文章编号:1004-0609(2015)-01-0233-08

采用碱浸预脱硅-氰化工艺从氰化尾渣中回收金

王维大1,冯雅丽1,李浩然2,杨志超1,张 旭1,易爱飞1

(1. 北京科技大学 土木与环境工程学院,北京 100083;

2. 中国科学院 过程工程研究所 生化工程重点实验室,北京 100190)

摘 要:采用高浓度碱浸对氰化尾渣进行预脱硅处理,考察搅拌速度、固液比、NaOH浓度及温度对硅浸出速率的影响,研究脱硅过程的反应动力学,得到相应的动力学方程。结果表明:当搅拌速度为400 r/min、固液比为1:5、NaOH浓度为80%、反应温度为280 ℃时,二氧化硅的浸出率为91.8%;碱浸过程受产物层内扩散控制,表观反应活化能为37.375 kJ/mol。通过正交实验对氰化浸金的条件进行了优化,在SiO2浸出率为91.8%,NaCN浓度为1.5 g/L,固液比为1:3,浸出时间为48 h的条件下,金的浸出率为87.83%。

关键词:氰化尾渣;脱硅;碱浸出;氰化浸出

中图分类号:TF 11.31 文献标志码:A

Recovering gold from cyanide residue by alkaline predesilication-cyanide leaching technique

WANG Wei-da1, FENG Ya-li1, LI Hao-ran2, YANG Zhi-chao1, ZHANG Xu1, YI Ai-fei1

(1. Civil and Environmental Engineering School, University of Science and Technology, Beijing 100083, China;

2. National Key State Laboratory of Biochemical Engineering, Institute of Process Engineering,

Chinese Academy of Sciences, Beijing 100190, China)

Abstract: High-concentration alkaline leaching was used to treat cyanide residue for predesilication. The effects of stirring speed, solid-liquid ratio, initial NaOH concentration and reaction temperature on the leaching rate of silicon dioxide were studied. The kinetics of the desilication process was studied and the corresponding kinetics equation was established. The results show that the leaching rate of SiO2 reaches 91.8% under the condition of alkaline leaching reaction temperature of 280 ℃, reaction time of 5 h, NaOH concentration of 80%, the solid-liquid ratio of 1:5. The alkaline leaching process is controlled by the internal diffusion on the solid product layer and the apparent activation energy is 37.375 kJ/mol. The cyanide leaching conditions of gold were optimized by the orthogonal experiment. The leaching efficiency of gold is 87.83% under the condition of the leaching rate of SiO2 of 91.8%, NaCn concentration of 1.5 g/L, the solid-liquid ratio of 1:3, leaching time of 48 h.

Key words: cyanide residue; desilication; alkaline leaching; cyanide leaching

随着中国黄金的迅猛发展,易处理金矿的日趋枯竭,难浸金矿和氰化尾渣已成为黄金冶炼的重要新资源[1]。相关资料表明,我国黄金系统每年排放的尾渣量可达2000多万t[2],这些尾渣中金的品位依然很高,尤其是在我国较早开采的黄金矿山以及难浸金矿的尾矿中,金的品位甚至可达7.13 g/t[3]。因此,将含金尾矿和氧化尾渣作为二次资源回收利用,对黄金产业的可持续发展有重要意义。

氰化提金具有回收率高、成本低的优点,是目前提取黄金的主要工艺。我国金矿每年排放的尾渣大部分为氰化后的尾渣,这些尾渣中含有大量的脉石矿物、残留的CN-和浮选药剂,各种矿物的粒度极细,并且可回收矿物受到氰化过程的影响,可浮性降低,很难活化,因此,加快推进氰化尾渣的处理和综合利用迫在眉睫[4-6]。采用适宜的工艺流程进一步回收氰化尾渣中的金,不仅能充分利用矿产资源,还将获得良好的经济效益。

