文章编号:1004-0609(2008)05-0764-07

7B50高强铝合金的均匀化

李国锋1, 2,张新明1,朱航飞1,李鹏辉1

(1. 中南大学 材料科学与工程学院 有色金属材料科学与工程教育部重点实验室,长沙 410083;

2. 长沙大学 机电工程系,长沙 410003)

摘 要:采用光学显微镜、扫描电镜和透射电镜等研究7B50高强铝合金铸态和均匀化态的显微组织与成分分布,确定了实验合金一级均匀化后的过烧温度及二级均匀化工艺。结果表明:实验合金经465 ℃,24 h均匀化后的过烧温度为480 ℃,其最佳二级均匀化退火工艺为随炉升温到465 ℃保温24 h,再随炉升温到475 ℃保温4 h;实验合金经二级均匀化处理后,成分均匀,残留共晶很少,基体上析出大小适中及分布均匀的Al3Zr质点。

关键词:7B50铝合金;均匀化;显微组织

中图分类号:TG 166.3 文献标识码:A

Homogenizing treatment of 7B50 high strength aluminum alloy

LI Guo-feng1, 2, ZHANG Xin-ming1, ZHU Hang-fei1, LI Peng-hui1

(1. School of Materials Science and Engineering, Key Laboratory of Non-Ferrous Metal Materials Science and Engineering,

Ministry of Education, Central South University, Changsha 410083, China;

2. Department of Mechanical and Electrical Engineering, Changsha University, Changsha 410003, China)

Abstract: The microstructure and the composition distribution of as-cast and homogenized aluminium alloy 7B50 were studied by means of optical micrography, scanning electron micrography and transmission electron micrography. The overheating temperature of the alloy homogenized at 465 ℃ for 24 h and the two-step homogenization parameters were determined. The results indicate that the overheating temperature of the alloy homogenized at 465 ℃ for 24 h is 480 ℃, and the two-step homogenizing process is optimized. After the studied alloy is treated with the two-step homogenizing process, the alloy elements are uniformly distributed, the pseudoeutectic is little and the Al3Zr particles are uniformly precipitated in the matrix.

Key words: 7B50 aluminum alloy; homogenization; microstructure

铸造过程中存在非平衡结晶,由此在高强铝合金的铸造组织中形成了大量的非平衡共晶,并产生严重的枝晶偏析和区域偏析,基体中主要合金元素处于过饱和状态,在快速冷却过程中,在铸锭内部形成很强的内应力,这种枝晶网状组织使得合金的压力加工性能变差,制品的强韧性降低,并增加了各向异性和腐蚀敏感性[1-6]。因此,在压力加工前,铸态高强铝合金必须经过均匀化退火,以消除枝晶偏析,使非平衡共晶溶解,降低内应力,从而提高合金的热塑性[7-8]。

高强铝合金均匀化退火有一级均匀化、二级均匀化、强化均匀化和连续均匀化等[9]。为防止过烧,通常一级均匀化加热温度较低,均匀化效果较差;强化均匀化是通过略高于传统均匀化温度,大幅度延长均匀化时间来达到均匀化的目的,生产效率较低;二级均匀化是较早就出现的一种均匀化方法,特别适用第二相变化比较复杂的高合金化合金[9]。目前,7050高强铝合金的均匀化主要是采用一级均匀化退火工 艺[10-12],其均匀化温度一般为460~465 ℃,保温时间为24 h,均匀化效果不理想。本文作者研究了7B50高强铝合金铸态与一级均匀化态的组织与成分分布,并确定了实验合金经一级均匀化后的过烧温度,在此基础上对二级均匀化工艺进行了研究,其结果对优化7050铝合金均匀化制度具有重要的指导意义。

1 实验

实验合金7B50锭坯在实验室制备。配料采用高纯铝、工业纯锌、工业纯镁和铝铜中间合金,锆以中间合金Al-5%Zr的形式加入,细化剂采用Al-5Ti-B。合金的熔炼在石墨坩埚电阻炉内进行,熔化温度780~800 ℃,精炼温度为730~740 ℃,铸造温度为710~720 ℃,除气剂采用C2Cl6,在铁模中铸造。铸锭均匀化处理采用空气电阻炉。

