文章编号:1004-0609(2010)03-0456-07

表面机械处理对5×××铝合金/涂层体系的结合强度和晶间腐蚀性能的影响

潘素平1,易丹青1,陈宇强1,林红吉2,王 斌1,周明哲1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 海军装备技术研究所,北京102442)

摘 要:采用金相显微镜、电化学交流阻抗和扫描电镜研究表面机械处理(喷砂和打磨)对5×××铝合金/涂层体系的结合强度及晶间腐蚀性能的影响。结果表明:试样经表面机械处理后,基体表面的清洁度提高,粗糙度增大,涂层与基体的结合强度显著提高;其中表面喷砂后,基体与涂层结合强度提高198.7%;表面打磨后,基体与涂层结合强度提高167.4%;表面机械处理后,基体的耐晶间腐蚀能力明显降低,但合金/涂层体系的耐晶间腐蚀能力显著提高;表面喷砂后,合金/涂层体系与基体的耐蚀性都强于表面打磨后的耐蚀性。

关键词:5×××铝合金;结合强度;表面机械处理;晶间腐蚀

中图分类号:TG172 文献标识码:A

Effects of surface mechanical treatment on coherent strength and intergranular corrosion of coated 5××× aluminium alloy

PAN Su-ping1, YI Dan-qing1, CHEN Yu-qiang1, LIN Hong-ji2, WANG Bin1, ZHOU Ming-zhe1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Naval Institute of Technology and Equipment, Beijing 102442, China)

Abstract: Metallographic microscope, electrochemical impedance spectroscope and scan electron microscope were used to study the effects of surface mechanical treatment (shot blasting and polishing) on the coherent strength and intergranular corrosion (IGC) of the coated 5××× aluminium alloy. The results show that the surface mechanical treatments (shot blasting and polishing) can markedly improve the adhesive strength by increasing the cleanliness and roughness of the substrate. The adhesive strengths after shot blasting and polishing are elevated by 198.7% and 167.4%, respectively. The IGC resistance of the substrate after surface mechanical treatment obviously decreases, while the IGC resistance of the coated alloy significantly increases. Moreover, the corrosive resistances of the coated alloy and the substrate after shot blasting are both better than those after polishing.

Key words: 5××× aluminum alloy; adhesive strength; surface mechanical treatment; intergranular corrosion

5×××铝合金属于Al-Mg系铝合金,具有较高的强度和较好的可焊性,广泛应用于舰艇、船舶、汽车车身等[1?5]。但是,在使用环境下,5×××铝合金会发生局部腐蚀[6]。因此,通常要对其表面进行防腐涂装,表面机械处理对涂层防腐性能有很重要的作用。

表面机械处理是指在涂装前,用机械方法除去基体表面附着物或生成的异物,以提高基体表面与涂层的附着力的过程[7]。目前,许多学者进行了表面处理对5×××合金及其涂层体系耐蚀性影响的研究。ABALLE等[8]研究了表面打磨度对5083铝合金在3.5%NaCl溶液中的表面局部碱性腐蚀的影响,发现试样的打磨度决定阴极金属间粒子的暴露程度,从而影响表面的局部碱性腐蚀。AFSETH等[9]和ZHOU等[10]研究了表面机械处理对5×××铝合金及其涂层体系的丝状腐蚀的影响,发现机械处理产生的严重变形层、包含氧化物的细小晶粒和弥散相使得合金及其涂层体系的丝状腐蚀更加敏感。赵月红等[11]研究了不同加工及表面处理状态下LF6铝镁合金的深海腐蚀行为,发现阳极氧化表面处理的合金的耐蚀性最强。LAZAREVIC等[12]对比不同表面化学处理对铝合金基体上环氧涂层防护性能的影响,发现经阳极化和磷化处理后,环氧涂层防护性能最好。作为一种重要的预处理手段,表面机械处理在5×××铝合金的实际应用中使用非常普遍;但是,关于5×××铝合金/涂层体系耐蚀性能的影响研究甚少。在此,本文作者对于喷砂和打磨2种表面机械处理方式对5×××铝合金/涂层体系结合力及晶间腐蚀性能的影响进行研究。

