文章编号:1004-0609(2013)05-1307-08

热处理对喷射沉积Al-27%Si合金显微组织及力学性能的影响

刘文水,王日初,彭超群,莫静贻,朱学卫,彭 健,马如龙

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用喷射沉积和热挤压致密化相结合的方法制备Al-27%Si合金,研究热处理对合金的组织及性能的影响。利用金相显微镜、扫描电镜和MTS-858型疲劳试验机等手段对Al-27%Si合金喷射沉积挤压态和热处理态的显微组织和力学性能进行观察与测试。结果表明:喷射沉积Al-27%Si合金组织细小均匀,初晶Si均匀弥散地分布在连续Al基体中,无针状共晶硅存在;采用合理的热挤压致密化工艺可以显著消除材料中的孔隙,致密度达到99.5%;热处理能够进一步改善材料的组织,但会降低材料的屈服强度。

关键词:喷射沉积;Al-27%Si合金;热挤压;热处理;组织;屈服强度

中图分类号:TG146 文献标志码:A

Effects of heat treatments on microstructures and mechanical properties of spray-deposited Al-27%Si alloy

LIU Wen-shui, WANG Ri-chu, PENG Chao-qun, MO Jing-yi, ZHU Xue-wei, PENG Jian, MA Ru-long

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: A kind of novel packaging material, Al-27% alloy, was prepared by a method comprised of spray deposition and subsequent hot extrusion, then, the effects of heat treatments on the microstructures and mechanical properties of the alloy were studied. The microstructures and mechanical properties of hot extruded and heat treated Al-27%Si alloy were investigated with optical microscope, scanning electronic microscope and MTS-858 type fatigue testing machine. The experimental results show that the spray-deposited Al-27%Si alloy after hot extrusion has fine, homogeneous microstructure with no needle-like eutectic Si but small primary Si particles uniformly dispersed in the Al matrix, besides an increase of size to some degree, even the following heat treatments make little difference to it. Appropriate hot extrusion process can eliminate the porosities remarkably, so as to improve the relative density of the alloy to 99.5%. The microstructures of Al-27%Si experience further improvement after certain heat treatments, while the transformations of mechanical properties are opposite.

Key words: spray deposition; Al-27%Si alloy; hot extrusion; heat treatments; microstructures; yield strength

随着现代电子技术的不断发展,半导体集成电路芯片(IC)的集成度、频率、组装密度以及计算速度日益提高,微型化、轻量化、高功率、高性能、低成本、高稳定性已成为其发展趋势。电子封装在电路中具有支撑电路、密封、散热、屏蔽和导电连接[1-2]等作用,对电路的性能和可靠性具有重要影响,据估计,目前限制芯片工作性能的主要因素中,约30%与电子封装材料有关[3]。电子封装材料对电子系统的工作性能及状态的影响几乎和芯片同等重要,这就要求电子封装材料性能有相应的提升。

热膨胀系数与芯片匹配、良好的散热性能、低密度和一定的力学性能是现代电子封装材料必须满足的基本综合性能。传统电子封装材料由于其固有缺陷,已经难以满足现代电子封装的要求[4]。近年来,人们研发出一种新型环保、易加工的Sip/Al电子封装材料,该材料体系的热膨胀系数与基片材料匹配(7×10–6~ 9×10–6 K–1),热传导率较高(>100 W/(m·K)),密度低(2.4~2.5 g/cm3),刚度较高(>100 GPa),Al相和Si相之间润湿良好,在制备过程中不发生反应形成中间化合物。由于基体在热传导率和增强体在热膨胀系数与密度方面的优势,该材料是一种很有前景的新型电子封装材料。

