文章编号:1004-0609(2008)10-1846-06

喷雾造粒制备SiC-AlN复合粉体特性及烧结性能

郭兴忠1,杨 辉1,张玲洁1,马 奇1,李海淼1,高黎华2,傅培鑫2

(1. 浙江大学 材料科学与工程学系,杭州 310027;

2. 浙江东新密封有限公司,乐清 325604)

摘 要:采用水基料浆与流态化喷雾造粒相结合制备SiC-AlN复合粉体,分析复合粉体的粉体特性、成形性能及烧结特性,探讨SiC-AlN复相陶瓷的增强增韧机制。结果表明:喷雾造粒后,复合粉体的流动特性显著提高,粒度级配合理;随着压强增加,坯体密度在40~80、80~160和160~220 MPa范围内呈现阶梯式增长,160 MPa以上成形后素坯均匀致密,无硬球颗粒存在;无压烧结SiC-AlN复相陶瓷具有优越的烧结性能和力学性能,这是由于AlN对SiC晶粒形成生长势垒,并反应生成2H型固溶体,从而细化晶粒,导致裂纹扩展产生了绕道与偏转效应,呈现晶粒撕裂与拨出现象,协同改善了复相陶瓷的强度及断裂韧性。

关键词:碳化硅;氮化铝;喷雾造粒;复相陶瓷;粉体;烧结

中图分类号:TB 332 文献标识码: A

Characteristics and sintering behaviors of SiC-AlN composite powders obtained by spray drying

GUO Xing-zhong1, YANG Hui1, ZHANG Ling-jie1, MA Qi1, LI Hai-miao1, GAO Li-hua2, FU Pei-xin2

(1. Department of Materials Science and Engineering, Zhejiang University, Hangzhou 310027, China;

(2. Zhejiang Dongxin Seals Limited Company, Leqing 325604, China)

Abstract: The SiC-AlN ceramic powders were prepared by combining aqueous slurry with fluidized spray drying, and the powder characteristics, sintering behaviors and strengthening mechanism of SiC-AlN multiphase ceramic were investigated. The results shows that the flow characteristics of SiC-AlN granulated powder is obviously promoted after spray drying and a suitable particles grade match. With the increasing of pressure, the density of green body increases by the style of ladder at the pressure range of 40-80 MPa, 80-160 MPa and 160-220 MPa, the green body is uniform and densification without hard pelleted particles above 160 MPa. The pressureless sintering SiC-AlN multiphase ceramic possesses superior sintering properties and mechanical properties. It is due to the rampart formation of AlN to SiC grain growth and the reaction of SiC and AlN to form 2H solid solution. It results in the grain fining, crack expansion producing bypass and deflection, fracture section producing tearing-open and pulling-out effects, which cooperatively improves the strength and fracture toughness of the multiphase ceramics.

Key word: silicon carbide; aluminum nitride; spray drying; multiphase ceramic; powder; sintering

SiC-AlN复合材料是利用SiC和AlN具有相同的原子尺寸、分子量、密度、化合物和晶胞参数,能在1 800~2 100 ℃的温度范围内和较宽的组成范围会形成固溶体(2H)而致密化的一种新型碳化硅复相陶瓷。由于形成了高温2H固熔体,不但改善了碳化硅的烧结特性,而且改变了陶瓷显微结构,使陶瓷力学性能、抗氧化性、高温强度均得到提高,受到人们的广泛关注[1-2]。

