DOI: 10.11817/j.ysxb.1004.0609.2020-35879

阴阳极距离对镁合金微弧氧化膜层性能及负载模型的影响

王 晟1, 2,刘康康1, 2,马 颖1, 2,李 彬1, 2,黄志杰2,王小龙2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 材料科学与工程学院,兰州 730050)

摘 要:在硅酸盐电解液体系中,采用不同的阴阳极距离制备镁合金微弧氧化膜层。通过TT260数字式涡流测厚仪、SEM、EDS和XRD分别检测膜层厚度、微观结构、元素及相组成。采用Image-J软件分析膜层表面孔隙率,利用电化学实验研究膜层耐蚀性能。基于波形图建立对应于微弧氧化系统的负载等效电路模型,并通过计算等效负载的数值和仿真,进一步分析其与膜层耐蚀性的关系。结果表明:随阴阳极距离的增加,膜层表面微孔孔数增多,孔径减小,孔隙率由26%逐渐降低到19%;膜层总体厚度随距离的增加呈减少趋势,但在距离为200 mm时略有增大;膜层耐蚀性呈先变好再变差的趋势,即在距离为10 mm时,膜层的耐蚀性最差;距离为200 mm时,膜层的耐蚀性最好,两者的腐蚀电流密度相差3个数量级。经过计算和仿真验证了负载模型的正确性,且计算的等效电阻R1与膜层耐蚀性具有对应关系,等效电阻R1值越大膜层耐蚀性越好,为现场评估膜层耐蚀性提供了依据。

关键词:镁合金;微弧氧化;阴阳极距离;微观结构;耐蚀性;负载模型

文章编号:1004-0609(2020)-12-2798-11 中图分类号:TG174 文献标志码:A

镁及镁合金具有质轻、韧性好、加工易、比强度高及资源丰富等优点,应用领域越来越广[1]。但镁合金易发生腐蚀,极大限制了其应用,因此需对其进行表面防护处理。目前,主要表面处理技术方法存在着膜层薄、耐蚀性差及环境污染等问题,难以满足防腐和环保要 求[2-3]。而微弧氧化是一种在镁、铝和钛等阀金属表面原位生成陶瓷膜的表面处理技术,因其电解液绿色环保,所得膜层具有较高的耐磨和耐蚀性能,日益受到人们的青睐[4-6]。随着对微弧氧化机理[7]的探索,对其工艺的研究也在持续进行,研究结果表明:微弧氧化膜层性能主要受到电解液[8]、添加剂[9]、基体材料[10]和电参数的影响,而电参数包括电压[11]、电流[12]、频率[13]、占空比[14]和处理时间[15]等。目前,关于阴阳极距离对膜层微观结构及耐蚀性能的研究,特别是关于其对系统负载模型定量影响和膜层性能与负载之间关系的研究较少。MELHEM等[16]认为,电极距离在微弧氧化中是可以发挥作用的,并取决于过程条件。蒋百灵等[17]认为极间距会影响电场分布的均匀性进而影响膜层性能。此外,FATKULLINA等[18]在研究中建立了不同正负电压下的等效负载模型。在对微弧氧化膜层性能的研究中,大多数研究者只单一研究某因素对膜层性能的影响,很少研究其对负载模型的影响;在对负载模型的研究中,研究者往往是对模型进行定性分析且缺乏对膜层性能的定量分析。

基于此,本文通过分析不同的阴阳极距离对膜层的微观结构、厚度、元素和物相组成的影响,并结合电化学实验来揭示其对耐蚀性的影响。同时,根据波形数据建立系统的负载等效电路模型,以自动控制理论为基础,使用Matlab和Multisim软件对模型的负载进行定量计算和仿真,分析负载模型中某些数值与阴阳极距离的关系,进而分析这些数值与膜层性能的对应关系及其对电源适应性的影响,以期达到通过负载值对膜层耐蚀性能进行现场评估和快速选择合适工艺的目的,并对阴阳极距离与电源适应性的关系进行研究,指导电源设备的进一步完善。

1 实验

1.1 实验设计

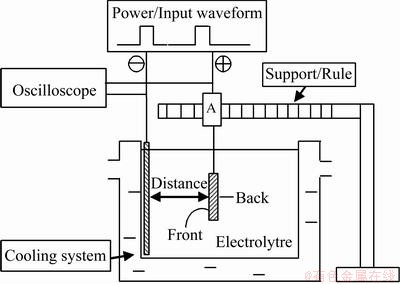

实验所用的基体材料为AZ31B镁合金,主要化学成分如表1所示。经线切割加工成规格为40 mm×40 mm×6 mm的长方体块状试样。在微弧氧化处理前,先依次用150、400、800、1200号CW的水砂纸对试样进行打磨、酒精清洗等预处理,获得洁净表面。在15 g/L Na2SiO3、2 g/L NaOH和13 g/L KF组成的碱性硅酸盐电解液体系中,采用自制的具有多种输出方式的脉冲电源,在双极性模式下以100 V/90 s的恒定加压速度进行微弧氧化处理,并在处理过程中通过循环冷却水使电解液温度保持在25 ℃以下。电解槽为500 mm×500 mm×600 mm的玻璃电解槽,阴极为40 mm×500 mm×1 mm的不锈钢薄板,为了研究距离的影响,所以单侧放置。阴阳极距离依次选取为10、50、100、200、300和400 mm。实验参数设定为频率600 Hz、占空比30%、终止电压为400 V,示波器采集电压400 V时的波形,然后关闭电源。处理完的试样取下洗净吹干,放入密封袋保存备用。实验装置如图1所示,示波器接在阴极阳极两端,通过调节支架上的导体滑块A来调节距离。

