DOI: 10.11817/j.issn.1672-7207.2016.03.004

扩散阻挡层对NiCrAlYSi涂层不同条件下热腐蚀行为的影响

许安1,杨阳1,李伟洲1, 2,秦泽华1,岑广1,刘会群2,易丹青2

(1. 广西大学 材料科学与工程学院,广西 南宁,530004;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:利用电弧离子镀技术在DSM11合金基体上制备含或不含扩散阻挡层(diffusion barrier,DB)的NiCrAlYSi涂层,对比研究2种涂层在900 ℃恒温热腐蚀行为和从900 ℃到室温的循环热腐蚀行为(表面混合盐质量分数为75% Na2SO4+25% K2SO4)。研究结果表明:在恒温热腐蚀条件下,含或不含扩散阻挡层的NiCrAlYSi涂层表面主要生成了α-Al2O3和γ/γ′相;腐蚀100 h后,NiCrAlYSi涂层出现了较多的Kirkendall孔洞,基体与涂层元素的互扩散明显。NiCrAlYSi/DB涂层的扩散阻挡层可有效地抑止基体与涂层的元素互扩散,防护效果比单一NiCrAlYSi涂层的效果好。在循环热腐蚀条件下,含或不含扩散阻挡层的NiCrAlYSi涂层表面主要生成α-Al2O3、尖晶石、TiO2和γ/γ′相;腐蚀100 h后,NiCrAlYSi涂层内氧化和内硫化现象严重,NiCrAlYSi/DB涂层的扩散阻挡层界面易开裂,影响扩散阻挡层的效力,导致涂层体系比单一NiCrAlYSi涂层更快失效。

关键词:NiCrAlYSi涂层;电弧离子镀;扩散阻挡层;高温热腐蚀;应力

中图分类号:TB43;TG174.44 文献标志码:A 文章编号:1672-7207(2016)03-0730-11

Influence of diffusion barrier on hot corrosion behavior of NiCrAlYSi coating under different test conditions

XU An1, YANG Yang1, LI Weizhou1, 2, QIN Zehua1, CEN Guang1, LIU Huiqun2, YI Danqing2

(1. School of Materials Science and Engineering, Guangxi University, Nanning 530004, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The NiCrAlYSi coatings with or without a diffusion barrier (DB) were prepared on a Ni-based superalloy DSM11 by arc ion plating technique. The hot corrosion behaviors of two kinds of the coatings under different conditions in molten 75% Na2SO4+25% K2SO4 (mass fraction) at 900 ℃ or 900 ℃ to room temperature were investigated and compared. The results show that during the isothermal hot corrosion, α-Al2O3 and γ/γ′ phases are formed on the NiCrAlYSi coating with or without a DB. After 100 h, NiCrAlYSi coating shows Kirkendall voids and the interdiffusion between the coating and substrate is obvious. NiCrAlYSi coating with a DB significantly suppresses the interdiffusion between the coating and substrate, and the defending effect is better than that of NiCrAlYSi coating without a DB. During the cyclic hot corrosion, the NiCrAlYSi coating with or without a DB consists of α-Al2O3, spinels,TiO2 and γ/γ′ phases. After 100 h, NiCrAlYSi coating presents the severe internal oxidation and sulfidation. The interface of barrier layer is prone to cleavage and will reduce its efficiency, which causes the NiCrAlYSi coating with a DB to display the earlier failure than the NiCrAlYSi coating without a DB.

Key words: NiCrAlYSi coating; arc ion plating; diffusion barrier(DB); hot corrosion; thermal stress

燃气轮机是十分重要的动力机械设备,广泛应用于航空航天、船舶和能源等领域。由于燃气轮机叶片常在复杂多变的高温环境下服役,会受到氧气氧化和热腐蚀的侵蚀破坏。为了提高燃气轮机的工作效率,延长叶片的服役寿命,研究们者提出了优化工艺设计,使用新型高温材料及添加防护涂层等方法,其中表面涂覆防护涂层因具有实现容易、效果明显和成本低等特点,被广泛采用[1-3]。MCrAlY(M为Ni,Co或Ni+Co)防护涂层具有优良的抗高温氧化和抗热腐蚀性能,常被单独作为外层或热障涂层的黏结层(bond coat,BC)[4-5]。NiCrAlY为MCrAlY体系中的一员,添加Si元素能进一步提高其抗高温氧化性和热腐蚀性[6]。但在高温条件下,NiCrAlYSi涂层与高温合金基体间的元素互扩散会影响涂层抗氧化性能,降低涂层的组织稳定性,加速涂层退化,其中包括涂层中的有益元素(Al和Cr)向基体内扩散,降低涂层的自愈能力,且基体中的难熔金属元素向涂层扩散,破坏表面氧化膜的连续致密性[7]。为解决高温下元素互扩散的问题,在涂层与基体间加入扩散阻挡层(diffusion barrier,DB)[8]。扩散阻挡层对防护涂层性能的影响已有不少研究发现:陶瓷型[9-10]和金属型[11]扩散阻挡层的加入能有效地抑止基体与涂层间的元素互扩散,界面结合良好,涂层的抗氧化能力得到显著提高。李伟洲等[12]通过一步沉积法制备含扩散阻挡层的多层体系,具有比不连续制备法获得的含扩散阻挡层多层体系更高的界面结合强度,扩散阻挡层在恒温和循环氧化过程中保持很好的抑制元素扩散能力。但这些研究主要集中在涂层的高温抗氧化性和元素扩散阻挡效果方面。用于涡轮叶片表面的防护涂层,在实际工作中,除了高温氧化之外,还有高温热腐蚀等复杂环境,在此服役环境下,扩散阻挡层对涂层界面结合力的影响,含扩散阻挡层的涂层体系质量及作用机理尚未清楚。本文作者利用电弧离子镀技术在DSM11高温合金一步法制备含或不含扩散阻挡层的NiCrAlYSi涂层。通过在样品表面涂覆盐膜(75% Na2SO4+25% K2SO4,质量分数),分别进行恒温和循环热腐蚀实验,对涂层的热腐蚀行为及涂层界面结合机理进行研究。

