铸造工艺对(Al3Zr+Al2O3)p/A356原位复合材料组织和性能的影响

李桂荣, 赵玉涛, 戴起勋, 程晓农, 曹建峰, 王宏明, 刘忠德, 陈 刚

(江苏大学 材料科学与工程学院, 镇江 212013)

摘 要: 采用A356-Zr(CO3)2组元通过熔体直接反应法原位合成了Al3Zr和Al2O3颗粒增强铝基复合材料, 在720℃时进行常规金属模浇注和挤压铸造成型。 挤压铸造是复合材料在高压下的结晶凝固和塑性变形和强制补缩-密实两过程的复合, 增加复合材料熔点, 改善模壁和熔体热交换条件, 增加基体形核率。 与金属模铸造试样的组织对比表明: 由于复合材料的高致密度和细晶强化, 挤压铸造成型复合材料组织中气泡和缩孔等浇注缺陷减少了, 而组织致密度提高了, 基体晶粒度减小2~3倍, 复合材料的抗拉强度和延伸率分别为345MPa和15.07%, 较金属模成型复合材料分别提高1.6和2.15倍, 且挤压铸造复合材料干滑动磨损性能明显提高。

关键词: 颗粒增强铝基复合材料; 挤压铸造; 凝固组织; 抗拉强度; 干滑动磨损性能 中图分类号: TG146

文献标识码: A

Effect of casting technologies on microstructures and properties of (Al3Zr+Al2O3)p/A356 in-situ composites

LI Gui-rong, ZHAO Yu-tao, DAI Qi-xun, CHENG Xiao-nong, CAO Jian-feng, WANG Hong-ming, LIU Zhong-de, CHEN Gang

(School of Materials Science and Technology, Jiangsu University, Zhenjiang 212013, China)

Abstract: The A356-Zr(CO3)2 components were used to synthesize in-situ Al3Zr, Al2O3 particulates reinforced aluminum matrix composites, which were cast by conventional permanent mold and squeeze casting at 720℃ respectively. Squeeze casting refers to crystallization, solidification and plastic deforming at high pressure, which combines the compulsory feeding and densification.It enhances the melting point of composites and nucleation rate and improves the heat exchange condition between mold wall and melt.Compared with composites cast by permanent mold, the amount of bubbles and shrinkage holes decreases largely in composites cast by squeeze casting . The tightness of microstructures increases. Meanwhile, the grain size of matrix is decreased by 2-3 times. The tensile strength and elongation are 345MPa and 15.07%, respectively, which are increased by 1.6 and 2.15 times.The dry sliding property is enhanced largely. The excellent properties are attributed to high tightness and grain strengthening.

Key words: particle reinforced aluminum matrix composites; squeeze casting; microstructure; tensile strength; dry sliding property

铝基复合材料因其独特的优越性能备受材料研究者的关注, 其中通过原位方法合成的颗粒增强铝基复合材料因其合成工艺简单、 材料耐磨性高及基体颗粒界面干净等受到更多青睐[1-3], 但由于增强相和基体热性能的差异, 使得常规金属模浇注成型的试样中存在较多的气泡、 缩孔和疏松等铸造缺陷, 严重影响了复合材料力学性能和耐磨性的进一步提高, 而通过挤压铸造工艺可以提高组织致密度[4-7]。 挤压铸造工艺是集压力铸造和模锻而发展起来的金属成形技术, 是将一定量的液态金属直接浇注入涂有润滑剂的模腔中, 然后施加机械静压力, 利用金属凝固成形时易流动和锻造技术使已凝固的封闭硬壳进行塑性变形, 使金属在压力下结晶凝固并强制消除因凝固收缩而形成的缩孔, 以获得无任何铸造缺陷的液锻件[8]。 液锻件接近工件最终加工尺寸, 质量高, 该技术在轻质铝合金和镁合金中应用较多[7], 也用于挤压铸造晶须或外加颗粒复合材料, 但在原位内生颗粒增强铝基复合材料中的应用鲜见报道。

