DOI: 10.11817/j.issn.1672-7207.2018.11.002

铜吹炼转炉渣主要元素分布及其矿相特征

杜柯,王成彦,王玲

(北京科技大学 冶金与生态工程学院,北京,100083)

摘要:通过X线衍射分析、化学物相分析、化学多元素分析等方法,并结合显微镜观测,研究铜吹炼转炉渣中主要元素分布规律及其矿相的产出特征。研究结果表明:赞比亚谦比希铜冶炼公司的铜吹炼转炉渣中的铁、铜和钴质量分数较高,质量分数分别为47.84%,3.60%与2.52%;80.94%的铜以金属态存在,12.71%以硫化态存在;钴与铁主要呈氧化态富集,钴在磁铁矿相与铁橄榄石相中的质量分数分别为40.71%和49.35%,而铁质量分数分别为56.34%,41.94%;转炉渣中主要物相为铁橄榄石相与磁铁矿相,质量分数分别为47.50%与38.91%;含铜物相主要为金属铜相与辉铜矿相,质量分数分别2.64%与1.17%;此外,渣中含有9.78%的玻璃相。铁橄榄石相与磁铁矿相相互包裹、夹杂,构成渣的基底物相;辉铜矿相、金属铜相及玻璃相夹杂在磁铁矿、铁橄榄石晶粒间,或被二者包裹;钴与铁元素的面分布一致,铁与氧、硅元素的面分布均一致,铜与硫元素的面分布一致。

关键词:铜吹炼转炉渣;化学物相分析;矿相特征;面分布

中图分类号:TF803.1 文献标志码:A 文章编号:1672-7207(2018)11-2649-07

Distribution of main elements and phase characteristics of copper converter slag

DU Ke, WANG Chengyan, WANG Ling

(School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The distribution rule of main elements and phase characteristics of copper converter slag were studied by using methods of X-ray diffraction analysis, chemical phase analysis, chemical multielement analysis, combined with microscopic observation. The results show that copper converter slag from the Chambishi Copper Smelter has high mass fractions of iron, copper and cobalt, which are 47.84%, 3.60% and 2.52%, respectively. There exists 80.94% of Cu in the slag in the form of metallic state, and 12.71% in the form of Vulcanized state. Co and Fe mainly exist in the form of oxidation state, and the mass fractions of Co in magnetite and fayalite are 40.71% and 49.35%, respectively, while that of Fe are 56.34% and 41.94%, respectively. The main phases of the slag are fayalite and magnetite, with their mass fractions being 47.50% and 38.91%, respectively. The main copper-bearing phases are metallic copper and chalcocite, the mass fractions of which are 2.64% and 1.17%, respectively. Additionally, 9.78% of glass phase also exists in the slag. Fayalite is mixed with the magnetite and forms the basement phase. The metallic copper, chalcocite and glass phase are mingled inside the grains of fayalite and magnetite, or coated by them. The surface distribution of cobalt is basically the same with that of iron. The surface distribution of iron is basically the same with that of oxygen and silicon, and so is the surface distribution of copper with that of sulfur.

Key words: copper converter slag; chemical phase analysis; phase characteristic; surface distribution