本研究中采用河南灵宝某含硫含砷金矿经焙烧-氰化后所产生的尾渣为研究对象,其金含量为3.3 g/t,前期实验中采用低浓度(5%~30%)碱浸出-氰化、酸浸-氰化、硫酸化焙烧-氰化等工艺都未获得理想的效果,经工艺矿物学分析,其主要原因为氰化尾渣中大量的石英对金产生了包裹,使其难以与氰化钠接触,因此,若想获得理想的浸金效果,需首先对氰化尾渣中的石英进行脱除。常压高浓度碱浸脱硅作为绿色冶金工艺,对矿物中二氧化硅具有较好的浸出效果。赵昌明等[7]在常压下采用高浓度氢氧化钠浸取红土镍矿中的二氧化硅,其脱除率达80%以上。XIAO等[8]研究了亚熔盐脱除含钒钢渣中的二氧化硅,结果表明,最佳条件下,二氧化硅的去除率可达95.72%,使浸出渣中V2O5的含量由8.46%增加到11.5%。杨波等[9]采用高浓度的NaOH对铝土矿进行了预脱硅,使铝硅比由7.6提高到12以上,满足了拜耳法生产氧化铝对铝土矿的要求。因此,不难看出,高浓度碱对矿物中的二氧化硅具有较好的脱除效果,使矿物中的有价金属满足回收的条件。在此,本文作者利用高浓度碱浸脱硅-氰化工艺回收氰化尾渣中的金,对工艺中脱硅和氰化的条件进行研究,建立硅脱除过程中的动力学模型,为氰化尾渣的二次回收利用提供了理论基础及实际意义。

1 实验

1.1 氰化尾渣

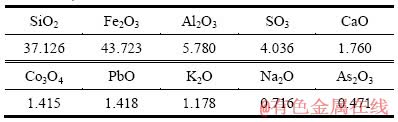

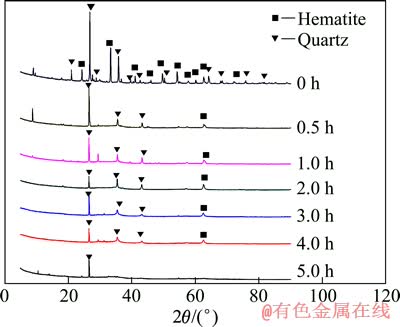

实验所用的氰化尾渣为河南灵宝某难处理金矿经沸腾炉焙烧-氰化后的尾渣,其金含量为3.3 g/t。氰化尾渣的主要成分(质量分数)见表1;其XRD谱如图1所示。由表1和图1可知,氰化尾渣中主要成分为石英和赤铁矿。

表1 氰化尾渣的化学成分

Table 1 Chemical compositions of cyanide residue (mass fraction, %)

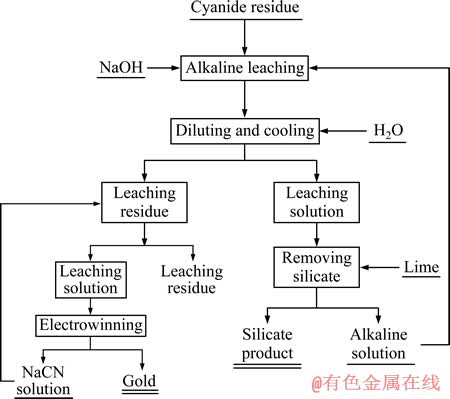

1.2 氰化层渣中金回收流程图及实验设备

高浓度碱浸预脱硅-氰化工艺回收氰化尾渣中金的流程图如图2所示,即氰化尾渣经高浓度碱浸后,稀释到一定浓度进行固液分离,浸出渣用于氰化浸出回收金,浸出液通过加石灰水或其他方法制备硅产品,稀释后的碱液经浓缩和补充NaOH后回用。

图1 氰化尾渣的XRD谱

Fig. 1 XRD pattern of cyanide residue

图2 氰化尾渣中金回收原则流程图

Fig. 2 Principle flow chart of gold recovery in cyanide residue

实验设备如下:特制的常压反应釜(不锈钢,容积为600 mL),坩埚炉,电动机械搅拌机,磁力搅拌器。

1.3 实验方法

脱硅实验步骤如下:按一定的浓度在反应釜中加入氢氧化钠和去离子水,启动机械搅拌并开通回流冷凝管中的水,然后加热至设定温度,按一定的液固比加入氰化尾渣,开始计时,定时取出一定量样品,经稀释冷却、过滤和洗涤后,测定浸出渣中SiO2的含量,计算SiO2的浸出率( )。

)。

氰化实验步骤如下:称取脱硅渣20 g,放入锥形瓶中,加入一定浓度的氰化钠溶液,用CaO调节pH至11左右,置于磁力搅拌器上搅拌,并通入空气,浸出一定时间后取下过滤,测定浸出渣中的含金量,计算金的浸出率( )。