本研究是将原位复合材料熔体制备和挤压铸造成型技术结合起来, 充分发挥二者在材料制备中的独特优越性, 对常规金属模具和挤压铸造成型复合材料的凝固组织、 拉伸性能和干滑动磨损性能进行了对比实验。

1 实验

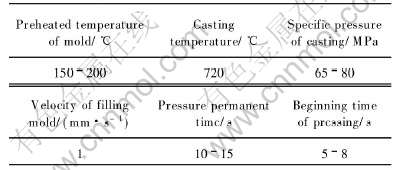

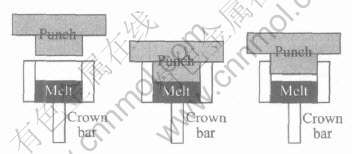

合成复合材料基体用A356硅铝合金(Al-7.39%Si-0.37%Mg-0.15Ti, 质量分数), 该合金具有优异的铸造性能, 反应物是碳酸锆Zr(CO3)2·nH2O, 烘烤去除结晶水后冷却、 研磨, 经筛分得到粒度小于75μm的粉末添加料。 同时将铝合金锭在电阻炉中熔化, 用氮气作为保护气体, 恒温在850℃, 除气精炼后分批加入Zr(CO3)2粉末(质量为铝锭质量的15%), 对应颗粒理论体积分数为20%。 用石墨钟罩将粉剂压入熔体, 原位反应开始, 用石墨棒进行机械搅拌, 并用便携式测温仪测定熔体温度, 反应结束后除气、 精炼、 静置, 于720℃时分别进行金属模浇注和挤压铸造浇注成型。 挤压铸造实验选用YB32-100型四柱挤压铸造机, 自行设计齿轮件模具, 相关挤压铸造参数如表1所列。 图1所示为挤压铸造过程示意图。

表1 挤压铸造成形工艺参数

Table 1 Operating parameters of squeeze casting

图1 挤压铸造过程示意图

Fig.1 Schematic diagram of squeeze casting process

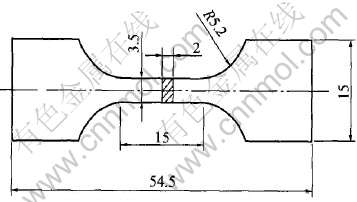

室温拉伸性能测试在WDW-11型微机控制电子式万能试验机上进行, 横梁步进速度为0.5mm/min, 试样尺寸如图2所示。 干滑动磨损性能测试在MM-200销盘式磨损实验机上进行, 试样尺寸为19.5mm×10mm×8mm, 对磨块材料为40Cr, 尺寸为d40mm×d16mm×10mm, 施加载荷和磨损速度分别为50N和0.42m/s, 耐磨性用试样磨损前后的质量差来衡量, 称重用电子天平精度1mg。 用JEOL-JXA-840A型扫描电镜观察试样凝固组织, 用D/max2500 PC型X射线衍射仪分析复合材料中颗粒种类, 试样用复膜-偏光法在MM-6型卧式显微镜上观察基体晶粒尺寸。

图2 室温拉伸性能测试试样的尺寸示意图

Fig.2 Schematic diagram of tensile specimen at room temperature(mm)

2 结果和分析

2.1 原位合成复合材料熔体

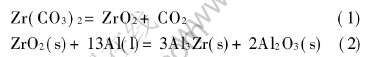

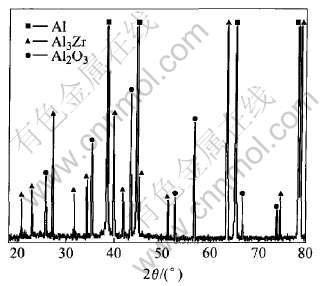

图3所示为复合材料试样的X射线衍射谱。 由图3可看出, 增强相为Al2O3和Al3Zr, 二者都是陶瓷颗粒。 合成过程中在高温铝液和Zr(CO3)2之间发生如下反应:

原位反应方程为

式(2)是原位反应生成增强相的关键步骤, 反应式中的ZrO2、 Al3Zr和Al2O3熔点分别为2600、 1350和2046℃, 在小于1000℃的原位反应体系中都不溶解, 或者说都是以固态物质存在。 在计算反应吉布斯自由能ΔG时, 若以纯物质作为标准态, 则在公式ΔG=ΔG+RTlnQ中, 活度项Q≡1, 即ΔG≡ΔG=-106 532.3+75.79T(单位: J/(mol·K)), 属于放热反应, 平衡温度为1405.6K, 低于该温度反应可以自发进行, 而测温结果显示合成过程中熔体温度不高于1000℃, 因此在实验温度范围内, ΔG〈0, 反应能够自发进行。

图3 A356-Zr(CO3)2组元合成复合材料增强相的X射线衍射谱

Fig.3 XRD pattern of reinforced phases in composites fabricated by A356-Zr(CO3)2 components

2.2 凝固组织

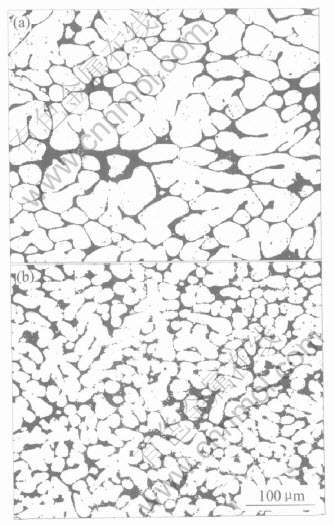

图4所示为常规金属模和挤压铸造成型复合材料试样的颗粒分布和组织致密度对比图。 由图4可看出, 成型工艺对复合材料中颗粒分布和尺寸影响不大, 颗粒粒度为2~3μm。 与常规铸件(图4(a))相比, 挤压铸造试样的组织致密, 没有气泡、 疏松和缩孔等浇注缺陷。 而对于在金属模成型的(Al2O3+Al3Zr)p/A356复合材料组织中, 出现大范围的气泡、 疏松和缩孔等浇注缺陷, 其原因主要是由于增强相和铝合金基体的热性能差异大, 在800℃时, Al、 Al3Zr和Al2O3的线膨胀系数分别为23.6×10-4、 12.1×10-4和7.92×10-4 ℃-1[9], 这导致复合材料内部凝固收缩时的不同步, 引起缩孔和组织疏松。 且铝在熔炼过程中吸氢严重, 精炼过程中部分气泡不能完全上浮, 残留在凝固组织中的气泡引起浇注缺陷。 另外, 富含内生增强颗粒的复合材料粘度较大, 熔体充型性能差, 在成型过程中容易出现吸气等现象。

图4 金属模(a)和挤压铸造(b)成型(Al3Zr+Al2O3)p/A356复合材料的颗粒分布和组织致密度

Fig.4 Particles distributions and tightness of microstructures of in-situ(Al3Zr+Al2O3)p/A356 composites cast by permanent mold (a) and squeeze casting(b)

采用挤压铸造成形可有效消除气泡、 疏松和缩孔等浇注缺陷, 由于挤压铸造是在高压下的结晶凝固和塑性变形, 是强制补缩和密实两过程的复合。 未加压时, 注入金属模膛内的熔体, 会在模壁四周和模底形成具有一定厚度的激冷凝固硬壳, 加压后上模封闭, 将待凝固熔体包围在型腔内, 在强大的机械压力作用下, 凝固壳体产生塑性变形补缩, 同时承受等静压, 熔体获得在压力下结晶凝固的各种属性, 并迅速使凝固前沿的金属液挤入因凝固收缩造成的间隙中, 达到完全补缩的目的。

