镍基单晶高温合金的表面再结晶行为

来源期刊:中国有色金属学报(英文版)2013年第5期

论文作者:张 兵 曹雪刚 刘德林 刘新灵

文章页码:1286 - 1292

关键词:单晶高温合金;再结晶;喷丸;热处理

Key words:single crystal superalloy; recrystallization; shot peening; heat treatment

摘 要:利用喷丸预变形,研究了热处理温度对单晶高温合金表面再结晶行为的影响以及固溶温度条件下再结晶组织的演变过程。结果表明,随着热处理温度的升高,再结晶层厚度不断增加;在1200 °C以下时,再结晶层厚度随着温度的升高而缓慢增加,而当温度高于1200 °C时,再结晶层厚度随着温度的升高而迅速增加;当热处理温度低于γ′相完全固溶温度时,再结晶以不连续的胞状组织的形式出现,而当热处理温度高于γ′相完全固溶温度时,再结晶以完整晶粒的形式出现;再结晶晶粒首先在喷丸表面的枝晶干区域形核,然后沿着枝晶干向内生长,但随着枝晶间粗大γ′相和γ/γ′共晶相的溶解,再结晶晶界穿过枝晶间区域而继续向内部迁移,最后形成厚度比较均匀的再结晶层;铸态γ′相的溶解是影响单晶高温合金再结晶行为的关键因素。

Abstract: As-cast single crystal (SC) superalloy samples were shot peened and then annealed at different temperatures to investigate the effect of annealing temperature on the surface recrystallization behavior of the SC superalloy. The results show that the depth of recrystallized layers increases with the increase of annealing temperature. Below 1200 °C, the recrystallization depth climbs slowly with temperature rising. Above 1200 °C, the recrystallization depth increases sharply with the rise of temperature. The morphology of recrystallized grains is significantly affected by annealing temperature. Below the γ′ solvus, cellular recrystallization may be observed. Above the γ′ solvus, recrystallization occurs through the growth of well developed recrystallized grains. In addition, the microstructure evolution of recrystallized grains at the homogenization annealing temperature was studied. It is found that recrystallized grains first nucleate in the dendritic core areas on the shot-peened surface and then grow inwards along the dendritic core areas. With the dissolution of the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas, the recrystallized grain boundaries move through the interdendritic areas. Finally, the fully developed grains nearly have a uniform depth. The dissolution of primary γ′ precipitates is a critical factor influencing the recrystallization behavior of SC superalloys.

Trans. Nonferrous Met. Soc. China 23(2013) 1286-1292

Bing ZHANG1,2,3, Xue-gang CAO4, De-lin LIU1,2,3, Xin-ling LIU1,2,3

1. AVIC Failure Analysis Center, Beijing Institute of Aeronautical Materials, Beijing 100095, China;

2. AVIC Testing Innovation Cooperation, Beijing 100095, China;

3. Beijing Key Laboratory of Aeronautical Materials Testing and Evaluation, Beijing 100095, China;

4. Nantong Higher Normal Institute, Nantong 226006, China

Received 15 March 2012; accepted 10 March 2013

Abstract: As-cast single crystal (SC) superalloy samples were shot peened and then annealed at different temperatures to investigate the effect of annealing temperature on the surface recrystallization behavior of the SC superalloy. The results show that the depth of recrystallized layers increases with the increase of annealing temperature. Below 1200 °C, the recrystallization depth climbs slowly with temperature rising. Above 1200 °C, the recrystallization depth increases sharply with the rise of temperature. The morphology of recrystallized grains is significantly affected by annealing temperature. Below the γ′ solvus, cellular recrystallization may be observed. Above the γ′ solvus, recrystallization occurs through the growth of well developed recrystallized grains. In addition, the microstructure evolution of recrystallized grains at the homogenization annealing temperature was studied. It is found that recrystallized grains first nucleate in the dendritic core areas on the shot-peened surface and then grow inwards along the dendritic core areas. With the dissolution of the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas, the recrystallized grain boundaries move through the interdendritic areas. Finally, the fully developed grains nearly have a uniform depth. The dissolution of primary γ′ precipitates is a critical factor influencing the recrystallization behavior of SC superalloys.