1 实验

1.1 材料

实验用5×××合金为6 mm厚的板材,基本成分及试样编号分别如表1和2所列。

表1 实验合金成分

Table1 Chemical composition of tested alloys(mass fraction, %)

表2 试样编号及表面处理状态

Table 2 Samples No. and surface mechanical treatment states

1.2 试样表面处理方法

原始试样为厂家提供的轧制板材。采用射吸式喷砂机对基体表面进行喷砂处理。喷砂使用氧化铝磨料粒子,砂粒直径约为550 μm,喷砂机喷嘴出口压力约为0.7 MPa,喷嘴距样品距离约为30 mm。打磨采用电动角向磨光机和氧化铝砂轮盘。样品4、5和6均采用涂刷的方式进行刷漆,待充分固化后使用。

1.3 性能测试

表面粗糙度测量:采用粗糙度对比板对照得出。 涂层结合力测试:由于本试验中所使用的板材太薄,不适于用对拉法测试涂层结合强度,故借鉴国标GB7124—86测定漆膜的拉伸剪切强度,以判断涂层与基体金属的结合强度。首先,在一个金属试片上涂布被测漆膜,然后,用AB胶将该试片的漆膜与另一金属试片粘接起来,在CSS万能拉伸试验机上进行拉伸剪切试验,测定试样能承受的最大剪应力。拉伸速度为0.5 mm/min,试样尺寸为100 mm×25 mm× 2 mm,数据取3个试样的均值。

晶间腐蚀试验:试样尺寸为40 mm×24 mm× 6 mm,每组3个试样,全浸于3%NaCl+10 mL HCl+ 1 L H2O溶液中,试样测试面积与溶液体积比为1?20,悬挂于(35±1)℃水中静止腐蚀24 h,清洗干燥、研磨抛光后在POLYVAR显微镜下观测。以上所有实验程序均依照标准GB/T 7998—2005进行。

交流阻抗试验:采用Princeton生产的PARATAT2273电化学工作站测试系统。测试频率范围为105~0.01 Hz,正弦波信号振幅为10 mV。电解池采用三电极体系,参比电极为饱和甘汞电极,辅助电极为铂片,带有涂层的试样为工作电极,测试面积为13 cm2,电解质溶液为3.5% NaCl溶液。

2 结果与讨论

2.1 机械处理前、后试样表面形貌

在机械处理前、后,直接截取基体试样进行表面扫描,其表面形貌与状态如图1所示。未经机械处理的试样表面有明显的白色附着物,经能谱(见图1(b))分析为铝的氧化物。该氧化物的存在会降低涂料在基材表面的润湿。而喷砂和打磨处理后,试样表面没有附着物,显示出均匀的金属色泽,涂料可以在基体表面充分铺展。从图1(a)中还可以看出,未经机械处理的基体表面比较平整,经比较法测定,其表面粗糙度约为 3 μm。喷砂处理后,在基体表面均匀分布形状不规则的敞开型凹坑,没有固定的取向,方向各异,粗糙度约为10 μm。打磨处理后,基体表面分布有高低不平的粗细条纹,条纹上还有许多细小的锯齿,粗糙度约为60 μm。

图1 机械处理前、后基体表面的SEM像及EDS谱

Fig.1 SEM images and EDS pattern of surfaces of alloys before and after mechanical treatment: (a) Original surface; (b) EDS spectrum of area A; (c) Shot blasted surface; (d) Polished surface