从氢在铝合金中的溶解度来看, 熔融铝液在平衡条件下凝固时, 氢按照不同的溶解度分别熔解在液相和固相中, 在液相中的溶解度比在固相中的溶解度要大的多, 在凝固过程中, 由于固相中氢的溶解度降低, 液相转变为固相时必将过剩气体留在剩余液相中, 增加了剩余液相中的氢浓度, 达到形成气泡的条件。 气泡形成有形核和长大过程, 要在液相中形核, 需要一个内部压力来克服外部压力, 并建立一个新表面[10], 因此抑制气泡产生的条件为

式中 ∑pmold为压机对型腔的压力之和; ∑pgas为液态铝液中气体的分压之和。 显然增加压机对型腔的压力(保压压力)就可防止气泡在液相中形核, 从而防止气泡的生成, 采用50MPa的成型比压就可抑制气泡的形成[11], 因此在此实验条件下施加比压可有效抑制气泡生成。

2.3 基体晶粒尺寸

图5所示为常规金属模和挤压铸造成型复合材料中的基体组织。 由图5可见, 在常规金属模铸造条件下, 晶粒粗大, 平均尺寸为40μm; 而采用挤压铸造后, 晶粒细小, 平均尺寸为10~15μm, 加压后可使晶粒细化1/3~1/2。

图5 金属模(a)和挤压铸造(b)成型(Al3Zr+Al2O3)p/A356复合材料基体的显微组织

Fig.5 Microstructures of matrix in (Al3Zr+Al2O3)p/A356 composites cast by permanent mold (a) and squeeze casting(b)

根据热力学推导, 改变金属的压力会引起熔点的变化, 压力与熔点之间的函数关系由克劳修斯—克拉珀龙方程表述:

式中 p为压力, Pa; Tmelt合金的熔点, K; Vl和Vs分别为单位质量的液相和固相合金的体积, m3/kg; Qmelt为单位质量金属的熔化潜热或结晶潜热, J。 由式(4)可得: 结晶时体积收缩的金属, 即Vl>Vs, 增压时熔点升高, 固相线向高温方向移动, 即熔体会在较高的温度下进行结晶, 从微观来看是由于压力增加降低了原子间距, 限制了原子运动, 为凝固创造了前提条件[7]。 铝硅合金的熔点约660℃, 结晶时的体积变化率为-6.5%, 铝合金的dTmelt/dp比率约为5.59×10-2 K/MPa, 在此实验条件下Tmelt可提高3.634~4.472K, 可使熔体在较高温度条件下满足过冷条件, 促进液态金属形核并长大, 并阻碍了未加压时枝晶的单向延伸, 从而利于形成等轴晶组织结构; 且在压力作用下, 正在成长的树枝晶容易破碎和脱落成为新的晶核, 有利于晶粒细化。 同时避免了未加压时先结晶区与后结晶区组织成分的差异, 即在挤压铸造复合材料中没有出现明显的颗粒偏析现象[12]。 特别对于(Al3Zr+Al2O3)p/A356颗粒增强复合材料来讲, 弥散分布的内生陶瓷颗粒阻碍了晶粒的进一步长大, 有利于晶粒细化。

另外, 压力作用下复合材料熔体与型腔壁紧密接触, 改善了铸型与铸件间的热交换条件, 有利于形核, 熔体在压力下成形, 除可以加速铸件凝固外, 还可以在结晶前沿的液态金属中产生较大的过冷度, 这对于在较小过冷度下具有较强形核能力的铝合金来讲, 具有明显的细化晶粒作用[13]。

