文章编号:1004-0609(2007)04-0554-06

Al-Ti熔体中C粉末的超声悬浮与TiC反应

李英龙1,曹富荣1,冯海阔2,陈彦博1

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 吉林大学 材料科学与工程学院,吉林 130025)

摘 要:设计了一种电致伸缩式单轴超声悬浮反应系统,在Al-Ti熔体中形成超声驻波,使C粉末悬浮在合金熔体中进行TiC合成反应,以制备Al-3Ti-0.15C晶粒细化剂。通过组织观察和声压分析,研究了C粉末的悬浮情况、合金的组织形态及其形成机制。结果表明:只有在声辐射功率较小的时候,超声波在辐射块与反射板间的熔体中形成声压节点,在声压梯度作用下,使C和TiAl3能稳定地悬浮在声压节点处,而声功率较大时,驻波的二次谐波增加,声压节点消失,C粉末的稳定性破坏;C粉末的反应过程为:超声的空化效应使TiAl3溶解形成活性Ti,并通过Ti、C发生合成反应形成TiC相,同时,对TiC粒子具有热激活作用。

关键词:Al-Ti-C合金;晶粒细化剂;超声悬浮;反应机制

中图分类号:TB 559 文献标识码:A

Ultrasonic levitation of C powder and TiC synthesis reaction in Al-Ti melt

LI Ying-long1, CAO Fu-rong1, FENG Hai-kuo2, CHEN Yan-bo1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. School of Materials Science and Engineering, Northeastern University, Jilin 130025, China)

Abstract: An electrostriction type uniaxial ultrasonic levitation reaction system was designed. Ultrasonic stationary wave is formed to suspend C powder in Al-Ti melt to perform TiC synthesis reaction and the Al-3Ti-0.15C grain refiner alloy was prepared. The suspension state of C powder, microstructural morphology and its formation mechanism of such alloy were investigated after microstructural observation and sound pressure analysis. The results show that only when the sound radiation power is small, the sound pressure node is formed between radiation block and reflection board by ultrasonic. Under the action of sound pressure gradient, C powder and TiAl3 can suspend stably in the sound pressure node. When sound power is large, the second harmonic of stationary increases, the sound pressure node disappears and the levitation stability of C powder is destroyed. The reaction process of C powder is that ultrasonic cavitation effect makes TiAl3 be dissolved to form active Ti, and TiC phase is formed through the synthesis reaction of Ti and C, meantime, such effect has thermal activation influence on TiC particles.

Key words: Al-Ti-C alloy; grain refiner; ultrasonic levitation; synthesis mechanism

晶粒细化剂Al-Ti-C与Al-Ti-B相比,其异质形核核心TiC比TiB2具有更小的聚集倾向,并对Zr、Cr、Mn、V等元素“中毒免疫”[1-3],Al-Ti-C是一种有良好应用前景并被重点研究的晶粒细化剂材料[4-10]。然而,C与Al熔体的润湿性差,Al熔体中C的溶解度极小,石墨粉末之间易产生氢键而聚集成团,Al熔体很难深入石墨团内部进行反应,而Al熔体表面的氧化膜也阻碍了反应的进行。因此,石墨粉末与Al-Ti合金熔体间几乎不能发生TiC合成反应。

声悬浮是高能超声作用下的一种非线性效应,其基本原理是超声驻波与物体间的相互作用,物体运动主要受到指向波节(或波腹)的声辐射力、Stokes拖力、重力以及浮力的影响,使物体稳定于超声波波节(或波腹)处,从而呈现一种悬浮状态[11-12]。

本文作者研制了一种电致伸缩式单轴超声悬浮反应系统,使石墨粉末悬浮于Al-Ti合金熔体中,其超声的空化与微冲流作用以及超声改善金属熔体的润湿性、降低Al熔体与C粉末的界面张力效应能消除C粉末因存在氢键的不良影响,进而增强了其反应活性,促进了TiC合成反应,同时,利用超声的热扰动效应,能激活TiC的形核活性。