Key words: single crystal superalloy; recrystallization; shot peening; heat treatment

1 Introduction

With excellent high-temperature mechanical properties, single crystal (SC) superalloys have been widely used to make blades for advanced military and civil aircraft engines. SC superalloys were developed to overcome the limited mechanical performance of polycrystalline materials at high temperature. Their superior mechanical properties enable an increased service temperature and thereby an improved overall efficiency of turbines.

The superior high-temperature mechanical properties of SC superalloys mainly result from the elimination of the grain boundaries perpendicular to the main stress axis [1]. Since the recrystallized grains may introduce disadvantageous orientations and high-angle grain boundaries, they will dramatically reduce the creep rupture strength and fatigue life of SC superalloy parts [2-4].

Recrystallization phenomena have been extensively studied in the past several decades. However, limited information concerning the recrystallization of complex superalloys can be found in the open literatures. Among these studies, most attention has been paid to wrought and powder metallurgy superalloys [5-8], whose microstructures and performance can be optimized by recrystallization during processing. Investigations on the recrystallization behavior of SC superalloys are rarely reported [9,10].

Typically, recrystallization behavior of alloys is affected by the following factors: annealing temperature, annealing time, deformation degree, solute elements and foreign precipitates. For SC superalloys, annealing temperature is a critical factor influencing recrystallization behavior [1]. In the present work, the effect of annealing temperature on the depth of recrystallized layers and morphology of recrystallized grains of a SC superalloy by shot peening was investigated. In addition, the microstructure evolution of recrystallized grains at the homogenization annealing temperature was observed and analyzed.

2 Experimental

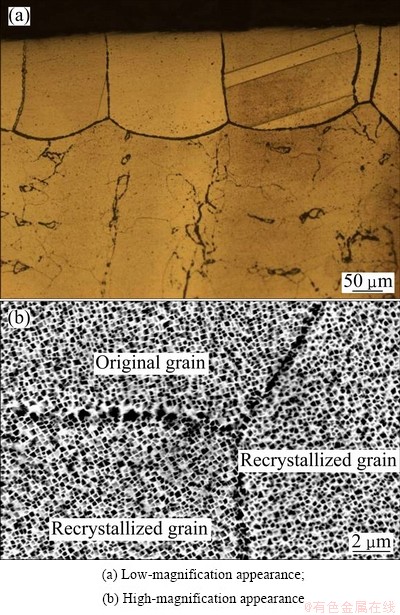

The chemical composition of the SC superalloy studied in the present work is listed in Table 1. As-cast bars were grown along [001] orientation through directional solidification process. The angle deviation from [001] direction was less than 15°.

Table 1 Chemical composition of SC superalloy studied in the present work (mass fraction, %)

Samples with the thickness of about 15 mm were cut down along the axis of the bars. The cross-sections of the samples were ground and then shot peened by steel balls for 2 min under 0.2 MPa. In order to avoid oxidation, the samples were tubed in silica glass tubes filled with argon gas.

Some shot-peened samples were annealed at different temperatures ranging from 900 °C to 1300 °C for 4 h to investigate the effect of annealing temperature on the recrystallization behavior. In addition, in order to investigate the microstructure evolution during recrystallization, some other samples were annealed at 1300 °C for different time ranging from 2 min to 1 h. All the heat treatments were followed by air cooling.

The samples were cut along the section perpendicular to the recrystallized surface by EDM after heat treatment. Then the sections were polished and etched in the reagent consisting of 20 g CuSO4, 100 mL HCl and 100 mL H2O. Microstructure observation was carried out by optical microscopy (OM) and scanning electron microscopy (SEM). The depth of the recrystallized layers was measured every 50 μm along the recrystallized surface, and at least 10 fields of view were measured for each sample.