2.4 复合材料的拉伸性能和干滑动磨损性能

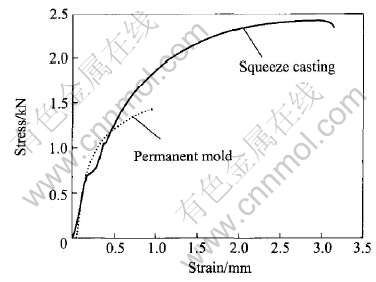

复合材料组织致密度的提高和基体晶粒度的减小都有助于提高复合材料的拉伸性能和耐磨性[14]。 图6所示为金属模成型和挤压铸造成型复合材料的应力—应变曲线。 金属模试样的抗拉强度为215MPa, 延伸率为7%, 而挤压铸造试样的抗拉强度为345MPa, 是金属模试样抗拉强度的1.6倍, 延伸率为15.07%, 是金属模试样延伸率的2.15倍, 可见挤压铸造复合材料的抗拉强度和延伸率都有明显提高。 细晶强化是其重要强化机制[15], 高组织致密度可降低拉伸过程中的局部应力集中, 减少初始裂纹生成的可能性。

图6 金属模和挤压铸造成型(Al3Zr+Al2O3)p/A356复合材料的应力—应变曲线

Fig.6 Stress—stain curves of (Al3Zr+Al2O3)p/A356 composites cast by permanent mold and squeeze casting

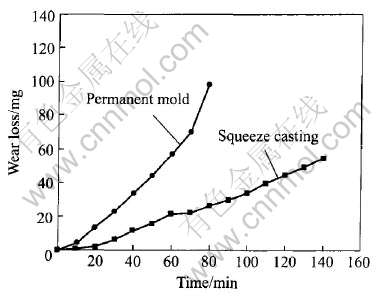

图7 金属模和挤压铸造成型(Al3Zr+Al2O3)p/A356复合材料的干滑动磨损性能

Fig.7 Dry sliding properties of (Al3Zr+Al2O3)p/A356 composites cast by permanent mold and squeeze casting

图7所示为金属模和挤压铸造试样的干滑动磨损结果。 由图7可看出, 挤压铸造试样的耐磨性比金属模试样的耐磨性好, 磨损80min后, 金属模试样的磨损量比挤压铸造试样多72.13mg, 且挤压铸造试样在经过140min后, 磨损量仍是缓慢增加, 平均增长量为0.463mg/min, 未见剧烈磨损的趋势; 而金属模试样在经过20min磨损后就出现剧烈磨损迹象, 平均增长量为1.415mg/min, 为挤压铸造试样磨损增长量的3.05倍。 晶粒细化和致密度的提高有助于提高耐磨性, 同时在模锻中, A356合金中的Si、 Mg和Ti在铝中固溶度的增加有利于提高耐磨性[15]。

3 结论

1) 选用A356-Zr(CO3)2组元合成了(Al3Zr+Al2O3)p/A356颗粒增强铝基复合材料熔体, 分别通过金属模和挤压铸造工艺成型, 金属模试样中常规浇注缺陷多, 晶粒粗大, 而挤压铸造试样的组织致密、 晶粒细小。 成型工艺对颗粒粒度没有大的影响, 颗粒粒度为2~3μm。

2) 挤压铸造试样的抗拉强度和延伸率分别为345MPa和15.07%, 较金属模试样分别提高1.6和2.15倍, 耐磨性明显提高, 性能提高的原因主要是由于高的组织致密度和细晶强化。

REFERENCES

[1]李桂荣, 戴起勋, 赵玉涛, 等. Al-Zr-O-B系原位合成颗粒增强铝基复合材料及其性能[J]. 中国有色金属学报, 2005, 15(4): 572-577.

LI Gui-rong, DAI Qi-xun, ZHAO Yu-tao, et al. Fabrication and properties of particles reinforced aluminum matrix composites in-situ synthesized in Al-Zr-O-B system[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 572-577.

[2]赵玉涛, 孙建祥, 戴起勋, 等. Al-Zr(CO3)2体系反应合成复合材料的反应机制及动力学模型[J]. 中国有色金属学报, 2005, 15(9): 1343-1349.

