DOI: 10.11817/j.issn.1672-7207.2016.03.022

救生舱防水承压研究

詹子娜1, 2,金龙哲1, 2,黄志凌1,李乾坤1

(1. 北京科技大学 土木与环境工程学院,北京,100083;

2. 矿山避险技术研究中心,北京,100083)

摘要:为提高矿井突水后救生舱综合防护能力,采用理论计算、数值模拟和现场试验相结合的方法,研究防水型救生舱外壳的承水压性能。基于潜艇设计理论,计算环肋圆柱壳承压性能的3个关键应力和2个稳定性临界载荷,得到外壳承压结构的关键因素(即壳板厚度、加强筋间距、加强筋型材)对其应力及稳定性的影响规律,提出一组防水型救生舱外壳设计的最优方案,并通过ANSYS数值模拟和现场试验进行验证。研究结果表明:制造的防水舱能承受水深300 m(3 MPa)静水压力,最大应力为288.6 MPa,最大形变量为3 mm。

关键词:救生舱;环肋圆柱壳;承压性能;关键应力;稳定性载荷

中图分类号:X924.4 文献标志码:A 文章编号:1672-7207(2016)03-0882-07

Research on waterproof and bearing pressure of refuge chamber

ZHAN Zina1, 2, JIN Longzhe1, 2, HUANG Zhiling1, LI Qiankun1

(1. Civil and Environmental Engineering Institute, University of Science and Technology Beijing, Beijing 100083, China;

2. Mine Emergency Technology Research Center, Beijing 100083, China)

Abstract: In order to improve the comprehensive protection of mine refuge chamber when the flooding accidents occurred, the bearing pressure performance of waterproof refuge chamber was studied by the combining theoretical calculation, numerical simulation and field test. Based on the submarine knowledge, three key stresses and two stability loads closely related to the ring stiffened cylindrical shell were calculated. Three crucial factors were taken into account, i.e. shell thickness, stiffeners distance and stiffener shapes, and the laws of the stress and stability influenced by the factors were found out. Finally, the optimal design of waterproof refuge chamber was proposed, which was verified by ANSYS numerical simulation and field test. The results show that the refuge chamber produced according to the program can bear hydrostatic pressure 3 MPa, being equivalent to the pressure of 300 m water depth, the maximum stress is 288.6 MPa, and the maximum displacement is 3 mm.

Key words: refuge chamber; ring stiffened cylindrical shell; bearing pressure performance; key stress; stability load

煤矿透水事故作为井下五大灾害之一[1],具有极大的危害性和爆发性,严重威胁着煤矿安全生产和矿工的生命[2-3]。现阶段,随着煤矿井下“6大系统”的构建,以救生舱为代表的紧急避险设备本着为井下遇险矿工提供生命保障空间的宗旨得到推广应用。针对救生舱舱体承压强度性能研究,国内外更侧重于瓦斯爆炸冲击波对其的影响[4-6],但其标准仍不能满足防水密闭耐压的功能定位,也无统一的检验标准以衡量其防水性能。本文作者为提高救生舱在井下的综合防护功能,借鉴潜艇结构设计理论,对其防水结构和耐高压性能进行深入研究,提出一套科学的救生舱防水耐压结构的设计方法和依据,并通过ANSYS数值模拟和现场试验对其结构和条件进行验证。

1 救生舱耐压性能关键影响因素

考虑到井巷和罐笼的限制,亦满足救生舱生命保障系统、应急逃生及耐高压的性能[7-8],进行救生舱耐压圆柱外壳、支撑肋骨和舱体开孔等结构的设计,而舱体耐压性能主要取决于外部承压外壳的设计。基于潜艇承压结构设计理论[9],采用承压最好的环肋圆柱壳结构[10],并利用其3个关键应力和2个稳定性指标校核稳定性和强度失效形式[11-12],以确定其关键因素的影响方式,提出防水耐压救生舱的理论设计方案。