利用传统熔铸法制备硅铝合金,形成粗大块状或板条状初晶Si与针状Al-Si共晶并存的组织,Si的分布极不均匀,粗大的脆性Si相在压力加工时易断裂产生裂纹,材料的力学性能差,难以进行机械加工等后续处理[5]。粉末冶金过程中Al粉极易发生活泼的氧化,形成一层稳定的氧化膜,在惰性气氛下难以被还原和破碎,对材料内部的各相之间的结合、组织、结构以及宏观综合性能都将产生不利影响。此外,粉末冶金法工序复杂,涉及参数多,难以进行精确控制[6]。利用传统制备工艺难以获得具有理想成分、组织、结构和性能的高硅铝合金。喷射沉积法是近年来材料工作者们开发出的一种新型制备工艺[7],其主要特点是冷却凝固速度快,可以显著减小材料的晶粒尺寸,细化微观组织,获得偏析少或者无偏析的均匀微观组织,优化材料综合性能,为高性能高硅铝合金的研发及应用打开了一个突破口[8-9]。国内外材料工作者们已经在喷射沉积制备高硅铝合金方面做了大量研究,并取得一定成果[10–13]。

Al-27%Si合金热传导性能良好,热膨胀系数和电子元件匹配,屈服强度高,是Al-Si系列电子封装用合金的研究热点之一,极具研究和实用价值。本文作者采用喷射沉积法制备Al-27%Si合金,并对其进行热挤压致密化,研究热挤压态喷射沉积Al-27%Si合金在热处理过程中的显微组织演变及机理,测试热处理后材料的屈服强度,具有重要的研究和实际意义。

1 实验

本实验所用原料为工业纯铝和工业纯Al-50%Si(纯度大于99.7%)中间合金。喷射沉积实验在中南大学金属材料研究所自行设计的往复扫描喷射沉积设备上进行。材料的熔化在感应熔炼炉中进行,采用环缝式气流雾化喷嘴,以高压N2为雾化冷却介质,雾化系统和沉积基底配合方式为斜喷直拉,喷射沉积制备Al-27%Si合金的具体工艺参数如下:倾斜角度为20°~25°,雾化气体压力为0.6MPa,熔体温度为1 273 K,偏心距为20~30 mm,沉积距离为300 mm,喷嘴直径为3 mm,基底旋转速度为500 r/min,下降速度为12.8 mm/min。制得沉积坯后对其进行热挤压致密化处理,工艺参数为:挤压温度480 ℃,挤压比7:1。在热挤压致密化后的喷射沉积Al-27%Si坯锭上切取10 mm×10 mm×3.5 mm试样块进行热处理,温度分别为420、470和560 ℃,在不同的温度下分别保温1、1.5、2和2.5 h。

材料的显微组织观察在XJP-6A宽视野金相显微镜和FEI QUANTA-200扫描电子显微镜上进行;材料密度测量采用阿基米德排水法;材料热处理在箱式电阻炉中进行;材料的拉伸实验在MTS-858型疲劳试验机上进行。

2 结果与讨论

2.1 热挤压对喷射沉积Al-27%Si合金显微组织的影响

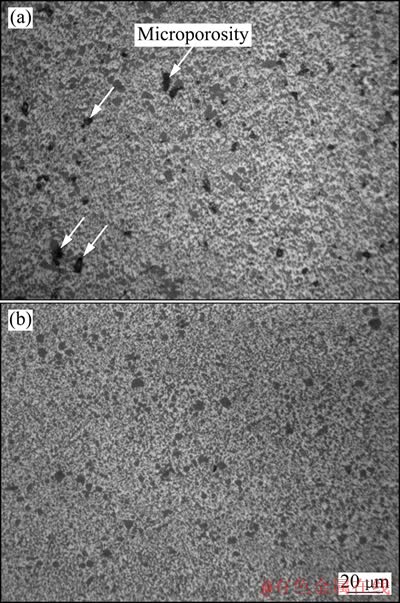

图1所示为喷射沉积Al-27%Si合金经热挤压致密化前后的显微组织。图1(a)所示为喷射沉积态Al-27%Si合金的显微组织,其组织由α(Al)相和Si相组成,细小初晶Si相均匀弥散地分布在α基体中,无常规(Si+α)共晶组织,初晶Si形貌不规则,主要呈颗粒状或块状,尺寸在1~7 μm之间。在喷射沉积快速冷凝条件下,熔体在高压高动量N2作用下破碎雾化成具有一定比例固态、液态和半固态粒子的射流,生成大量达到临界晶核尺寸的晶胚,并发生溶质截留,在Si含量一定的情况下,初晶Si的充分结晶和择优取向生长受到抑制,在沉积阶段,射流在高压气体的作用下不断地高速冲击沉积坯表面半固态熔池,使已经凝固的枝晶Si破碎、变形,Si颗粒数量增加,形成新的非均匀形核核心并结晶长大,从而得到细小均匀的组织[14]。