用差热分析(DSC)方法确定低熔点共晶的熔化温度,差热分析的升温速率为10 ℃/min。铸态试样分别经465℃,24 h、465 ℃,24 h+475 ℃,2 h、465 ℃,24 h+480 ℃,2 h及465 ℃,24 h+485 ℃,2 h均匀化处理后出炉水淬,采用金相分析方法研究它们的组织特征,确定是否过烧。

为了对比研究,将铸态7B50分别进行一级均匀化和二级均匀化。其中一级均匀化工艺:随炉升温至465 ℃保温不同时间,出炉水淬;二级均匀化工艺:随炉升温至465 ℃保温24 h,再升温至475 ℃保温不同时间,出炉水淬。

组织观察在XJP-6A型光学显微镜、KYKY-2800型与Philips Sirion200型扫描电镜以及TecnaiG220和JEM-3010型透射电镜下进行,利用电子探针技术对铸态组织和各种均匀化态组织的形貌、枝晶偏析以及合金的成分分布情况进行了分析。

2 结果与分析

2.1 铸态组织及其成分分布

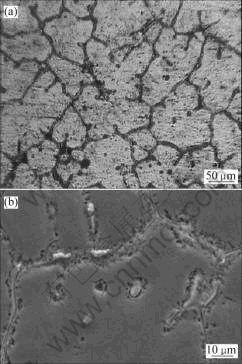

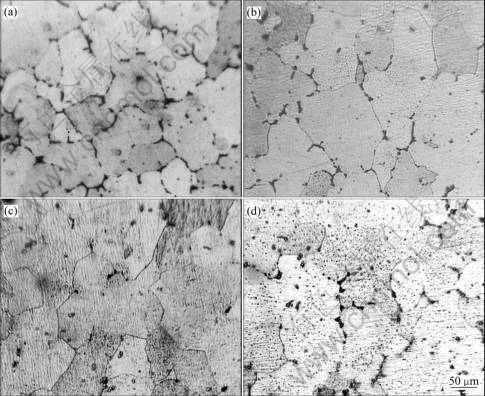

实验合金在光学显微镜和扫描电镜下观察到的组织形貌如图1所示。

图1 实验合金的铸态组织

Fig.1 Microstructures of as-cast alloy: (a) OM image; (b) SEM image

由图1可见,合金的铸态组织主要由树枝状α(Al)固溶体与晶界上和枝晶间的低熔点共晶相组成,晶粒呈等轴状,在晶界附近分布有大量细小的第二相,晶内也存在较粗大的第二相,晶界共晶化合物基本上呈网状连续分布。这种网状共晶相脆性大,塑性低,由于合金组织具有遗传性,这种不均匀组织在加工后会极大影响合金的强韧性,并增加合金的各向异性。

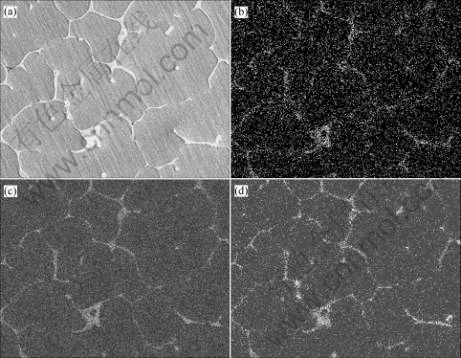

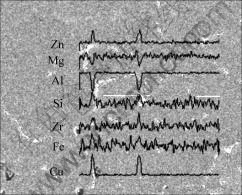

对铸态组织中的合金元素分别进行面扫描和线扫描,其结果分别如图2和3所示。由图2可见,铸态组织中合金元素的分布是不均匀的。在晶界与枝晶间及其非平衡第二相中主要合金元素显著富集,存在严重的枝晶偏析;在晶粒内部,越靠近晶界附近,合金元素含量越高,存在区域偏析。由图3可看出,在较宽大的共晶化合物处,其线扫描的波峰往往有两个峰,说明共晶体内合金元素的分布也是不均匀的。因此,在热加工前必须进行均匀化退火,以消除成分偏析。

图2 铸态组织及其主要合金元素的面分布

Fig.2 Microstructure of as-cast alloy(a) and corresponding elements planar distributions of Zn(b), Mg(c) and Cu(d)