1 实验材料及方法

基体材料选用DSM11镍基高温合金,其化学成分如表1所示。经线切割加工成长×宽×高为15 mm×10 mm×2 mm的试片,并在试片一端钻直径为1.5 mm的小孔,便于悬挂。试片经除油,逐级研磨至1000号SiC砂纸后倒边角,用粒径为74 μm的玻璃丸进行湿喷砂处理,之后经去离子水和无水乙醇超声清洗,再装入离子镀样品室。

涂层沉积在国产MIP-8-800型电弧离子镀设备上进行。扩散阻挡层及外层的靶材均为NiCrAlYSi合金,化学成分见表1。在涂层沉积前,先将真空室抽至≤7×10-3 Pa,通入氩气使气压达到0.2 Pa,在电压为-800 V和-600 V下分别对试样表面进行弧光轰击清洗3 min和2 min。在沉积扩散阻挡层(DB)时,通入氧气流量为100 mL/min,总压为0.6 Pa,其他为氮气,沉积时间为40 min;沉积外层的时间为360 min,其他参数为:偏压-240 V,占空比30%,靶基距200 mm,电弧电压18~20 V,电流65~70 A。当沉积结束后,对涂层样品进行真空热处理(600 ℃处理20 h,再以 900 ℃处理4 h),目的是降低涂层沉积时形成的应力。热处理升温速度≤7 ℃/min,热处理后样品随炉冷却。

恒温热腐蚀和循环热腐蚀测试在马弗炉内进行。恒温热腐蚀的具体做法是将表面涂覆混合盐(75% Na2SO4+25% K2SO4,质量分数)的涂层样品放入 900 ℃的炉中保温,指定时间后将样品取出称质量;而样品每保温10 h后取出1次,空冷后经沸水清洗5 min,再经烘干后称质量,然后再涂盐放入炉内加热,为循环热腐蚀测试。用3个试样做平行实验,结果取平均值,总的保温时间为100 h,称质量所用的天平精度为1×10-4 g。

利用X线衍射仪对涂层表面进行物相分析,采用配有能谱仪(EDS,Hitachi S-3400N)的扫描电镜(SEM)对涂层表面和截面形貌及线扫描结果进行分析。在制备截面样品时,预先在腐蚀后的试样表面化学镀Ni层,以保护腐蚀产物。

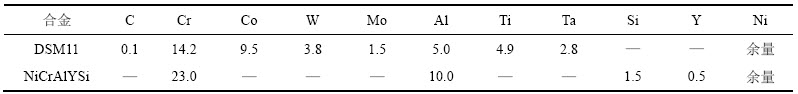

表1 基体DSM11和靶材NiCrAlYSi的化学成分(质量分数)

Table 1 Chemical composition of DSM11 substrate and NiCrAlYSi target (mass fraction) %

2 实验结果与分析

2.1 涂层的恒温热腐蚀行为

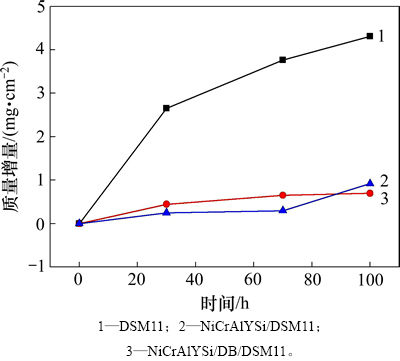

图1所示为DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层样品在900 ℃的(Na2SO4+K2SO4)混合盐中恒温热腐蚀100 h的动力学曲线。由图1可以看出:腐蚀过程中基体合金样品质量增量明显,质量增量与腐蚀时间呈抛物线关系,100 h时质量增量为4.31 mg/cm2。无扩散阻挡层的NiCrAlYSi涂层腐蚀至70 h后质量增加突然加速(与腐蚀过程中表面氧化膜的脱落和再生有关),100 h后样品的质量增量为0.92 mg/cm2。含扩散阻挡层NiCrAlYSi涂层的腐蚀质量增加较为平缓,100 h的质量增量为0.69 mg/cm2。涂层的加入明显改善了基体的抗热腐蚀性能。

图1 DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层在(Na2SO4+K2SO4)混合盐中经900 ℃恒温热腐蚀100 h的动力学曲线

Fig. 1 Isothermal hot corrosion kinetic curves of DSM11 substrate alloy, NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 at 900 ℃ for 100 h