3 Results and discussion

3.1 Effect of annealing temperature on depth of recrystallized layers

After annealing at different temperatures for 4 h, the depth of recrystallized layers of the shot-peened samples was measured. The relationship between the depth of recrystallized layers and the annealing temperature is shown in Fig. 1. It can be seen that the threshold temperature for recrystallization of the shot-peened samples is between 1000 °C and 1050 °C under the condition of annealing for 4 h. Below 1200 °C, the recrystallization depth climbs slowly with temperature going up. While above 1200 °C, the recrystallization depth increases rapidly with the rise of temperature. This trend can be explained in terms of the effect of second-phase precipitates. The effect of second-phase precipitates on recrystallization is related to their volume fraction (φ) and particle size (radius, r). It is generally accepted that if φ/r>0.2 μm-1, recrystallization will be inhibited [11]. In the as-cast samples, the γ′ volume fraction is about 63%, the average radius of the γ′ precipitates in dendritic core areas is about 0.35 μm, and that in interdendritic areas is about 0.6 μm. It is obvious that φ/r is much higher than 0.2 μm-1. So, it can be concluded that the presence of the γ′ precipitates will severely retard the growth of the recrystallized grains. At the temperature below 1200 °C, only a small fraction of γ′ precipitates are dissolved. So, the grain boundaries move slowly inwards owing to the pinning and retardation of the residual γ′ precipitates. At the temperature above 1200 °C, with the rise of temperature, the number of the dissolved γ′ precipitates increases rapidly, and the reduction of retardation to migrating grain boundaries leads to the sharp increase in the depth of recrystallized layers.

Fig. 1 Relationship between depth of recrystallized layer and annealing temperature

3.2 Effect of annealing temperature on morphology of recrystallized grains

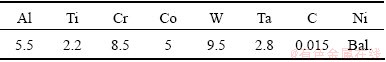

Microstructure examination shows that annealing temperature has a significant effect on the morphology of recrystallized grains. At the temperature below 1250 °C, cellular recrystallized structure can be observed (Fig. 2). The strain-free recrystallized cells consist of a number of columnar γ′ precipitates in the γ matrix. The columnar γ′ precipitates elongate in the growth direction of the cells. The columnar γ′ precipitates in the cellular structure are different from the cubical ones in the original grain in both pattern and size. So, it can be assumed that primary γ′ precipitates are dissolved at the recrystallization interface and then reprecipitate as columnar γ′ precipitates in the new grains. OBLAK and OWCAZRSKI [12] studied cellular recrystallization in a nickel-based superalloy by transmission electron microscopy. They found that the orientation of the γ′ precipitates in the cellular structure was different from that in the original grain, and the recrystallization front was a high-angle interface. Therefore, dissolution of primary γ′ precipitates must have occurred in the vicinity of the high-angle interface. They assumed that the dissolution of primary γ′ precipitates in the vicinity of the high-angle interface was a critical factor influencing recrystallization. Cellular structure was also observed by PORTER and RALPH [13], when they studied the recrystallization of several nickel-based superalloys of different γ′ volume fractions. According to their studies, the dissolution and reprecipitation of γ′ phase were attributed to the high solubility and diffusivity of the moving recrystallization interface. During the migration, recrystallized grain boundaries take nearly all the γ′ precipitates when they encountered into solution. As a result, the moving grain boundaries soon become supersaturated with γ′-forming elements. This supersaturation is unstable and is relieved by the forming of columnar γ′ precipitates.

Fig. 2 OM images showing cellular recrystallized structures after heat treatment at temperature below 1250 °C