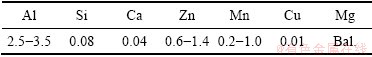

表1 AZ31B镁合金主要化学成分

Table 1 Chemical composition of AZ31B magnesium alloy (mass fraction, %)

图1 实验装置示意图

Fig. 1 Schematic diagram of experimental device

1.2 检测方法

使用TT260数字式覆层测厚仪测量微弧氧化膜层厚度。使用JSM-5600LV型场发射扫描电子显微镜(SEM)研究膜层表面和截面形貌,并用EDS检测膜层元素组成。利用ImageJ 软件对膜层表面的微孔分布状况和孔隙率进行统计。选用日本理光D/MAX-2400 型X射线衍射仪(XRD)检测膜层的相组成,其中阳极选用铜靶,扫描角度为20°~80°,扫描步长为0.02°。

2 结果与讨论

2.1 膜层微观形貌分析

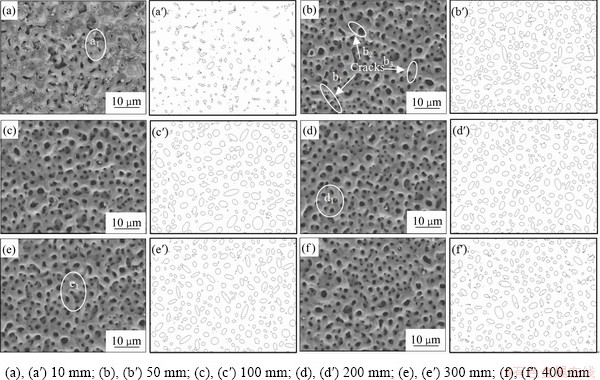

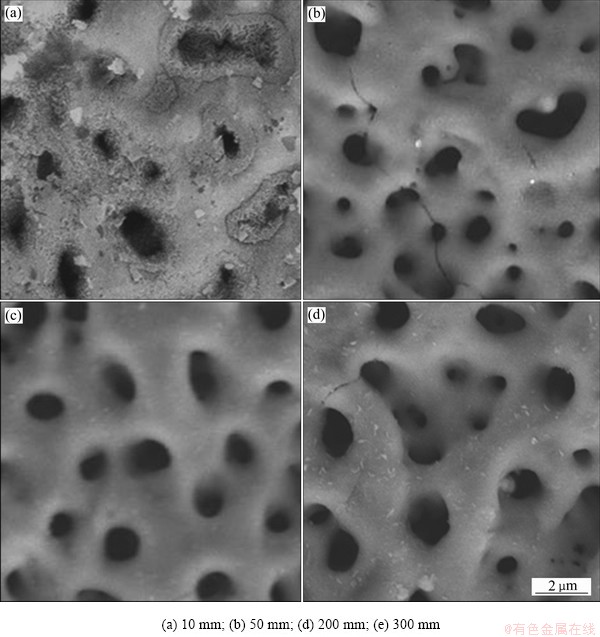

图2所示为不同阴阳极距离下所得微弧氧化膜层的表面形貌图及表面孔隙分布图。膜层表面的微观结构呈现出“火山口”形貌特征,这是由于火花放电过程中所形成的通道造成的。阴阳极距离为10 mm时,微孔大部分被融合成了大孔,且孔洞口堆积有疏松的针状组织,这可能降低膜层的耐蚀性能。究其原因,距离过近时,试样表面电流过大,易造成微孔壁熔断形成大孔,且进一步的燃烧使膜层溶解出现针状组织。结合图3可知,阴阳极距离为50 mm和100 mm时所得膜层表面凹凸不平,其上分布有较多的大孔和微裂纹,为腐蚀介质穿透膜层腐蚀基体提供了通道,不利于膜层耐蚀性的改善。这是由于在加压初期,距离较小时电阻较小,整体电流较大,使各个起弧位置间的电流差较大,所以生长速度不同,造成膜层表面凹凸不平,且熔融物较多导致冷却时的热应力集中而使表面产生微裂纹。随着阴阳极距离增大到200 mm时,膜层表面变得比较平整,微孔孔径整体上较小且分布比较均匀,大孔、裂纹等缺陷几乎消失。当距离继续增大到300 mm和400 mm时,膜层表面小孔增多,大孔减少,但表面再次出现轻微的凹凸状,且有裂纹。这是因为随着距离增加,电阻也增大,电流减小,微弧氧化开始时只有局部起弧长膜,当局部膜层厚度到一定程度不易击穿时,其他容易击穿的位置开始起弧,但较先起弧位置膜层还较薄,会呈现出轻微的凹凸不平。