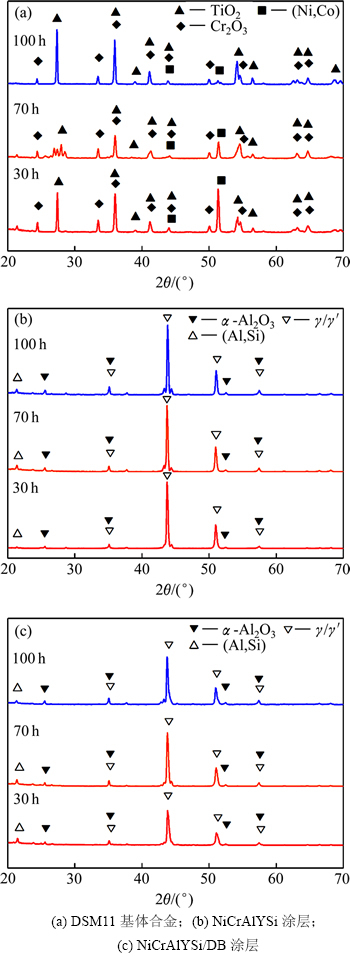

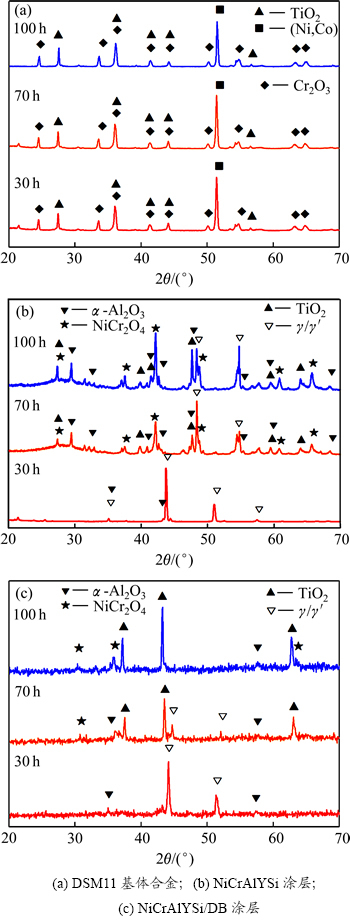

图2所示为DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层样品经恒温热腐蚀后的XRD谱。由图2可见:基体合金的腐蚀产物主要为Cr2O3和TiO2,含少量Ni和Co的沉淀相(Ni, Co)。经腐蚀后涂层样品表面主要生成了α-Al2O3和γ/γ′相,还检测到少量的(Al,Si)固溶体相,衍射峰随腐蚀时间的延长变化较小。

图2 DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层在(Na2SO4+K2SO4)混合盐中经900 ℃恒温热腐蚀不同时间后的XRD谱

Fig. 2 XRD patterns of DSM11 substrate alloy, NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 after isothermal hot corrosion at 900 ℃ for different time