20世纪90年代以来,SiC-AlN复相陶瓷的研究集中在陶瓷烧结工艺、陶瓷抗氧化性等方面[3-5],研究了SiC-AlN复相陶瓷在惰性气氛[2]、氮气氛[6]和真空[7]下的热压烧结,获得高性能复相陶瓷及增强机制。但由于热压或热等静压设备昂贵,工艺复杂,成本高,所以,近年来,人们对该复相陶瓷的研究转向常压(无压)烧结,发现SiC晶粒原位生长成无序排列的棒状晶结构[8],虽然常压烧结复相陶瓷的力学性能不如热压烧结,但优于B、C固相烧结碳化硅陶瓷,且烧结温度(2 000~2 100 ℃)也低于固相烧结(2 200~2 300 ℃)。目前,无压烧结SiC-AlN复相的研究主要是考察烧结助剂种类及含量、烧结温度和时间、烧结气氛及是否埋粉[9]等,很少关注复合陶瓷粉体的形态、分布情况及成形性能[10]。事实上,SiC-AlN复相陶瓷的固熔反应及低温烧结与AlN在SiC基体中分布直接相关,几乎所有研究的复合粉体原料均采用直接机械共混+干燥破碎的方式制备,不但AlN和SiC的成分均匀分布难以保证,而且还由于长时间球磨导致AlN的水解反应而改变原料化学成分。

为此,本文作者采用水基料浆+流态化喷雾造粒的方式制备成分均匀分布、流动性良好的复合粉体,分析喷雾造粒复合粉体的粉体特性、成形性能及烧结特性,探讨了复相陶瓷的增强增韧机制,为喷雾造粒技术在SiC-AlN复合材料的应用以及高性能常压SiC-AlN复相陶瓷的制备奠定重要基础。

1 实验

实验时,首先将SiC粉体(市售,平均粒径为0.74 μm,纯度大于96%)、AlN(市售,分析纯)、油酸(AlN抗水解剂)、粘结剂、分散剂、SiC球磨砂子(d 5 mm)和去离子水(浙江大学化学系自制)按一定比例配制成后,放入球磨混料装置,球磨混料2~6 h。将混合好的水基料浆(固相含量为40%~60%)采用国产GL-5型离心式喷雾干燥机对浆料进行喷雾干燥,工艺参数为:热风进口温度200~250 ℃、出口温度80~100 ℃、雾化器调数为20~60 Hz、料浆进料速率为5~10 kg/h。造粒粉粒经过40~220 MPa双面干压成形,分析造粒粉的成形性能。成形好的陶瓷素坯放在真空无压烧结炉中,埋粉后,升温到2 050 ℃并保温4 h。

采用Winner 2000激光粒度分布仪对原粉进行粒度分析,而采用杭州蓝天化验仪器厂生产8411型电动振筛机测试造粒粉的粒度分布。采用XJ10-60型X射线衍射仪对烧结体进行物相分析,工作电压35 kV,工作电流15 mA,辐射源Cu靶,扫描速度4 (?)/min,步宽0.02?;通过HITACHI S-570扫描电镜观察素坯和烧结体的断面形貌,用Genesis 4000 EDAX能谱仪对陶瓷断面部分进行成分分析。对经过研磨加工的样品采用阿基米德排水法测量烧结体的密度,样品的质量用分析天平测得,精确到0.000 1 g。实验使用HV-5型小负荷维氏硬度计测量显微硬度,载荷为98 N。采用压痕法计算复相陶瓷断裂韧性,利用以下公式[11] 计算:

式中 KIC为断裂韧性;H为维氏硬度;E为弹性模量(对于LPS-SiC估计为400 GPa);a为压痕对角线长的一半;c为径向裂纹的半裂纹长。

2 结果及讨论

2.1 粉体特性及成形性能

松装密度和休止角是最常用来表征粉体的流动特性两个重要参数。SiC-AlN复合造粒粉的粉体特性如表1所列。从表1中看出,与SiC原微粉参数相比,喷雾造粒后,复合粉体的松装密度提高56%以上,而休止角也大副减小,说明经过喷雾造粒处理,SiC-AlN复合粉体的流动性能得到明显改善。