)。

1.4 分析方法

物相分析采用X射线衍射(Rigaku,日本理学公司生产);矿物形貌采用电子扫描显微镜(SM-7001F及X-Max,日本电子及牛津仪器公司生产)观察;成分分析采用岛津 ICPQ-100 型等离子体光量计及其配件CTM-50型单色扫描仪组成的电感耦合等离子发光分光分析(ICP-AES分析) 装置。

2 结果与讨论

2.1 高浓度碱浸脱硅

2.1.1 搅拌速度的影响

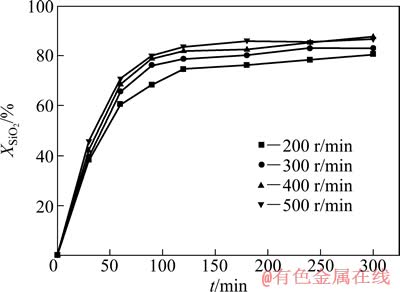

在反应温度为280 ℃、氢氧化钠浓度为60%、固液比为1:5的条件下,搅拌速度对脱硅效果的影响结果如图3所示。

图3 搅拌速度对脱硅效果的影响

Fig. 3 Effect of stirring speed on leaching rate of SiO2

由图3可以看出,搅拌速度对脱硅效果的影响较小,在125 min时,反应趋于平衡,此时搅拌速度由200 r/min提高到500 r/min时,其二氧化硅浸出率仅提高9%,而在固液反应过程中,液膜扩散为控制步骤时,搅拌强度对反应的影响较大,反应率一般可提高40%~65%[9]。故利用高浓度NaOH浸出氰化尾渣中二氧化硅时,液膜扩散不是反应过程的控制步骤,搅拌速度400 r/min较为适合。

2.1.2 固液比的影响

在反应温度为280 ℃,氢氧化钠浓度为60%,搅拌速度为400 r/min的条件下,固液比对脱硅效果的影响如图4所示。

图4 固液比对脱硅效果的影响

Fig. 4 Effect of solid-liquid ratio on leaching rate of SiO2

由图4可以看出,二氧化硅的浸出率随固液比的减小而升高,因为氰化尾渣中的二氧化硅与氢氧化钠为主要反应物,固液比减小时,一定程度上增加了二者的接触几率,从而加速了传质速度,提高二氧化硅的浸出效率。相比而言,固液比为1:2时,二氧化硅的浸出率相对较低,其主要原因为体系中氰化尾渣较多时,生产的硅酸钠也相应较多,此外,氰化尾渣中其他成分(如Al2O3等)也会消耗一定的碱,不仅增加了体系中的黏度,还使碱浓度下降,影响固液之间的传质,降低了浸出率。当固液比分别为1:5和1:10时,其浸出效果相差较小,而碱的增加会导致后续分离难度,故固液比选用1:5。

2.1.3 氢氧化钠浓度的影响

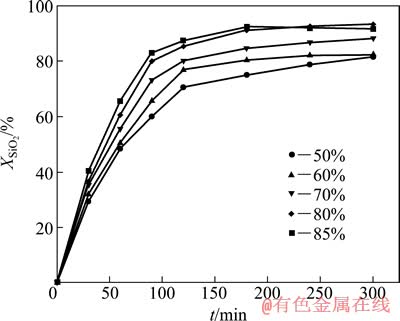

在反应温度为280 ℃、固液比为1:5、搅拌速度为400 r/min的条件下,氢氧化钠浓度对脱硅的影响如图5所示。

由图5可以看出,二氧化硅的浸出率随着氢氧化钠浓度的增大而升高,随着体系中氢氧化钠浓度的增大,氢氧根离子活度增加,反应物之间的传质阻力提高[10],使氰化尾渣中二氧化硅与氢氧化钠反应更加充分,从而提高了二氧化硅的浸出率。当氢氧化钠浓度由80%提高到85%时,二氧化硅的浸出率升高较小,故选择氢氧化钠浓度为80%较为合适。

2.1.4 反应温度的影响

在氢氧化钠浓度为80%、搅拌速度为400 r/min、固液比为1:5的条件下,反应温度对脱硅效果的影响如图6所示。

图5 NaOH浓度对脱硅效果的影响

Fig. 5 Effect of NaOH concentration on leaching rate of SiO2

图6 不同反应温度对脱硅效果的影响

Fig. 6 Effect of reaction temperature on leaching rate of SiO2

由图6可以看出,温度对二氧化硅的浸出效果有着显著的影响,随着温度的升高,二氧化硅的浸出速率不断提高。二氧化硅与氢氧化钠反应为吸热反应,温度升高有利于反应的进行。当温度由280 ℃提高到300 ℃时,反应30 min后二氧化硅的浸出率仅增加1.5%,温度过高,体系中水分蒸发加剧,导致体系中反应物的黏度增大,影响了固液之间的传质,故选用反应温度280 ℃较为适合。