ZHAO Yu-tao, SUN Jian-xiang, DAI Qi-xun, et al. Reaction mechanism and kinetic model of in situ synthesized composites in system Al-Zr(CO3)2[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(9): 1343-1349.

[3]Roy D, Ghosh S, Basumallick A, et al. Preparation of Fe-aluminide reinforced in situ metal matrix composites by reactive pressing[J]. Mater Sci Eng A, 2006, A415: 202-206.

[4]Tjong S C, Wang G S, Mai Y W. High cycle fatigue response of in situ Al-based composites containing TiB2 and Al2O3 submicron particles[J]. Composites Sci Tech, 2005, 65: 1391-1400.

[5]Zhang X N, Geng L, Wang G S. Fabrication of Al-based hybrid composites reinforced with SiC whiskers and SiC nanoparticles by squeeze casting[J]. J Mater Pro Tech, 2006, 176: 146-156.

[6]赵龙志, 曹小明, 田冲, 等. 挤压铸造SiC/Zl109铝合金双连续相复合材料的凝固组织[J]. 金属学报, 2006, 42(3): 325-330.

ZHAO Long-zhi, CAO Xiao-ming, TIAN Chong, et al. Solidification structure of squeeze casting SiC/Al alloy ZL109 co-continuous composites[J]. Acta Metal Sinica, 2006, 42(3): 325-330.

[7]陈国钦, 朱德志, 占荣, 等. 挤压铸造法制备高致密Mo/Cu及其导热性能[J]. 中国有色金属学报, 2005, 15(11): 1864-1868.

CHEN Guo-qin, ZHU De-zhi, ZHAN Rong, et al. Highly dense Mo/Cu composites fabricated by squeeze casting and their thermal conduction properties[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1864-1868.

[8]Ghomashchi M R, Vikhrov A. Squeeze casting: an overview[J]. J Mater Pro Technol 2000, 101: 1-9.

[9]上海交通大学. 挤压铸造[M]. 北京: 北京国防工业出版社, 1981.

Shanghai Jiaotong University. Liquid Die Casting[M]. Beijing: Beijing Defence Industry Press, 1981.

[10]Ghomashchi M R. Cleanliness of Capped Steel[R]. BHP/U-SA Report, 1991.

[11]Maeng D Y, Lee J H, Won C W, et al. The effects of processing parameters on the microstructure and mechanical properties of modified B390 alloy in direct squeeze casting[J]. J Mater Pro Tech, 2000, 105: 196-203.

[12]赵恒义, 周天西, 袁燕. 挤压铸造工艺及发展应用现状[J]. 热加工工艺, 2000(2): 45-47.

ZHAO Heng-yi, ZHOU Tian-xi, YUAN Yan. Development and application of squeeze casting technology[J]. Heat Pro Tech, 2000(2): 45-47.

[13]齐丕骧. 挤压铸造[M]. 北京: 国防工业出版社, 1984.

QI Pi-rang. Squeeze Casting[M]. Beijing: National Defence Industry Press, 1984.

[14]DASGUPYA R, MEENAI H. Sliding wear properties of Al-Cu based alloys with SiC particles reinforced composites under varying experimental conditions[J]. J Mater Sci Letters, 2003, 22: 1573-1576.

[15]ZHAO Yu-tao, LI Zhong-hua, CHENG Xiao-nong, et al. In-situ synthesizes ZrAl3(p)+Al2O3(p)/A356 composites by direct melt reaction in Al-Zr-O system[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 669-773.

(编辑李艳红)

基金项目: 江苏省高技术研究资助项目(BG2005026);江苏省科技成果转化资助项目(BA2005054);江苏省铝基复合材料工程中心研发基金资助项目(BM2003014);江苏省高校自然科学研究指导性项目(05KJD450043)

收稿日期: 2006-07-17; 修订日期: 2006-10-08

通讯作者: 李桂荣, 博士; 电话: 0511-8780192; E-mail:whmlgr@ujs.edu.cn