文章编号:1004-0609(2013)05-1471-08

富氧底吹熔炼炉内氧枪结构参数的优化分析

张振扬1, 2,闫红杰1,刘方侃1,王计敏1, 3

(1. 中南大学 能源科学与工程学院,长沙 410083;

2. 三一重工 泵送事业部,长沙 410100;

3. 安徽工业大学 冶金与资源学院,马鞍山 243002)

摘 要:以提高底吹熔炼炉反应区的熔炼效率及优化底吹炉反应区的氧枪结构参数为目标,运用数值模拟的方法,建立底吹熔池熔炼炉内气液两相流动的三维数学模型。应用正交表设计数值模拟的试验方案,以气含率、熔池内熔体平均速度以及平均湍动能为优化指标,采用田口方法对底吹熔池熔炼炉进行了氧枪结构多目标优化研究。结果表明,通过统计分析方法得到氧枪结构最优组合如下:氧枪直径为0.06 m,氧枪间距为0.98 m,氧枪倾角为17°。对优化结果进行统计验证,表明采用田口方法优化底吹炉氧枪结构可行,优化结果可靠。

关键词:底吹熔炼炉;氧枪结构;田口方法;多目标优化

中图分类号:TF811 文献标志码:A

Optimization analysis of lance structure parameters in oxygen enriched bottom-blown furnace

ZHANG Zhen-yang1, 2, YAN Hong-jie1, LIU Fang-kan1, WANG Ji-min1, 3

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Pumping Division, Sany Heavy Industry, Changsha 410100, China;

3. Institute of Metallurgy and Resources, Anhui University of Technology, Ma’anshan 243002, China)

Abstract: In order to improve the reaction rate and optimize the lance structure of the bottom-blown furnace, a three- dimensional gas/liquid two-phase flow model was established by employing numerical simulation method. By applying the gas holdup, the mean velocity and turbulent kinetic energy of the melt as optimum indexes in bottom-blown furnace, an orthogonal array was selected as the computational fluid dynamics (CFD) experimental plan and the multiple-objective optimization of the lance parameters in bottom-blown furnace was studied employing Taguchi design method. The results show that the optimal parameters of lance were determined by statistical analysis method and the optimal combination can be achieved with the lance size of 0.06 m, the lance spacing of 0.98 m and the lance angle of 17°. The results of statistical validation show that the optimization method is feasible and the optimization results are available.

Key words: bottom-blown furnace; Taguchi design method; lance structure; multiple-objective optimization

底吹熔池熔炼技术广泛应用于冶金过程中,如铜、铅、锌等有色金属的熔炼。熔池熔炼过程是一个包含传热、传质以及化学反应等复杂的多相流动过程,整个过程处于非平衡、非均一、非稳定和非线性的“四非”状态。各过程之间相互耦合,相互影响,很难通过测试或者实验的方法对其内部各种参数进行研究,因此,前期的研究主要借助于水模型实验法对熔池熔炼炉进行相关的研究[1]。ZHONG等[2-5]通过建立顶底侧吹转炉吹炼物理模型,研究了顶底侧吹工艺参数对顶底侧吹转炉熔池搅拌混匀的影响。ZHOU等[6]以流动相似理论和自模化理论为理论基础,以底吹炉水模型为研究对象,研究了底吹熔炼炉内流动特征,分析了影响气泡直径的因素,如超过临界速度后的喷射锥的形成及运动状态,喷嘴对气泡形成及脱离喷嘴后运动的影响。然而,现场试验研究方法非常耗时耗力且费用昂贵,水模型实验结果在实际应用过程中有很大的局限性。