2.1.5 脱硅动力学分析

颗粒浸出过程是一种固液之间的反应,对于矿物颗粒在溶液中的浸出过程可以通过液固多相反应的收缩核模型来描述。包括化学反应、浸出剂在矿石颗粒外表面上的膜扩散和矿石颗粒中的内扩散等各种可能的速率控制过程。高浓度碱浸出氰化尾渣的过程中主要发生的化学反应为

SiO2+2NaOH=Na2SiO3+2H2O (1)

氰化尾渣中的Al2O3也可能发生如下反应:

Al2O3+2NaOH+3H2O=2NaAl(OH)4 (2)

溶液中生成的Na2SiO3可与NaAl(OH)4反应生成水合铝硅酸钠,并沉淀析出[11],反应式如下:

nNa2SiO3+2NaAl(OH)4=Na2O·Al2O3·nSiO2+2nNaOH+(4-n)H2O (3)

在浸出过程中,从0~120 min为反应加速阶段,反应速率受界面化学反应控制或固态产物层内扩散控制[12],为了确定高浓度碱脱硅的控制步骤,即分别利用界面化学反应动力学方程式(4)和产物层内扩散控制动力学方程式(5)对反应过程进行拟合。结果表明利用高浓度碱浸出氰化尾渣中的二氧化硅在加速阶段较符合产物层内扩散控制动力学模型:

(4)

(4)

(5)

(5)

式中:X为t时刻SiO2的脱除率,%;k′和k″分别为反应速率常数。

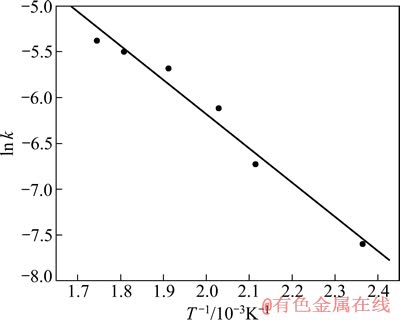

根据Arrhenius公式[13]得出速率常数和反应温度关系,以ln k对1/T作图,其斜率为k=-E/R求出反应的活化能E。

(6)

(6)

(7)

(7)

式中:E为反应的活化能,kJ/mol;T为反应温度,K;R为摩尔气体常数;k为反应速率常数;A为频率因子。

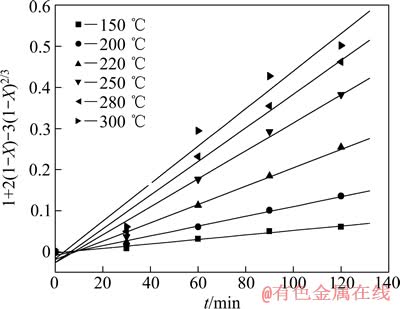

不同反应温度下, 与反应时间t的关系如图7所示。

与反应时间t的关系如图7所示。

图7 不同温度下1+2(1-X)-3(1-X)2/3与反应时间的关系

Fig. 7 Relationship between 1+2(1-X)-3(1-X)2/3 and reaction time under various reaction temperatures

由图7可以得出,在反应温度范围内, 与反应时间t之间呈良好的线性关系,说明利用高浓度碱浸出氰化尾渣中的二氧化硅可以用式(5)来描述,即反应过程为产物层内扩散控制。以不同温度下ln k对1/T作图,结果如图8所示。

与反应时间t之间呈良好的线性关系,说明利用高浓度碱浸出氰化尾渣中的二氧化硅可以用式(5)来描述,即反应过程为产物层内扩散控制。以不同温度下ln k对1/T作图,结果如图8所示。

图8 lnk与1/T的关系

Fig. 8 Relationship between lnk and 1/T

由图8中直线斜率可求得反应(4)表观活化能E=37.375 kJ/mol,根据图8中截距可以求得A=exp(1.28965)=3.6315 min-1;从而可求出高浓度碱浸出氰化尾渣中二氧化硅的宏观反应动力学方程:

(8)

(8)