在喷射沉积成坯过程中,由于凝固颗粒或沉积间空隙、气体卷入、溶解气体的参与以及凝固收缩,坯件中不可避免地存在一些疏松和孔隙[15](如图1(a)中箭头所示),破坏基体连续性,降低材料有效载荷,易引起应力集中,恶化材料使用性能[16]。因此,有必要对喷射沉积高硅铝合金进行致密化处理,消除孔隙,破碎颗粒表面的氧化膜,接近或者达到理论密度,进一步提高材料性能。

图1(b)所示为喷射沉积Al-27%Si合金经热挤压致密化后的显微组织。由图1(b)可知,Si相粒子没有明显长大甚至有小幅度的细化,合金中的疏松和孔隙几乎消失,测试结果表明热挤压后材料致密度达到99.5%。挤压态组织中没有出现纤维带状组织特征。

图1 喷射沉积Al-27%Si合金热挤压前后的显微组织

Fig. 1 Microstructures of as-deposited Al-27%Si alloy (a) before and (b) after hot extrusion

在热挤压三向压应力作用下,延性α相获得足够的流动性填充组织内部的疏松和孔隙。热挤压过程中Si相粒子尺寸主要受两个过程因素的影响:一方面,初晶Si颗粒获取过饱和固溶体中脱溶析出的Si原子长大,较小Si颗粒周围的Si原子在化学势差的作用下向较大Si颗粒周围扩散并在其表面析出[17];另一方面,脆性Si相颗粒在压应力作用下破碎细化。综合结果表现为Si相颗粒尺寸变化不大。脆性相破裂产生的裂纹被高压作用下的延性α相缝合,组织中观察不到明显缺陷。喷射沉积Al-27%Si合金基体组织细小,保温时间较短,在热挤压过程中晶粒形变程度有限,且大量弥散分布的脆性Si相颗粒对其形变也有较强的阻碍作用,材料在热挤压后仍能较好地保持细小均匀各向同性的组织特征。