在铜的火法冶炼工艺流程中,通常会对前期造锍熔炼环节产出的铜锍进行吹炼,以除去铜锍中的铁、硫及其他杂质而产出粗铜。在吹炼过程中,铁、钴等元素被氧化,几乎全部富集在转炉渣中;金、银及铂族元素等几乎全部富集在粗铜中。目前,铜锍的吹炼过程绝大多数在P-S转炉内进行,整个吹炼过程为间歇式的周期性作业,整个过程分为造渣期与造铜期2个阶段[1-3]。在造渣期,铜锍中的FeS与鼓入空气中的氧发生强烈氧化反应,生成FeO和Fe3O4,FeO与造渣剂中的SiO2结合生成铁橄榄石(FeO·SiO2),并与磁铁矿构成炉渣的含铁相,即为磁铁矿饱和的铁橄榄石熔体。与此同时,随着氧位和锍品位增大,冰铜中的CoS也逐渐被氧化为CoO进入渣相,最后只有极少量钴保留在冰铜中。由于锍和渣相互之间的溶解度很小且密度不同,因此渣相位于锍相的上层;在造铜期,铁与钴已氧化完全,Cu2S开始被氧化,其先氧化为中间产物Cu2O,再与未被氧化的Cu2S反应,产出粗铜。转炉渣中因富含磁铁矿,其黏度较大,易夹杂少量粗铜粒。除此之外,渣中还夹杂有少量的硫化物如FeS,Cu2S及CoS,其质量分数较低。铜吹炼转炉渣富集了大量的铁、钴、铜等有价元素[4-6],为回收这些金属提供了条件,尤其在非洲赞比亚及刚果(金)的交界地带,所产的高钴铜精矿经冶炼产出的转炉渣中钴质量分数更是高达2%以上[7-9],极具回收价值;而研究转炉渣中铁、铜、钴元素的分布规律及主要矿相的微观结构及嵌布规律,对后续有价元素的回收起到较大的理论指导作用。本文作者选择赞比亚谦比希铜冶炼有限公司的铜吹炼缓冷转炉渣作为研究对象,研究渣中铁、铜、钴在不同矿相中的分布情况,探究渣中主要矿相的质量分数和矿相特征,以及渣中主要元素的相互依存特征。

1 转炉渣中元素分布规律

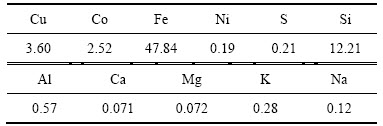

转炉渣试样化学成分如表1所示。

表1 转炉渣的化学成分分析(质量分数)

Table 1 Chemical composition analysis of converter slag %

由表1可知:转炉渣中Fe,Cu和Co质量分数较高,分别为47.84%,3.60%和2.52%;S质量分数较低,仅为0.21%;Si质量分数较高,为12.21%;其他金属元素质量分数均较低。

表2,表3和表4所示分别为转炉渣中Cu,Co和Fe的化学物相分析。

表2 转炉渣中铜的化学物相分析

Table 2 Chemical phase analysis of Cu in converter slag

表3 转炉渣中钴的化学物相分析

Table 3 Chemical phase analysis of Co in converter slag

表4 转炉渣中铁的化学物相分析

Table 4 Chemical phase analysis of Fe in converter slag

由表2,表3和表4可知:转炉渣中铜主要以金属态存在,分布率达到80.94%,其次以硫化态存在,分布率为12.71%,而以氧化态存在的铜所占比例很小;钴未单独成相,主要呈氧化态富集在磁铁矿与铁橄榄石中,分布率相差不大,另外约有9.94%的钴分布在玻璃相中;铁亦主要分布在磁铁矿与铁橄榄石中,并有少量赋存于玻璃相与硫化铁。

2 转炉渣主要矿相矿相特征

结合转炉渣试样的X线衍射分析、化学物相分析及化学成分分析结果,可确定转炉渣所含物相的种类及质量分数,如表5所示。

由表5可见:转炉渣中主要物相为铁橄榄石相与磁铁矿相,其质量分数分别为47.50%与38.91%,二者也是主要的含铁矿相;含铜物相主要为金属铜相,质量分数为2.64%,其次为辉铜矿,质量分数为1.17%;其次渣中有一定量的玻璃相赋存,质量分数为9.78%;渣中未见钴的单独矿相。

表5 转炉渣物相组成(质量分数)