图3 铸态组织的成分分布

Fig.3 Elements linear distributions along grains and boundaries

2.2 二级均匀化过烧温度的确定

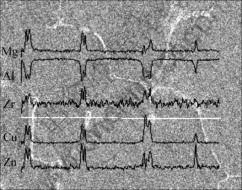

实验合金的DSC分析结果如图4所示。由图4(a)可见,分别在479.40、488.5和642.3 ℃处有吸热峰,显然642.3 ℃为合金熔化终了温度,其他两个温度点分别对应两种非平衡共晶的熔化温度,相差约9 ℃。

根据均匀化理论[1],均匀化退火温度通常为0.90~ 0.95Tm,Tm为合金实际熔化温度。因此,本研究将7B50铸态合金的第一级均匀化温度确定为465 ℃。

由图4(b)可见,合金经过一级均匀化后,低熔点共晶已基本上溶入基体,残留的共晶熔点上升到了约547.7 ℃。因此,第二级均匀化温度较第一级可适当提高。

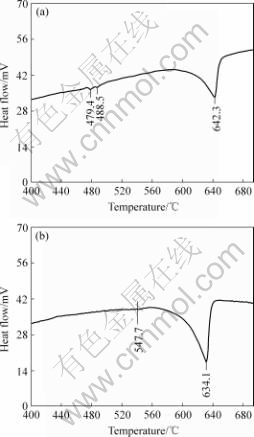

为此,将铸造合金分别经465 ℃,24 h、465 ℃,24 h+475 ℃,2 h、465 ℃,24 h+480 ℃,2 h及465 ℃,24 h+485 ℃,2h均匀化处理后,其组织状态如图5所示。

图4 实验合金的DSC分析曲线

Fig.4 DSC analysis curves of tested alloys: (a) As-cast alloy; (b) Alloy homogenized at 465 ℃ for 24 h

图5 不同均匀化工艺条件下退火后合金的组织状态

Fig.5 Microstructures of alloys homogenized under different conditions:

(a) 465 ℃, 24 h; (b) 465 ℃, 24 h+475 ℃, 2 h; (c) 465 ℃, 24 h+480 ℃, 2 h; (d) 465 ℃, 24 h+485 ℃, 2 h

由图5可看出,经465 ℃,24 h一级均匀化后,非平衡共晶数量较铸态大大减少,网状晶界化合物基本上不再连续,晶界显著变细,但依然有部分枝晶存在,晶内也还存在粗大的第二相(见图5(a));提高均匀化温度至475 ℃保温2 h后,第一级均匀化后残留的共晶在此温度下进一步溶解,因此组织中残留的共晶已经很少,枝晶基本被消除(见图5(b));经过第一级均匀化后,残留共晶在480 ℃下继续溶解,但已有少量发生了熔化(见图5(c))。第一级均匀化后残留的共晶中一小部分的熔点仍然较低,在480 ℃下将发生了熔化,因此最后的组织中残留的共晶虽然很少,枝晶完全消除,晶界细小光滑,但在局部区域出现了少量的三角晶界和复熔球这种典型的过烧特征(见图5(c));由于第二级均匀化温度过高,一级均匀化后残留的共晶中有相当部分在此温度下发生熔化,因而组织中出现了大量三角晶界和复熔球,局部晶界呈断续点状变粗或连续加粗的特征,出现了严重过烧(见图5(d))。

通过以上分析可以确定,实验合金经一级均匀化后,其二级均匀化的过烧温度为480 ℃。考虑到实验炉的炉温控制误差一般为±3 ℃,为安全起见,取 475 ℃为二级均匀化的第二级温度比较合适。

2.3 均匀化态的组织与成分分布

2.3.1 一级均匀化

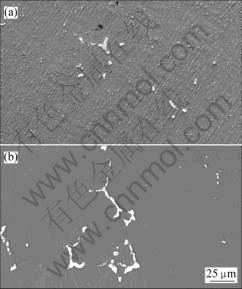

在扫描电镜下观察一级均匀化后的显微组织,结果如图6(a)所示,可见组织中仍残留较多的共晶。为了研究一级均匀化的保温时间对均匀化效果的影响,对经过465 ℃,24 h均匀化处理的合金也进行电镜扫描,结果如图6(b)所示。