2.2 热处理对喷射沉积Al-27%Si合金显微组织的影响

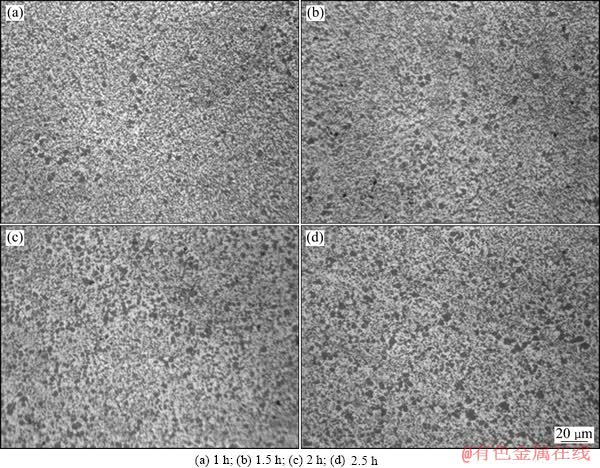

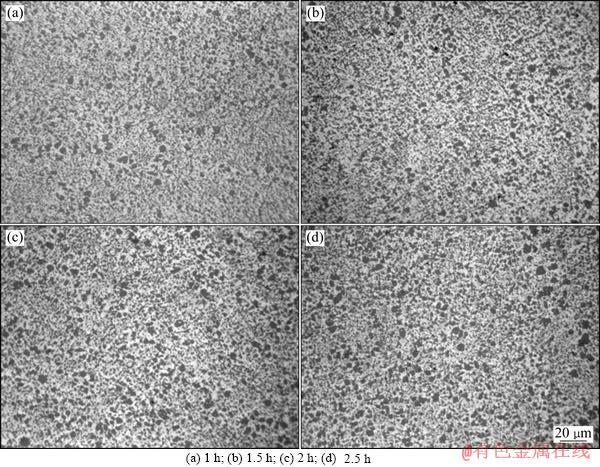

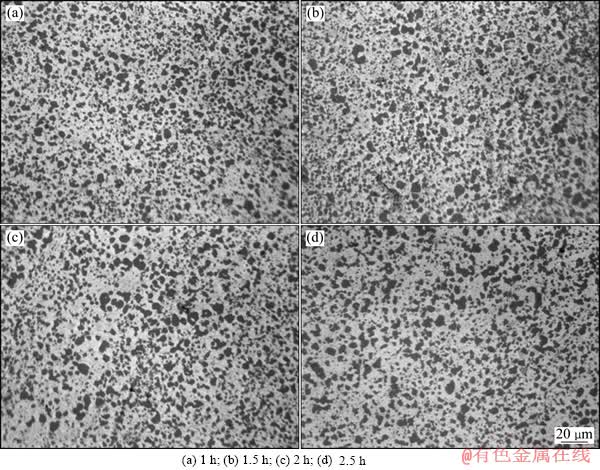

图2~4所示分别为热挤压喷射沉积Al-27%Si合金在420、470和560 ℃下保温1、1.5、2和2.5 h后的显微组织。结合热挤压喷射沉积态显微组织(见图1(a)),比较分析图2~4可知:Al-27%Si合金经不同热处理后仍然保持细小Si相均匀弥散分布在Al基体中的良好组织特征,没有出现针状共晶(Si+α)组织,Si相颗粒最大粒径不超过20 μm。在同一温度下,随着保温时间延长,Si相颗粒粒径逐渐增大,小尺寸Si相颗粒数量减少;保持时间不变,升高温度,材料的显微组织变化也呈现以上演变规律。在420 ℃下保温1 h后,组织变化不明显,可能是由于温度较低,时间过短。Si相颗粒钝化状况良好,球化度较高,在合适的温度和时间下,温度越高,时间越长,该形貌特征越明显,在560 ℃下保温1 h(见图4(a))时,钝化状况和球化度最好,继续升高温度或延长保温时间,较大尺寸Si相颗粒之间开始出现搭接。

图2 热挤压喷射沉积Al-27%Si合金在420 ℃下保温不同时间后的显微组织

Fig. 2 Microstructures of extruded spray-deposited Al-27%Si alloy heated at 420 ℃ for different times

图3 喷射沉积Al-27%Si合金在470 ℃下保温不同时间后的显微组织

Fig. 3 Microstructures of extruded spray-deposited Al-27%Si alloy heated at 470 ℃ for different times

图4 喷射沉积Al-27%Si合金在560 ℃下保温不同时间后的显微组织

Fig. 4 Microstructures of extruded spray-deposited Al-27%Si alloy heated at 560 ℃ for different times

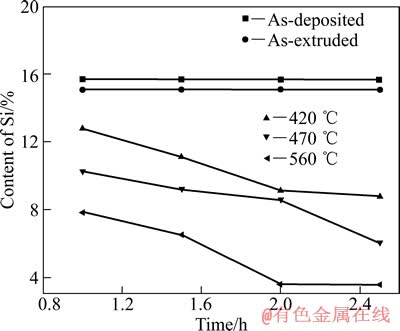

由Al-Si二元相图[18]可知,Al和Si不会发生反应生成化合物,只生成固溶体,Al在Si中几乎不固溶,平衡凝固条件下Si在α基体中的固溶度最多也只有1.59%左右。在喷射沉积非平衡冷凝条件下发生溶质截留,Si 的固溶度上升至10%~16%,固溶度大幅度提高[19],这是喷射沉积Al-27%Si合金在热处理条件下组织发生演变的重要组织基础之一。图5所示为喷射沉积Al-27%Si合金在不同状态下Si的固溶度[20]。由图5可知,Si的固溶度在喷射沉积非平衡快速凝固条件下达到15.66%,热挤压对Si固溶度影响不大,强大的三向压应力抑制Si原子从基体中析出。在同一温度下,Si的固溶度随时间延长而递减;保温时间不变,提高热处理温度,Si的固溶度变化也呈相同规律。在420 ℃下保温2.5 h后,Si的固溶度仍保持8.77%的较高水平;在560 ℃下保温2 h后,Si的固溶度降至3.60%;保温时间为2.5 h时,固溶度为3.57%,说明此时扩散析出过程已基本完成。温度越高,扩散析出驱动力越强,时间越长,扩散析出过程进行得越充分。热挤压喷射沉积Al-27%Si合金经热处理后,Si相尺寸和形貌发生显著变化的原因可能有两个:一是过饱和固溶体中的Si原子扩散析出,能谱分析表明,喷射沉积Al-27%Si合金热挤压后基体中Si的固溶度高达15.06%,在本实验热处理温度下,其平衡固溶度仍远低于该值,过饱和固溶体仍有继续分解的趋势,这与基体能谱分析结果一致;二是小尺寸Si相颗粒周围的Si原子在自由能差的作用下向较大尺寸Si相颗粒周围扩散并析出,最终小尺寸Si颗粒不断消失,较大尺寸Si颗粒进一步长大粗化。