随着计算机技术及数值计算方法的迅速发展,计算流体动力学(Computational fluid dynamics,CFD)是一种能够真实揭示熔炼炉内流场、温度场和浓度场分布情况的有效方法。因此,许多学者[7-9]开始运用CFD技术对熔炼炉内流场及温度场进行数值模拟研究。HUDA等[10] 应用CFD方法研究了顶吹锌还原熔炼炉内流场、温度场、化学反应过程,研究表明,熔池反应效率与气液两相的接触面积有着很重要的影响。此外,熔池熔炼炉内喷溅现象对熔炼炉寿命影响很大,因此PAN和LANGBERG[11]通过实验和数值模拟技术对熔炼炉内喷溅现象进行了研究。通过以上文献可知,前述研究内容主要集中于熔炼炉内各场的分布情况分析以及操作参数对熔炼过程的影响分析,对影响熔池熔炼过程的氧枪结构参数及其布置方式未进行过具体系统的研究,且传统上对熔炼炉工艺参数的影响分析主要通过“单因素轮换试验法”来实现,由此得到适当的参数。这不仅耗时耗力,而且由于忽略因素之间的相互作用,通常无法得到各因素的最佳组合。而田口方法是一种集安排试验和评估多因素影响分析于一体的试验设计方法,它能够通过有限的试验次数得到预期的最优参数组合。近几年来,田口方法作为迅速找出最优方案手段已经在各个领域得到广泛和成功的应用[12-13]。而通过田口方法对氧气底吹熔炼炉的氧枪结构进行优化的研究迄今尚未发现相关的理论及数值模拟的研究报道。

本文作者首先以底吹熔炼炉为研究对象,通过水模型实验与数值模拟相结合的方法对所建数学模型的可靠性进行验证,然后根据影响底吹熔池熔炼过程的特性要因,以反应区为研究重点,基于正交表设计数值模拟方案,对影响底吹熔池熔炼性能的氧枪结构参数进行基于田口方法的多目标优化研究,得出氧枪结构最优组合,为底吹熔炼炉的结构设计、生产控制优化提供依据和指导。

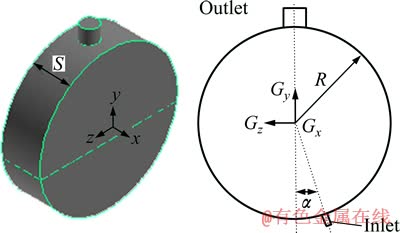

1 研究对象及其网格划分

根据生产实践可知[14],氧枪双排布置有波动叠加问题,在铅锌冶炼过程中,多采用单排布置,因此本研究以单排氧枪设计方式作为研究重点进行底吹炉反应区氧枪结构参数的计算分析。底吹熔炼炉反应区单氧枪模型示意图如图1所示,其中S为氧枪间距,R为熔炼炉半径,α为氧枪倾角。入口气体为可压缩氧气,质量流量为0.48 kg/s,湍流强度为3.2%;出口为压力出口,大小为-10 Pa,湍流强度为4.6%。铜熔池熔炼炉内主要是铜锍和渣,熔体总高度为1.5 m,其中上部为0.25 m渣层,下部为1.25 m铜锍,铜锍的参数如表1所示。

图1 反应区单氧枪模型图

Fig. 1 Sketch of single lance model in reation zone

由于氧枪入口及烟气出口区流速较大,且氧枪与炉体的结构悬殊较大,因此在对底吹熔炼炉进行网格划分时,采用尺寸函数来控制整个模型的网格划分,对熔体区、氧枪出口及烟气出口区进行局部加密。为了保证计算精度并加快收敛速度,最终控制网格数为40×104~50×104,时间步长为0.000 5 s,并通过软件自带的自适应性网格的修改功能获得不依赖于网格的解。

表1 铜锍参数

Table 1 Parameters of copper-matte

2 数学模型及模型验证

2.1 模型简化与假设

1) 由于底吹熔炼炉反应区对熔炼过程有着重要的影响且氧枪等间距布置,截取其中一单氧枪模型作为研究对象,不但可以节约计算时间,而且具有代表性。

2) 由于熔炼过程处于一个相对稳定的状态,且本研究主要关注炉内多相流动过程,因此本研究中不考虑化学反应,设熔池内熔体温度均匀分布。

3) 静止熔体初始高度为1.5 m,忽略渣的影响,假设熔池内熔体为铜锍。

4) 将固体壁面看作无滑移边界,靠近壁面处的边界层内,采用标准的壁函数进行处理。

2.2 数学模型

应用VOF模型来追踪气液两相界面,描述VOF两相流模型的基本控制方程如下。

1) 体积分数方程

在VOF模型中,通过求解各相(本研究中为气、液两相)体积分数的连续性方程来实现对各相相界面的追踪。气、液相体积分数的连续性方程分别如式(1)、式(2)所示:

(1)

(1)

(2)

(2)

式中: 是单位时间单位体积内气相到液相的质量输送,kg/(m3·s);

是单位时间单位体积内气相到液相的质量输送,kg/(m3·s); 是单位时间单位体积内液相到气相的质量输送, kg/(m3·s);aq和ay分别为气相和液相的体积分数;

是单位时间单位体积内液相到气相的质量输送, kg/(m3·s);aq和ay分别为气相和液相的体积分数; 和

和 分别为气相和液相的源相,默认情况下为0;Uq和Uy分别为气相和液相的速度,m/s;ρq和ρy分别为气相和液相的密度,kg/m3;

分别为气相和液相的源相,默认情况下为0;Uq和Uy分别为气相和液相的速度,m/s;ρq和ρy分别为气相和液相的密度,kg/m3; 表达为

表达为 ;对于一个矢量Φ函数,

;对于一个矢量Φ函数, 表示为Φ的散度。

表示为Φ的散度。

2) 动量方程

通过求解整个区域内单一的动量方程,作为结果的速度场是由各相共享的,如式(3)所示。

(3)

(3)

式中:p′为修正压力,Pa;B为作用于控制容积上的体积力,N;U为流体速度,m/s;μeff为有效黏度,Pa·s;上标T为矩阵转置操作符; 为并矢,

为并矢,

式中:(uij+uji)为应变率张量E;(uij-uji)为旋转角速度Ω; 为两速度矢量张量乘积:

为两速度矢量张量乘积:

由于底吹熔池熔炼过程中的高压富氧空气由氧枪进入熔池时为圆柱射流且在铜锍区域形成漩涡,因此采用目前应用最广泛的k-ε湍流模型模拟这类流动,该模型成功地模拟了许多复杂的流动问题。在k-ε模型中,标准k-ε模型是一种高雷诺数的模型,只适合于模拟完全湍流的流动过程;RNG理论提供了一个考虑低雷诺数流动粘性的解析公式,且RNGk-ε湍流模型中考虑了平均流动中的旋转及旋流流动情况,可以更好地处理高应变率及流线弯曲程度较大流动,使得RNGk-ε模型具有更高的可信度和精度。根据前人的研究结果,引入VOF模型后,由RNGk-ε模型模拟出的结果与实测值吻合良好[15-17]。鉴于以上原因,采用RNGk-ε模型对底吹炉内湍流过程进行模拟。

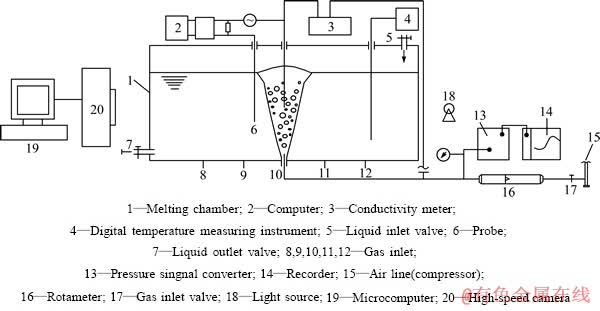

为验证本研究所建立的数值模型的可靠性,利用前面所介绍的数学模型及数值模拟的方法,对水模型试验装置(见图2)中水-氮气两相流动过程进行数学建模与数值计算,并将计算结果与实验结果进行定性与定量分析,以此来对所用模型进行验证。模型以某公司富氧底吹熔炼炉为原型,尺寸比例为1:10, 模型尺寸及实验参数如表2所列。