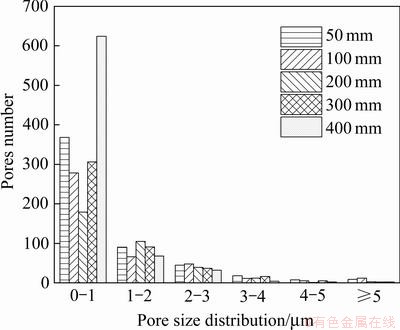

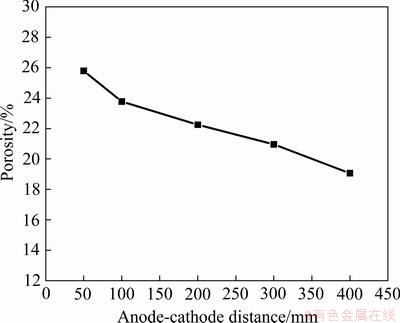

图4所示为不同孔径孔隙数目分布图,图5所示为不同阴阳极距离下微弧氧化膜层表面孔隙率。阴阳极距离为10 mm时,膜层表面结构被破坏,所以并未做统计。由图4和5可知,随着阴阳极距离的增加,膜层的孔隙率从26%逐渐降低到19%,在一定程度上能阻止腐蚀介质渗入膜层,能为基体提供较好的保护作用。但是在距离为50 mm和100 mm时,膜层表面大孔较多,使腐蚀介质更易进入基体;而距离为300 mm和400 mm时,虽然膜层表面孔隙率低,但小孔很多,为腐蚀介质渗透进入膜层提供了更多的通道。这些表面特征对耐蚀性能都是不利的。

图2 不同阴阳极距离下微弧氧化膜表面形貌和相应的微孔分布

Fig.2 Surface morphologies and corresponding micropore distributions of MAO coatings at different anode-cathode distances

图3 图2中微弧氧化膜层局部放大形貌

Fig. 3 Partially enlarged views of MAO coatings in Fig. 2

图4 不同阴阳极距离下微弧氧化膜的表面微孔统计结果

Fig. 4 Statistical results of surface micropores of MAO coatings at different anode-cathode distances

图5 不同阴阳极距离下微弧氧化膜层的表面孔隙率

Fig. 5 Surface porosity of MAO coatings at different anode-cathode distances

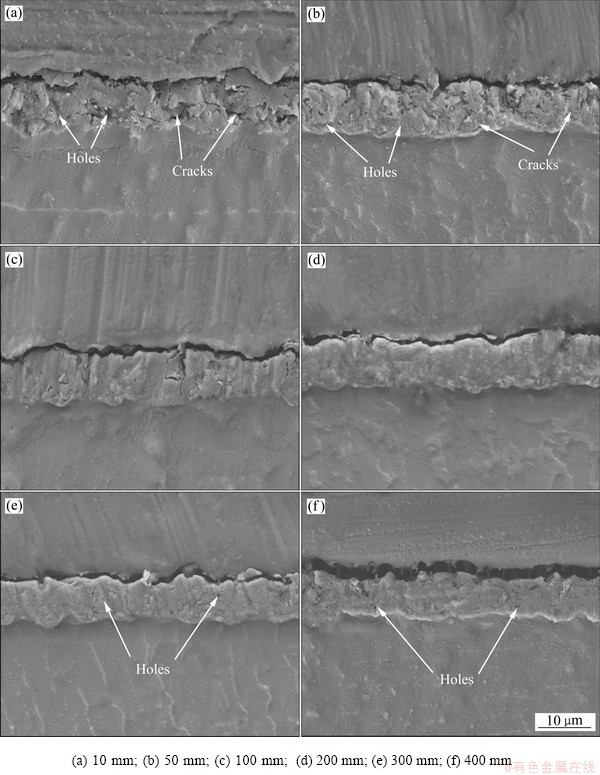

图6 不同阴阳极距离下微弧氧化膜层的截面形貌

Fig. 6 Cross-sectional morphologies of MAO coatings at different anode-cathode distances

图6所示为膜层截面形貌,膜层为典型微弧氧化膜层的双层结构。通常,微弧氧化膜层包括两个子层[19]:内部致密层和外部疏松层;前者与基体结合且比较薄,呈现波浪状;后者具有不规则孔隙和放电通道。在阴阳极距离较小时,膜层较厚,但外部疏松层中存在大量形状不一的微孔和微裂纹。在距离增加到200 mm过程中,膜层中缺陷逐渐减少致密性逐渐增加,但随距离继续增加,微孔和微裂纹再次出现。综合而言,膜层的致密性随距离的不断增加先变好再变差。

2.2 膜层元素及相组成分析

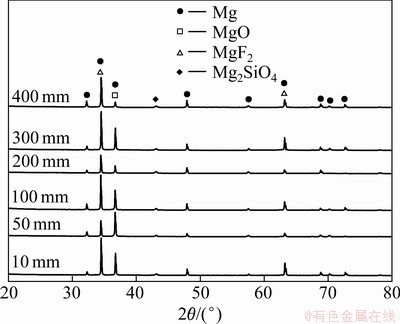

经EDS分析可知,微弧氧化膜层主要由Mg、O、F和Si元素组成[20]。随着阴阳极距离的增加,所有膜层中的元素含量没有明显变化。XRD分析结果如图7所示,所有膜层的相组成主要是MgO、MgF2和Mg2SiO4。考虑到其他条件相同,所以可推断阴阳极距离对膜层的元素和相组成影响不大。Mg峰是X射线穿透微弧氧化膜层到达镁基体测得的。在距离200 mm时,产生的膜层Mg峰强度最低,表明此时产生的微弧氧化膜层致密性最好。