图5 不同热处理后Si在基体中的固溶度[20]

Fig. 5 Solubilities of Si in matrix after different heat treatments[20]

在热处理T温度下,c为α相中原始溶质浓度,cβ和cα分别为Si相和α相的平衡浓度。在α相内部存在一浓度差c-cα,在该浓度差的作用下α相内部的溶质原子发生体扩散,相界处的浓度平衡被破坏,为重新达到平衡,Si原子从Si相附近溶质浓度较高的α相中越过界面进入Si相,宏观表现为Si相粒子析出且其界面向α基体迁移长大。

根据OSTWALD熟化机制,若基体中有两个粒径不同(分别为r1和r2,r1>r2) 的相邻Si相粒子,尺寸较小的Si相粒子比表面积大,分布在其表面的原子分数较大,单位数量脱溶Si相的平均自由能较尺寸大者更高(r1>r2, <

< ),这种自由能正是Si相质点粗化的驱动力。α基体与脱溶Si相平衡时,其固溶度与脱溶Si相颗粒尺寸是密切相关的:当粒径为r1时,α基体固溶度为

),这种自由能正是Si相质点粗化的驱动力。α基体与脱溶Si相平衡时,其固溶度与脱溶Si相颗粒尺寸是密切相关的:当粒径为r1时,α基体固溶度为 ,当粒径为r2时,α基体固溶度为

,当粒径为r2时,α基体固溶度为 ,

, <

< ,这就在尺寸不同Si相颗粒周围的α基体之间产生浓度差。在这种浓度差和α基体中Si的浓度梯度的共同作用下,尺寸较小Si相粒子周围的Si原子向尺寸较大Si相粒子周围扩散并析出,较小质点不断溶解消失,较大质点不断粗化,Si相粒子数量减少。

,这就在尺寸不同Si相颗粒周围的α基体之间产生浓度差。在这种浓度差和α基体中Si的浓度梯度的共同作用下,尺寸较小Si相粒子周围的Si原子向尺寸较大Si相粒子周围扩散并析出,较小质点不断溶解消失,较大质点不断粗化,Si相粒子数量减少。

形貌不规则的Si相颗粒曲率半径小处原子平均界面能和化学势高,与它处于平衡态的母相中的溶质原子浓度也高,曲率半径较小处界面附近的浓度高于曲率半径较大处界面附近的浓度,Si原子在这一浓度差的作用下扩散,不规则形状Si相颗粒钝化,球化度提高,颗粒形貌得到改善。