比较图6(a)与(b)可见,在一级均匀化条件下保温时间从24 h延长到36 h,残留共晶数量及分布状态基本没有变化,说明在465 ℃下保温24 h后低熔点共晶基本上已溶解,残留的共晶已转化为较高熔点的共晶,此时过分延长保温时间并不能有效改善均匀化效果。

图6 一级均匀化后合金的显微组织

Fig.6 Microstructures of alloys homogenized at 465 ℃ for different times: (a) 36 h; (b) 24 h

为了进一步研究一级均匀化处理后合金的成分均匀性和第二相的析出情况,对经过465 ℃,36 h均匀化处理试样进行电子探针微区成分分析和透射电镜观察,其结果分别如图7和8所示。比较图7与3可见,一级均匀化态组织的成分分布在晶界和晶内仍然不均匀,只是比铸态组织大有改善,其中Zn、Mg和Zr的改善幅度较大。线扫描的波峰处不再有两个峰,共晶体内细小分散的金属间化合物已经溶解,留下的是那些较难溶解的大块金属间化合物。此外,从图7来看,Fe和Si在晶界略有富集。显然,这种组织对后续加工和合金的性能是非常不利的。

图7 一级均匀化后合金的元素成分分布

Fig.7 Elements linear distributions in alloy homogenized at 465 ℃ for 36 h

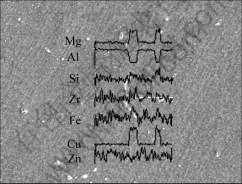

由图8可见,经一级均匀化处理后,基体的局部区域析出有少量Al3Zr质点,大小约为10 nm,分布不均匀,显然这种Al3Zr质点对抑制再结晶的效果是不好的。

图8 一级均匀化Al3Zr的TEM像

Fig.8 TEM image of Al3Zr in alloy homogenized at 465 ℃ for 36 h

2.3.2 二级均匀化

在扫描电镜下观察二级均匀化后的显微组织,结果如图9所示。比较图9(a)与6(a)可知,经二级均匀化处理后,非平衡共晶数量较一级均匀化大幅度减少,残留的共晶已经很少,效果非常好。为了研究第二级均匀化时间对均匀化效果的影响,对经过465 ℃,24 h+475 ℃,2 h均匀化处理的合金也进行电镜扫描,结果如图9(b) 所示。比较图9(a)与(b)可发现,合金经第一级均匀化后,尚残留大量的共晶,在进行第二级均匀化时,这些残留的共晶将继续溶解,但需要保温适当的时间。这个时间不能太短,否则达不到充分均匀化的目的;但也不能太长,否则会造成晶粒长大。且高强铝合金在均匀化过程中过饱和基体会析出第二相质点,这些第二相质点在高温下长时间保温将粗化,不利于控制后续加工的组织与提高合金性能。

图9 二级均匀化退火后合金的显微组织

Fig.9 Microstructures of alloys homogenized under two-stage homogenization condition: (a) 465 ℃, 24 h+475℃, 4 h; (b) 465 ℃, 24 h+475 ℃, 2 h

为此,对经过465 ℃,24 h+475 ℃,4 h二级均匀化处理的试样进行电子探针微区成分分析和透射电镜分析,其典型结果分别如图10和11所示。

图10 二级均匀化后合金元素的成分分布

Fig.10 Elements linear distributions in alloy homogenized at 465 ℃ for 24 h and 475 ℃ for 4 h

图11 二级均匀化态Al3Zr的TEM像

Fig.11 TEM image of Al3Zr in alloy homogenized at 465 ℃ for 24 h and 475 ℃ for 4 h