Table 5 Contents of phases in converter slag %

试验选用XJZ-6型正置式金相显微镜与JSM-6071F冷场发射扫描电镜观测转炉渣的矿相矿相特征及嵌布规律,并采用电子探针测试各矿相的化学组成。

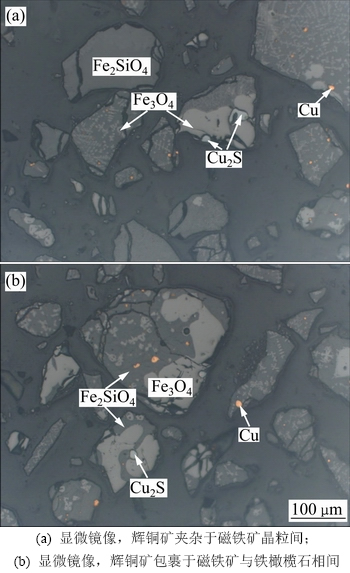

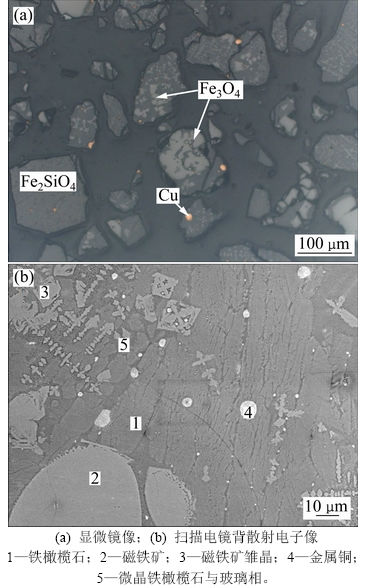

2.1 辉铜矿相

辉铜矿是转炉渣中铜的次要存在形式,由吹炼过程中铜锍中的Cu2S夹杂在渣相中而形成[10-12]。图1所示为渣中辉铜矿的矿相特征。由图1可见:辉铜矿主要以颗粒状夹杂在磁铁矿、铁橄榄石晶粒间或被上述矿相包裹,其产出粒度通常小于0.03 mm。电子探针测试结果表明:辉铜矿中Cu2S,FeO,SiO2和CoO的平均质量分数分别为92.73%,4.65%,2.16%和0.46%。

图1 转炉渣中辉铜矿的矿相特征

Fig. 1 Phase characteristics of chalcocite in converter slag

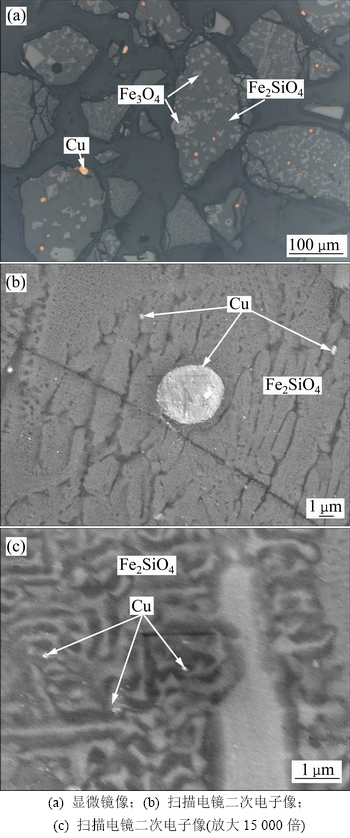

2.2 金属铜相

金属铜相是转炉渣中铜的主要存在形式,由吹炼过程中产出的粗铜夹杂在渣中而形成[10-12]。图2所示为渣中金属铜相的矿相特征。由图2可见:金属铜相呈金属液滴状,产出粒度通常小于0.02 mm,主要分布在铁橄榄石与磁铁矿的晶粒间。在扫描电镜下,放大倍数为15 000时,可观测到小于100 nm的金属铜晶粒分布于铁橄榄石树枝晶的晶粒间。电子探针测试结果表明:金属铜中Cu,Fe,Co和Ni的平均质量分数分别为99.69%,0.17%,0.02%和0.12%。