2.1.6 浸出渣的分析

在搅拌速度为400 r/min、固液比为1:5、NaOH浓度为80%、温度为250 ℃的条件下,对不同反应时间的脱硅渣进行XRD、SEM以及EDS元素面扫描分析,所得结果如图9收和图10所示。

由图9可以看出,随着反应时间的延长,石英和赤铁矿的强衍射峰逐渐减弱,部分弱衍射峰逐渐消失;在反应时间为5 h时,石英的衍射峰仍存在,但赤铁矿衍射峰消失,结合不同反应时间后浸出渣的分析结果可知,渣中二氧化硅的含量逐渐减少,而渣中铁(以Fe2O3计)的含量逐渐增加,其原因可能是浸出渣中铁以无定形氧化铁的形式存在[14]。

图9 不同浸出时间后浸出渣的XRD谱

Fig. 9 XRD patterns of residues after leaching for different times

图10 不同浸出时间后浸出渣的SEM像

Fig. 10 SEM images of residues after leaching for different times

由图10可以看出,在高浓度碱处理前,氰化尾渣呈块状,表面空隙较少,但随着反应时间的延长,氰化尾渣表面逐步变得疏松,粒度逐渐变小,其主要原因是NaOH碱溶液中存在高活性负氧离子和氢氧根离子,且对矿物中的硅有很强的分解作用[15-16],生成了可溶性的硅酸钠的进入溶液,而少量生成的Na2O·Al2O3·nSiO2附着在颗粒的表面形成固体产物层,因此,利用高浓度碱浸出氰化尾渣中的二氧化硅的反应遵循收缩核模型。

2.2 氰化提金实验

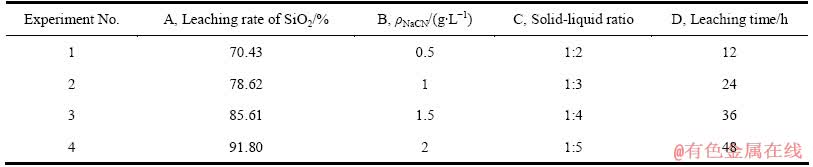

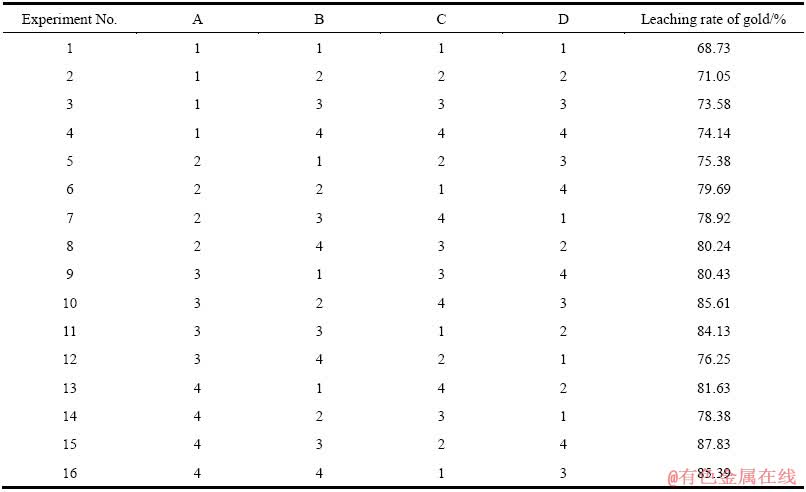

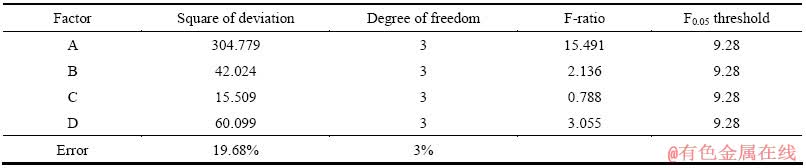

为了获得不同脱硅率下脱硅渣氰化浸出金的最佳工艺条件,实验对不同二氧化硅浸出率下的脱硅渣、氰化钠的浓度、固液比以及浸出时间4个影响因素进行了研究,通过四因素四水平正交实验L16(44)来研究各因素对金浸出率的影响,得到氰化浸出脱硅渣中金的最佳工艺条件,其因素水平表如表2所列,正交实验表如表3所列。