1 实验

1.1 实验装置

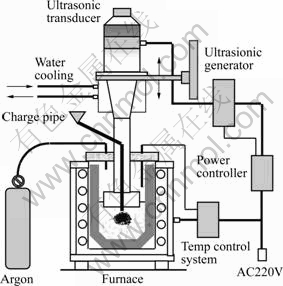

实验采用的超声悬浮反应系统由超声波发生器、超声悬浮铸造装置、气体保护装置、超声功率调节装置组成。图1所示是该系统的结构原理图。

图1 超声悬浮反应系统示意图

Fig.1 Schematic diagram of ultrasonic levitation reaction system

换能器发射的超声波由指数型速度变换器进行振幅放大后,通过钛合金振动辐射块,直接耦合到![]() 金属熔体中;通过调节辐射块与钛合金坩锅底面(反射板)间的距离恰为λ/2,从而使金属熔体处于谐振状态。同时,超声波经钛合金坩锅底面反射后与一次声波叠加形成驻波,此时,超声驻波节点位于熔体中部。

金属熔体中;通过调节辐射块与钛合金坩锅底面(反射板)间的距离恰为λ/2,从而使金属熔体处于谐振状态。同时,超声波经钛合金坩锅底面反射后与一次声波叠加形成驻波,此时,超声驻波节点位于熔体中部。

超声波发生器为频率自动跟踪式设计,以减少熔体温度变化引起系统谐振频率的波动。超声波发生器的频率为20 kHz,调节范围为±500 kHz,最大电功率1 000 W,系统的声/电效率约为75%。

在超声悬浮铸造装置中,采用循环水对速度变换器冷却,由电阻加热炉和测控温装置保持或控制金属熔体温度。同时,钛合金坩锅底部制造成平面与锥面组合型式,以提高C粉末悬浮的径向稳定性。

1.2 实验材料

实验材料为Al-3Ti合金和C粉末,C粉末平均尺寸为22 μm,纯度≥99%(质量分数,%)。

1.3 实验流程

首先在800 ℃将C粉末进行热活化处理1 h,之后,在声强密度为15 W/mm2的超声振动条件下,通过喂料管将C粉末逐渐加入到温度为800 ℃的Al-3Ti熔体中,其总加热量为Al-3Ti熔体质量的0.3%。待C粉末完全加入后,吹氩气冷却熔体,熔体凝固后制成中间合金铸锭,以研究C粉末的悬浮和反应情况。同时,在800 ℃保温与超声悬浮条件下,进行TiC合成反应,并在反应的30 min后停止加热,制取目标合金Al-3Ti-0.15C铸锭。

在金属铸锭上距振动辐射块底面约35 mm的近声场位置,截取金相试样,用数码相机观察C粉末的悬浮情况,用光学显微镜和扫描电镜研究Al-3Ti- 0.15C晶粒细化剂合金的组织形态与反应过程。

采用Al-3Ti-15C晶粒细化剂的A1075的细化实验,在特制的细化实验模中进行。实验模由低密度耐火材料加工制成,以降低冷却速度和温度梯度对细化效果的影响。其模孔直径d 30 mm,有效高度35 mm,细化温度为(730±5)℃。

2 结果与讨论

2.1 C粉末的悬浮情况

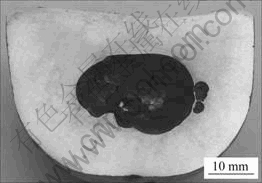

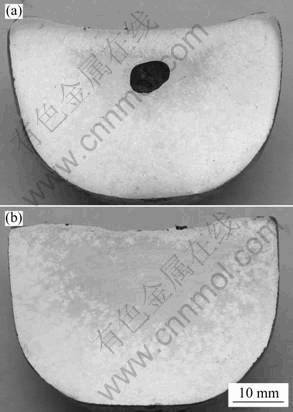

图2(a)所示为声强密度为15 W/mm2时,Al-Ti熔体中C粉末悬浮照片。由图可见黑色区域为C粉末,呈团状形态稳定地悬浮在熔体中部,并且在熔体上部没有出现C粉末的上浮现象。