图2 转炉渣中金属铜相的矿相特征

Fig. 2 Phase characteristics of metallic copper in converter slag

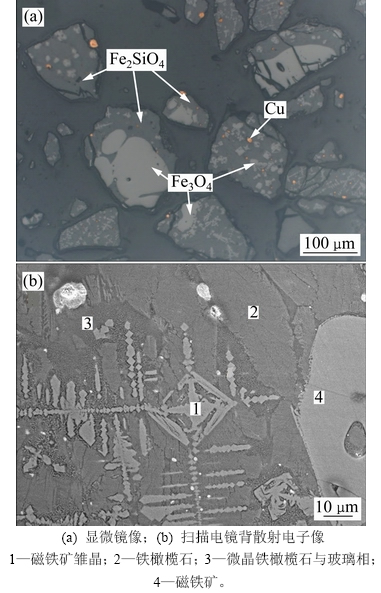

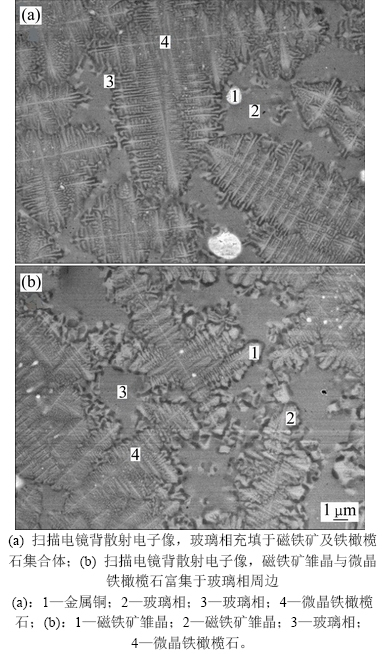

2.3 磁铁矿相

磁铁矿是转炉渣中含铁的主要物相,主要成分为Fe3O4,是钴的主要载体[13-14]。图3所示为磁铁矿的矿相特征。由图3可知:渣中磁铁矿呈2种形态产出:一种是结晶粒度较粗的磁铁矿,呈半自形-他形晶粒状产出,其粒度一般为0.02~0.20 mm;另一种是呈八面体状或树枝状雏晶形式分布在铁橄榄石晶粒间,其结晶粒度一般小于10 μm。

磁铁矿的电子探针分析结果表明:磁铁矿中SiO2,FeO,Cu2O和CoO的平均质量分数分别为0.61%, 91.39%,4.52%和3.48%。

图3 转炉渣中磁铁矿的矿相特征

Fig. 3 Phase characteristics of magnetite in converter slag

2.4 铁橄榄石相

铁橄榄石是转炉渣的主要物相之一,主要成分为Fe2SiO4,也是钴的主要载体[13-14]。图4所示为铁橄榄石相的矿相特征。由图4可见:铁橄榄石相的结晶粒度比较粗,其与磁铁矿相相互包裹、夹杂,组成渣的基底物相。另外可见磁铁矿雏晶、微晶金属铜、玻璃相等相包含其中,或分布在其晶粒间。铁橄榄石的电子探针分析结果表明:磁铁矿中SiO2,FeO,Cu2O和CoO平均质量分数分别为30.69%,61.08%,3.77%和4.46%。

2.5 玻璃相

玻璃相是转炉渣中的次要矿相,是渣相中最晚结晶出来的部分[15-16]。图5所示为玻璃相的矿相特征。由图5可见:玻璃相呈胶状充填于磁铁矿及铁橄榄石集合体中,也可见部分金属铜夹杂其间,并常有磁铁矿雏晶与微晶铁橄榄石富集在玻璃相周边。电子探针分析结果表明:玻璃相成分以FeO和SiO2为主,Cu2O,Al2O3,K2O及Na2O等也较为集中地分布于其中。