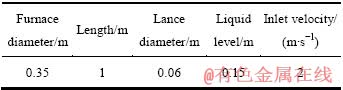

表2 模型尺寸及实验参数

Table 2 Model dimensions and experimental parameters

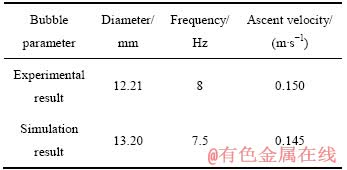

通过对底吹熔炼炉水模型实验的数值模拟结果与实验结果进行定性比较分析可以看出:实验与数值模拟所得到的气泡运动过程结果基本一致[18],同时对模型中气泡相关重要参数进行了定量的比较分析,其结果如表3所列。

图2 水模型实验整体装置图

Fig. 2 Schematic diagram of experimental set-up for water model

从表3中可以看出,模型中气泡参数的数值仿真结果与实验结果相比,各参数存在不同程度的误差。其中气泡直径、频率及上浮速度的误差分别为8.1%、-6.2%和-3.3%。通过对底吹熔炼炉水模型数值模拟结果与实验结果的定性和定量分析比较可以看出:气泡运动规律一致,实验所得到的结果与数值模拟所得到的结果基本吻合,说明本文作者所采用的模型与方法能够较准确地模拟底吹熔炼炉内气液两相流动情况。

表3 数值模拟结果与实验结果的比较

Table 3 Comparison of simulation results with experimental data

3 田口方法的试验设计

田口方法是在试验设计原理的基础之上发展起来的,也称三次设计(系统设计,参数设计,容差设计),是一种统计技术和工程技术相结合的技术[19]。田口方法的主要工具是信噪比和正交表,参数设计是该方法的核心,其主要特点是引进信噪比作为判别产品质量特性是否稳健的指标,结合正交表及统计分析,找出最优组合,提高产品质量。本研究首先确立各影响因素及其水平,随后确立优化指标及其指标权重,整理出无量纲化综合优化指标,并以此为基础进行信噪比分析,确立最优组合。

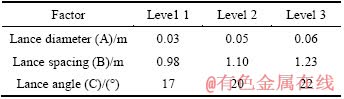

3.1 试验安排及影响因素水平的选定

依据田口品质工程法原则[20],结合底吹铜熔池熔炼相关工艺知识,确定熔炼炉反应区氧枪直径、氧枪倾角及氧枪间距为可控因素。结合对氧枪倾角、氧枪直径及氧枪间距各因素对底吹铜熔池熔炼过程的单因素影响分析结果[21],对三因素进行组合优化。各因素均采用三水平,各因素水平配置见表4。

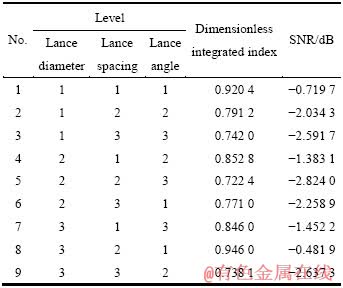

在田口方法中,不仅需要考虑可控因素,还应该考虑不可控因素,即噪声因素,但在本数值模拟试验中,如果考虑其他因素,则计算量非常大,因此本研究不考虑噪声因素。正交试验的安排选用L9(33)进行试验,试验正交表见表5。

3.2 优化指标及其权重的确定

通过对各次数值模拟试验结果的分析,发现熔池熔炼效率与气含率、熔池平均速度及熔池平均湍动能有关[21]。一方面,提高熔池气含率,可提高气液接触面积,促进氧气与物料之间的反应;另一方面,提高熔池反应区内部熔体平均速度,可以加速物料与高温熔体的混合,防止物料过冷,影响化学反应的进行;其次,提高反应区熔池平均湍动能,有利于熔池内部大气团的破碎,增大气相与熔体的接触面积,有利于熔池熔炼过程的快速进行。故选取熔池内部气含率、熔池平均速度及熔池平均湍动能进行静态特性信噪比的多指标评价分析。

表4 因素水平配置表

Table 4 Levels of each factor

表5 正交试验表及优化指标

Table 5 Orthogonal table and evaluation criteria

为了实现底吹熔炼炉的多目标优化,优化指标需要统一量度,然后通过各指标的权重转化为综合指标,故需对气含率、质量平均速度及质量平均湍动能进行无量纲化处理,本研究采用的方法为:各优化指标与其相应的最大值的比值作为无量纲化方式。在底吹熔池熔炼过程中,各个优化指标的重要程度有所不同,对于综合指标的影响也不同,为此通过建立模糊判断矩阵的方法可确定各个优化指标的相对重要性,进而确定各个优化指标在综合指标中所占的权重[22]。判断矩阵的形式如下:

式中:aij表示第i个因素相对于第j个因素的权重之比的最小值;反之,bij表示第i个因素相对于第j个因素的权重之比的最大值;aij、bij一般取1~9之间的数值;aji、bji则分别取其倒数。以w来代表权重,则有判断矩阵可得: 。试验选取的优化指标为气含率、平均速度和平均湍动能,其权重分别以w1、w2和w3来表示。经过分析比较,得到3个优化指标权重之间的模糊判断矩阵:

。试验选取的优化指标为气含率、平均速度和平均湍动能,其权重分别以w1、w2和w3来表示。经过分析比较,得到3个优化指标权重之间的模糊判断矩阵:

通过引入变量w0,依据判断矩阵构造如式(4)的线性规划,进行求解,得到优化指标的权重向量为w={ w1, w2, w3}={0.505, 0.330, 0.165},w0=0.165。

Max z=w0 (4)

根据各优化指标的权重得到各组数值模拟试验结果的无量纲综合优化指标见表5。

4 结果讨论与验证

4.1 各因素影响统计分析

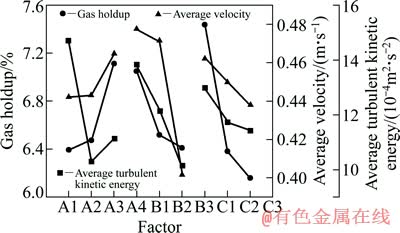

通过对9组试验进行数值模拟,可得出各因素水平对优化指标的影响。其中因素A(氧枪直径)、B(氧枪间距)、C(氧枪倾角)各水平对熔池内气含率、平均速度、平均湍动能大小的响应图如图3所示。

从图3可以看出:

1) 熔池内气含率及平均速度随着氧枪直径的增大而增大。随着氧枪直径的增大,脱离氧枪出口时气团直径增大,一方面提升了上浮过程中气团夹带周围熔体的能力,增大熔池熔体平均速度;另一方面气团在上浮过程中气团破碎回流到熔池的概率增大,增大了熔池内部的气含率。熔池内平均湍动能大小与熔体的脉动大小有关,是衡量湍流混合能力的重要指标。在入口流量一定的条件下,脱离氧枪出口时单气团直径的增大,气团生成频率减小,这总体上减弱了气相引起熔体湍流速度涨落作用。

2) 随着氧枪间距的增大,3个优化指标逐渐减小,当氧枪间距为水平B1时,3个优化指标同时达到最大值。在熔池熔炼过程中,合理的氧枪间距有利于保持熔池反应区良好的搅拌状态,有效地利用气相所产生的搅动能,防止反应区死区的存在。氧枪间距的增大,两氧枪之间的影响逐渐变小,在氧枪之间区域所受到的扰动减弱,其卷吸上层物料及周围气团的能力减弱。整个熔池内的平均速度及湍动能减小,不利于熔炼过程的进行。

3) 底吹熔炼炉内氧枪倾角的增大,一方面缩短气团的上浮路程,另一方面减小气团在垂直方向上速度分量,增大其在水平方向的速度分量。当氧枪倾角水平为C1时,各指标同时达到最大值。气团上浮路程的增大,增加了气相在熔池内的停留时间,增大了熔池气含率。而垂直方向上速度的增大,有利于提高气相夹带熔体向上运动的能力,增强熔池内部的扰动,增大熔池内部熔体的平均速度和平均湍动能。

图3 各因素对熔池气含率、平均速度及湍动能的响应图

Fig. 3 Effect on every factor of gas holdup, average velocity and turbulent kinetic energy of bath

4.2 信噪比分析

信噪比(SNR)原本是通信领域的一种指标,在参数设计中,将其引进作为评价设计优劣的一种测度。信噪比越大,该水平越好,信噪比的极差(最大值与最小值之间的差值)越大,说明该因子对熔炼性能的影响水平就越高。