表1 造粒粉的流动特性

Table 1 Flow characteristics of granulated powder

图1所示为喷雾造粒前后复合粉体的粒径分布和SEM像。从图1中看出,SiC原粉的粒度分布呈双峰不连续,分别在0.04~0.41 μm,0.85~2.12 μm,且分布范围较窄,而从SEM像可以看出粉体为不规则形状块状,且大多呈片状或尖角状的颗粒。喷雾造粒后,造粒粉成球状,成球性好,粒度分布在10~40 μm之间,分布宽度较大,使粉粒的粒度级配较为合理,有利于获得较高的成形性能。

图1 SiC粉体喷雾造粒前后的粒度分布及SEM像

Fig.1 Particle size distribution and SEM photos of SiC-AlN before and after spray drying: (a) SiC powder; (b) SiC-AlN granulated powder

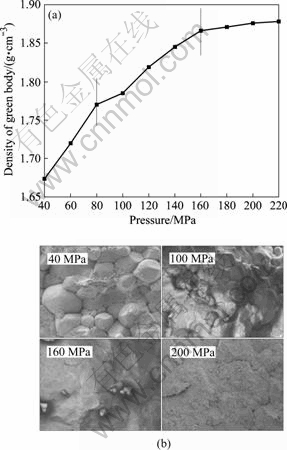

图2所示为喷雾造粒SiC-AlN复合粉体的干压成形性能及断面显微结构。从图2中看出,在40~80 MPa之间密度随压强增长较快;80~160 MPa之间,密度增加接近线性变化但是密度增加放缓;而160~220 MPa之间呈平台状,且成形压强为160 MPa时,素坯相对密度达到58.6%,当压强增加到220 MPa时,相对密度增加甚微。从SEM像可以看出,40 MPa压强成形素坯的结构较为疏松,大部分造粒粉仍保持球状,且相互之间存在较大宏观的空隙,这种空隙在烧结过程中很难消除,会在陶瓷中残留较大的孔洞;100 MPa压强成形素坯致密性大幅增加,但是断面仍保留部分造粒球,表明造粒球仍未完全破碎;而经过160 MPa和200 MPa压强成形的素坯断面均非常致密,没有出现未破碎造粒球,说明造粒球已完全破碎,继续增加成形压力,素坯微观结构变化甚微。素坯密度随成形压强变化的关系说明,表面强度较大的球状造粒粉较低压强下(100 MPa)不能够被破坏,只有当压强达到160 MPa时才得以破坏,待在这种硬球粒被破坏以后,素坯密度增长趋势也随之放缓。

图2 SiC-AlN素坯的干压成形性能及显微结构

Fig.2 Molding properties and microstructure of SiC-AlN green body: (a) Pressure vs green body density; (b) SEM images

2.2 烧结特性及力学性能

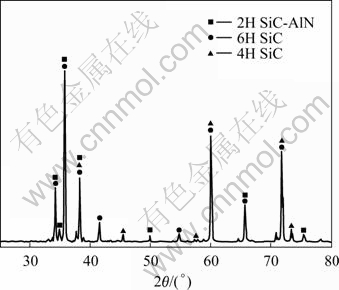

图3所示为SiC-AlN素坯在2 050 ℃保温4 h后烧结体的XRD谱。从图3看出,复相陶瓷烧结体主要存在6H、4H和少量15R晶型的SiC以及2H型SiC-AlN固溶体。由于AlN的晶格常数与SiC非常接近(α-SiC:a=0.307 63 nm,c=0.504 8 nm;AlN:a=0.311 14 nm,c=0.497 92 nm),容易在较宽的范围内可以形成2H-固溶体[1]。从SiC-AlN二元相图中可以看出,AlN-SiC二元体系低温区(<2 000 ℃),在高SiC区或高AlN区,2H-固溶体是稳定的[12]。