图4 转炉渣中铁橄榄石的矿相特征

Fig. 4 Phase characteristics of fayalite in converter slag

图5 转炉渣中玻璃相的矿相特征

Fig. 5 Phase characteristics of glass phase in converter slag

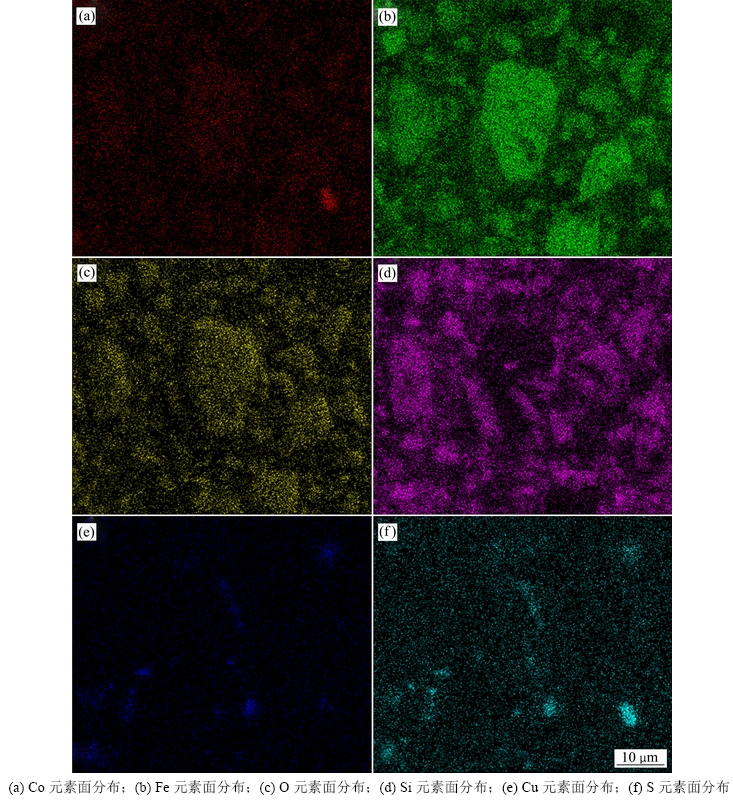

3 转炉渣中主要元素依存分布特征

图6所示为转炉渣中Co,Fe,Cu,S,Si和O的面扫描图[5]。由图6可见:Fe与Co的面分布表现出明显的一致性,这是由于在转炉渣中,钴元素以类质同象的形式取代铁橄榄石与磁铁矿中的铁而赋存其间,并保持原有晶型不变[17-22],因此,Co的分布依存于Fe的分布,Fe质量分数高的地方,Co质量分数一定随之增高;Fe与O和Si的面分布也保持着较高的一致性,这是由于Fe元素是渣中主要元素,且其主要赋存在铁橄榄石与磁铁矿2种矿相中,即Fe主要与O和Si化合而赋存在一起;Cu与S的面分布呈现一致性,这是由于转炉渣中Cu除以金属态存在外,还以硫化态形式存在,而渣中S也主要赋存在辉铜矿相中的Cu2S中,其他金属元素的硫化物质量分数极小。

图6 转炉渣中主要元素面扫描图

Fig. 6 Area scan images of main elements in converter slag

4 结论

1) 赞比亚谦比希铜冶炼公司的铜吹炼转炉渣中铁、铜、钴质量分数较高,分别为47.84%,3.60%与2.52%;转炉渣中80.94%的铜以金属态存在,12.71%以硫化态存在;钴主要呈氧化态富集在磁铁矿与铁橄榄石中,分布率分别为40.71%与49.35%,约有9.94%的钴分布在玻璃相中;铁主要分布在磁铁矿与铁橄榄石中,分布率分别为56.34%与41.94%,并有少量赋存在玻璃相与硫化铁中。

2) 转炉渣中主要物相为铁橄榄石相与磁铁矿相,质量分数分别为47.50%与38.91%;含铜物相主要为金属铜相,质量分数为2.64%,其次为辉铜矿,质量分数为1.17%;另外渣中含有9.78%的玻璃相。