由图10可见,经过二级均匀化后,合金元素Zn和Zr在晶界上(残留共晶化合物中)和晶内的分布基本上已经均匀化,Mg在晶内的分布也较一级均匀化大有改善,只是在残留的共晶化合物内明显存在Mg和Cu的偏聚。这说明经二级均匀化处理后,合金的成分分布较一级均匀化大有改善。由图11可看出,实验合金经过该二级均匀化处理后,从过饱和基体中析出了尺寸约为30 nm的球形Al3Zr质点,且分布均匀弥散。锆在高强铝合金中的主要作用就是抑制再结晶,细化晶粒,其尺寸大小和分布间距决定再结晶抑制效 果[13]。根据第二相颗粒阻碍晶界迁移的条件[14](粒子间距l<1 μm,粒子直径d<0.3 μm),这种弥散析出的Al3Zr质点显然能阻碍大角度晶界迁移而抑制再结晶核心的生长,使再结晶受阻。由此可见,二级均匀化组织对后续加工的组织和性能的影响是十分有利的。

3 讨论

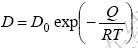

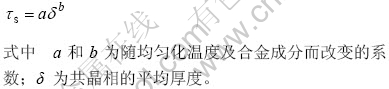

根据均匀化理论[1],合金元素在固溶体中的扩散系数与温度的关系可用下式表示:

此式表明,温度稍有升高将使扩散过程大大加速。而非平衡共晶相在固溶体中的溶解时间又与其尺寸大小、均匀化温度及合金成分有关:

由此可见,为了达到充分均匀化的目的,在尽可能提高均匀化退火温度的同时,应视温度高低选取恰当的保温时间。

在一级均匀化条件下,加热温度较低,合金元素扩散系数低,金属间化合物溶解速度较慢。在均匀化过程中,对低熔点共晶来说,在保温前期已经大量溶解,延长保温时间,溶解量有所增加但效果不大;对高熔点共晶来说,尚未达到其溶解温度,基本上不溶解,且部分低熔点共晶在均匀化过程中逐步转化为高熔点共晶,由此必然会造成较多的残留共晶。因此,要想充分均匀化,只有进一步提高均匀化温度。在本研究中,当一级均匀化的保温时间从24 h延长到36 h时,均匀化效果并没有什么变化充分说明了进一步提高均匀化温度能使合金充分均匀化。

在二级均匀化条件下,由于第二级温度较高,合金元素扩散较容易,且经过第一级均匀化后,残留共晶的尺寸大大减小,其溶解速度有所加快,难溶共晶变得较易溶解,因此,在第二级均匀化阶段的保温初期,残留共晶会大量溶解。但随着均匀化过程的进行,晶内浓度梯度不断减小,扩散物质的量也在不断减小,从而使均匀化过程自动减缓,在此情况下,如果过分延长保温时间,不仅达不到理想的均匀化效果,还将造成晶粒长大,亚微第二相颗粒Al3Zr聚集粗化,反而不利于在后续加工中抑制再结晶和弥散强化,对合金的组织与性能产生不利影响[15]。因此,在提高第二级均匀化温度的同时,必须要确定一个最佳保温时间。

通过以上分析可以确定,二级均匀化明显优于一级均匀化,实验合金的二级均匀化工艺为:随炉加热到465 ℃保温24 h,再随炉加热到475 ℃保温4 h。经过二级均匀化处理,能使实验合金的非平衡共晶充分溶解,残留的共晶很少,合金元素在基体内分布均匀,基体中析出分布均匀、大小适中的Al3Zr质点。

4 结论

1) 7B50高强铝合金的铸态组织成分分布不均匀,存在严重枝晶偏析,非平衡共晶呈网状分布,晶粒呈等轴状。

2) 铸态7B50高强铝合金的二级均匀化效果明显优于一级均匀化。实验合金的二级均匀化工艺为:随炉加热到465 ℃保温24 h,再随炉升温到475 ℃保温4 h。经二级均匀化处理后,合金成分均匀,残留伪共晶很少,过饱和基体中析出的亚微Al3Zr质点大小适中,分布均匀。

3) 铸态实验合金经465 ℃保温24 h均匀化后的过烧温度为480 ℃。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000: 64-65.

WANG Zhu-tang, TIAN Rong-zhang. Manual of aluminium alloy and its processing[M]. Changsha: Central South University Press, 2000: 64-65.

[2] 苏北华. LC4铝合金铸锭的高温均匀化[J]. 轻合金加工技术, 1995, 23(4): 13-17.

SU Bei-hua. High temperature homogenization of LC4 aluminium ally ingot[J]. Light Alloy Fabrication Technology, 1995, 23(4): 13-17.