2.3 热处理对喷射沉积Al-27%Si合金力学性能的影响

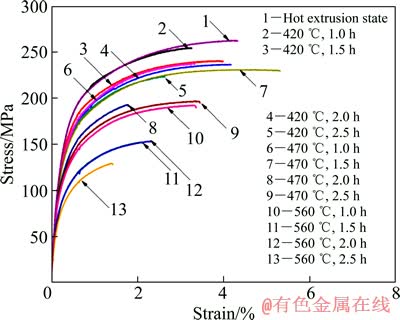

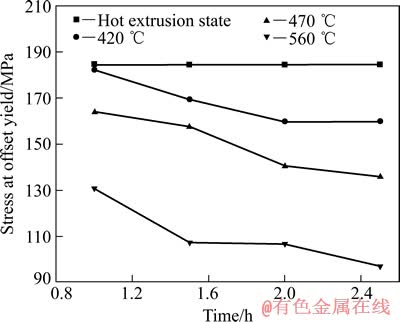

图6和7所示分别为热挤压态喷射沉积Al-27%Si合金及其经不同条件热处理后的拉伸曲线和屈服强度。由图6可知,热挤压态喷射沉积Al-27%Si合金在热处理后,拉伸性能发生了显著变化。由图7可进一步发现,热处理后材料的屈服强度出现不同程度的降低。在同一温度下,随着时间延长,屈服强度降低。在420和470 ℃下,材料保温时间为1、1.5和2 h时,屈服强度下降幅度较大;保温时间超过2 h,屈服强度变化较为平缓,在420 ℃下保温2.5 h后,屈服强度与2 h时几乎相同;在560 ℃下,材料的屈服强度保温1.5 h后已趋于稳定,保温2 h后的屈服强度与1.5 h时的相当,进一步延长保温时间,Si相粒子之间开始出现搭接现象,屈服强度突然出现较大幅度下降;在同一时间下,随着温度升高,屈服强度也呈降低趋势。改变时间或温度,屈服强度都会产生明显变化。

在热挤压喷射沉积Al-27%Si合金中,影响材料力学性能的主要因素有: 1) 合金组元的相应力学性能;2) Si相的含量、尺寸、形貌和分布;3) 固溶度和位错等。Al和Si的力学性能参数相对稳定,本文作者以喷射沉积Al-27%Si合金为研究对象,各状态下Si相颗粒边沿较为圆滑,钝化状况良好,在此主要讨论Si相的尺寸、分布及材料内部缺陷对材料力学性能的影响。

合金的屈服强度与晶粒尺寸满足HALL-PETCH关系式:

σy=σi+kyd -1/2 (1)

式中:σy为合金的屈服强度,σi和ky均为与材料相关的常数,d为晶粒直径。由式(1)可知,材料组织越细小,强度越高。喷射沉积Al-27%Si的显微组织观察表明,材料组织细小均匀,小尺寸初晶Si均匀弥散地分布在α基体中,Si相尺寸不超过10 μm,晶界能够阻滞位错滑移,晶粒越细,分布越均匀,Al-Si界面越多,这种阻滞效应越强,材料的强度越高。

图6 热挤压喷射沉积Al-27%Si合金及其热处理后的拉伸曲线

Fig. 6 Tensile curves of extruded spray-deposited Al-27% Si alloy before and after different heat treatments

喷射沉积使Al-27%Si能够获得大量细小脆性第二相Si颗粒均匀弥散地分布在延性Al基体中的理想组织,位错在组织中的运动符合OROWAN机制,位错绕过脆性Si颗粒所需的临界切应力主要受粒子尺寸及其相互间距的影响,满足以下关系式:

Δτ≈Gb/d∝αf-1/2r-1 (2)

式中:Δτ为临界切应力,G为切变模量,b为柏氏矢量的模,d为粒子间距,α为与位错类型相关的常量(刃型位错时α为0.093,螺型位错时为0.14),f和r分别为第二相粒子的体积分数和半径。由式(2)可知,在体积分数一定的条件下,粒子间距d和粒子半径r越小,强化效应越明显,材料的屈服强度越高。根据OROWAN机制,位错每绕过一个粒子都会留下一个位错环,位错环的存在能进一步减小第二相粒子间距,后续位错绕过粒子的阻力增大,进一步提高材料的强度。

图7 热挤压喷射沉积Al-27%Si合金热处理前后的屈服强度

Fig. 7 Yield strength of extruded spray-deposited Al-27%Si alloy before and after heat treatments

喷射沉积非平衡凝固条件下形成Si固溶在α基体中的过饱和固溶体,Al和Si的晶格常数不同,在Al晶胞中产生点缺陷,阻碍位错的运动,提高材料的强度。文献[21]指出,FRIEDEL与FLEISCHER等研究了屈服应力τc与固溶体中溶质浓度c的关系,结果表明:τ∝c1/2。

Al和Si的热膨胀系数分别为23.6×10-6和4.1×10-6 K-1,在喷射沉积快速凝固和热挤压等过程中,材料因形变不一致和外应力作用产生大量位错,位错和缺陷阻滞在界面处大量增殖并相互缠结产生位错强化效应。