3) 辉铜矿相、金属铜相分别以细粒状和液滴状夹杂在磁铁矿、铁橄榄石晶粒间;磁铁矿呈半自形-他形晶粒状产出,或以呈八面体状或树枝状雏晶形式分布在铁橄榄石晶粒间;铁橄榄石相粒度较粗,与磁铁矿相相互包裹、夹杂,并构成了渣的基底物相;玻璃相呈胶状充填于磁铁矿及铁橄榄石集合体中。

4) 钴元素因以类质同象形式取代铁,其与铁元素的面分布保持一致;铁作为主要元素,与氧、硅因化合作用,其面分布也呈现出较高的一致性;铜有较高比例呈硫化态存在,因此,与硫元素的面分布呈现一致性。

参考文献:

[1] 翟秀静. 重金属冶金学[M]. 北京: 冶金工业出版社, 2011: 47-48.

ZHAI Xiujing. Heavy metal metallurgy[M]. Beijing: Metallurgical Industry Press, 2011: 47-48.

[2] NAGAMORI M, MACKEY P J. Thermodynamics of copper matte converting: part I. fundamentals of the noranda process[J]. Metallurgical and Materials Transactions B, 1978, 9(2): 255-265.

[3] E Jiaqiang, WANG Yaonan, MEI Chi, et al. Chaotic behavior of crude copper composition time series in the process of matte converting and its predicable time scale[J]. Nonlinear Analysis Real World Applications, 2006, 7(4): 651-661.

[4] YU Zhengjun, FENG Qiming, OU Leming, et al. Recovery of cobalt, nickel and copper from nickel converter slag by reduction-sulfurization process[J]. Minerals & Metallurgical Processing, 2006, 26(1): 49-55.

[5] LI Hongxu, DU Ke, SUN Shi, et al. The distribution rules of element and compound of cobalt/iron/copper in the converter slag of copper smelting process[C]// REDDY R G, CHAUBAL P, PISTORIUS P C, et al. Advances in Molten Slags, Fluxes, and Salts: Proceedings of the 10th International Conference on Molten Slags, Fluxes and Salts. Seattle,America: Springer, 2016: 1343-1350.

[6] DU Ke, LI Hongxu, ZHANG Mingming. Calculation of distribution coefficients of cobalt and copper in matte and slag phases in reduction–vulcanization process of copper converter slag[J]. Journal of the Minerals Metals & Materials Society, 2017, 69(11): 2379-2382.

[7] ZHAI Xiujing, LI Naijun, ZHANG Xu, et al. Recovery of cobalt from converter slag of Chambishi Copper Smelter using reduction smelting process[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 2117-2121.

[8] ZHAO Xingguo. Geological characteristics of Chambishi Copper Deposit in Zambia[J]. Geology & Exploration, 2010, 46(1): 183-190.

[9] FRANC G, JUTAND A. On the origin of copper catalysts from copper precursors in C—N and C—O cross-couplings[J]. Dalton Transactions, 2010, 39(34): 7873-7875.

[10] 李磊, 胡建杭, 魏永刚, 等. 铜渣中铜的回收工艺及新技术[J]. 材料导报, 2013, 27(11): 21-26.

LI Lei, HU Jianhang, WEI Yonggang, et al. Progress in copper recovery from copper slags and the new technology[J]. Materials Review, 2013, 27(11): 21-26.

[11] 朱茂兰, 熊家春, 胡志彪, 等. 铜渣中铜铁资源化利用研究进展[J]. 有色冶金设计与研究, 2016, 37(2): 15-17.

ZHU Maolan, XIONG Jiachun, HU Zhibiao, et al. Research progress in resource utilization of iron and copper in copper smelting slag[J]. Nonferrous Metals Engineering & Research, 2016, 37(2): 15-17.

[12] 杨慧芬, 袁运波, 张露, 等. 铜渣中铁铜组分回收利用现状及建议[J]. 金属矿山, 2012, 41(5): 165-168.