图7 不同阴阳极距离下微弧氧化膜层的XRD谱

Fig. 7 XRD patterns of MAO coatings at different anode- cathode distances

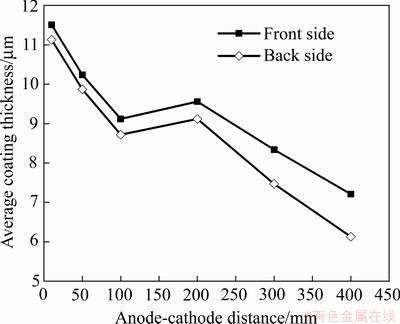

2.3 膜层厚度分析

图8所示为正反面膜层的平均厚度。由图8可知,随着阴阳极距离的增加,正反面膜层厚度值均先减小。当距离增加到200 mm时,膜层厚度较距离为100 mm时的有所增加,但仍低于距离为10 mm和50 mm时的膜层厚度;随着距离的进一步增加,膜层厚度再次减小。同时,在阴阳极距离增加的过程中,正面的膜层厚度始终高于反面的,且在距离增加到200 mm之前,正反面膜层厚度差值较小,随后两面厚度差值显著增加。这意味着随着阴阳极间距离增加,试样正反面膜层厚度差别越来越大,这可能不利于膜层更好的应用。

图8 不同阴阳极距离下正反面微弧氧化膜层的厚度

Fig. 8 Thickness of front and back MAO coatings at different anode-cathode distances

众所周知,整个试样表面的阳极电压和电流分布对膜层表面特性和膜层厚度的均匀性有着决定性的影响[21]。随阴阳极距离的增加,溶液电阻增大,试样上的电压减小,电流也减小,所以膜层厚度逐渐减小。当距离增到200 mm时,加压初期试样上电流密度小则长膜速度慢,所以此时的膜层较薄,因而此时的电流相对于100 mm时的电流是增加的,长膜速度相对变快,在处理结束时,膜层厚度较100 mm时的有所增加,但小于10 mm和50 mm时的厚度。随着距离继续增加,膜层厚度再次逐渐减小,这是由于在处理过程中,电流的增加已无法弥补前期造成的差距。正反面膜层的厚度差是因为试样对电流存在一个屏蔽效应,使正面膜层的电流密度大于背面膜层的电流密度。而厚度差在阴阳极距离较远时增大,是由于随着阴阳极距离增加,系统的电流减小,屏蔽作用影响表现更为明显。

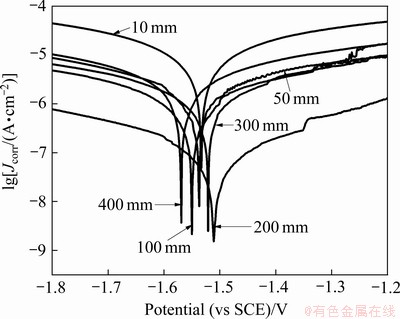

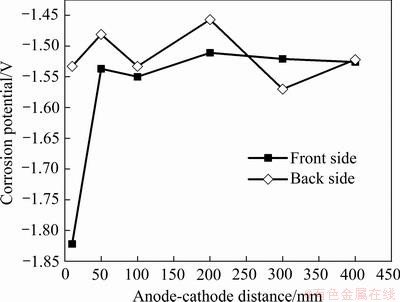

2.4 膜层耐蚀性分析

图9 不同阴阳极距离下微弧氧化膜层动电位极化曲线

Fig. 9 Potentiodynamic polarization curves of MAO coatings at different anode-cathode distances

图10 不同阴阳极距离下微弧氧化膜层的腐蚀电位

Fig. 10 Corrosion potentials of MAO coatings at different anode-cathode distances

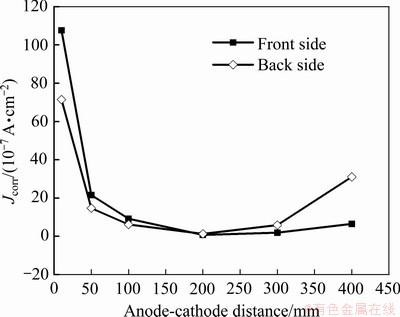

图9所示为不同阴阳极距离下微弧氧化膜层的Tafel极化曲线,图10所示为正反面膜层的腐蚀电位。结合图9和10的结果,可以看出不同阴阳极距离下膜层的电化学测试结果。在距离为10 mm时,膜层耐蚀性最差,随着距离的增加,腐蚀电位先正移后负移,在距离为200 mm时,膜层的腐蚀电位最大,为-1.511 V;腐蚀电流密度整体降低,在距离为200 mm时,达到最小值,比距离为10 mm时高了3个数量级。同时,极化电阻达到最大值,膜层的耐蚀性最好。结合膜层的表面、截面形貌可知,改变阴阳极距离能够显著影响膜层的耐蚀性,这是因为阴阳极距离的增大使膜层表面微孔孔数增多,孔径减小,孔隙率降低,而且膜层中微孔和裂纹减少,又导致致密性增加;但当阴阳极距离超过200 mm时,膜层再次出现微孔和裂纹缺陷,致密性变差,且厚度减小,其耐蚀性就开始下降。图11所示为膜层正反面的腐蚀电流密度,由图10和11可知,在距离较小时,虽然正面膜层厚度比反面膜层厚度大,但反面膜层耐蚀性比正面膜层耐蚀性好,这可能是因为反面膜层更为致密;在距离较大时,正面膜层厚度比反面膜层厚度大,而致密性可能相近,所以正面膜层耐蚀性又好于反面膜层耐蚀性。