图2 C粉末的超声悬浮照片

Fig.2 Photograph of C powder levitation

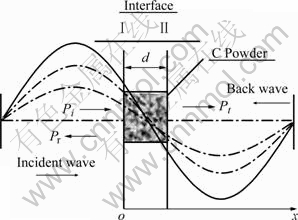

C粉末的悬浮现象与超声的传播与干涉情况有关。在图1所示装置中,换能器端面S1发射的一次波,于金属熔体中传播,并经坩锅底部的Ti板表面S2反射形成二次波,一次声波与二次声波叠加后形成驻波,如图3所示。

图3 超声波的传播与C粉末界面的声压

Fig.3 Propagation of ultrasonic and interface sound pressure of C powder

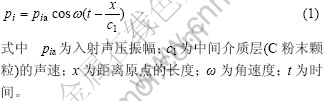

如果将C粉末简化成为厚度为d特征阻抗为R1=ρ1c1中间层介质,置于特征阻抗为R2=ρ2c2 的Al熔体介质中,并设一次声波和反射声波以平面波形式垂直入射到中间介质层上、一次声波的声压为方程为

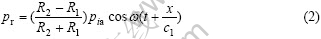

则pi经界面Ⅰ反射后的声压方程为

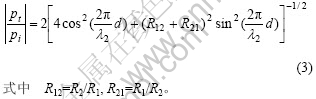

根据平面声波的声压与声速关系,以及界面Ⅰ、Ⅱ处的声压连续条件,可以计算出透射波声压pt在x=d处的声压与入射波在x=0处的声压pi之比为[13]

由于C粉末的平均直径d=22 μm,对于频率为20 kHz的发生波在铝熔体传播时的波长λ2=210 mm,2πd/λ2=6.5×10-4?1,所以,pt≈pi。

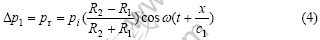

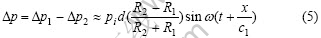

因此,在一次声波作用下,C粉末在界面Ⅰ和界面Ⅱ处的声压差Δp1为:

同样,当一次声波经坩锅底部反射形成二次声波,也会在C粉末的界面Ⅰ和界面Ⅱ处存在声压差Δp2。

因此,C粉末在一次波和二次波场中,所受到的综合声压差为

由于R2>R1,所以,只要C粉末不在声压波形的节点处或波腹处,在声压差Δp的作用下,C粉末受到指向波节的作用力,使C粉末在声压波节处聚集。

然而,实验发现:当声强密度为25 W/mm2时,C粉末不能在Al-Ti熔体中悬浮,表明C粉末的悬浮明显受超声功率的影响。这是因为声悬浮是高能超声作用下的一种非线性效应,其基本原理是超声驻波与物体间的相互作用,物体受到指向波节(或波腹)的声辐射力作用,使物体稳定于超声波波节(或波腹)处,从而呈现一种声悬浮状态。因此,只有在Al-Ti熔体中形成稳定的驻波时,C粉末才能出现悬浮现象,然而,当声强密度较大时,驻波的谐波分量降低,使C的悬浮稳定性降低,同时,强超声的声流效应,使Al-Ti熔体出现环流现象,同样会影响C粉末超声悬浮的稳定性。