YANG Huifen, YUAN Yunbo, ZHANG Lu, et al. Present situation and proposed method of recycling iron and copper from copper slag[J]. Metal Mine, 2012, 41(5): 165-168.

[13] MIHAILOVA I, MEHANDJIEV D. Characterization of fayalite from copper slags[J]. Journal of the University of Chemical Technology and Metallurgy, 2010, 45(3): 317-326.

[14] 邓彤, 凌云汉. 含钴铜转炉渣的工艺矿物学[J]. 中国有色金属学报, 2001, 11(5): 881-885.

DENG Tong, LING Yunhan. Process mineralogy of cobalt- bearing copper converter slag[J]. Chinese Journal of Nonferrous Metals, 2001, 11(5): 881-885.

[15] 刘柳, 闫红杰, 周孑民, 等. 氧气底吹铜熔池熔炼过程的机理及产物的微观分析[J]. 中国有色金属学报, 2012, 22(7): 2116-2124.

LIU Liu, YAN Hongjie, ZHOU Jiemin, et al. Mechanism of copper smelting process by oxygen bottom blowing and microanalysis of smelting products[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2116-2124.

[16] BUSOLIC D, PARADA F, PARRA R, et al. Recovery of iron from copper flash smelting slags[J]. Mineral Processing & Extractive Metallurgy, 2014, 120(1): 32-36.

[17] SRIDHAR R, TOGURI J M, SIMEONOV S. Copper losses and thermodynamic considerations in copper smelting[J]. Metallurgical and Materials Transactions B, 1997, 28(2): 191-200.

[18] 刘英俊. 元素地球化学导论[M]. 北京: 地质出版社, 1987: 220-222.

LIU Yingjun. Introduction to elemental geochemistry[M]. Beijing: Geological Publishing House, 1987: 220-222.

[19] 闫朋, 安鹏升, 刘志超, 等. 澳大利亚布朗斯炭质页岩铜镍钴矿工艺矿物学研究[J]. 金属矿山, 2017, 46(4): 91-95.

YAN Peng, AN Pengsheng, LIU Zhichao, et al. Study on process mineralogy of carbonaceous shale copper-cobalt-nickel ore from Browns Area in Australia[J]. Metal Mine, 2017, 46(4): 91-95.

[20] 徐莺, 杨磊, 刘飞燕. 金川铜镍矿贫矿石选矿产品的工艺矿物学研究[J]. 矿产综合利用, 2013(3): 52-55.

XU Ying, YANG Lei, LIU Feiyan. Study on process mineralogy of mineral processing products in the low-grade ore at Jinchuan[J]. Multipurpose Utilization of Mineral Resources, 2013(3): 52-55.

[21] 陈彪, 戚长谋. 钴的赋存状态及其在找矿和资源评估中的意义[J]. 长春科技大学学报, 2001, 31(3): 217-218.

CHEN Biao, QI Changmou. The occurrence state of cobalt and its significance in prospecting and resource assessment[J]. Journal of Changchun University of Science and Technology, 2001, 31(3): 217-218.

[22] 佟立永, 肖骏, 李剑鹭. 国外某炭质页岩铜钴镍矿选矿工艺研究[J]. 矿产综合利用, 2017(5): 45-51.

TONG Liyong, XIAO Jun, LI Jianlu. Study on beneficiation process technology of a foreign carbonaceous shale copper cobalt nickel ore[J]. Multipurpose Utilization of Mineral Resources, 2017(5): 45-51.

(编辑 伍锦花)

收稿日期:2017-12-11;修回日期:2018-02-28

基金项目(Foundation item):中央高校基本科研专项资金资助项目(230201606500078);国家自然科学基金资助项目(U1302274,51674026) (Project(230201606500078) supported by Fundamental Research Funds for the Central Universities; Projects(U1302274, 51674026) supported by the National Natural Science Foundation of China)

通信作者:王成彦,博士,教授,从事有色冶金方向研究;E-mail: chywang@yeah.net