1.1 承压外壳应力校核方法

根据潜艇承压结构校核方法,重点考虑跨度中点处壳纵剖面的中面应力 、跨端中点处壳横剖面内表面应力

、跨端中点处壳横剖面内表面应力 和加强筋剖面应力

和加强筋剖面应力 等3个关键应力[9],计算方法为

等3个关键应力[9],计算方法为

(1)

(1)

式中:p为外压载荷,MPa;R为舱体半径,mm;t为舱体外壳厚度,mm;ε1,ε3和ε4分别为应变参数,无量纲;μ为泊松比,取0.3。

由式(1)可知:计算得到的实际应力应满足其小于许用应力的条件。

1.2 承压外壳稳定性校核方法

即使承压外壳的各处应力均在允许范围内,舱体仍可能会失稳,进行壳体稳定性校核尤为重要,主要包括局部稳定性和整体稳定性,取其最小临界载荷作为舱体稳定性的极限载荷[13],则整体稳定性临界载荷pE计算公式为

(2)

(2)

局部稳定性临界载荷pD计算公式为

(3)

(3)

式中: 和

和 为外壳参数,

为外壳参数, =πR/L,

=πR/L, =πR/l;L为舱体单元长度,mm;l为加强筋的距离,mm;n为舱体变形的波数;D为舱体的抗弯强度系数,

=πR/l;L为舱体单元长度,mm;l为加强筋的距离,mm;n为舱体变形的波数;D为舱体的抗弯强度系数, ;E为材料的弹性模量,MPa;I为计带板的加强筋惯性矩,mm4。

;E为材料的弹性模量,MPa;I为计带板的加强筋惯性矩,mm4。

1.3 救生舱环肋圆柱壳耐压性能的关键因素

影响救生舱肋圆柱壳耐压性能的关键因素包括壳板材料、壳板厚度、加强筋间距和型材等,通过理论计算,对比分析得到环肋圆柱壳耐压性能设计的最佳方案,并采用数值模拟的方法对其进行验证。

取救生舱外直径为2 m,单元长度为2 m,为满足救生舱可承载150 m深水压,引入安全系数为1.5,即所承受载荷按2.25 MPa进行理论研究。

由于材料的屈服极限与3个关键应力密切相关,材料的选取直接决定着救生舱耐压性能的好坏。从防护性能、综合成本、制造可行性的角度考虑,比较不同金属材料的抗拉、抗压性能指标,采用强度较高的Q620钢作为舱体壳板。

1.3.1 壳板厚度

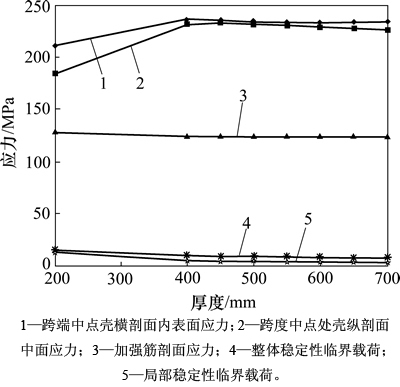

潜艇壳板厚度一般为20~30 mm,由于防水舱半径较小,强度要求也较低,考虑到耗材和舱体整体质量要求,从壳板厚度5~25 mm进行分析和校核以确定最佳厚度。以潜艇设计运用较多的T型钢加强筋,间距400 mm为例进行理论分析,结果如图1所示。

由图1可知:在相同加强筋结构下,壳板厚度对舱体所受3个关键应力影响较大,随着壳板厚度的增加,关键应力逐渐减小,尤其在壳板厚度较小时,对跨度中点壳纵剖面的中面应力、跨端中点壳横剖面应力影响更为显著,而对加强筋剖面应力影响较小;壳板越厚,舱体的整体稳定性临界载荷越大,但整体稳定性临界载荷曲线变化较为平缓,表明壳板厚度对其整体稳定性影响并不显著。局部稳定性载荷曲线随壳板厚度增加呈上升趋势,说明壳板厚度的增加可显著提高其局部稳定性。但由于壳板整体稳定性并未显著增加,当厚度增至某临界值时,外载荷到达局部失稳临界载荷前,舱体已整体失稳,即壳板厚度为5 mm,舱体局部在压力为0.94 MPa即会失稳。