2.2 C粉末的反应情况

随超声作用时间的延长,C粉末团尺寸逐渐减小,在30 min后,C粉末完全消失,如图4所示。

图4 C粉末悬浮过程的反应情况

Fig.4 Reaction process of C powder during levitation: (a) 20 min; (b) 30 min

这表明在C粉末的悬浮过程中,C与Al-Ti熔体界面间发生了充分的化学反应。根据文献[14]给出的Ti、C在Al熔体中的平衡浓度cTi和cC与温度T间的关系式,可以计算出反应温度条件下,C在Al熔体中的平衡浓度cC为1.8×10-2,可见,C在Al熔体中的溶解度极小,此实验温度下C很难在铝熔体中溶解,如果不发生化学反应,则主要以固体颗粒的形式存在。因此,C粉末悬浮区的减小过程就是C粉末的反应过程。

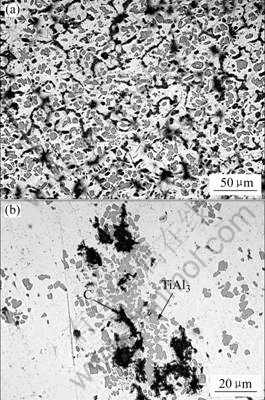

在反应的中间过程,C粉末及Al附近区域出现了C粉末的分散区(见图5),其组织特点为:在C粉末区域周围富集了大量的TiAl3粒子。同时,随超声作用时间的延长TiAl3的聚集程度增强,表明在超声振动过程中,超声的悬浮效应不仅使C出现集聚,而且使Al熔体中的TiAl3粒子也出现了集聚现象。这是由于超声悬浮的实质是:在超声驻波场中的波节处为低压区,即Al-3Ti熔体中存在声压梯度,TiAl3粒子两侧存在压力差。当TiAl3粒子与Al熔体的声对比因子系数大于0时,TiAl3粒子受到指向波节的声辐射力作用,出现向C粉末区域集聚的现象。这种组织特征为TiC的形成提供了有利的反应界面条件。

图5 反应过程中C粉末反应区的金相组织

Fig.5 Metallographs of C powder dispersive zone during reaction: (a) 10 min; (b) 20 min

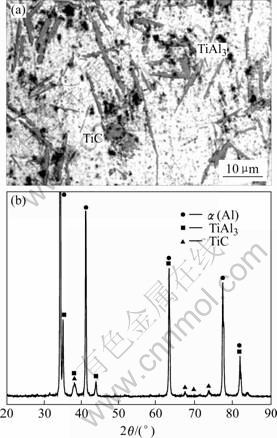

图6所示为制备的目标合金Al-3Ti-0.15C的金相组织。由图可见,组织中TiAl3相呈细小块状和细小针状两种形态,块状相的尺寸仅为5 μm,与中间合金组织中的TiAl3相相比,目标合金组织中的块状TiAl3相明显细化,并且其外形近乎球形;针状TiAl3相的长度尺寸小于8 μm,宽度尺寸仅为1 μm,其针状特征表明针状TiAl3相是从过饱和Al-Ti熔体中析出形成的[15]。X射线衍射分析结果表明,超声悬浮反应法获得的Al-3Ti-0.15C晶粒细化剂由α(Al)、TiAl3和TiC组成,符合常规Al-Ti-C晶粒细化剂组织特征。

图6 Al-3Ti-0.15C的金相组织和XRD谱

Fig.6 Metallograph (a) and XRD pattern (b) of Al-3Ti-0.15C

块状TiAl3组织向针片状TiAl3组织演化可以解释为,辐射块前端所产生的强声波激活熔体中的空化气核,气泡崩溃时伴随有强烈的冲击波或射流,释放到熔体中作用于TiAl3相并产生局部高温,击碎与高温熔断TiAl3相,使部分TiAl3出现溶解现象。当合金熔体凝固时,TiAl3从过饱和熔体中析出,并在其析出过程受超声波提高金属熔体润湿性的作用,使TiAl3择优生长趋势明显增加,从而呈现细小的针片状形态。

超声空化作用使TiAl3溶解,并使C粉末周围出现了Ti元素的富集现象。这种组织形态说明:在超声场作用下TiAl3出现了溶解并扩散至C粉末的周围。因此,TiC是由C与溶解的态的Ti反应形成的,溶解的Ti原子环绕在石墨颗粒周围,并在其界面上发生反应生成TiC,其反应式为