2.2 涂层的结合强度

对涂漆后的试样进行拉伸剪切强度测试,检测其涂层在基体表面的附着情况,其测试结果如表3所列。

表3 涂层拉伸剪切强度的测定结果

Table 3 Test results of tensile shear strength of coatings on metals

与未处理试样相比,表面喷砂和打磨后的试样的拉伸剪切强度明显提高。其中,喷砂试样的拉伸剪切强度提高198.7%,打磨试样的拉伸剪切强度提高167.4%。

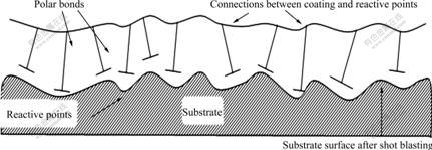

图2所示为表面机械处理后的基体与涂层的结合示意图。在铝合金表面,能量较高的局部能够化学吸附液体中的分子。这一局部位置就是通常所说的活性中心。喷砂和打磨后,基体表面发生很强的塑性变形,晶内位错密度增加[13],其周围的原子具有较高的能量,即为涂层提供更多的活性中心,有利于涂层与基体的结合;另外,机械处理后,在基体金属表面形成的峰和谷显著增大了表面积,即增加了活性中心的数目,从而增大了涂层对金属的附着力[14]。

图2 涂层与基体的结合示意图

Fig.2 Schematic diagram of combination between coating and substrate

2.3 晶间腐蚀试验

晶间腐蚀后各试样截面金相对比照片如图3所示,其最大腐蚀深度如图4所示,试样表面对比照片如图5所示。

图3 晶间腐蚀后试样的截面金相照片

Fig.3 Cross-sectional metallographs of alloys after IGC test: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; (e) Sample 5; (f) Sample 6

图4 不同表面处理后的合金晶间腐蚀的最大腐蚀深度 比较

Fig.4 Maximum corrosion depths of IGC for alloys after corrosion under different surface treatment conditions

图5 不同表面处理后再晶间腐蚀试样的表面宏观对比照片

Fig.5 Macro-morphologies of samples after IGC test: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; (e) Sample 5; (f) Sample 6

从图3和4可知,样品2和3的最大腐蚀深度分别为70 μm和80 μm,腐蚀级别均为3级,高于样品1的40 μm。说明经机械处理后,基体的耐蚀性降低。5×××铝合金的晶间腐蚀敏感性与Mg的含量有关。尽管添加4.6%的Mg使合金在变形过程中可以获得很高的应变硬化,但是,它通常会以β相(Mg5Al8)的形式沿晶界连续析出,很少在晶内析出,β 相的电极电位和α固溶体相比较低[15?16] (β相的腐蚀电位为?1.15 V,α 固溶体的腐蚀电位为?0.82 V),在腐蚀液中为阳极而优先腐蚀。在机械处理前,基材在空气中放置了一段时间,已经发生氧化,生成具有保护作用的氧化膜,减少了暴露在腐蚀介质中的β相的数目,提高了基体的耐蚀性。在机械处理后,表面粗糙度增加,同时,暴露在表面没有氧化的金属增多,暴露的β相也增多,当基体置于腐蚀介质中时更易发生腐蚀。

样品4、5和6的晶间腐蚀都是分散的,深度各不相同。其中,样品4的晶间腐蚀沿晶界向基材内部延伸,最大深度约为40 μm,腐蚀级别属于3级,而样品5和6的晶间腐蚀很微弱,最大深度分别只有10 μm(1级)和15 μm(2级)。5×××合金的涂层可以隔离被保护基体与腐蚀介质的直接接触;但是,涂层总有一定的透水性和渗水性,不可能达到完全屏蔽的效果。当涂层与基体的结合强度不够时,涂层很容易被破坏;当局部丧失附着力时会产生鼓泡,这是涂层防腐能力不足的外观表现。从图5可以看出,经过24 h浸泡后,样品1、2和3的表面发白,产生大量的氧化产物;样品4、5和6的试样表面油漆已出现大小不均、数量不等的鼓泡,其中样品4的鼓泡最大,且边部有剥落,表示此时涂层已经被破坏,腐蚀介质通过破损处到达基体,使基体金属迅速发生腐蚀。而样品5和6的涂层与基体结合强度较大,鼓泡较小,没有剥落,在浸入腐蚀液中的很长一段时间都具有较强的防护性能,腐蚀介质不易透过涂层,所以,基体金属的晶间腐蚀程度较小。