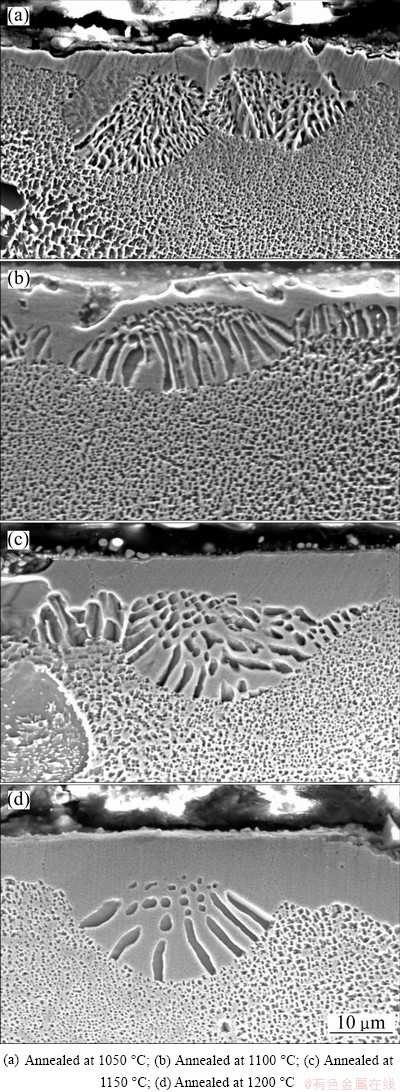

From Fig. 2, it can be seen that cellular recrystallized structure can be divided into three parts: the areas near the shot-peened surface where no columnar γ′ precipitates exist, the central area where the columnar γ′ precipitates are short, and the outer area near the boundary of the cellular structure where the columnar γ′ precipitates are longer. Figure 3 schematically illustrates the cellular structure. The three parts of the cellular structure mentioned above correspond to areas (1), (2) and (3) in Fig. 3.

Fig. 3 Schematic illustration of cellular recrystallized structure

Recrystallization begins on the shot-peened surface, and then the recrystallized grains grow inwards. When the grain boundaries move forward, they will become supersaturated with γ′-forming elements, resulting in the nucleation and growth of columnar γ′ precipitates. In the initial stage, because only a small number of γ′ precipitates are dissolved by the moving grain boundaries, low local solute concentration near the moving boundaries cannot provide sufficient supersaturation for the nucleation of columnar γ′ precipitates, resulting in the surface area without columnar γ′ precipitates. With the grain boundaries moving further, the supersaturation of γ′-forming elements near the grain boundaries becomes higher, resulting in the forming of columnar γ′ precipitates. However, because of the high migration rate of the grain boundaries, the diffusion of γ′-forming elements along the boundaries cannot provide sufficient elements for continuous growth of the columnar γ′ precipitates. As a result, the columnar γ′ precipitates in the central area are short. In the last stage, the migration rate of the boundaries becomes lower, and thus the diffusion of γ′-forming elements along the boundaries can continuously provide elements for the growth of columnar γ′ precipitates, resulting in the longer columnar γ′ precipitates in the outer area near the boundaries.

Since the columnar γ′ precipitates in the cellular recrystallized structure is much bigger than the primary γ′ precipitates in the original grain, the forming of columnar γ′ precipitates can reduce the γ/γ′ interface energy per unit volume, and thus promote the growth of the cellular structure. The reduction in the free energy associated with cellular recrystallization, △GRX, may be decomposed into three terms:

△GRX=△Gmechanical+△Gγ/γ′ interface+△Ggrain boundary

where the first term (sign -), △Gmechanical, reflects the annihilation of dislocations; the second term (sign -), △Gγ/γ′ interface, stands for the reduction of γ/γ′ interface energy; the third term (sign +), △Ggrain boundary, represents the increase of free energy resulting from the creation of high-angle grain boundary.

The recrystallized grains formed at 1250 °C are shown in Fig. 4. It can be seen that nearly all the recrystallized grains exist in the dendritic core areas and the migration of the boundaries is impeded by the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas. No columnar γ′ precipitates are found in the recrystallized grains. The γ′ precipitates in the dendritic core areas can be dissolved more easily than those in the interdendritic areas [14]. While the samples are annealed at 1250 °C (below the homogenization annealing temperature of this SC superalloy, 1300 °C), nearly all the γ′ precipitates in the dendritic core areas are dissolved, but few of the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas are dissolved. Because the residual γ′ precipitates retard the nucleation and growth of recrystallized grains, recrystallized grains first nucleate and grow in the dendritic core areas. When the grain boundaries reached the interface between the dendritic core areas and the interdentritic areas, they are impeded by the residual coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas. Because nearly all the γ′ precipitates in the dentritic core areas can be dissolved at 1250 °C, which can be looked on as the solvus of the γ′ precipitates in the dentritic core, there are few residual γ′ precipitates to be dissolved during the migration of grain boundaries. Low local solute concentration near the moving boundaries cannot provide sufficient supersaturation for the nucleation of columnar γ′ precipitates. So, there are no columnar γ′ precipitates forming in the recrystallized grains.