图3 SiC-AlN复相陶瓷烧结体的X射线衍射谱

Fig.3 XRD patterns for SiC-AlN sintered body

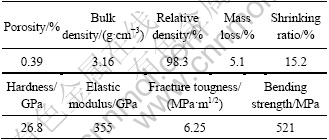

SiC-AlN复相陶瓷在2 050 ℃保温4 h烧结后的烧结特性及力学性能列于表2。从表2中看出,复相陶瓷的相对密度为98.3%,高于B、C为烧结助剂的固相烧结碳化硅陶瓷[13],质量损失率为5.1%,收缩率15.2%,明显低于YAG为烧结助剂的液相烧结碳化硅陶瓷[14-15]。显微硬度、弹性模量、抗折强度、断裂韧性等力学性能指标也达到或超过其他无压烧结碳化硅陶瓷,显示出优越的综合性能。

表2 SiC-AlN复相陶瓷的烧结特性及力学性能

Table 2 Sintering and mechanical properties of SiC-AlN multiphase ceramics

2.3 显微结构

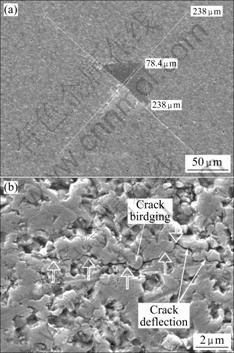

图4所示为SiC-AlN复相陶瓷维氏硬度压痕和裂纹扩展的SEM像。从图4中看出,压痕尖端裂纹呈放射性扩展,观察裂纹扩展形态,可以发现裂纹较曲折,沿着晶粒表面扩展,出现裂纹偏转和裂纹桥联效应。裂纹在扩展过程中如果沿晶界断裂,会出现裂纹偏转或桥联,可以延长裂纹扩展的路径,消耗较多的断裂能,提高陶瓷的断裂韧性。

图4 SiC-AlN复相陶瓷维氏硬度压痕和裂纹扩展SEM像

Fig.4 SEM images of Vickers indentation and crack paths from SiC-AlN multiphase ceramics: (a) Vickers indentation; (b) Crack paths

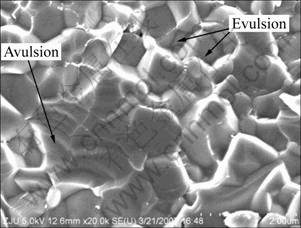

图5和图6(a)所示为SiC-AlN复相陶瓷的断面及晶界显微结构像。从图5中看出,SiC-AlN复相陶瓷晶粒细小,直径主要在0.5~1.5 μm,最大粒径<2 μm,晶粒多呈等轴状;晶粒间相物质减少,晶界干净,晶粒棱角清晰,晶粒接触面平整,断面出现晶体拔出和撕裂留下的痕迹。从断面整体形貌上看,各样品断面凸凹不平,犬牙交错,均可以看到有晶粒拔出留下的凹坑,说明出现沿晶断裂方式。