通过增加板厚可提高舱体的强度和稳定性,但考虑到制造成本、整舱质量和内部空间要求等问题,选取局部稳定性临界载荷为5.61 MPa的10 mm壳板为最优方案。

图1 壳板厚度对应力和稳定性影响规律

Fig. 1 Influence of shell thickness on stress and stability

1.3.2 加强筋间距

为保证壳体具有良好的稳定性,在耐压圆柱壳体内部设置环向加强筋。通过分析不同间距对舱体承压结构的影响规律以确定其最优设置方式,如图2所示。

由图2可知:在相同型号加强筋下,随着间距增大,跨端中点壳横剖面和跨度中点壳纵剖面所受应力呈先增大后基本平稳的趋势。可见,加强筋间距越大,跨端中点壳横剖面和跨度中点壳纵剖面所受应力越大,但当间距增加到450 mm时,其基本上不再对应力有影响。加强筋的间距对加强筋剖面应力影响较小,因剖面应力与加强筋型材紧密相关,与加强筋间距并无关联性。加强筋的间距越大,舱体的整体稳定性和局部稳定性的临界载荷越小,但整体稳定性与加强筋间距关联性并不大;局部稳定性临界载荷影响程度随之逐渐减小,当l>650 mm时,壳体在3 MPa时局部失稳。虽加强筋间距越小所受应力越小,稳定性越高;但确定加强筋间距时,为达到加强筋的最高承压性能和材料的最大利用率,在满足应力和失稳临界载荷2方面的要求下选取有效最大间距为500 mm。

图2 加强筋间距对应力和稳定性的影响

Fig. 2 Influence of stiffeners distance on stress and stability

1.3.3 加强筋型号

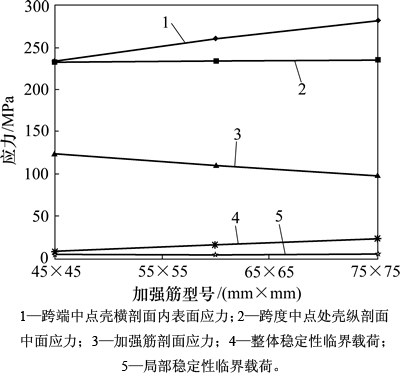

由于加强筋处需布置隔热材料,其型号(腹板高 度×翼板宽度)不能大于75 mm×75 mm,针对以下3种加强筋进行分析,如图3所示。

图3 加强筋型号对应力和稳定性的影响

Fig. 3 Influence of stiffener shapes on stress and stability

由图3可知:随着加强筋型号递增,其剖面应力递减,而跨端中点壳横剖面应力随之增大,跨度中点壳纵剖面应力基本不变。加强筋剖面和跨端横剖面应力变化趋势相反,要综合考虑加强筋剖面和跨端横剖面受力情况,取最优点。加强筋型号对舱体局部稳定性没有影响,因局部稳定性载荷主要是壳板厚度和加强筋间距决定的。但整体稳定性临界载荷随加强筋型号递增而增大,即舱体也不易失稳。3种加强筋下舱体的关键应力与稳定性临界载荷均能满足救生舱的耐压要求,为了留有足够的安全余量,并达到最低的成本,选取腹板高度×翼板宽度为60 mm×60 mm的T型加强筋。