Fig. 4 SEM images showing recrystallized grains after heat treatment at 1250 °C for 4 h

Fig. 5 SEM images showing recrystallized grains after heat treatment at 1300 °C for 4 h

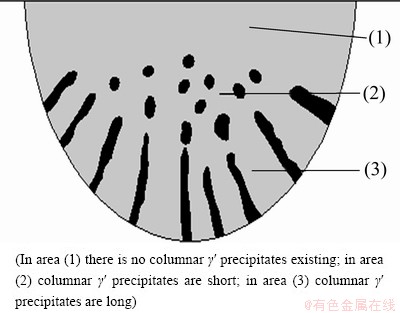

Figure 5 shows the recrystallized grains formed at 1300 °C. The fully developed recrystallized grains nearly have a uniform depth from the surface. The size and pattern of the γ′ precipitates in the recrystallized grains are similar to those in the original grain. Annealing twins can be clearly seen in the recrystallized grains. Annealing twins are key features in the microstructure of recrystallized materials having low to medium stacking fault energy [15]. 1300 °C is the homogenization annealing temperature of this SC superalloy. When annealed at this temperature, nearly all the γ′ precipitates are dissolved into the γ matrix. So, the recrystallization virtually takes place in a single phase γ matrix. When annealed at 1300 °C, both the recrystallized grains and the original grain are composed of a single phase. During the following cooling process, a large number of cubical γ′ particles precipitate both in the recrystallized grains and in the original grain.

3.3 Microstructural evolution during recrystallization

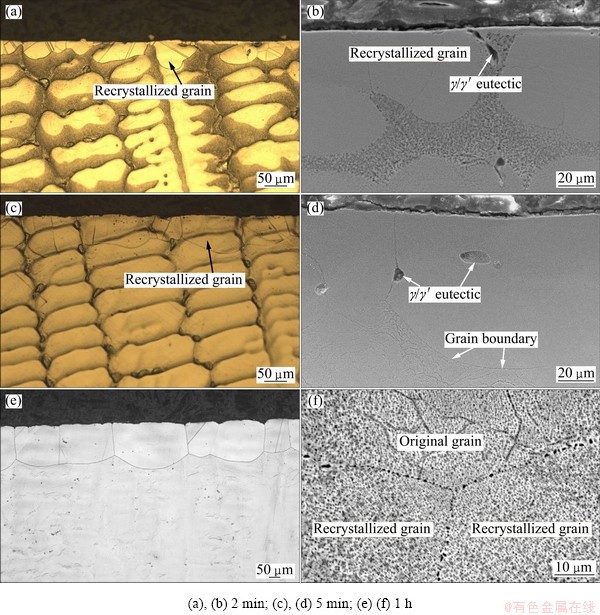

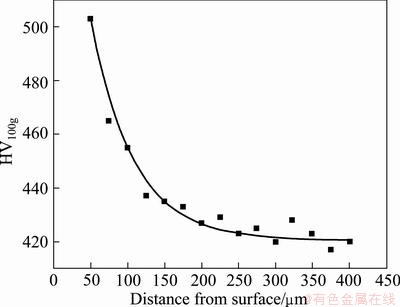

Figure 6 shows the recrystallization process at 1300 °C. It can be seen that recrystallization begins on the shot-peened surface, and then the recrystallized grains grow inwards. The nucleation of recrystallized grains merely takes place on the surface for the following two reasons. One reason is that nucleation along a free surface will reduce new interface, which means that less interface energy will be generated. In addition, according to the microhardness profile beneath the surface of a short-peened sample before heat treatment (Fig. 7), there is a decrease in hardness in the deformed layer induced by shot peening; the hardness is the greatest on the surface and then it decreases gradually with the increase of distance from the surface, which means that there exists the greatest plastic strain on the surface.