图5 SiC-AlN复相陶瓷断面的SEM像

Fig.5 SEM image of fracture surface of SiC-AlN composites ceramics

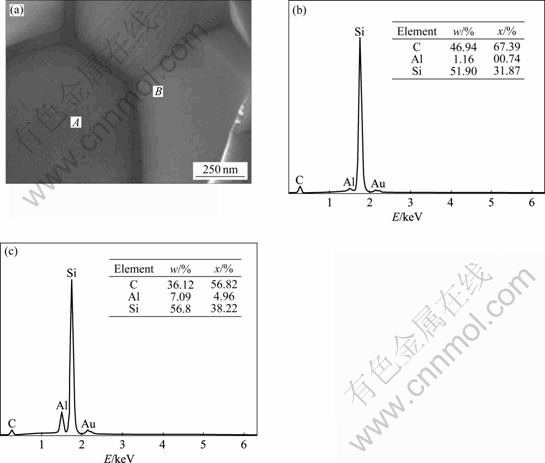

从图6(b)陶瓷断面A处EDS谱中看出,Si元素峰左侧出现了不太明显的Al元素峰,Al元素的含量仅为0.74%(摩尔分数),从而图6(c)晶界处B处EDS图谱发现,Al元素的峰明显增强,Al的含量为4.96%,晶粒中心和边缘Al元素含量不同,说明晶粒边缘或晶界处AlN的含量远高于晶粒中心,而AlN又以固溶体的形式存在,可以认为固溶体中AlN呈不均匀分布状态,晶粒边缘或晶界处浓度高于晶粒中心位置。烧结过程中AlN通过蒸发—凝聚、溶解沉淀等机制扩散至SiC颗粒的表面,最初AlN并未全部生成SiC-AlN固溶体,只有当AlN与SiC开始相互扩散的时候才能形成固溶体,随后晶粒逐渐长大和均化,且在晶粒达到完全均化之前,SiC晶粒外层的AlN浓度要高于晶粒内部。

图6 SiC-AlN复相陶瓷晶界特征

Fig.6 Grain boundary of SiC-AlN composites ceramics: (a) SEM image showing grain boundary; (b) EDS pattern of dot A; (c) EDS pattern of dot B

SiC晶粒的细化与AlN和SiC在较宽的范围内可以形成固溶体有关,因为在烧结过程中AlN具有更高的蒸发汽压和更大的扩散系数[16],AlN向SiC颗粒表面的迁移率远大于其逆向迁移率,以至于AlN能优先扩散到SiC晶粒的表面,一方面形成对SiC晶粒的生长势垒,抑制SiC晶粒的长大,另一方面他又能与SiC发生固溶反应,并在二者界面重新成核,生成新的晶粒,对原来的晶粒进行蚕食,从而细化晶粒。晶粒的细化有助于降低材料中的临界尺寸,提高陶瓷强度。固溶体的存在改善了SiC陶瓷中的晶界能,使裂纹扩展产生了绕道与偏转效应,断面处会呈现凸凹不平,犬牙交错的复杂结构,延长的裂纹扩散的路径,更多的消耗了断裂能量,宏观上将改善了陶瓷的断裂韧性。

3 结论

1) SiC-AlN水基料浆采用流态化喷雾造粒后,SiC-AlN复合粉体的松装密度、休止角等流动特性显著提高,较宽的粒度分布有利于实现合理的粒度级配和成形。

2) 采用干压成形进行复合粉体成形,随着压强增加,坯体密度在40~220 MPa范围内呈现阶梯式增长,40~80、80~160和160~220 MPa下素坯密度的增长幅度不一,造粒粉球需要在一定压强下才能被破碎,160 MPa以上成形后,素坯均匀致密,无硬球颗粒存在。

3) 与B、C固相烧结和YAG液相烧结陶瓷相比,无压烧结SiC-AlN复相陶瓷具有更为优越的综合性能。在烧结过程中,AlN对SiC晶粒形成生长势垒,同时,两者反应生成2H型固溶体,抑制晶粒生长,形成细晶结构。压痕尖端裂纹呈放射性扩展,产生了绕道与偏转效应,断裂方式呈现撕裂与拨出现象,从而协同改善了SiC-AlN复相陶瓷的强度及断裂韧性。

REFERENCES

[1] RUH R, ZANGVIL A. Composition and properties of hot-pressed SiC-AIN solid solutions[J]. J Am Ceram Soc, 1982, 65(5): 260-265.

[2] RAFANIELLO W, CHO K, VIRKAR V A. Fabrication and characterization of SiC-AlN alloys[J]. J Mater Sci, 1981, 16: 3479-3488.

[3] LI J F, WATANABE R. Pressureless sintering and high-temperature strength of SiC-AlN ceramics[J]. J Ceram Soc Japan, 1994, 102(8): 727-731.

[4] CHOI H J, LEE J G, KIM Y W. Oxidation behavior of liquid-phase sintered silicon carbide with aluminum nitride and rare-earth oxides (Re2O3, where Re = Y, Er, Yb)[J]. J Am Ceram Soc, 2002, 85(9): 2281-2286.