在热处理过程中,Si从过饱和固溶α基体中析出,过饱和度降低,较大Si颗粒吞并较小Si颗粒进一步粗化,Si颗粒的平均尺寸增大,数量减少,Si颗粒之间的平均间距增大,固溶强化、第二相沉淀强化和细晶强化效应减弱;Al合金的堆垛层错能较高而位错分裂较少,在热处理过程中位错易滑移、攀移、重新组合,异号位错对消,位错密度降低,位错强化效应也减弱,材料的屈服强度降低。

3 结论

1) 喷射沉积Al-27%Si合金显微组织细小均匀,细小初晶Si颗粒边角钝化状况良好,弥散地分布在α(Al)基体中,无常规针状(Si+α)共晶组织出现,基体相晶界不明显。

2) 喷射沉积Al-27%Si合金组织中有一定小尺寸的疏松和孔隙,严重影响合金的性能,对其进行合适的热挤压致密化处理可有效地消减疏松和孔隙,经热挤压后材料的致密度可达99.5%。

3) 在热处理过程中,过饱和α(Al)基体中的Si逐渐脱溶析出,较大尺寸的Si相颗粒逐渐“吞并”较小尺寸的Si相颗粒而长大;温度越高,时间越长,脱溶析出进行得越完全,较大尺寸的Si相颗粒粗化越明显;温度过高,保温时间过长,Si相颗粒之间出现搭接现象。

4) 喷热挤压喷射沉积Al-27%Si合金的屈服强度在热处理后降低。时间越长,温度越高,合金的屈服强度越低。

REFERENCES

[1] 王晓峰, 赵九洲, 田 冲. 喷射沉积制备新型电子封装材料70%Si-Al的研究[J]. 金属学报, 2005, 41(12): 1277-1279.

WANG Xiao-feng, ZHAO Jiu-zhou, TIAN Chong. Study of novel electronic packaging material 70%Si-Al prepared by the spray deposition[J]. Acta Metallurgica Sinica, 2005, 41(12): 1277-1279.

[2] 李志辉, 张永安, 熊柏青, 朱宝宏, 刘红伟, 王 锋, 魏衍广, 张济山. 快速凝固硅铝合金材料的组织与性能[J]. 稀有金属材料与工程, 2010, 39(9): 1659-1663.

LI Zhi-hui, ZHANG Yong-an, XIONG Bai-qing, ZHU Bao-hong, LIU Hong-wei, WANG Feng, WEI Yan-guang, ZHANG Ji-shan. Microstructure and properties of rapidly solidified silicon-aluminum alloy materials[J]. Rare Metal Materials and Engineering, 2010, 39(9): 1659-1663.

[3] 蔡 杨, 郑子樵, 李世晨, 冯 曦. 轻质Si-Al电子封装材料制备工艺的研究[J]. 粉末冶金技术, 2004, 22(3): 168-172.

CAI Yang, ZHENG Zi-qiao, LI Shi-chen, FENG Xi. The technique and mechanism to fabricate lightweight Si-Al composites for electronic packaging[J]. Powder Metallurgy Technology, 2004, 22(3): 168-172.

[4] 王敬欣, 张永安. 应用于电子封装的新型硅铝合金的研究与开发[J]. 材料导报, 2001, 15(6): 18-21.

WANG Jing-xin, ZHANG Yong-an. Research and development of novel aluminium-silicon alloys for electronic packaging[J]. Materials Review, 2001, 15(6): 18-21.

[5] 刘红伟, 张永安, 朱宝宏, 王 锋, 魏衍广, 熊柏青. 喷射成形70Si30Al 电子封装材料致密化处理及组织性能研究[J]. 稀有金属2007, 312(4): 446-450.

LIU Hong-wei, ZHANG Yong-an, ZHU Bao-hong, WANG Feng, WEI Yan-guang, XIONG Bai-qing. Research on densification processing, microstructure and properties of spray-formed 70Si30Al alloys used for electronic packaging[J]. Chinese Journal of Rare Metals, 2007, 312(4): 446-450.

[6] 张济山. 新型喷射成形轻质、高热导、低膨胀Si-Al电子封装材料[J]. 材料导报, 2002, 16(9): 1-4.

ZHANG Ji-shan. New spray formed light-weighted Al-Si electronic packaging materials with low thermal expansion and high heat conducting[J]. Materials Review, 2002, 16(9): 1-4.