图11 不同阴阳极距离下微弧氧化膜层正反面的腐蚀电流密度

Fig. 11 Corrosion current density of front and back of MAO coatings at different anode-cathode distances

2.5 负载等效电路模型的建立与计算分析

2.5.1 负载等效电路模型的建立

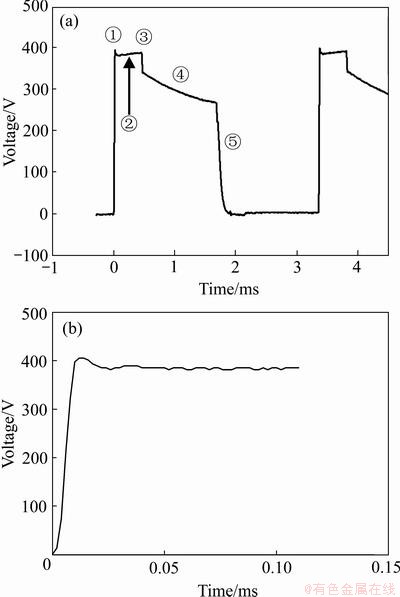

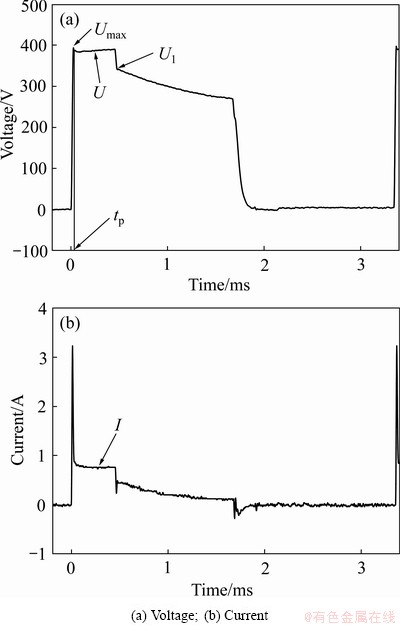

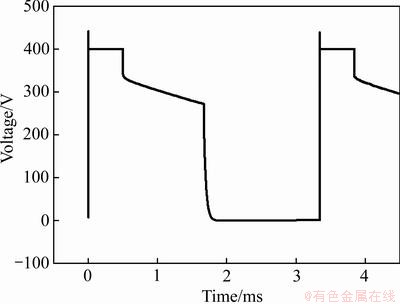

图12(a)所示为在距离200 mm和电压400 V下制备膜层时采用示波器采集得到的波形图,图12(b)所示为图12(a)中①经Matlab软件处理放大的波形。一个脉冲周期可分为五个阶段,如图12(a)所示,①是打开正脉冲时输出端的反应;②为电弧稳定燃烧阶段;③是关断正脉冲时的电阻分压表现;④为关断正脉冲后,一般电容性负载的放电反应;⑤反映了打开负脉冲时输出端的反应。

图12 电压400V时的波形图和①阶段的放大图

Fig. 12 Waveform diagram at 400V and magnified view of stage ①

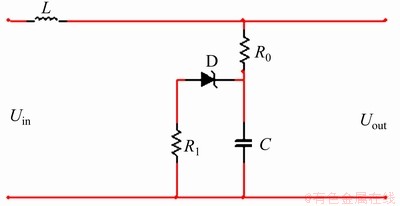

图13所示为基于对图12中的波形进行分析所建立的等效电路。由图12(b)可看出,① 瞬态是一个典型的二阶振荡环节,它由电感、电容和电阻构成,非零稳态意味着电容与电阻并联,用L、C、R1表示;③ 瞬态为正脉冲关断瞬间,其产生一个突降的台阶,这是由一个电阻与另一个电阻串联分压造成的,紧接着④为一个典型的电容通过电阻放电的环节,它们由R0、R1、C来实现;⑤ 瞬态为负脉冲开通瞬间,为一阶下降环节。其中,L代表设备和线路带来的电感,C为阴阳两极及其中间介质构成的电容,R1表示膜层电阻,R0是除膜层电阻外的其他电阻,稳压管D表明了电弧燃烧和熄灭两个阶段是独立的,负载模型是非线性电路。

图13 微弧氧化系统等效电路图

Fig. 13 Equivalent circuit diagram of micro-arc oxidation system

2.5.2 模型的定量计算及仿真

利用复阻抗来求图13所示等效电路的传递函数关系式,在“电路分析”中,元件的伏安关系可以在复频域中进行表示,即电阻元件:V=RI,电感元件:V=sLI,电容元件:I=sCV。所以首先计算出ZL、Zb、Uin、Uout。

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:ZL为电感L的阻抗,Ω;Zb为R1C并联的阻抗,Ω;Uin为输入端电压,V;Uout为输出端电压,V;IL为电感的电流,A;L为电感值,h;C为电容值,f;R1为电阻R1的阻值,Ω;R0为电阻R0的阻值,Ω;s为拉氏变换后的变量。