[5] RIXECKER G , WIEDMANN I, ROSINUS A, ALDINGER F. High-temperature effects in the fracture mechanical behaviour of silicon carbide liquid-phase sintered with AlN-Y2O3 additives[J]. J Eur Ceram Soc, 2001, 21(8): 1013-1019.

[6] MANDAL S, DHARGUPTA K K, GHATAK S. Gas pressure sintering of SiC-AlN composite in nitrogen atmosphere[J]. Ceram Int, 2002, 28: 145-151.

[7] ZANGVIL A, RUH R. Phase relationships in the silicon carbide-aluminium nitride system[J]. J Am Ceram Soc, 1988, 71(10): 884-890.

[8] 陈忠明, 谭寿洪, 江东亮. 高性能SiC-AlN复相陶瓷[J]. 无机材料学报, 1997, 12(5): 763-767.

CHEN Zhong-ming, TAN Shou-hong, JIANG Dong-ling. High performance SiC-AlN composites[J]. J Inorg Mater, 1997, 12(5): 763-767.

[9] MAGNANI G , BEAULARDI L. Long term oxidation behaviour of liquid phase pressureless sintered SiC-AlN ceramics obtained without powder bed[J]. J Eur Ceram Soc, 2006, 26: 3407-3413.

[10] 郭兴忠, 杨 辉, 朱潇怡, 李海淼, 马 奇, 高黎华, 傅培鑫. 水基SiC料浆的分散稳定机制及喷雾造粒[J]. 硅酸盐学报, 2008, 36(5): 642-647.

GUO Xing-zhong, YANG Hui, ZHU Xiao-yi, LI Hai-miao, MA Qi, GAO Li-hua, FU Pei-xin. Dispersibility mechanism and spray drying of SiC aqueous slurry[J]. Journal of the Chinese Ceramic Society, 2008, 36(5): 642-647.

[11] NIIHARA K, MORENA R. HASSELMAN D P H. Evaluation of KIC of brittle solids by the indentation method with low crack-to-indent ratios[J]. J Mater Sci Lett, 1982, 1: 13-16.

[12] SUZUKI K, SASAKI M. Microstructure and mechanical properties of liquid-phase-sintered SiC with AlN and Y2O3 additions[J]. Ceram Int, 2005, 31(5): 749-755.

[13] GUO Xing-zhong, YANG Hui. Investigation of compaction and sintering behavior of SiC powder after ultra-fine treatment[J]. J Zhejiang Univ Sci, 2004, 5(8): 950-955.

[14] GUO Xing-zhong, YANG Hui. Sintering and microstructure of silicon carbide ceramic with Y3Al5O12 added by sol-gel method[J]. J Zhejiang Univ Sci, 2005, 6B(3): 213-218.

[15] 郭兴忠, 杨 辉, 王建武, 高黎华, 李祥云. YAG引入方式对碳化硅陶瓷烧结特性、力学性能及结构的影响[J]. 中国有色金属学报, 2005, 15(4): 524-530.

GUO Xing-zhong, YANG Hui, WANG Jian-wu, GAO Li-hua, LI Xiang-yun. Effects of adding methods of YAG on sintering behaviour, mechanical properties and microstructure of SiC ceramic[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 524-530.

[16] BISWAS K, RIXECKER G. Liquid phase sintering and microstructure—property relationships of silicon carbide ceramics with oxynitride additives[J]. Mater Chem and Phys, 2001, 67(1/3): 180-191.

基金项目:高等学校博士点基金资助项目(20070335017);浙江省重大科技攻关资助项目(2006C11184).

收稿日期:2008-02-29;修订日期:2008-06-10

通讯作者:杨 辉,教授;电话:0571-87951408;传真:0571 87953054;E-mail: yanghui@zju.edu.cn

(编辑 陈爱华)