[7] SINGER A. Spray forming of metals [P]. British Patent: 1262471, 1972-02-12.

[8] 张 建, 赵润娴, 刘 杰, 崔宏祥, 毕大森. 喷射沉积硅铝合金组织结构与性能的分析[J]. 有色金属, 2004, 56(3): 1-3.

ZHANG Jian, ZHAO Run-xian, LIU Jie, CIU Hong-xiang, BI Da-sen. Texture and property of spraying deposition Si-Al alloy[J]. Nonferrous Metals, 2004, 56(3): 1-3.

[9] 田 冲, 陈桂云, 杨 林, 赵九洲, 张永昌. 喷射沉积新型电子封装用70%Si-Al材料的研究[J]. 粉末冶金技术, 2005, 23(2): 108-111.

TIAN Chong, CHEN Gui-yun, YANG Lin, ZHAO Jiu-zhou, ZHANG Yong-chang. Study of novel 70 %Si-Al alloy for electronic packaging prepared by the spray deposition technique[J]. Powder Metallurgy Technology, 2005, 23(2): 108-111.

[10] CUI C,SCHULZ A, SCHIMANSKI K, ZOCH H W. Spray forming of hypereutectic Al-Si alloys[J]. Journal of Materials Processing Technology, 2009, 209(11): 5220-5228

[11] WANG Feng, XIONG Bai-qing, ZHANG Yong-an,ZHU Bao-hong,LIU Hong-wei,WEI Yan-guang. Microstructure, thermo-physical and mechanical properties of spray-deposited Si-30Al alloy for electronic packaging application[J]. Materials Characterization, 2008, 59(10): 1455-1457.

[12] 刘红伟, 朱宝宏, 张永安, 熊柏青. 喷射成形70Si30Al合金的显微组织与性能[J]. 稀有金属, 2009, 33(5): 742-745.

LIU Hong-wei, ZHU Bao-hong, ZHANG Yong-an, XIONG Bai-qing. Microstructure and properties of spray-formed 70Si30Al alloy[J]. Chinese Journal of Rare Metals, 2009, 33(5): 742-745.

[13] JACOBSON D M, OGILVY A J W. Spray-deposited Al-Si (Osprey CE) alloys and their Properties[J]. Materials Science and Engineering Technology, 2003, 34(4): 381-384.

[14] CHIANG C H, TSAO C Y A. Si coarsening of spray-formed high loading hypereutectic Al-Si alloys in the semisolid state[J]. Materials Science and Engineering, 2005, 396(1/2): 263-270.

[15] 彭超群. 喷射成形技术[M]. 长沙: 中南大学出版社, 2004.

PENG Chao-qun. Technology of spray forming[M]. Changsha: Central South University Press, 2004.

[16] CHIEN C W,LEE S L,LIN J C,JAHN M T. Effects of SiP size and volume fraction on properties of Al/SiP composites[J]. Materials Letters, 2002, 52(4/5): 334-341.

[17] R.W.卡恩, 物理金属学[M]. 北京:科学出版社, 1985.

[18] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. England: William Clowes & Sons Limited, 1976: 368-372.

[19] 张大童, 李元元, 罗宗强. 快速凝固过共晶铝硅合金材料的研究进展[J]. 轻合金加工技术, 2001, 29(2): 1-6.

ZHANG Da-tong, LI Yuan-yuan, LUO Zong-qiang. A review on the progress of rapidly solidified hypereutectic Al-Si alloy materials[J]. 2001, 29(2): 1-6.

[20] 李松瑞, 周善初, 田荣璋. 金属热处理[M]. 长沙: 中南大学出版社, 2003.

LI Rui-song, ZHOU Shan-chu, TIAN Rong-zhang. Heat treatment of metal[M]. Changsha: Central South University Press, 2005.

[21] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005.

ZHENG Zi-qiao. Foundation of materials science[M]. Changsha: Central South University Press, 2005.

(编辑 何学锋)

基金项目:国家军品配套项目(JPPT-125-GH-039)

收稿日期:2012-07-11;修订日期:2012-12-15

通信作者:王日初,教授,博士;电话:0731-88836638;E-mail:wrc910103@163.com