由表4 中数据分析可知,各因素对金浸出率影响大小顺序为脱硅率、浸出时间、氰化钠浓度、固液比;脱硅率的偏差平方和最大,且在正交实验表中,随着脱硅率的上升,金的浸出率也呈增加趋势,说明脱硅对金的浸出率有直接的影响。氰化浸出脱硅渣中金最佳工艺水平为A4B3C2D4,即脱硅率为91.8%,氰化钠用量为1.5 g/L,固液比1:3,浸出时间为48 h,在此条件下金的浸出率为87.83%。

表2 脱硅渣氰化浸金实验因素水平确定表

Table 2 Determination of factors and levels for cyanide leaching of gold from cyanide residue

表3 脱硅渣氰化浸金正交实验表

Table 3 Orthogonal analysis of cyanide leaching of gold from cyanide residue

表4 氰化浸出金方差分析结果

Table 4 Variance analysis of cyanide leaching of gold

3 结论

1) 利用高浓度碱浸出氰化尾渣中的二氧化硅时,最佳条件为搅拌速度400 r/min;固液比1:5,NaOH浓度80%,温度250 ℃时,此条件下二氧化硅的浸出率可达91.8%。

2) 脱硅动力学结果表明高浓度碱浸出氰化尾渣中的二氧化硅的过程受产物层内扩散控制,表观活化能E=37.375 kJ/mol,相应的动力学方程为

3) 氰化尾渣经高浓度碱预处理后,在脱硅率为91.8%、氰化钠浓度为1.5 g/L、固液比为1:3、浸出时间为48 h的条件下,金的浸出率可达87.83%,说明利用高浓度碱预脱硅-氰化浸出工艺回收氰化尾渣中金具有一定的可行性。

REFERENCES

[1] 徐晓军, 白荣林, 张 杰. 黄金及二次资源分选与提取技术[M].化学工业出版社, 2008.

XU Xiao-jun, BAI Rong-lin, ZHANG Jie. The separation and extraction technology of gold and secondary resources[M]. ChemicalIndustry Publishing House, 2008.

[2] 朱 磊, 康广凤, 李淑芬, 楚宪锋, 吴向阳. 氰化尾渣多元素资源化回收技术研究[J]. 环境科技, 2010, 23(2): 5-7.

ZHU Lei, KANG Guang-feng, LI Shu-fen, CHU Xian-feng, WU Xiang-yang. Research on multi-element resources of utilizing cyaniding tailings[J]. Environmental Science and Technology, 2010, 23(2): 5-7.

[3] 张亚莉, 于先进, 张丽鹏. 高铁氰化渣湿法处理的研究进展及工艺开发[J]. 山东冶金, 2010, 32(5): 3-5.

ZHANG Ya-li, YU Xian-jin, ZHANG Li-peng. Research progress on hydrometallurgical treatment of cyanide tailings with high iron content and process development[J]. Shandong Metallurgy, 2010, 32(5): 3-5.

[4] 王志刚, 彭殿军. 氰化尾渣中金银回收技术研究进展[J].有色冶金设计与研究, 2013, 34(5): 15-17.

WANG Zhi-gang, PENG Dian-jun. Research development of gold and silver recovery from cyanide tailings[J]. Nonferrous Metals Engineering & Research, 2013, 34(5): 15-17.

[5] 张福元, 张玉华. 氰渣综合利用提取金银的试验研究[J]. 稀有金属材料与工程, 2007, 36(3): 335-338.

ZHANG Fu-yuan, ZHANG Yu-hua. Study on the recovery of gold and silver from cyanide residue[J]. Rare Metal Materials and Engineering, 2007, 36(3): 335-338.

[6] 姚志通, 李金惠, 刘丽丽, 谢亨华, 任玉森. 黄金尾矿的处理及综合利用[J]. 中国矿业, 2011, 20(12): 60-63.

YAO Zhi-Tong, LI Jin-hui, Liu Li-li, XIE Heng-hua, REN Yu-shen. The treatment and comprehensive utilization of gold tailings[J]. China Mining Magazine, 2011, 20(12): 60-63.

[7] XIAO Q G, CHEN Y, GAO Y Y, XU H G, ZHANG Y. Leaching of silica from vanadium-bearing steel slag in sodium hydroxide solution[J]. Hydrometallurgy, 2010, 104(2): 216-221.

[8] 杨 波, 王京刚, 张亦飞, 张 懿. 常压下高浓度NaOH浸取铝土矿预脱硅[J]. 过程工程学报, 2007, 7(5): 922-927.