为了进一步了解涂层的防护性能,对合金/涂层体系的电化学阻抗进行测试。不同浸泡时期合金/涂层体系在3.5%NaCl溶液中的EIS波特图如图(6)所示。从图6(a)可以看出,浸泡30 min时,3种涂漆样的lg|Z|—lg f均为斜率接近?1的直线,说明此时有机涂层相当于一个电阻值很大、电容值很小的隔绝层,能够很好地阻止电解质溶液渗入到基体金属与涂层的界面,保护基体金属免受腐蚀,这个阶段称为浸泡初期,此时,阻抗谱所对应的等效电路模型如图7(a)所示。此时涂层的阻抗表达式为[7]

式中:Rs为溶液电阻;Cc为涂层电阻;Rc为涂层电容;ω为角频率。

图6 合金/涂层体系在3.5%NaCl溶液中不同浸泡时期的EIS波特图

Fig.6 EIS Bode graphs of coated samples in 3.5% NaCl solution for different times: (a) 30 min; (b) 7 d

在浸泡初期,随着电解质溶液向有机涂层的渗透,涂层电容随浸泡时间延长而增大,涂层电阻则随浸泡时间的延长而减小,阻抗模也相应减小,表现为lg|Z|—lg f曲线朝低频方向移动,低频阻抗模降低。当浸泡7 d以后(见图6(b)),3种试样的低频阻抗模出现不同程度的降低。样品4的涂层体系阻抗模下降最多,由100 MΩ/cm2降至约10 kΩ/cm2,且在低频区出现一小段平台,涂层下电化学反应已经开始,这个阶段称为浸泡中期,此时涂层的等效电路如图7(b)所示,涂层的阻抗表达式为[7]

式中:Rpo代表微孔内电阻;Cdl代表双电层电容;Rt代表转移电阻。

样品5和6的阻抗模也有下降,但仍处于吸水阶段,也可用图7(a)所示的等效电路模型。这表明,表面未进行机械处理的试样,涂层下的电化学反应会较早开始,涂层防护性能较差;喷砂处理的试样,涂层防护性能最好。

图7在3.5%NaCl溶液中浸泡不同时间后合金/涂层体系的等效电路图

Fig.7 Equivalent-circuit diagrams of coated samples in 3.5% NaCl solution for different times: (a) 30 min; (b) 7d

3 结论

1) 表面机械处理(喷砂和打磨)能增加基体表面的清洁度和粗糙度,显著提高涂层与基体的结合强度。表面喷砂后,涂层与基体结合强度为11.56 MPa,比未处理试样强度提高198.7%;表面打磨后,涂层与基体的结合强度为10.35 MPa,比未处理试样强度提高167.4%。

2) 对比表面未处理试样,喷砂和打磨处理后,基体的耐晶间腐蚀性能明显降低,且喷砂处理的样品耐蚀性较高,喷砂和打磨后基体的最大晶间腐蚀深度分别为70 μm和80 μm。

3) 喷砂和打磨后,涂层与基体紧密结合,阻碍了电解质溶液渗入到结合面,合金/涂层体系的耐蚀性明显增强。喷砂后涂漆的合金/涂层体系的耐蚀性比打磨后的更好,喷砂和打磨后合金/涂层体的最大晶间腐蚀深度分别为10 μm和15 μm。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000: 240?250.

WANG Zhu-tang, TIAN Rong-zhang. Aluminium alloys and its processing handbook[M]. Changsha: Central South University Press, 2000: 240?250.

[2] CHEN H H, WANG J Y, LEE J, LEE S. Superplasticity of AA5083 alloy as processed by equal channel angular extrusion[J]. Journal of Alloys and Compounds, 2008, 460(1/2): 305?308.

[3] SHARMA M M, ZIEMIAN C W. Pitting and stress corrosion cracking susceptibility of nanostructured Al-Mg alloys in natural and artificial environments[J]. Journal of Materials Engineering and Performance, 2008, 17(6): 870?878.

[4] TANAKA H, NAGAI Y, OGURI Y, YOSHIDA H. Mechanical properties of 5083 aluminum alloy sheets produced by isothermal rolling[J]. Materials Transactions, 2007, 48(8): 2008?2013.