Fig. 6 SEM images showing recrystallized grains after annealing for different time

Fig. 7 Microhardness profile beneath shot-peened surface

At the beginning, recrystallization first occurs in the dendritic core areas where γ′ precipitates are dissolved faster [14] and the boundary migration of the recrystallized grains is impeded by the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas, which are dissolved more slowly (Figs. 6(a) and (b)). With the dissolution of the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas, the boundaries of recrystallized grains move through the interdendritic areas (Fig. 6(c) and (d)). During the moving of the grain boundaries through the interdentritic areas, if there exist a small fraction of residual γ/γ′ eutectics in front, the moving boundaries will cross them and leave them behind, as shown in Fig. 6(d). With the prolongation of annealing time, the recrystallized grains grow further until all of the plastically strained material above the threshold is consumed, and simultaneously, the new grains grow up in the direction parallel to the surface. As shown in Figs. 6(e) and (f), fully developed recrystallized grains nearly have a uniform depth from the surface, and both the recrystallized grain and the original grain are composed of a large number of fine cubical γ′ precipitates in the γ matrix, which reprecipitate during the cooling process. The final depth of the recrystallized grains is independent of the existing phases, even though coarse primary γ′ and γ/γ′ eutectics impede the growth of recrystallized grains at the beginning of recrystallization. Uniform depth of recrystallized grains is a result of full dissolution of existing phases into the γ matrix during full solution. Figure 8 schematically displays the inward recrystallization process with the prolongation of annealing time.

Fig. 8 Schematic representation of inward recrystallization process

4 Conclusions

1) Under the condition of annealing for 4 h, the threshold temperature for recrystallization of the shot-peened SC superalloy is between 1000 and 1050 °C. Below 1200 °C, the recrystallization depth climbs slowly with temperature rising. Above 1200 °C, the recrystallization depth increases rapidly with the rise of temperature.

2) The morphology of recrystallized grains is significantly affected by annealing temperature. Below the γ′ solvus, cellular recrystallization may be observed. Above the γ′ solvus, recrystallization occurs through the growth of well developed recrystallized grains.

3) Cellular recrystallized structure can be divided into three parts: the area near the surface where no columnar γ′ precipitates exist, the central area where the columnar γ′ precipitates are short, and the outer area near the boundary of the cellular structure where the columnar γ′ precipitates are long. The forming of columnar γ′ precipitates in cellular recrystallized structure can reduce the γ/γ′ interface energy, and thus promote the recrystallization process.

4) Recrystallized grains first nucleate in the dendritic core areas on the shot-peened surface and then grow inwards along the dendritic core areas. With the dissolution of the coarse γ′ precipitates and γ/γ′ eutectics in the interdendritic areas, the recrystallized grain boundaries move through the interdendritic areas. Finally, the fully developed grains nearly have a uniform depth.

5) The dissolution of primary γ′ precipitates is a critical factor influencing the recrystallization behavior of SC superalloys.

References

[1] TAO Chun-hu, ZHANG Wei-fang, LI Yun-ju, SHI Hui-ji. Recrystallization of directionally solidified and single crystal superalloy [J]. Failure Analysis and Prevention, 2006, 1(4): 1-9. (in Chinese)

[2] GOLDSCHMIDT D, PAUL U, SAHM P R. Porosity clusters and recrystallization in single-crystal components [C]// ANTOLOVICH S D, et al. Superalloys 1992. Warrendale, PA: TMS, 1992: 155-164.

[3] JO C Y, KIM H M. Effect of recrystallization on microstructural evolution and mechanical properties of single crystal nickel base superalloy CMSX-2. Part 2—Creep behavior of surface recrystallized single crystal [J]. Materials Science and Technology, 2003, 19: 1671-1676.

[4] ZHANG B, LIU C K, LU X, TAO C H, JIANG T. Effect of surface recrystallization on creep rupture property of a single-crystal superalloy [J]. Rare Metals, 2010, 29(4): 413-416.