把式(1)、(2)分别代入到式(3)、(4)中,再由式(5)求出系统的传递函数式(6)。

(5)

(5)

(6)

(6)

(7)

(7)

式中:G(s)为传递函数关系式;K为R0阻值与R0R1阻值和的比。

将式(6)与一阶系统、二阶系统传递函数的标准形式对照得到式(8)、阻尼振荡周期式(9)和阻尼比式(10)。

(8)

(8)

(9)

(9)

(10)

(10)

式中:τ为时间常数,s;ζ为阻尼比;T为阻尼振荡周期,s。

使用Matlab软件对在不同阴阳极距离下采集的400 V时的波形数据进行画图,波形采集端为电路的输出端Uout,结合波形图与等效电路图进行分析。如图14所示,在①阶段可以读出电压的峰值Umax和峰值时间tp;在②阶段电路处于稳定状态,只有R0、R1在工作,可以得到稳态电压U为两者的电压之和,以及电路中稳态电流I;在③阶段下降的电压为R0的电压,下降到的电压值U1为R1的电压。所以可以由式(11)、(12)、(13)求出数据R0、R1,同时求出了K值。

(11)

(11)

(12)

(12)

(13)

(13)

式中: 为超调量;Umax为最大电压值,V;U为稳态电压值,V;I为稳态电流,A;U1为电阻R1的电压,V。

为超调量;Umax为最大电压值,V;U为稳态电压值,V;I为稳态电流,A;U1为电阻R1的电压,V。

图14 波形图读数示意图

Fig. 14 Schematic diagram of waveform reading

通过自动控制理论可知:

(14)

(14)

(15)

(15)

式中: 为超调量;ζ为阻尼比;T为阻尼振荡周期,s;tp为电压最大值上升时间,s。

为超调量;ζ为阻尼比;T为阻尼振荡周期,s;tp为电压最大值上升时间,s。

将式(14)、(15)与式(8)、(9)联立并把求得的 、R0、R1、K代入求解,可以得到等效电路中的L、C的值。

、R0、R1、K代入求解,可以得到等效电路中的L、C的值。

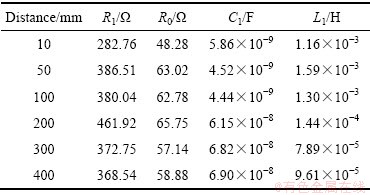

不同阴阳极距离下的等效负载值计算结果如表2所示。由表2可知,膜层电阻R1随阴阳极距离的增加先增大后减小。而膜层电阻的大小受膜层厚度及致密性的影响,从性能分析中已知膜层厚度先减后增再减,而致密性是先变好后变差,两者结合使膜层耐蚀性先变好再变差。发现膜层电阻的大小跟膜层的耐蚀性有对应关系,膜层电阻R1越大膜层耐蚀性越好,这在实际生产中可以用于现场评估膜层耐蚀性,从而指导微弧氧化工艺的选择。

表2 不同阴阳极距离下微弧氧化系统的等效负载值

Table 2 Equivalent load value of micro-arc oxidation system at different anode-cathode distances

电容主要由阴阳极和两极间各种介质的电容构成,它受到阴阳极距离和介电常数的影响,与阴阳极距离成反比,与介电常数成正比。在本实验中,随阴阳极距离的增加,距离对电容的影响大于介电常数的,所以电容先减小;随后孔隙率降低使膜层对离子的束缚和隔绝能力越强,介电常数对电容的影响大于距离,所以电容越来越大。电容的大小影响放电进而影响膜层冷却,因此,在微弧氧化过程中要考虑到电容的影响。

微弧氧化过程中产生的冲击主要由电感引起。随着阴阳极距离的增加,电感总体呈减小趋势,实际采集的电压波形的上升也随之变化,这对保护电源设备中的开关功率器件是有利的。

在Multisim中建立图13所示等效电路的模型,以阴阳极距离为200 mm为例,把计算结果代入进行仿真验证其可靠性,得到的波形如图15所示,此仿真波形与图12(a)所示波形对比,发现两者上升的冲击、下降台阶、下降曲线阶段、负电压的开通都基本一致,验证了等效电路模型和计算过程的正确性。

图15 等效电路的仿真波形

Fig. 15 Simulation waveform of equivalent circuit

3 结论

1) 阴阳极距离从10 mm逐渐增加到400 mm时,膜层表面孔数逐渐增多,但大孔减少,孔隙率从26%逐渐降低到19%,表面平整度先变好后变差。但距离为10 mm时,由于距离过小使电流过大,导致膜层结构被破坏。

2) 阴阳极距离对膜层的元素和相组成基本没有影响;随阴阳极距离增加,膜层总体厚度呈减小的趋势,但在距离为200 mm附近时略有增大。电流的屏蔽效应使正面膜层厚度始终大于反面膜层厚度,厚度差随距离增加而增大,不利于膜层的应用。膜层的致密性和耐蚀性随阴阳极距离增加先变好后变差,且在距离为200 mm时,膜层因具有最佳的致密性和厚度,从而呈现出最优异的耐蚀性能,其腐蚀电流密度比距离为10 mm时高了3个数量级。

3) 通过Matlab和Multisim软件建立并定量计算负载等效电路模型,将计算结果代入模型进行仿真分析,验证了本实验的负载等效模型和定量计算过程的正确性,为电源和负载的适应性研究提供理论依据。

4) 计算得到的等效膜层电阻R1值先增大后减小,与膜层耐蚀性有对应关系,R1值越大耐蚀性越好,可为膜层耐蚀性的现场评估提供依据;而电容先减小后增大和电感逐渐减小的变化规律说明,在选择工艺时既要考虑负载特性对膜层性能的影响,还需考虑其对电源设备的影响。

REFERENCES

[1] 李 轶, 程培元, 华 林. 镁合金在汽车工业和3C产品中的应用[J]. 江西有色金属, 2007, 21(2): 30-33.