其中气含率、熔池平均速度及熔池平均湍动能均具有望大特性,故由综合指标按计算式(5)可知:综合指标也具有望大特性。望大特性的S/N比计算公式如(6)所示。

(5)

(5)

(6)

(6)

式中:w1、w2和w3 为指标权重;n为每组工况下试验次数,本试验取1。

为得出各因素水平对综合指标的响应值,获得各因素的最佳组合,根据式(6)计算9组试验中各因素水平对综合优化指标的信噪比,可得各控制因素对综合指标的信噪比效应图如图4所示。

从图4可以推知:1) 当因素A取A3时,S/N达到最大值,故取A3为最佳值;2) 当因素B分别取B1时,其SNR达到最大值,因此取B1为最佳值;3) 当因素C分别取C1时,其SNR达到最大值,因此取C1为最佳值。

图4 各控制因素水平对综合控制指标的信噪比的响应图

Fig. 4 Effect of integrated control index on SNR of every factor

为了了解各因素对富氧底吹熔炼炉熔炼效率影响作用的主次,利用数值模拟数据整理出三因素对信噪比的贡献率(Rc),贡献率的计算公式如下:

(7)

(7)

式中:j表示第j个控制因素;m为控制因数的总数;极差为( )。贡献率越大,说明该因素对熔炼性能的影响就越大。

)。贡献率越大,说明该因素对熔炼性能的影响就越大。

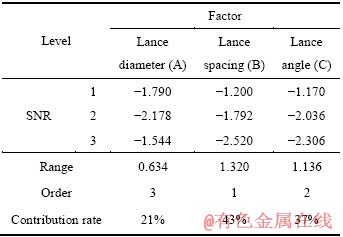

各因素对综合指标的S/N比和均值的贡献率见表6。依据试验结果,氧枪间距、氧枪角度和氧枪直径对熔炼过程的优化指标都有重要影响,尤其是氧枪间距和氧枪倾角的影响较大。因此通过各因素对综合指标的S/N比的贡献率的比较,得出各控制因素对优化指标影响作用由大到小的顺序为氧枪间距、氧枪角度、氧枪直径。通过信噪比分析和极差分析,推定本试验最佳优化参数组合为:A3B1C1, 即氧枪直径为0.06 m,氧枪倾角为17°,氧枪间距为0.98 m。

表6 各控制因素对综合指标的信噪比响应表

Table 6 Effect of integrated control index on SNR of every factor

4.3 试验验证

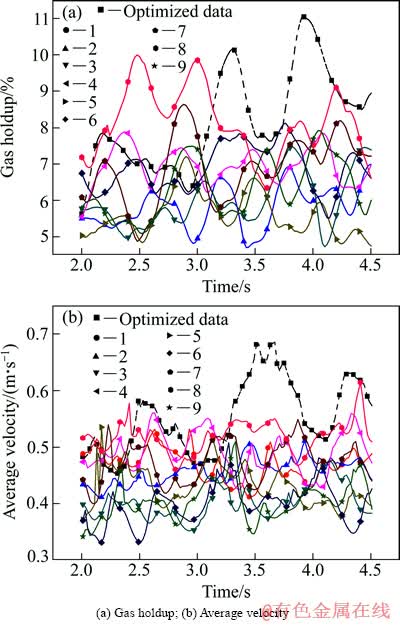

通过对优化组合条件下的熔池熔炼过程进行数值模拟,得出熔炼过程达到动态稳定的时候,熔池内部的气含率、平均速度及湍动能分别为8.32%、0.551 4 m/s和0.001 393 m2/s2。对3个指标进行无量纲化处理,然后结合式(5)和(6)可得优化组合条件下的信噪比为0.002 2 dB。通过对优化结果与正交试验结果进行对比,可知优化后组合的信噪比远大于正交试验中的最大信噪比-0.481 9 dB。对优化后的工况与正交试验中9种工况进行比较,其中气含率与平均速度随时间的变化如图5所示。