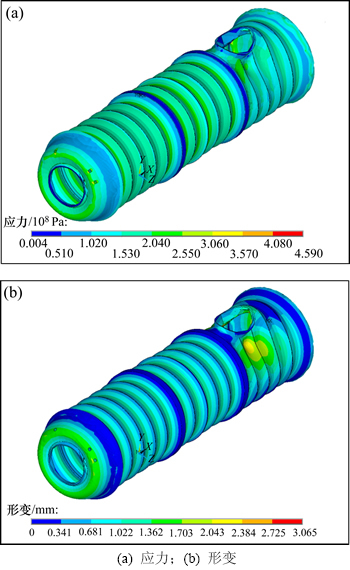

1.4 环肋圆柱壳单元耐压性能数值模拟

舱体单元结构主要包括耐压壳体、内部加强筋与法兰3部分。构建直径为2 m,长为2 m的单元模型,法兰厚为70 mm,每片法兰共40个螺栓孔,螺栓孔直径为60 mm。单元结构采用SHELL181,内部加强筋和法兰采用SOLID187进行定义[14],其应力和形变云图如图4所示。

图4 环肋圆柱壳应力和形变分析图

Fig. 4 Stress and deformation nephograms of ring stiffened cylindrical shell

由图4可知:环肋圆柱壳单位最大变形在相邻加强筋的壳板中心点,最大应力位于加强筋与舱端的壳板中心处,是跨端中点壳的表面应力,即3个关键应力之一。

表1所示为理论计算和仿真模拟计算结果,两者关键应力基本一致,相对误差较小,其主要是由模型简化和网格引起的,在可接受范围内,验证了模型构建与数值模拟的正确性,为下一步整舱耐压稳定性的研究提供了可行有效的方法。

2 整舱模型耐压稳定性能数值模拟

构建防水舱模型,主要由舱体外壳、椭圆形封头[15]、法兰、加强筋与开孔5部分构成。根据压力容器开孔补强结构形式原则,采用等面积法厚壁管补强[16],舱门处补强2 150 mm2,应急舱门补强1 900 mm2。

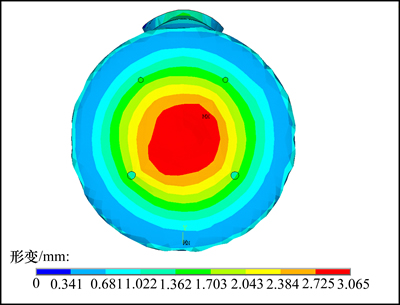

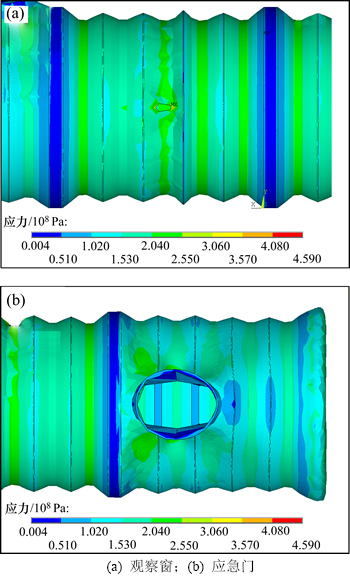

舱体采用Q620钢,外径R=1 m,长度L=6 m,单节长2 m,壳板厚度t=10 mm,加强筋采用腹板高度×翼板宽度为60 mm×60 mm 的T型钢,间距l=500 mm;实际施加的载荷P=2.25 MPa,作用于环肋圆柱壳的外表面[17-18]。在开孔区域、连接区域进行网格细化处理,模拟结果如图5~7所示。

图5 整舱应力和形变云图

Fig. 5 Stress and deformation nephograms of refuge chamber

表1 环肋圆柱壳关键应力模拟结果和计算结果对比

Table 1 Contrast of simulation and calculation results of ring stiffened cylindrical shell