YANG Bo, WANG Jing-gang, ZHANG Yi-fei, ZHANG Yi. Pre-desiliconization of a bauxite ore through leaching by high concentration NaOH solution under atmospheric pressure[J]. The Chinese Journal of Process Engineering, 2007, 7(5): 922-927.

[9] 赵昌明, 翟玉春, 刘 岩, 段华美. 红土镍矿在NaOH 亚熔盐体系中的预脱硅[J]. 中国有色金属学报, 2009, 19(5): 948-954.

ZHAO Chang-ming, ZHAI Yu-chun, LIU Yan, DUAN Hua-mei. Pre-desilication of laterite in NaOH sub-molten salt system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 948-954.

[10] 刘玉民, 齐 涛, 王丽娜, 初景龙, 张 懿. KOH亚熔盐法分解钛铁矿[J]. 过程工程学报, 2009, 9(2): 319-323.

LIU Yu-min, QI Tao, WANG Li-na, CHU Jing-long, ZHANG Yi. Decomposition of ilmenite in KOH sub-molten salt[J]. The Chinese Journal of Process Engineering, 2009, 9(2): 319-323.

[11] 陈 超, 韦 萍, 栗海锋, 文衍宣, 赖旺坤, 黄 静, 羊 丹. 常压碱溶法提取软锰矿酸浸渣中的硅[J]. 无机盐工业, 2012, 44(9): 36-38.

CHEN Chao, WEI Ping, LI Hai-feng, WEN Yanxuan, LAI Wang-kun, HUANG Jing, YANG Dan. Leaching silicon from acid leaching residue of pyrolusite by alkaline leaching method at atmospheric pressure[J]. Inorganic Chemicals Industry, 2012, 44(9): 36-38.

[12] 于洪浩, 贺 燕, 薛向欣, 王余莲. NaOH-NaNO3熔盐法分解铁尾矿的动力学[J]. 中国有色金属学报, 2011, 21(11): 2958-2963.

YU Hong-hao, HE Yan, XUE Xiang-xin, WANG Yu-lian. Decomposition kinetics of iron ore tailings by NaOH-NaNO3 molten salt method[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2958-2963.

[13] 杨显万, 邱定蕃. 湿法冶金[M]. 北京: 冶金工业出版社, 1998: 164-211.

YANG Xian-wan, QIU Ding-fan. Hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 1998: 164-211.

[14] 刘挥彬, 杜 浩, 刘 彪, 王少娜, 郑诗礼, 张 懿. KOH亚熔盐中钒渣的溶出行为[J]. 中国有色金属学报, 2013, 23(4): 1128-1139.

LIU Hui-bin, DU Hao, LIU Biao, WANG Shao-na, ZHENG Shi-li, ZHANG Yi. Dissolution behavior of vanadium slag in KOH sub-molten salt[J] .The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1128-1139.

[15] 李兰杰, 陈东辉, 白瑞国, 郑诗礼, 杜 浩, 王少娜, 张 懿. 含钒尾渣NaOH亚熔盐浸出提钒[J]. 过程工程学报, 2011, 11(5): 747-754.

LI Lan-jie, CHEN Dong-hui, BAI Rui-guo, ZHENG Shi-li, DU Hao, WANG Shao-na, ZHANG Yi. Leaching of vanadium from vanadium-containing residue by NaOH sub-molten salt[J]. The Chinese Journal of Process Engineering, 2011, 11(5): 747-754.

[16] 赵中伟, 龙 双, 陈爱良, 霍广生, 贾希俊, 李洪桂, 阎海泉. 难选高硅型氧化锌矿机械活化碱法浸出研究[J]. 中南大学学报: 自然科学版, 2010, 41(4): 1246-1250.

ZHAO Zhong-wei, LONG Shuang, CHEN Ai-liang, HUO Guang-sheng, JIA Xi-jun, LI Hong-gui, YAN Hai-quan. Alkali leaching of refractory high silica zinc oxide ore by mechanical activation[J]. Journal of Central South University: Science and Technology, 2010, 41(4): 1246-1250.

(编辑 龙怀中)

基金项目:中国大洋矿产资源研究计划资助项目(DY125-15-T-08);国家自然科学基金资助项目(21176026,21176242)

收稿日期:2014-05-30;修订日期:2014-09-30

通信作者:冯雅丽,教授,博士;电话:010-62311181;E-mail:ylfeng126@126.com