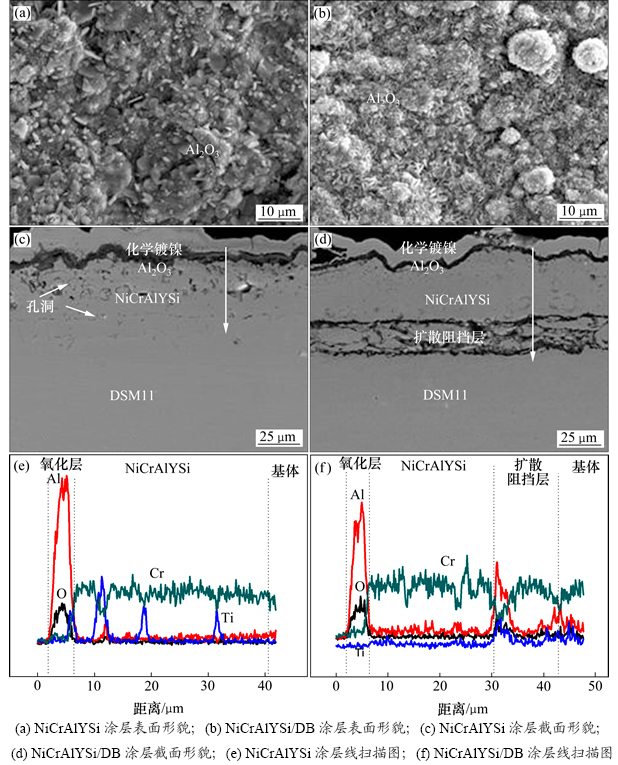

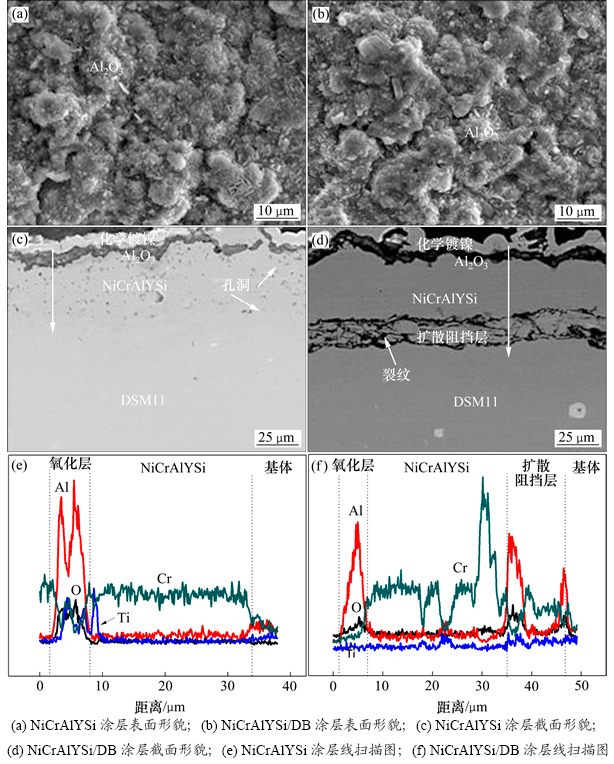

图3所示为单一NiCrAlYSi涂层及含扩散阻挡层NiCrAlYSi涂层恒温热腐蚀30 h后的表面形貌、截面形貌及元素沿界面的分布情况。由图3可以看出:两涂层表面均以鳞片状α-Al2O3为主,没有发现脱落,无裂纹。两涂层表面富集Al和O元素,说明生成了连续致密的Al2O3膜,这与XRD的结果相符;单一NiCrAlYSi涂层与基体界面处生成了富Cr的金属间化合物;在含扩散阻挡层的NiCrAlYSi涂层中,阻挡层较为连续致密,与外层及基体结合良好;由线扫描图推测扩散阻挡层腐蚀产物以Al2O3为主,有效阻挡了基体元素Cr和Ti等元素向涂层扩散。

图4所示为单一NiCrAlYSi涂层及含扩散阻挡层NiCrAlYSi涂层恒温热腐蚀100 h后的表面形貌、截面形貌及元素沿界面的分布情况。由图4可以看出:单一NiCrAlYSi涂层表面Al2O3颗粒随腐蚀时间增加而明显长大。涂层出现了内氧化,涂层与基体界面附近出现了较多的Kirkendall孔洞[13],但表面氧化膜保持连续。而EDS检测表明单一NiCrAlYSi涂层在恒温热腐蚀后期出现了较多Ti元素,涂层中的Ti元素平均质量分数达1.58%;线扫描说明涂层与基体间元素互扩散较为明显。含扩散阻挡层NiCrAlYSi涂层表面Al2O3颗粒随腐蚀时间的增加长大并不明显,观察不到开裂和脱落等现象。涂层表面的Al2O3膜依旧连续均匀致密,而扩散阻挡层出现了开裂和分层,这应该是扩散阻挡层中界面应力过大,腐蚀过程中应力释放造成的。EDS检测结果表明,涂层中的Ti质量分数仅为0.6%,线扫描结果说明Ti元素主要聚集于扩散阻挡层和基体中,证明此时扩散阻挡层仍能有效地抑止了基体元素的扩散。因此,在恒温热腐蚀过程中,含扩散阻挡层NiCrAlYSi涂层比单一的NiCrAlYSi涂层有更好的抗热腐蚀性能。

图3 NiCrAlYSi涂层和NiCrAlYSi/DB涂层在900 ℃下(Na2SO4+K2SO4)混合盐中恒温热腐蚀30 h的表面和截面形貌及线扫描图

Fig. 3 Surface, cross-sectional morphologies and line scan images of NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 after isothermal hot corrosion at 900 ℃ for 30 h

图4 NiCrAlYSi涂层和NiCrAlYSi/DB涂层在900 ℃下(Na2SO4+K2SO4)混合盐中恒温热腐蚀100 h的表面和截面形貌及线扫描图

Fig. 4 Surface, cross-sectional morphologies and line scan images of NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 after isothermal hot corrosion at 900 ℃ for 100 h

2.2 涂层的循环热腐蚀行为

图5所示为DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层样品在900 ℃的(Na2SO4+K2SO4)混合盐中循环热腐蚀100 h的动力学曲线。由图5可以看到:DSM11基体合金前期质量增加速度较快,腐蚀50 h质量增量达16.42 mg/cm2,之后质量增加有所减少,但仍高于腐蚀前的质量,说明初期氧化物生长速度比其脱落的速度快,而在腐蚀后期,氧化物厚度增加对它的生长有一定的阻碍,其脆裂脱落速度加快并超过生长速度,从而出现质量损失现象。而含或不含扩散阻挡层的NiCrAlYSi涂层在腐蚀50 h内质量变化不明显,但50 h后质量明显减小。这是循环热腐蚀过程中涂层表面氧化物生长过快、应力过大从而导致氧化膜剥落的结果。

图5 DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层在(Na2SO4+K2SO4)混合盐中经900 ℃循环热腐蚀100 h的动力学曲线

Fig. 5 Cyclic hot corrosion kinetic curves of DSM11 substrate alloy, NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 at 900 ℃ for 100 h

图6所示为DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层样品经循环热腐蚀后的XRD谱。与恒温热腐蚀一样,基体合金产物以Cr2O3和TiO2为主,含少量(Ni,Co)沉淀相。单一NiCrAlYSi涂层表面在腐蚀30 h前以α-Al2O3为主,之后形成了较多的NiCr2O4尖晶石和TiO2。其中,TiO2是应力高、脆性大的氧化物,其形成将降低NiCrAlYSi涂层的防护能力[14-15]。NiCrAlYSi/DB涂层样品腐蚀初期表面由α-Al2O3和γ/γ′相组成,经100 h后以NiCr2O4尖晶石和TiO2为主,几乎检测不到α-Al2O3相。

图6 DSM11基体合金、NiCrAlYSi涂层和NiCrAlYSi/DB涂层在(Na2SO4+K2SO4)混合盐中经900 ℃循环热腐蚀不同时间后的XRD谱

Fig. 6 XRD patterns of DSM11 substrate alloy, NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 after cyclic hot corrosion at 900 ℃ for different time