图6 舱尾形变云图

Fig. 6 Deformation nephogram of tail

图7 观察窗和应急门应力分析图

Fig. 7 Stress nephogram of observation window and emergency door

2.1 应力分析

1) 舱体在2.25 MPa的载荷下,绝大部分区域应力为100~300 MPa,舱体开孔处都出现了应力集中现象,其最大应力点位于舱体观察窗处,由于未对其进行补强,应力达到了459 MPa,后期设计中需单独对观察窗采取补强措施。

2) 正门和应急门处均有应力集中现象,虽门孔直径远大于观察窗,由于门框的设置很大程度上加强了其强度,最大应力由2 020 MPa降至255 MPa,具有补强效果,圆柱壳轴向开孔强度强于径向开孔。

2.2 形变分析

1) 在2.25 MPa的实际载荷下,整舱最大形变位置在舱尾椭圆封头的中心处,为3 mm;其次较大的形变位置在舱首椭圆封头,最大值约为1.7 mm,是由于两处都无结构件支撑。

2) 开孔部位虽有应力集中现象,但形变没有特殊变化,说明应力与形变并没有直接关系。

3) 舱体环肋圆柱壳未发生屈服或失稳,3 mm的形变在可接受的范围内;应力均未超过各部位的许用应力,证明救生舱的设计能够满足承压1.5 MPa静水压的技术指标,验证了方案的可行性。

3 防水型救生舱性能检测

为进一步验证防水型救生舱理论设计和数值模拟的可靠性,系统性考察舱体在静水压下应力变化规律,建立了水压模拟试验中心,构建了耐压舱、注水加压系统、应变监测系统与附属系统等4大系统。

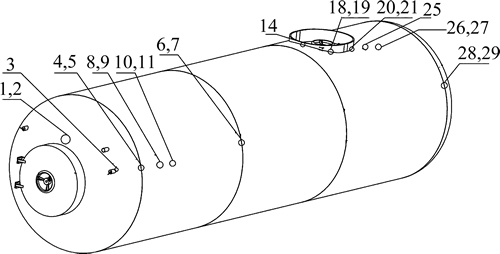

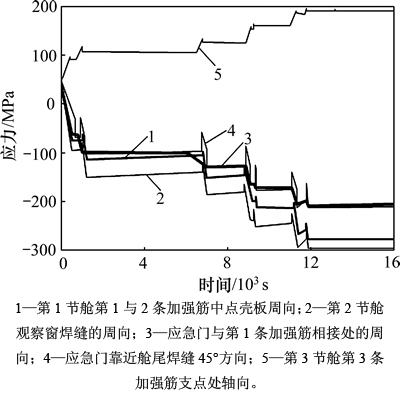

根据整舱模拟结果,在应力偏大或特殊薄弱部位共布置了32个测点进行应变监测,舱体测点布置方案和应变片编号1~29如图8所示,其中5个应变较大位置的检测数据如图9所示。

图9中各测点数据应力值为负表示受压,为正表示受拉,各条曲线均出现4段平台,其对应的时间段分别为保压1.5,2.0,2.5和3.0 MPa。应变仪所测应变对应的应力变化平稳,并与水压变化趋势完全一致,数据可靠。整个试验压力未出现波动或失压,说明舱体未出现泄漏或大变形,救生舱与水压模拟设备的承压与水密性能良好。

图8 救生舱应变片布置图

Fig. 8 Layout of strain gauges on refuge

图9 5个关键测点应力变化曲线

Fig. 9 Stress detection curve of five key pots

整个试验所测得的最大应变为-1.401×10-3,应力约为288.6 MPa,位于观察窗附近,属于跨端中点壳横剖面应力,其值远小于许用应力527 MPa,可见设计的舱体耐压强度足以承载3 MPa静水压。

4 结论

1) 借鉴潜艇设计原则,提出了救生舱耐压结构设计时,校核3个关键应力和2个稳定性临界载荷可满足救生舱的耐压和稳定性技术要求,分别为跨度中点处壳纵剖面的中面应力、跨端中点处壳横剖面的表面应力和加强筋剖面应力及整体稳定性临界载荷、局部稳定性临界载荷。

