色金属学报, 2017, 27(12): 2484-2487.

DU Chun-ping, WANG Pei-ji. Effect of post-weld heat treatment on microstructure and properties of Al-Zn-Mg alloy welded joint[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2484-2487.

[15] 王星星, 杜全斌, 彭 进, 崔大田, 于涛源. AgSnZnSn钎料的热力学特性[J]. 中国有色金属学报, 2018, 28(6): 1160-1166.

WANG Xing-xing, DU Quan-bin, Peng Jin, CUI Da-tian, YU Tao-yuan. Thermodynamics characteristics of AgCuZnSn brazing fillers metals[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(6): 1160-1166.

[16] 金玉花, 甘瑞根, 邵庆丰, 李常锋. 焊后退火Al-Mg界面金属间化合物生长行为[J]. 焊接学报, 2017, 38(8): 69-71.

JIN Yu-hua, GAN Rui-gen, SHAO Qing-feng, LI Chang-feng. Growth behavior of Al-Mg intermetallic during post weld annealing treatment[J]. Transactions of the China Welding Institution, 2017, 38(8): 69-71.

[17] 韩丽青, 王自东, 龙 斌, 林国标, 张 鸿. 钛/不锈钢焊接界面金属间化合物的生成动力学[J]. 材料热处理学报, 2011, 32(2): 63-64.

HAN Li-qing, WANG Zi-dong, LONG Bin, LIN Guo-biao, ZHANG Hong. Formation kinetics of interfacial intermetallic compounds of TA2/316L welding joints[J]. Transactions of Materials and Heat Treatment, 2011, 32(2): 63-64.

[18] FOADIAN F, SOLTANIEH M, ADELI M, ETMINAN- BAKHSH M. The kinetics of TiAl3 formation in explosively welded Ti-Al multilayers during heat treatment[J]. Metallurgical and Materials Transactions B, 2016, 47(5): 2931-2937.

[19] 武靖伟, 张忠科, 车朋卫. 钎料Zn对钛/铝搅拌摩擦钎焊接头组织及性能的影响[J]. 材料导报, 2019, 33(9): 3067-3072.

WU Jing-wei, ZHANG Zhong-ke, CHE Peng-wei. Influence of brazing filler Zn on microstructure and properties of titanium and aluminum joint by friction stir brazing[J]. Materials Reports, 2019, 33(9): 3067-3072.

[20] 潘钱付, 蒋明忠, 戴 训, 王贯春. 退火方式对N36高合金包壳管性能的影响[J]. 金属热处理, 2015, 40(12): 135-138.

PAN Qian-fu, JIANG Ming-zhong, DAI Xun, WANG Guan-chun. Influence of annealing processes on properties of N36 zirconium alloy cladding tube[J]. Heat Treatment of Metals, 2015, 40(12): 135-138.

[21] 叶大伦, 胡建华. 实用无机热力学数据手册[M]. 北京: 冶金工业出版社, 2002: 1518-1614.

YE Da-lun, HU Jian-hua. Practical inorganic thermodynamics data handbook[M]. Beijing: Metallurgical Industry Press, 2002: 1518-1614.

[22] 梁英教, 车荫昌. 无机热力学数据手册[M]. 沈阳: 东北大学出版社, 1993: 1213-1256.

LIANG Ying-jiao, CHE Yin-chang. Handbook of inorganic thermodynamic data[M]. Shenyang: Northeast University Press, 1993: 1213-1256.

[23] KATTNER U R, LIN J C,CHANG Y A. Thermodynamic assessment and calculation of the Ti-Al system[J]. Metallurgical Transactions A, 1992, 23(8): 2081-2090.

[24] ZHAO Yang-yang, LI Jiu-yong, QIU Ran-feng, SHI Hong-xin. Growth characterization of intermetallic compound at the Ti/Al solid state interface[J]. Materials, 2019, 12(3): 574-576.

[25] XU L, CUI Y L, HAO R Y. Growth of intermetallic layer in multi-laminated Ti/Al diffusion couples[J]. Materials Science and Engineering A, 2006, 435: 638-647.

[26] TO S, ZHU Y H, LEE W B. Effects of cutting depth on the surface microstructure of a Zn-A1 alloy during ultra-precision machining[J]. Applied Surface Science, 254(6): 1559-1564.

[27] 徐 瑞, 荆天辅. 材料热力学与动力学[M]. 哈尔滨: 哈尔滨工业大学出版社, 2003: 54-56.

XU rui, JING Tian-fu. Thermodynamics and kinetics of materials[M]. Harbin: Harbin Industry University Press, 2003: 54-56.

Effect of annealing treatment on interfacial microstructure and properties of Ti/Al FSB joint

ZHANG Zhong-ke1, WU Jing-wei1, ZHAO Hua-xia2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Aeronautical Key Laboratory for Welding and Joining Technologies, AVIC Manufacturing Technology Institute AECC, Beijing 100024, China)

Abstract: The paper investigated the microstructure of the friction stir brazing dissimilar joints between 6082 aluminum alloy and TC4 titanium alloy by adding the filler Zn and Ni and the type and formation sequence and kinetic growth model of IMCs during post welding annealing treatment. The results show that the IMC layer consisted of AlZn, TiAl, TiAl2 and TiAl3 and the formation sequence is TiAl2→TiAl3→TiAl→AlZn on the filler Zn. The IMC layer consisted TiNi, Al3Ni2, Ti3Al and TiAl and the formation sequence is Al3Ni2→TiNi→TiAl→Ti3Al below 776 K and Al3Ni2→ TiNi→TiAl→Ti3Al above 776 K on the filler Ni. The growth kinetic models are obtained. The thickness of the IMC layer increases with increasing the annealing temperature and/or holding time. The shearing strength increases from 154MPa during unheat-treatment to 194 MPa by adding filler Zn, and from 142 MPa to 166 MPa by adding filler Ni.

Key words: Ti/Al dissimilar metal; friction stir brazing; brazing filler; inter-metallic compounds; thermodynamics and formation kinetics

Foundation item: Project(18ZD2GC013) supported by the Major Science and Technology Project in Gansu Province, China; Project(201611U2001) supported by the Aeronautical Science Foundation of China

Received date: 2019-04-16; Accepted date: 2019-12-30

Corresponding author: ZHANG Zhong-ke; Tel: +86-931-2973892; E-mail: zhangzke@lut.cn

(编辑 何学锋)

基金项目:甘肃省科技重大专项(18ZD2GC013);航空科学基金资助项目(201611U2001)

收稿日期:2019-04-16;修订日期:2019-12-30

通信作者:张忠科,副教授,博士;电话:0931-2973892;E-mail:zhangzke@lut.cn