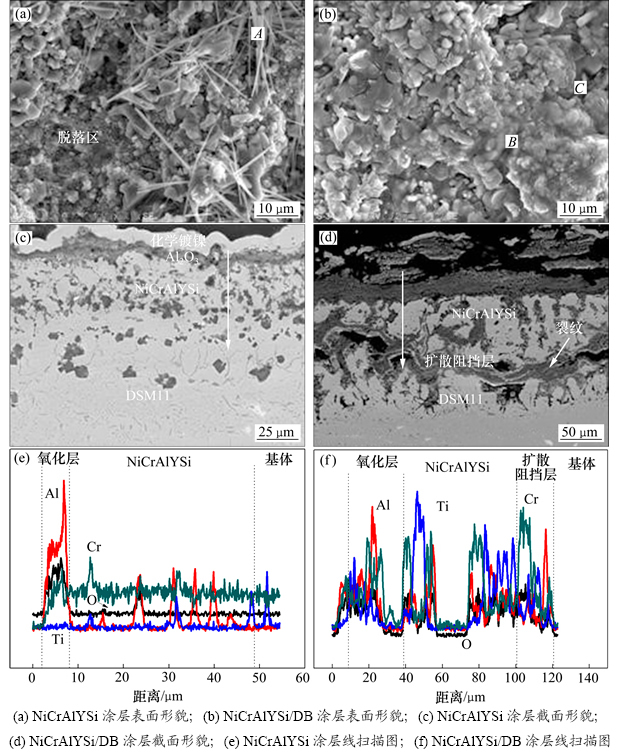

图7所示为单一NiCrAlYSi涂层及含扩散阻挡层NiCrAlYSi涂层循环热腐蚀30 h后的表面形貌、截面形貌及元素沿界面的分布情况。由图7可知:单一NiCrAlYSi涂层表面大部分是鳞片状的α-Al2O3;α-Al2O3膜较致密,涂层出现较多孔洞,这是涂层与基体的元素互扩散造成的。EDS分析表明表面Ti元素平均质量分数为1.66%,线扫描结果也证实涂层表面主要以Al和O为主,基体中部分Ti元素扩散至涂层,说明循环热腐蚀30 h时涂层与基体的互扩散已较为显著。而含扩散阻挡层NiCrAlYSi涂层表面出现较多大块状颗粒。表面氧化膜依然保持致密,涂层孔洞较少,而扩散阻挡层在循环热腐蚀初期就出现了开裂分层现象。EDS结果显示表面Ti元素平均质量分数为1.31%。线扫描图可看出阻挡层与外层的界面富Cr,基体向涂层扩散的Ti元素质量分数较低,阻挡层富Al和O,生成的Al2O3膜还能有效阻挡来自基体元素的扩散。说明扩散阻挡层在循环热腐蚀初期较高应力作用下出现开裂,但还保留其效力。

图7 NiCrAlYSi涂层和NiCrAlYSi/DB涂层在900 ℃下(Na2SO4+K2SO4)混合盐中循环热腐蚀30 h的表面和截面形貌及线扫描图

Fig. 7 Surface, cross-sectional morphologies and line scan images of NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 after cyclic hot corrosion at 900 ℃ for 30 h

图8所示为单一NiCrAlYSi涂层及含扩散阻挡层NiCrAlYSi涂层循环热腐蚀100 h后的表面形貌、截面形貌及元素沿界面的分布情况。由图8可知:NiCrAlYSi涂层表面出现脱落现象,还生成了较多针状物质,该涂层表面各种元素的质量分数分布为20.82%Al,28.03%O,6.17%Ti,17.65%Cr和0.52%S。检测针状物质A点,Ti质量分数高达13.61%。结合EDS、线扫描和XRD结果推测表面氧化膜是Al2O3、TiO2和NiCr2O4尖晶石的混合物。腐蚀后期出现的尖晶石和TiO2会导致表面氧化膜的脱落[9]。NiCrAlYSi涂层表面发生开裂,内氧化和内硫化现象严重,涂层与基体间元素扩散明显,但涂层表面还是保留部分Al2O3,涂层还未完全退化失效;而含扩散阻挡层的NiCrAlYSi涂层表面几乎观察不到鳞片状α-Al2O3,该涂层表面元素的质量分数分布为5.10%Al,29.68%O,18.28%Ti,11.17%Cr和0.30%S。检测B点,发现Al质量分数仅为0.56%,而黑色孔处C区域则检测到较多的S元素,质量分数为2.62%,这应该是循环热腐蚀导致界面开裂后熔盐进入的结果,说明此时表面Al2O3膜脱落严重,处于氧化膜下的NiCr2O4尖晶石和TiO2的混合氧化物暴露出来。由截面形貌和线扫描结果可以看出含扩散阻挡层NiCrAlYSi涂层腐蚀严重,扩散阻挡层已被破坏,腐蚀产物中的Ti和Cr质量分数较初期有明显的增加,涂层与基体间元素扩散较为严重,说明NiCrAlYSi/DB涂层在循环热腐蚀100 h后失效,失去对基体的保护作用。

图8 NiCrAlYSi涂层和NiCrAlYSi/DB涂层在900 ℃下(Na2SO4+K2SO4)混合盐中循环热腐蚀100 h的表面和截面形貌及线扫描图

Fig. 8 Surface and cross-sectional morphologies and line scan images of NiCrAlYSi coating and NiCrAlYSi/DB coating in Na2SO4+K2SO4 after cyclic hot corrosion at 900 ℃ for 100 h