[5] HU Ben-fu, CHEN Huan-ming, JIN Kai-sheng, LI Hui-ying. Static recrystallization mechanism of FGH95 superalloy [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 901-906. (in Chinese)

[6] XU W, ZHANG L W, GU S D, ZHANG J L. Hot compressive deformation behavior and microstructure evolution of HIPed FGH96 superalloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 66-71.

[7] LEE H T, HOU W H. Development of fine-grained structure and the mechanical properties of nickel-based superalloy 718 [J]. Materials Science and Engineering A, 2012, 555: 13-20.

[8] HOSSEINIFAR M, ASGARI S. Static recrystallization behavior of AEREX350 superalloy [J]. Materials Science and Engineering A, 2010, 527: 7313-7317.

[9] BURGEL R, PORTELLA P D, PREUHS J. Recrystallization in single crystals of nickel base superalloys [C]// POLLOCK T M, et al. Superalloys 2000. Warrendale, PA: TMS, 2000: 229-238.

[10] COX D C, ROEBUCK B, RAE C M F, REED R C. Recrystallization of single crystal superalloy CMSX-4 [J]. Materials Science and Technology, 2003, 19: 440-446.

[11] PIERRON X, LINDSLEY B. Sub-solvus recrystallization mechanisms in UDIMET alloy 720LI [C]// POLLOCK T M, et al. Superalloys 2000. Warrendale, PA: TMS, 2000: 59-68.

alloy 720LI [C]// POLLOCK T M, et al. Superalloys 2000. Warrendale, PA: TMS, 2000: 59-68.

[12] OBLAK J M, OWCZARSKI W A. Cellular recrystallization in a nickel-base superalloy [J]. Transactions of the Metallurgical Society of AIME, 1968, 242: 1563-1568.

[13] PORTER A, RALPH B. The recrystallization of nickel-base superalloys [J]. Journal of Materials Science, 1981, 16: 707-713.

[14] KARUNARATNE M S A, COX D C, CARTER P, REED R C. Modelling of the microsegregation in CMSX-4 superalloy and its homogenisation during heat treatment [C]// POLLOCK T M, et al. Superalloys 2000. Warrendale, PA: TMS, 2000: 263-272.

[15] DAVIES P, RANDLE V. Grain boundary engineering and the role of the interfacial plane [J]. Materials Science and Technology, 2001, 17(6): 615-626.

张 兵1,2,3,曹雪刚4,刘德林1,2,3,刘新灵1,2,3

1. 北京航空材料研究院 中航工业失效分析中心,北京 100095;

2. 中航(试金石)检测科技有限公司,北京 100095;

3. 航空材料检测与评价北京市重点实验室,北京 100095;

4. 南通高等师范学校,南通 226006

摘 要:利用喷丸预变形,研究了热处理温度对单晶高温合金表面再结晶行为的影响以及固溶温度条件下再结晶组织的演变过程。结果表明,随着热处理温度的升高,再结晶层厚度不断增加;在1200 °C以下时,再结晶层厚度随着温度的升高而缓慢增加,而当温度高于1200 °C时,再结晶层厚度随着温度的升高而迅速增加;当热处理温度低于γ′相完全固溶温度时,再结晶以不连续的胞状组织的形式出现,而当热处理温度高于γ′相完全固溶温度时,再结晶以完整晶粒的形式出现;再结晶晶粒首先在喷丸表面的枝晶干区域形核,然后沿着枝晶干向内生长,但随着枝晶间粗大γ′相和γ/γ′共晶相的溶解,再结晶晶界穿过枝晶间区域而继续向内部迁移,最后形成厚度比较均匀的再结晶层;铸态γ′相的溶解是影响单晶高温合金再结晶行为的关键因素。

关键词:单晶高温合金;再结晶;喷丸;热处理

(Edited by Hua YANG)

Foundation item: Project (2010ZF21007) supported by the Aeronautical Science Foundation of China

Corresponding author: Bing ZHANG; Tel: +86-10-62496236; E-mail: zhbenglish@126.com

DOI: 10.1016/S1003-6326(13)62595-9