LI Yi, CHENG Pei-yuan, HUA Lin. Current application of magnesium alloy in automotive industry and 3C product fields[J]. Jiangxi Nonferrous Metals, 2007, 21(2): 30-33.

[2] 张荣发, 单大勇, 韩恩厚, 曾志亮. 镁合金阳极氧化的研究进展与展望[J]. 中国有色金属学报, 2006, 16(7): 1136-1148.

ZHANG Rong-fa, SHAN Da-yong, HAN En-hou, ZENG Zhi-liang. Status and prospect of anodization on magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1136-1148.

[3] 薛文斌, 邓志威, 来永春, 陈如意, 张通和. 有色金属表面微弧氧化技术评述[J]. 金属热处理, 2000(1): 3-5.

XUE Wen-bin, DENG Zhi-wei, LAI Yong-chun, CHEN Ru-yi, ZHANG Tong-he. Review of micro-arc oxidation technique on surface of non-ferrous metals[J]. Treatment of Metals, 2000(1): 3-5.

[4] 周湧翔. 铝合金微弧氧化膜的组织控制与性能[D]. 广州: 华南理工大学, 2016.

ZHOU Yong-xiang. Microstructure control and properties of microarc oxidation coatings on aluminum alloy[D]. Guangzhou: South China University of Technology, 2016.

[5] SANKARA NARAYANAN T S N, PARK I S, LEE M H. Strategies to improve the corrosion resistance of microarc oxidation (MAO) coated magnesium alloys for degradable implants: Prospects and challenges[J]. Progress in Materials Science, 2014, 60: 1-71.

[6] MATYKINA E, ARRABAL R, MOHEDANO M, MINGO B, GONZALEZ J, PARDO A, MERINO M C. Recent advances in energy efficient PEO processing of aluminium alloys[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1439-1454.

[7] HUSSEIN R O, NIE X, NORTHWOOD D O. An investigation of ceramic coating growth mechanisms in plasma electrolytic oxidation (PEO) processing[J]. Electrochimica Acta, 2013, 112: 111-119.

[8] 乔丽萍, 江龙发, 黄华德, 曲 彪, 张淑芳, 张荣发, 向军淮. 钙盐和氢氧化钾浓度对钛合金微弧氧化膜表面形貌及成分的影[J]. 中国有色金属学报, 2015, 25(6): 1590-1596.

QIAO Li-ping, JIANG Long-fa, HUANG Hua-de, QU Biao, ZHANG Shu-fang, ZHANG Rong-fa, XIANG Jun-huai. Effects of calcium salts and KOH concentrations on surface morphology and chemical compositions of micro arc oxidation coatings on titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1590-1596.

[9] 安凌云, 马 颖, 刘云坡, 王宇顺, 王 晟, 王占营. V2O5和NaVO3对镁合金微弧氧化膜耐蚀性影响的对比[J]. 中国有色金属学报, 2018, 28(8): 1542-1550.

AN Ling-yun, MA Ying, LIU Yun-po, WANG Yu-shun, WANG Sheng, WANG Zhan-ying. Comparison of effects of V2O5 and NaVO3 on corrosion resistance of micro-arc oxidation coatings on magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(8): 1542-1550.

[10] 贺 星, 宋仁国, 孔德军. 海洋钢微弧氧化膜层组织与性能[J]. 中国有色金属学报, 2019, 29(8): 1701-1711.

HE Xing, SONG Ren-guo, KONG De-jun. Microstructure and properties of micro-arc oxidation coatings on offshore steel[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(8): 1701-1711.

[11] 杜翠玲, 陈 静, 汤 莉, 芦 笙, 卢向雨, 许 蕾. 正向电压对ZK60镁合金微弧氧化过程及膜层的影响[J]. 中国有色金属学报, 2014, 24(5): 1118-1126.

DU Cui-ling, CHEN Jing, TANG Li, LU Sheng, LU Xiang-yu, XU Lei. Effect of positive voltage on micro-arc oxidation process and coating of ZK60 Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1118-1126.

[12] XIANG Nan, SONG Ren-guo, ZHUANG Jun-jie, SONG Ruo-xi, LU Xiao-ya, SU Xu-ping. Effects of current density on microstructure and properties of plasma electrolytic oxidation ceramic coatings formed on 6063 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 806-813.

[13] ZOU Bin, Lü Guo-hua, ZHANG Gu-ling, TIAN Yu-ye. Effect of current frequency on properties of coating formed by microarc oxidation on AZ91D magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1500-1505.

[14] 孙 磊, 芦 笙, 吕伟刚, 王泽鑫, 周 磊. 阶段占空比模式下微弧氧化膜层的性能[J]. 材料保护, 2017, 50(2): 44-47.