2.3 涂层抗腐蚀机理

一般而言,MCrAlY防护涂层主要通过表面生成的Al2O3或Cr2O3产生保护作用,抑制高温热腐蚀的破坏[8]。高温热腐蚀的温度一般为825~950 ℃。本实验的温度高于(Na2SO4+K2SO4)混合盐的熔点(约823 ℃[16]),混合盐以液态膜的形式存在,与基体合金、和涂层试样发生化学反应,腐蚀产物既有防护作用的Al2O3和Cr2O3,又有无防护效果的TiO2和NiCr2O4 等[15]。含或不含扩散阻挡层的NiCrAlYSi涂层都是依靠表面形成连续致密的Al2O3来阻挡O2-和S2-的扩散侵入,减缓热腐蚀进程。Al2O3膜在保护基体中不断生长、脱落及自我修复,直至涂层中Al元素消耗殆尽。涂层没有氧化膜的保护作用后会进入加速腐蚀阶段,最终退化失效。高温热腐蚀中,保护性氧化膜遭到熔盐溶解或冷热循环作用而破坏[16]。根据盐熔模型[17],认为热腐蚀是涂层表面保护性氧化膜在熔盐作用下发生酸性或碱性溶解,生成无保护性氧化物,腐蚀向更深方向扩展,最终导致涂层失效的现象。在高温热腐蚀过程中,发生下列反应[18]:

→

→

涂层表面生成的Al2O3膜可在中性硫酸盐中保持稳定,却能在碱性硫酸盐中溶解。随着腐蚀时间的延长,中性 发生可逆反应,高温条件下SO3的挥发利于反应向右进行,增加了熔盐碱度。扩散能力较高的S元素通过表面氧化膜缓慢进入到涂层形成硫化物被消耗,进一步增加熔盐碱度,另一方面,Al2O3膜与熔盐中O2-发生碱性熔融,降低了熔盐碱度。如此长时间反复将使氧化膜的连续性被破坏,当Al不断被消耗且来不及新生成Al2O3对破损的氧化膜修复时,O2- 和S2-的扩散通道增加,渗入涂层内部加速了热腐蚀的进程[19]。

发生可逆反应,高温条件下SO3的挥发利于反应向右进行,增加了熔盐碱度。扩散能力较高的S元素通过表面氧化膜缓慢进入到涂层形成硫化物被消耗,进一步增加熔盐碱度,另一方面,Al2O3膜与熔盐中O2-发生碱性熔融,降低了熔盐碱度。如此长时间反复将使氧化膜的连续性被破坏,当Al不断被消耗且来不及新生成Al2O3对破损的氧化膜修复时,O2- 和S2-的扩散通道增加,渗入涂层内部加速了热腐蚀的进程[19]。

除熔盐溶解外,应力也是导致涂层退化的一个不容忽视因素。含或不含扩散阻挡层的NiCrAlYSi涂层抗循环热腐蚀性能不如恒温热腐蚀,循环热腐蚀具有更强的破坏力,这与循环热腐蚀产生的热应力及元素互扩散引入的生长应力较高有关[9],较高的应力导致表面氧化膜/涂层/基体间的界面开裂。扩散阻挡层出现开裂分层现象,影响其对元素互扩散的抑制作用。恒温热腐蚀中,含或不含扩散阻挡层的NiCrAlYSi涂层中Al2O3生成速度大于溶解速度,经腐蚀100 h后仍能很好保护合金基体。扩散阻挡层的加入对基体中Ti等元素向涂层扩散起到很好的抑制效果,防止涂层出现孔洞等内氧化和内硫化现象,以及表面氧化膜过早生成高应力的腐蚀产物,延长保护时间。在循环热腐蚀过程中,含或不含扩散阻挡层的NiCrAlYSi涂层生成了较多尖晶石和高应力产物TiO2,容易导致表面氧化膜出现裂纹和脱落,加快熔盐对涂层的入侵和腐蚀。

由文献[20-22]可知:Al2O3和NiCrAlYSi涂层及DSM11基体合金的热膨胀系数分别约为8.1×10-6,18.9×10-6和16.0×10-6 K-1。NiCrAlYSi涂层的弹性模量约为200 GPa[23]。涂层或扩散阻挡层在温度变化时产生的应力可根据Oxx公式[20]计算,即

其中: 和E分别为涂层或扩散阻挡层中的应力和弹性模量,GPa;

和E分别为涂层或扩散阻挡层中的应力和弹性模量,GPa; 为腐蚀(氧化)温度与冷却温度之差,K;