2) 通过理论分析得到救生舱的壳板厚度、加强筋型号与加强筋间距等主要因素对其防水舱耐压应力和稳定性的影响规律,在救生舱承压外壳设计中具有参考意义,不仅可提高防水舱耐压性能,更可达到最低经济成本的要求。

3) 提出了1组最佳防水舱设计方案:舱体长度为3.5 m,采用10 mm 的Q620钢材,加强筋采用腹板高度×翼板宽度为60 mm×60 mm的T型钢,间距为500 mm;基于ANSYS数值模拟验证此方案可承受2.25 MPa的静水载荷,验证了理论计算的可行性,得到其最大应力位于救生舱观察窗,最大的应变位于舱尾封头中心,为水压模拟试验的开展奠定了基础。

4) 基于研发的水压模拟试验平台,救生舱在3 MPa水压下保压18 h,舱体未出现明显变形,最大应变出现在舱体观察窗处,应力达288.6 MPa,试验结果与模拟结果基本一致,救生舱可承受3 MPa(即300 m水深)的静水压。

参考文献:

[1] 葛及, 付净, 刘辉, 等. 矿井水灾应急救援技术及装备研究[J]. 吉林化工学院学报, 2012, 29(11): 147-150.

GE Ji, FU Jing, LIU Hui, et al. Research on emergency rescue technology and equipment of mine flood [J]. Journal of Jilin Institute of Chemical Technology, 2012, 29(11): 147-150.

[2] 程健维, 杨胜强, 程涛. 国外矿井救生舱研究现状及问题分析[J]. 煤炭科学技术, 2010, 38(11): 93-96.

CHENG Jianwei, YANG Shengqiang, CHENG Tao. Present research status of overseas mine refuge chamber and issues analysis[J]. Coal Science and Technology, 2010, 38(11): 93-96.

[3] 邢冬梅, 叶义成, 赵雯雯. 我国矿山透水事故的统计分析及安全管理对策[J]. 金属矿山, 2010(6): 178-181.

XING Dongmei, YE Yicheng, ZHAO Wenwen. Statistical analysis and safety management countermeasure of mine water inrush accident in china[J]. Metal Mine, 2010(6): 178-181.

[4] 王磊, 范世平, 龚建宇, 等. 矿井KJYF-96/8 型救生舱抗爆有限元分析[J]. 煤炭科学技术, 2014, 42(3): 69-72.

WAGN Lei, FAN Shiping, GONG Jianyu, et al. Finite element analysis of antiknock performance for KJYF-96/8 refuge chamber[J]. Coal Science and Technology, 2014, 42(3): 69-72.

[5] 樊小涛. 矿用救生舱抗爆性能试验研究[J]. 矿业安全与环保, 2010, 37(3): 25-30.

FAN Xiaotao. Experimental on anti-knock properties of mine refuge chamber[J]. Mining Safety and Environmental Protection, 2010, 37(3): 25-30.

[6] 杨俊玲, 马跃征, 杨鲁伟, 等. 煤矿救生舱防爆性能分析[J]. 煤炭学报, 2013, 38(1): 159-163.

YANG Junling, MA Yuezheng, YANG Luwei, et al. Explosion- proof performance analysis of mine refuge chamber[J]. Journal of China Coal Society, 2013, 38(1): 159-163.

[7] 栗婧, 金龙哲, 汪声. 基于应急避难空间的矿山安全防护体系研究[J]. 中国安全科学学报, 2010, 20(4): 155-159.

LI Jing, JIN Longzhe, WANG Sheng. Research of mine safety protection system based on emergency refuge space[J]. China Safety Science Journal, 2010, 20(4): 155-159.

[8] 杨大明, 武越. 中美两国煤矿井下紧急避险相关规定对比分析[J]. 煤炭科学技术, 2012, 40(2): 40-44.