Ti+C(s)=TiC (6)

式中 C(s)是固态的石墨颗粒,Ti是溶解到Al熔体中的Ti。

反应形成TiC的自由能ΔG[16]为:

ΔG=-163.382×103+80.374T+0.460×10-3T2+

3.096×105/T-0.962TlnT (7)

根据式(2)的计算可知:2 100 K以下,ΔG<0,即在923~2 100 K时,TiC在Al熔体中是容易形成的。在超声作用下,Al熔体与TiC粒子的良好润湿性阻止了TiC粒子的聚集长大,最终在反应区域形成大量的TiC粒子,其平均尺寸约1 μm,并呈现明显的弥散分布形态。超声空化效应为TiC的分散提供了能量条件,如图6所示。由此可见:通过超声悬浮和普通的熔铸工艺,利用活化的C与Al-Ti熔体间的反应,可以制备Al-Ti-C晶粒细化剂。

2.3 Al-3Ti-0.15C晶粒细化剂的细化性能

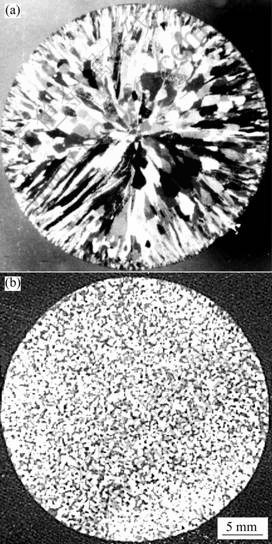

图7所示为被Al-3Ti-0.15C细化前后的A1075合金组织。

图7 被Al-3Ti-0.15C细化前后的A1075合金组织

Fig.7 Microstructures of A1075 alloy refined by Al-3Ti-0.15C: (a) Primary microstructure; (b) Refiner addition

图7(a)所示为A1075合金的原始铸态组织,呈粗大的柱状晶,平均尺寸约3 mm。图7(b)所示为A1075合金添加0.2%的Al-3Ti-0.15C晶粒细化剂时的组织呈细小的等轴晶,平均晶粒尺寸为210 μm。通过绘制平均晶粒尺寸—时间关系曲线,并进行回归处理,得出Al-3Ti-0.15C细化剂对A1075合金细化的最佳作用时间(接触时间)为10 min,保温过程中Al晶粒组织出现明显粗化的时间(细化衰减时间)为110 min。由此可见,Al-3Ti-0.15C细化剂具有较强的细化能力和良好的抗细化衰减性能。这表明通过超声悬浮制备的Al-3Ti-0.15C细化剂,由于超声空化的热扰动作用,有效抑制了Al4C3化合物的形成,同时超声空化的能量在TiC粒子表面形成局部高温区,进一步激活了TiC粒子,提高了其形核能力。

3 结论

1) 在超声波在振动辐射块和坩锅底部间的Al-Ti熔体中传播时,一次声波与二次声波干涉形成稳定驻波时,从而形成稳定的声压梯度,可使C粉末向波节处聚集,出现声悬浮现象,并使TiAl3粒子聚集在C粉末周围。

2) 超声空化效应使部分TiAl3溶解,为TiC的合成反应提供了良好的界面条件,其形成机制为溶解态的Ti与C反应形成TiC。

3) 超声空化的热机制,对TiC粒子具有热激活作用,从而使Al-3Ti-0.15C细化剂合金具有良好的对α(Al)的形核与细化能力。

REFERENCES

[1] LI Jian-guo, HUANG Min, MA Mo, et al. Performance comparison of AlTiC and AlTiB master alloys in grain refinement of commercial and high purity aluminum[J]. Transactions of Nonferrous Metals Society of China, 2006,16: 242-253.