[3] 刘晓涛, 董 杰, 崔建中, 赵 刚. 高强铝合金均匀化热处理[J]. 中国有色金属学报, 2003, 13(4): 909-913.

LIU Xiao-tao, DONG Jie, CUI Jian-zhong, ZHAO Gang. Homogenizing treatment of high strength aluminium alloy cast under electric magnetic field[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 909-913.

[4] STILLER K, WARREN P J, HANSEN V, ANGENETE J, GJONNES J. Investigation of precipitation in an AI-Zn-Mg alloy after two-step aging treatment at 100 ℃ and 150 ℃[J]. Mater Sci Eng A, 1999, A270(1): 55-63.

[5] ENGDAHL T, HANSEN V, WARREN P J, STILLER K. Investigation of fine scale precipitates in Al-Zn-Mg alloys after various heat treatments[J]. Mater Sci Eng A , 2002, A327(1): 59-64.

[6] ROBSON J D. Optimizing the homogenization of zirconium containing commercial aluminium alloys using a novel process model[J]. Mater Sci Eng A, 2002, A338(1/2): 219-229.

[7] PURDY G R, KIRKALKY J S. Homogenization by diffusion[J]. Metall Trans, 1971, 2(2): 371-378.

[8] COLE G S. Inhomogeneities and their control via solidification[J]. Metall Trans, 1971, 2(2): 357-370.

[9] 仲志国, 左秀荣, 翁永刚, 宋天福, 王明星, 刘忠侠, 杨 升. 变形铝合金均匀化热处理的应用现状与研究进展[J]. 轻合金加工技术, 2006, 34(1): 10-13.

ZHONG Zhi-guo, ZUO Xiu-rong, WENG Yong-gang, SONG Tian-fu, WANG Ming-xing, LIU Zhong-xia, YANG Sheng. The application situation and the study development of the wrought aluminium alloy’s homogenization[J]. Light Alloy Fabrication Technology, 2006, 34(1): 10-13.

[10] 邱宏伟, 于淑滨, 马洪武. 7050铝合金厚板RRA处理过程中性能和组织的变化[J]. 轻合金加工技术, 1997, 25(9): 34-37.

QIU Hong-wei, YU Shu-bin, MA Hong-wu. Microstructural and mechanical properties evolution of aluminium alloy 7050 in thick board during RRA processing[J]. Light Alloy Fabrication Technology, 1997, 25(9): 34-37.

[11] 赵英涛, 汝继刚. 7050铝合金T74(原T736)热处理状态的研究[J]. 材料工程, 1990, 1: 23-27.

ZHAO Ying-tao, Ru Ji-gang. A study on heat treatment T74 of aluminum alloy 7050[J]. Journal of Materials Engineering, 1990, 1: 23-27.

[12] ROBSON J D. Microstructural evolution in aluminium alloy 7050 during processing[J]. Materials Science and Engineering A, 2004, A382(1/2): 112-121.

[13] 贺永东, 张新明, 游江海. 7A55合金均匀化处理[J]. 中国有色金属学报, 2006, 16(4): 638-644.

HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai. Homogenizing treatment of 7A55 alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 638-644.

[14] 余 琨, 李松瑞, 黎文献, 肖于德. 微量Sc和Zr对2618铝合金再结晶行为的影响[J]. 中国有色金属学报, 1999, 9(4): 709-713.

YU Kun, LI Song-rui, LI Wen-xian, XIAO Yu-de. Effect of trace Sc and Zr on recrystallization behavior of 2618 alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 709-713.

[15] 《有色金属及其热处理》编写组. 有色金属及其热处理[M]. 北京: 国防工业出版社, 1981.

Compile Group of Nonferrous Metal Materials and Their Thermal Treatments. Nonferrous metal materials and their thermal treatments[M]. Beijing: National Defence Industry Press, 1981.

基金项目:国家重点基础研究发展规划资助项目(2005CB623700);湖南省教育厅科研基金资助项目(05C054)

收稿日期:2007-09-24;修订日期:2007-12-26

通讯作者:李国锋,副教授,博士;电话:0731-4261359;E-mail: lg123456@public.cs.hn.cn

(编辑 李艳红)