SUN Lei, LU Sheng, Lü Wei-gang, WANG Ze-xin, ZHOU Lei. Performance of micro-arc oxidation coating prepared under steps duty ratio mode[J]. Materials Protection, 2017, 50(2): 44-47.

[15] 董海荣, 马 颖, 郭惠霞, 张玉福, 郝 远. AZ91D镁合金微弧氧化膜的致密性及其对耐蚀性的影响[J]. 中国有色金属学报, 2015, 25(4): 844-851.

DONG Hai-rong, MA Ying, GUO Hui-xia, ZHANG Yu-fu, HAO Yuan. Compactness of micro-arc oxidation coatings on AZ91D magnesium alloys and its effect on coating corrosion resistance[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 844-851.

[16] MELHEM A, HENRION G, CZERWIEC T, BRIANCON J L, DUCHANOY T, BROCHARD F, BELMONTE T. Changes induced by process parameters in oxide layers grown by the PEO process on Al alloys[J]. Surface & Coatings Technology, 2011, 205: 133-136.

[17] 严为刚, 蒋百灵, 施文彦, 李洪涛. 极间距对6061铝合金微弧氧化的影响[J]. 表面技术, 2016, 45(10): 7-12.

YAN Wei-gang, JIANG Bai-ling, SHI Wen-yan, LI Hong-tao. Effects of inter-electrode distance on micro-arc oxidation of 6061 aluminum alloy[J]. Surface Technology, 2016, 45(10): 7-12.

[18] FATKULLINA A R, PARFENOV E V, YEROKHIN A, LAZAREV D M, ALLAN M. Effect of positive and negative pulse voltages on surface properties and equivalent circuit of the plasma electrolytic oxidation process[J]. Surface & Coatings Technology, 2015, 284: 427-437.

[19] DEHNAVI V, LIU X Y, LUAN B L, SHOESMITH D W, ROHANI S. Phase transformation in plasma electrolytic oxidation coatings on 6061 aluminum alloy[J]. Surface & Coatings Technology, 2014, 251: 106-114.

[20] 王 晟, 马 颖, 宋承娣, 李 彬, 郝 远. 镁合金微弧氧化持续电弧破坏机制的研究[J]. 稀有金属材料与工程, 2020, 49(6): 1970-1976.

WANG Sheng, MA Ying, SONG Cheng-di, LI Bin, HAO Yuan. Destruction mechanism of sustained arc on magnesium alloy coated by MAO[J]. Rare Metal Materials and Engineering, 2020, 49(6): 1970-1976.

[21] WEI C B, TIAN X B, YANG S Q, WANG X B, FU RICKY K Y, CHU PAUL K. Anode current effects in plasma electrolytic oxidation[J]. Surface & Coatings Technology, 2007, 201: 5021-5024.

Effects of distance between anode and cathode on properties and load model of micro-arc oxidation coatings on magnesium alloys

WANG Sheng1, 2, LIU Kang-kang1, 2, MA Ying1, 2, LI Bin1, 2, HUANG Zhi-jie2, WANG Xiao-long2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. School of Material Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The micro-arc oxidation coatings were prepared on AZ31B magnesium alloys in silicate-containing electrolyte at different anode-cathode distances. The thickness, microstructure, elements and phase composition of the coatings were measured by TT260 digital eddy current thickness gauge, SEM, EDS and XRD. The surface porosity of the coatings was analyzed by Image-J, and the corrosion resistance of the film was investigated by electrochemical experiments. Based on the waveform diagram, the equivalent circuit corresponding to the micro-arc oxidation system was established, and the equivalent load value was calculated to analyze the relationship between equivalent load value and corrosion resistance of the film. The results show that, with the increase of anode-cathode distances, the number of micro-pores increases while the size of micro-pores decreases, and the porosity gradually decreases from 26% to 19%. The film thickness decreases generally with the increase of the distance, but increases slightly at the distance of 200 mm. While the corrosion resistance of the film shows a tendency to become better first and then worse, that is, the corrosion resistance of the coating is the worst at the distance of 10 mm, and the corrosion resistance is the best the distance of at 200 mm. Their corrosion current density differs by three orders of magnitude. The calculated equivalent resistance R1 has a corresponding relationship with the corrosion resistance of the coatings. The greater the equivalent resistance R1, the better the corrosion resistance, which can be used to evaluate the corrosion resistance of the film layer on site.

Key words: magnesium alloy; micro-arc oxidation; anode-cathode distance; microstructure; corrosion resistance; load model

Foundation item: Project(17JR5RA112) supported by the Innovation Base and Talent Program-Youth Science and Technology Fund of Gansu Province, China; Project(SKLAB02015006) supported by the Open Fund of State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, China

Received date: 2019-12-06; Accepted date: 2020-10-15

Corresponding author: MA Ying; Tel: +86-931-2976688; E-mail: maying@lut.cn

(编辑 李艳红)

基金项目:甘肃省创新基地和人才计划-青年科技基金计划资助项目(17JR5RA112);有色金属先进加工与再利用国家重点实验室开放基金资助项目(SKLAB02015006)

收稿日期:2019-12-06;修订日期:2020-10-15

通信作者:马 颖,教授;电话:0931-2976688;E-mail:maying@lut.cn