当熔池被气相充分搅动起来后,可得到优化组合条件下熔池内平均气含率为8.32%,大于正交试验中的最大值8.1%。增大了熔池气含率,能够有效地增大气相与熔体的接触面积,提高熔池的熔炼效率。优化组合条件下熔池内部的平均速度为0.551 4 m/s,比9组正交试验结果都要大。说明优化组合能够提高熔池的搅拌能力,加速氧枪上部物料进入高温熔体的速率,可提高熔炼炉内料的处理量。通过对优化组合与9组正交试验组合优化指标及信噪比的比较分析,可确认优化组合确实优于其他组合。试验设计准确,优化后所得的组合能提高熔池熔炼过程的工艺性能。

图5 优化组合与正交试验各组合条件下熔池内气含率及平均速度随时间的变化

Fig. 5 Changes of gas holdup and average velocity with time between optimal combination and orthogonal experiment combination

5 结论

1) 对水模型实验的数值模拟结果与实验结果进行定性和定量分析可以看出:数值模拟结果与实验结果的平均误差在5%左右,气泡运动规律一致,实验所得到的结果与数值模拟所得到的结果基本吻合,验证了VOF模型的可用性。

2) 最优的氧枪参数及布置方式组合为A3B1C1,即氧枪直径为0.06 m,氧枪倾角为17°,氧枪间距为0.98 m。各因素对底吹熔池熔炼过程影响程度按由大到小的顺序为氧枪间距、氧枪倾角、氧枪尺寸。

3) 对优化组合下的熔炼炉进行了数值模拟,得到该组合下的熔炼炉的信噪比为0.002 2 dB,大于正交试验中的9种试验结果中的任意项,说明该组合确实优于其他工况。

REFERENCES

[1] ANAGBO P E, BRIMACOMBE J K. Plume characteristics and liquid circulation in gas injection through a porous plug[J]. Metallurgical Transaction B, 1990, 21: 637-648.

[2] ZHONG Liang-cai, LEI Zhe-long, JI Chen-xi, ZHU Ying-xiong, JIANG Mao-fa, CHEN Jun-ying. Physical modeling and optimization of bottom tuyere configuration and blowing parameters in a top and bottom combined blowing converter[J]. Developments in Chemical Engineering and Mineral Processing, 2006, 14(3/4): 343-352.

[3] LAI Z Y, XIE Z, ZHONG L C. Influence of bottom tuyere configuration on bath stirring in a top and bottom combined blown converter[J]. ISIJ Int, 2008, 48(6): 793-798.

[4] ZHONG L C, WANG X, ZHU Y X, CHEN B Y, HUANG B C, KE J X. Bath mixing behavior in top-bottom-side blown convert[J]. Ironmaking & Steelmaking, 2010, 37(8): 578-582.

[5] 钟良才, 朱英雄, 赖兆奕, 陈伯瑜. 顶底侧吹转炉熔池搅拌混匀物理模拟[J]. 东北大学学报: 自然科学版, 2010, 31(6): 843-847.

ZHONG Liang-cai, ZHU Ying-xiong, LAI Zhao-yi, CHEN Bai-yu. Physical modeling of stirring and mixing in bath of top-bottom-side blown converter[J]. Journal of Northeastern University: Natural Science, 2010, 31(6): 843-847.

[6] ZHOU Jie-min, GAO Qiang, LIU Liu, LIU Fang-kan, YAN Hong-jie. Fluid-flow characteristics and critical phenomenon in a bottom blowing bath[J]. Advanced Materials Research, 2012, 402: 365-370.

[7] 罗 雷, 毛小南, 雷文光, 于兰兰, 杨冠军. 电子束冷床熔炼TC4合金温度场模拟[J]. 中国有色金属学报, 2010, 20(S1): 404-409.

LUO Lei, MAO Xiao-nan, LEI Wen-guang, YU Lan-lan, YANG Guan-jun. Temperature field simulation of electron beam cold hearth melting TC4 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 404-409.