[2] Van P, Wiggen S, Belgraver J. From Al-Ti-B to Al-Ti-C developments in aluminum grain refiners[J]. Aluminum, 1999, 75(11): 989-994.

[3] Chneider M, Kearns M, Garry A. Comparison of the behavior of AlTiB and AlTiC grain refiners[A].The 127th TMS Annual Meeting[C]. San Antio, Texas: Light Metals, 1998: 953-961.

[4] 柳延辉, 刘相法, 李廷斌, 边秀房,张均艳. Al-Ti-C中间合金对Mg-Al合金的晶粒细化作用[J]. 中国有色金属学报, 2003, 13(3): 623-625.

LIU Yan-hui, LIU Xiang-fa, LI Ting-bin, BIAN Xiu-fang, ZHANG Jun-yan. Grain refining effect of Al-Ti-C master alloy on Mg-Al alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 623-625.

[5] WANG Zhen-qing, LIU Xiang-fa, LIU Yan-hui. Structural heredity of TiC and its influences on refinement behaviors of AlTiC master alloy[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 790-793.

[6] ZHAHG Zhong-hua, BIAN Xiu-fang, WANG Yan, et al. TEM observations of rapidly solidified AlTiC alloy[J]. Journal of Alloys and Compounds, 2003, 34(9): 121-128.

[7] LIU Xiang-fa, WANG Zhen-qing. The relationship between microstructures and refining performances of Al-Ti-C master alloys[J]. Mater Sci Eng A, 2002, A332: 70-74.

[8] WANG Zhen-qing, LIU Xiang-fa, LIU Yan-hui, et al. Structural heredity of TiC and its influences on refinement behaviors of AlTiC master alloy[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 790-793.

[9] 李英龙, 温景林, 陈彦博, 曹富荣,占国灿. SHS技术制备Al-3Ti-0.15C晶粒细化剂[J]. 中国有色金属学报, 2004, 14(2): 179-183.

LI Ying-long, WEN Jing-lin, CHEN Yan-bo, CAO Fu-rong, ZHAN Guo-chan. Al-3Ti-0.15C grain refiner prepared by SHS[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 179-183.

[10] Banerji A, Reif W. Grain refinement of Aluminium by TiC[J]. Metall Trans A, 1995, A16: 2065-2068.

[11] 解文均, 曹崇德, 魏炳波. 声悬浮的实验研究和数值模拟分析[J]. 物理学报, 1999, 48(2): 250-256.

XIE Wen-jun, CAO Chong-de, WEI Bing-bo. Experimental investigation and numerical analysis on acoustic levitation[J]. Acta Physica Sinica, 1999, 48(2): 250-256.

[12] Yosikoka K, Kawasima Y. Acoustic Radiation Pressure on a Compressible Sphere[J]. Acoustic, 1995, 5: 167-173.

[13] 杜功涣, 朱哲民, 龚秀芬. 声学基础[M]. 南京: 南京大学出版社, 2000: 1216.

DU Gong-huan, ZU Ze-min, GONG Xiu-fen. Acoustics Foundation[M]. Nanjing: Nanjing University Press, 2000: 1216.

[14] Dorward R C. Discussion of comments on the solubility of carbon in molten aluminum[J]. Metall Trans A, 1990, A21: 255-257.

[15] Mayes C D, Cartney D G, Tatlock G J. Observations on the microstructure and performance of an Al-Ti-C grain-refining master alloy[J]. Mater Sci Eng A, 1994, A188: 283-290.

[16] Rapp R A, Zheng X. Thermodynamic consideration of grain refinement of aluminum alloys by titanium and carbon [J]. Metall Trans A, 1991, A22: 3071-3075.

基金项目:辽宁省科学技术基金资助项目(20042014)

收稿日期:2006-09-26;修订日期:2006-12-20

通讯作者:李英龙,副教授;电话:024-83686459;E-mail:lyl-neu@tom.com

(编辑 何学锋)