YANG Daming, WU Yue. Comparison analysis on underground mine related emergent refuge regulations of China and USA[J]. Coal Science and Technology, 2012,40(2): 40-44.

[9] GJB/Z 21A—2011, 潜艇结构设计计算方法[S].

GJB/Z 21A—2011, Methods for design and calculation of submarine structure[S].

[10] 伍莉, 徐治平, 张涛, 等. 球形大深度潜水器耐压壳体优化设计[J]. 船舶力学, 2010, 14(5): 509-515.

WU Li, XU Zhiping, ZHANG Tao, et al. Optimum design of spherical deep-submerged pressure hull[J]. Journal of Ship Mechanics, 2010, 14(5): 509-515.

[11] 刘朝骏, 张达宽, 杨宇华. 纵筋环肋圆柱壳结构理论与试验研究[J]. 中国舰船研究, 2011, 6(5): 11-15.

LIU Chaojun, ZHANG Dakuan, YANG Yuhua. Experimental and theoretical analysis of ring-stiffened cylindrical shells with longitudinal stiffeners[J]. Chinese Journal of Ship Research, 2011, 6(5): 11-15.

[12] 张伟, 张圣坤, 崔维成, 等. 潜艇耐压圆柱壳结构的可靠性研究[J]. 中国造船, 2000, 41(4): 35-39.

ZHANG Wei, ZHANG Shengkun, CUI Weicheng, et al. Reliability analysis of submarine cylindrical pressure hulls[J]. Shipbuilding of China, 2000, 41(4): 35-39.

[13] 徐秉汉, 朱邦俊, 欧阳吕伟, 等. 现代潜艇结构强度的理论与试验[M]. 北京: 国防工业出版社, 2007: 45-57.

XU Binghan, ZHU Bangjun, OUYANG Lüwei, et al. The theory and experiment of modern submarine structure strength[M]. Beijing: National Defence Industry Press, 2007: 45-57.

[14] 王碧浩. 煤矿井下安全舱结构强度计算[D]. 哈尔滨: 哈尔滨工业大学航天学院, 2013: 43-45.

WANG Bihao. Numerical simulation of structural strength of refuge chamber[D]. Harbin: Harbin Institute of Technology. School of Astronautics, 2013: 43-45.

[15] KHEDMATI M R, RIGO P. Sensitivity analysis on the elastic buckling and ultimate strength of continuous stiffened aluminium plates under combined in-plane compression and lateral pressure[J]. Thin-Walled Structures, 2009, 47(11): 1232-1245.

[16] GB 150—2011, 压力容器[S].GB 150—2011, Pressure vessels[S].

[17] 王进军, 陈光柱, 夏小东. 煤矿井下救生舱舱体结构设计与分析[J]. 煤矿机械, 2011, 32(12): 13-15.

WANG Jinjun, CHEN Guangzhu, XIA Xiaodong. Structure design and analysis of refuge chamber shell used in underground coal mine[J]. Coal Mine Machinery, 2011, 32(12): 13-15.

[18] 杨旭东, 金亮亮, 李家春. 煤矿救生舱的爆炸模拟分析[J]. 煤矿机械, 2012, 32(2): 113-114.

YANG Xudong, JIN Liangliang, LI Jiachun. Explosion simulation and analysis of coal mine rescue capsule[J]. Coal Mine Machinery, 2012, 32(2): 113-114.

(编辑 刘锦伟)

收稿日期:2015-03-13;修回日期:2015-05-12

基金项目(Foundation item):“十二五”国家科技支撑计划项目(2012BAK09B00) (Project(2012BAK09B00) supported by the National Science and Technology Pillar Program during the 12th “Five-year” Plan Period)

通信作者:金龙哲,教授,博士生导师,从事矿山紧急避险系统技术、矿山安全和应急救援研究;E-mail: lzjin@ustb.edu.cn