为腐蚀(氧化)温度与冷却温度之差,K; 为相同温度下涂层或扩散阻挡层与基体的热膨胀系数之差,K-1。

为相同温度下涂层或扩散阻挡层与基体的热膨胀系数之差,K-1。

通过计算可知NiCrAlYSi涂层与基体从900 ℃冷却到室温时,其界面应力仅约为0.51 GPa,在恒温热腐蚀初期,扩散阻挡层还未完全反应生成与基体或外层热膨胀系数相差较大的Al2O3,应力造成的损坏相对较轻,阻挡层保持连续完整,有效阻挡了涂层与基体间的元素扩散;而由元素线扫描结果可知,扩散阻挡层在恒温热腐蚀后期和循环热腐蚀生成Al2O3为主,冷却到室温时将有约1.9 GPa的应力在涂层和扩散阻挡层界面产生。若过高的应力不能及时释放,则会导致阻挡层出现开裂,界面发生破坏。恒温热腐蚀后期,扩散阻挡层出现了开裂分层现象,但仍能有效阻挡基体元素扩散,保护涂层有益元素;而在循环热腐蚀过程中,冷热循环热应力的累积致使涂层微裂纹的生成和加速元素的高温扩散,氧化膜破裂脱落的概率大大提高,涂层消耗有益元素速率加快,扩散阻挡层的作用受到影响和破坏。NiCrAlYSi/DB涂层经循环热腐蚀后的截面形貌可以看出扩散阻挡层界面处出现了多处裂纹,这是应力来不及释放的后果。裂纹于界面孔穴进一步扩展,加上表面氧化膜由于熔盐溶解和热应力作用而破裂,加剧O2-和S2-的渗入速率,极易加快涂层的退化。

以上分析说明了含扩散阻挡层的NiCrAlYSi涂层可以明显提高涂层的抗热腐蚀性能,但会导致涂层体系界面结合强度的降低。在应力过高的情况下,破坏首先在扩散阻挡层的界面处发生[9],使涂层过早退化。一步法制备含扩散阻挡层的NiCrAlYSi涂层体系虽在循环热腐蚀100 h后先于单一NiCrAlYSi涂层失效,但不能否认扩散阻挡层对涂层的有益作用。在恒温热腐蚀和循环热腐蚀初期,其对涂层和基体元素互扩散还是具有很好的抑制作用,保护效果比单一NiCrAlYSi涂层的效果好。KNOTEK等[24]的研究也表明扩散阻挡层可有效阻挡元素扩散,但界面在应力过大的情况下可能会出现断层,降低涂层性能。因此,更有效发挥扩散阻挡的作用,改进制备方法增强涂层与基体间的结合强度和改善扩散阻挡层的力学性能是需考虑的关键因素。

3 结论

1) 在恒温热腐蚀条件下,基体合金表面主要生成Cr2O3和TiO2, 含或不含扩散阻挡层的NiCrAlYSi涂层表面主要生成α-Al2O3和γ/γ′相;在循环热腐蚀条件下,基体合金表面主要生成Cr2O3和TiO2,含或不含扩散阻挡层的NiCrAlYSi涂层表面主要生成α-Al2O3及较多尖晶石、TiO2和γ/γ′相;有涂层样品在900 ℃下的恒温热腐蚀和循环热腐蚀过程中表面均形成连续致密的Al2O3膜,从而减缓热腐蚀的进程,提高了DSM11合金基体的抗热腐蚀性能。

2) 在恒温热腐蚀低应力条件下,腐蚀100 h后NiCrAlYSi涂层中出现较多Kirkendall孔洞,基体中较多Ti元素扩散至涂层。NiCrAlYSi/DB涂层的扩散阻挡层可以有效阻挡基体与涂层的元素互扩散,保护涂层中的有益元素,防护效果比单一NiCrAlYSi涂层的效果好;循环热腐蚀在较高应力条件下,腐蚀30 h后NiCrAlYSi/DB涂层的扩散阻挡层出现开裂分层,但仍能阻挡涂层与基体间的元素互扩散。腐蚀100 h后涂层体系界面遭到破坏,扩散阻挡层失效,比单一NiCrAlYSi涂层出现更早失效的情况。

参考文献:

[1] 周宏明, 易丹青. 低压等离子喷涂NiCoCrAlYTa涂层的组织结构及抗氧化性能[J]. 中南大学学报(自然科学版), 2008, 39(4): 741-747.

ZHOU Hongming, YI Danqing. Phase structure and oxidation resistance of NiCoCrAlYTa coating prepared by LPPS[J]. Journal of Central South University (Science and Technology), 2008, 39(4): 741-747.

[2] LI Weizhou, WANG Qimin, BAO Zebin, et al. Microstructural evolution of the NiCrAlY/CrON duplex coating system and its influence on mechanical properties[J]. Materials Science and Engineering A, 2008, 498(1/2): 487-494.

[3] AAHLEY D S, SARIM A Z. Gas turbine performance at varying ambient temperature[J]. Applied Thermal Engineering, 2011, 31(14/15): 2735-2739.

[4] WANG Hongyu, ZUO Dunwen, CHEN Xinfeng, et al. Microstructure and oxidation behaviours of nano-particles strengthened NiCoCrAlY cladded coatings on superalloys[J]. Chinese Journal of Mechanical Engineering, 2010, 23(3): 297-304.

[5] LI Yong, LI Changjiu, YANG Guanjun, et al. Thermal fatigue behaviour of thermal barrier coatings with the MCrAlY bond coats by cold spraying and low-pressure plasma spraying[J]. Surface and Coatings Technology, 2010, 205(7): 2225-2233.

[6] ZHANG Ke, WANG Qimin, SUN Chao, et al. Preparation and oxidation behavior of NiCrAlYSi coating on a cobalt-base supperalloy[J]. Corrosion Science, 2008, 50(6): 1707-1715.

[7] PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications[J]. Science, 2002, 296(5566): 280-284.

[8] NICHOLLS J R. Advances in coating design for high- performance gas turbines[J]. Materials Research Society, 2003, 28(9): 659-670.

[9] LI Weizhou, YAO Yong, WANG Qimin, et al. Improvement of oxidation- resistance of NiCrAlY coatings by application of CrN or CrON interlayer[J]. Journal of Materials Research, 2008, 23(2): 341-352.