[5] LOMBARD H, HATTINGH D G, STEUWER A, JAMES M N. Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminium alloy[J]. Engineering Fracture Mechanics, 2008, 75(3/4): 341?354.

[6] EZUBER H, EL-HOUD A, EL-SHAWESH F. A study on the corrosion behavior of aluminum alloys in seawater[J]. Materials and Design, 2008, 29(4): 801?805.

[7] 高 瑾, 米 琪. 防腐蚀涂料与涂装[M]. 北京: 中国石化出版社, 2007: 221?224.

GAO Jin, MI Qi. Anti-corrosion coatings and painting[M]. Beijing: China Petrochemical Press, 2007: 221?224.

[8] ABALLE A, BETHENCOURT M, BOTANA F J, MARCOS M, SANCHEZ-AMAYA J M. Influence of the degree of polishing of alloy AA5083 on its behaviour against localised alkaline corrosion[J]. Corrosion Science, 2004, 46(8): 1909?1920.

[9] AFSETH A, NORDLIEN J H, SCAMANS G M, NISANCIOGLU K. Influence of heat treatment and surface conditioning on filiform corrosion of aluminium alloys AA3005 and AA5754[J]. Corrosion Science, 2001, 43(12): 2359?2377.

[10] ZHOU X, THOMPSON G E, SCAMANS G M. The influence of surface treatment on filiform corrosion resistance of painted aluminium alloy sheet[J]. Corrosion Science, 2003, 45(8): 1767?1777.

[11] 赵月红, 林乐耘. 不同加工及表面处理状态LF6铝镁合金的深海腐蚀行为[J]. 中国有色金属学报, 2001, 11(1): 27?30.

ZHAO Yue-hong, LIN Le-yun. Corrosion behaviors of LF6 Al-Mg alloy with different processing and surface treatment in deep seawater[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 27?30.

[12] LAZAREVIC Z Z, MISKOVIC-STANKOVIC V B, KACAREVIC-POPOVIC Z, DRAZIC D M. Determination of the protective properties of electrodeposited organic epoxy coatings on aluminium and modified aluminium surfaces[J]. Corrosion Science, 2005, 47(3): 823?834.

[13] 肖 刚, 胡 秋, 周 立. 铝型材表面喷砂预处理及其对阳极氧化膜性能的影响[J]. 轻合金加工技术, 2001, 29(8): 38?40.

XIAO Gang, HU Qiu, ZHOU Li. Surface grit blasting pretreatment of aluminium profile and its effect on quality of anodize oxidization film[J]. Light Alloy Fabrication Technology, 2001, 29(8): 38?40.

[14] 黎完模, 宋玉苏, 邓淑珍. 涂装金属的腐蚀[M]. 长沙: 国防科技大学出版社, 2003: 168.

LI Wan-mo, SONG Yu-su, DENG Shu-zhen. Corrosion of the coated metals[M]. Changsha: National University of Defense Technology Press, 2003: 168.

[15] CHANG J C, CHUANG T H. Stress-corrosion cracking susceptibility of the superplastically formed 5083 aluminum alloy in 3.5% NaCl solution[J]. Metallurgical and Materials Transaction A, 1999, 30(12): 3191?3199.

[16] 罗兵辉, 单毅敏, 柏振海. 退火温度对淬火后冷轧5083铝合金组织及腐蚀性能的影响[J]. 中南大学学报: 自然科学版, 2007, 38(5): 802?808.

LUO Bing-hui, SHAN Yi-min, BAI Zhen-hai. Effect of annealing temperature on microstructure and corrosive properties of cold-rolled 5083 aluminum alloy after quenching[J]. Journal of Central South University: Science and Technology, 2007, 38(5): 802?808.

基金项目:国家自然科学基金资助项目(50771089, 50671088);教育部博士点专项科研基金资助项目(20070530006, 20080530005)

收稿日期:2009-05-06;修订日期:2009-12-31

通信作者:易丹青,教授,博士;电话:0731-88836320;E-mail: danqing@mail.csu.edu.cn

(编辑 杨 华)