[10] LI Haiqing, WANG Qimin, JIANG Sumeng, et al. Ion-plated Al-Al2O3 films as diffusion barriers between NiCrAlY coating and orthorhombic-Ti2AlNb alloy[J]. Corrosion Science, 2010, 52(5): 1668-1674.

[11] BAI Zhiming, LI Dongqing, PENG Hui, et al. Suppressing the formation of SRZ Ni-based single crystal superalloy by RuNiAl diffusion barrier[J]. Progress in Natural Science: Materials International, 2012, 22(2): 146-152.

[12] 李伟洲, 王启民, 宫骏, 等. 一步法制备含扩散阻挡层的多层体系及其界面结合强度[J]. 金属学报, 2010, 46(5): 561-568.

LI Weizhou, WANG Qimin, GONG Jun, et al. One-step deposition and interfacial adhesive strength of the multilayer system with a diffusion barrier[J]. Acta Metallurgica Sinica, 2010, 46(5): 561-568.

[13] 彭新, 姜肃猛, 段绪海, 等. (MCrAlY+AlSiY)复合涂层的高温氧化行为[J]. 金属学报, 2009, 45(3): 378-384.

PENG Xin, JIANG Sumeng, DUAN Xuhai, et al. High temperature oxidation behavior of a (MCrAlY+AlSiY) composite coating[J]. Acta Metallurgica Sinica, 2009, 45(3): 378-384.

[14] LI Zhiming, QIAN Shiqiang, WANG Wei. Characterization and oxidation behavior of NiCoCrAlY coating fabricated by electrophoretic deposition and vacuum heat treatment[J]. Applied Surface Science, 2011, 257(10): 4616-4620.

[15] 王启民, 武颖娜, 柯培玲, 等. 电弧离子镀Ni-Co-Cr-Al-Y-Si-B涂层的热腐蚀性能[J]. 金属学报, 2004, 40(4): 399-403.

WANG Qimin, WU Yingna, KE Peiling, et al. Hot corrosion behavior of Ni-Co-Cr-Al-Y-Si-B coating deposited by AIP[J]. Acta Metallurgica Sinica, 2004, 40(4): 399-403.

[16] SIMMS N J, ENCINAS Q A, NICHOLLS J R. Hot corrosion of coated and uncoated single crystal gas turbine materials[J]. Materials and Corrosion, 2008, 59(6): 476-483.

[17] KRISHNAN V, BHARANI S, KAPAT J S, et al. A simplistic model to study the influence of film cooling on low temperature hot corrosion rate in coal gas/syngas fired gas turbines[J]. International Journal of Heat and Mass Transfer, 2008, 51(5/6): 1049-1060.

[18] 鲍泽斌. 梯度NiCoCrAlYSi涂层的制备及腐蚀性能研究[D]. 沈阳: 中国科学院金属研究所, 2008: 126-128.

BAO Zebin. Preparation of a gradient NiCoCrAlYSi coating and the investigation on corrosion behaviors[D]. Shenyang: Chinese Academy of Sciences. Institute of Metal Research, 2008: 126-128.

[19] ELIAZ N, SHEMESH G, LATANISION R M. Hot corrosion in gas turbine components[J]. Engineering Failure Analysis, 2002, 9(1): 31-43.

[20] DEADMORE D L, LOWELL C E. The effect of △T (oxidizing temperature minus cooling temperature) on oxide spallation[J]. Oxidation of Metals, 1977, 11(2): 91-106.

[21] ZHU W Z, DEEVI S C. Development of interconnect for solid oxide fuel cells[J]. Materials Science and Engineering A, 2003, 348(1/2): 227-243.

[22] DAVIS J R. 金属手册 [M]. 金锡志, 译. 北京: 机械工业出版社, 2011: 1024-1026.

DAVIS J R. Metals Handbook[M]. JIN Xizhi, trans. Beijing: China Machine Press, 2011: 1024-1026.

[23] MARTENA M, BOTTO D, FINO P, et al. Modeling of TBC system failure: stress distribution as a function of TGO thickness and thermal expansion mismatch[J]. Engineering Failure Analysis, 2006, 13(3): 409-426.

[24] KNOTEK O, LUGSCHEIDER E,  F, et al. Diffusion barrier coatings with active bonding, designed for gas turbine blades[J]. Surface and Coatings Technology, 1994, 68/69: 22-26.

F, et al. Diffusion barrier coatings with active bonding, designed for gas turbine blades[J]. Surface and Coatings Technology, 1994, 68/69: 22-26.

(编辑 刘锦伟)

收稿日期:2015-03-12;修回日期:2015-04-29

基金项目(Foundation item):国家自然科学基金资助项目(51371059, 51361003, 51001032);广西自然科学基金资助项目(2014GXNSFCA118013, 0731013);广西高等学校高水平创新团队项目(第二批);广西自然科学基金创新研究团队项目(2011GXNSFF018001) (Projects(51371059, 51361003, 51001032) supported by the National Natural Science Foundation of China; Projects(2014GXNSFCA118013, 0731013) supported by the Guangxi Natural Science Foundation; Project(the Second Batch) supported by the High-level Innovative Team and Outstanding School Program in Guangxi Colleges;Project(2011GXNSFF018001) supported by the Guangxi Natural Science Foundation for Innovative Research Team)

通信作者:李伟洲,博士,研究员,从事材料表面防护研究;E-mail: liwz2008@hotmail.com