[8] 雷文光, 于兰兰, 毛小南, 罗 雷, 张英明, 候智敏. 电子束冷床熔炼TC4钛合金连铸凝固过程数值模拟[J]. 中国有色金属学报, 2010, 20(S1): 381-386.

LEI Wen-guang, YU Lan-lan, MAO Xiao-nan, LUO Lei, ZHANG Ying-ming, HOU Zhi-ming. Numerical simulation of continuous casting solidification process of TC4 titanium alloy during EBCHM[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 381-386.

[9] NAN Wang, SHAN Yu, LEI Shao. Numerical simulation of fluid flow and temperature field of iron-bath reactor[C]//TMS Annual Meeting. San Francisco: Metals & Materials Society, 2009: 653-658.

[10] HUDA N, NASER J, BROOKS G, REUTER M A, MATUSEWICZ R W. Computational fluid dynamic modeling of zinc slag fuming process in top-submerged lance smelting furnace[J]. Metallurgical and Materials Transactions B, 2012, 43(1): 39-55.

[11] PAN Y H, LANGBERG D. Two-dimensional physical and CFD modeling of large gas bubble behavior in bath smelting furnaces[J]. The Journal of Computational Multiphase Flows, 2010, 2(3): 151-164.

[12] JAFARI A, TYNJALA T, MOUSAYI S M, SARKOMAA P. CFD simulation and evaluation of controllable parameters effect on thermomagnetic convection in ferrofluids using Taguchi technique [J]. Computers & Fluids, 2008, 37: 1344-1353.

[13] COMAKLI K, SIMSEK F, COMAKLI O, SAHIN B. Determination of optimum working conditions R22 and R404A refrigerant mixtures in heat-pumps using Taguchi method[J]. Applied Energy, 2009, 86: 2451-2458.

[14] 崔志祥, 申殿邦, 王 智, 李维群, 边瑞民. 高富氧底吹熔池炼铜新工艺[J]. 有色金属, 2010(3): 17-20.

CUI Zhi-xiang, SHEN Dian-bang, WANG Zhi, LI Wei-qun, BIAN Rui-min. New process of copper smelting with oxygen enriched bottom blowing technology[J]. Non-ferrous Metals, 2010(3): 17-20.

[15] HU Xiao-zhou, LIU Shao-jun. Numerical simulation of calm water entry of flatted-bottom seafloor mining tool[J]. Journal of Central South University of Technology, 2011, 18(3): 658-665.

[16] ABBASPOUR A, FARSADIZADEH D, DALIR A H, SADRADDINI A A. Numerical study of hydraulic jumps on corrugated beds using turbulence models[J]. Turkish Journal of Engineering and Environmental Sciences, 2009, 33(1): 61-72.

[17] JALALABADI R, NOURI N M. Numerical simulation of cavitation and aeration in discharge gated tunnel of a dam based on VOF method[J]. Applied Mechanics and Materials, 2012, 110/116: 2754-2761.

[18] 张振扬, 陈 卓, 闫红杰, 刘方侃, 刘 柳, 崔志祥, 申殿邦. 富氧底吹熔炼炉内气液两相流动的数值模拟[J]. 中国有色金属学报, 2012, 22(6): 1826-1834.

ZHANG Zhen-yang, CHEN Zhuo, YAN Hong-jie, LIU Fang-kan, LIU Liu, CUI Zhi-xiang, SHEN Dian-bang. Numerical simulation of gas-liquid flows in oxygen enriched bottom-blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1826-1834.

[19] TAGUCHI G, CHOWDHURY S, WU Y. Taguchi’s quality engineering handbook[M]. Hoboken: John Wiley & Sons, 2005.

[20] 王毓芳, 肖诗唐. 质量改进的策划与实施[M]. 北京: 中国经济出版社, 2005.

WANG Yu-fang, XIAO Shi-tang. Planning and implementation of quality improvement[M]. Beijing: China Economic Press, 2005.

[21] 闫红杰, 刘方侃, 张振扬, 高 强, 刘 柳, 崔志祥, 申殿邦. 氧枪布置方式对底吹熔炼过程的影响[J]. 中国有色金属学报, 2012, 22(8): 2393-2400.

YAN Hong-jie, LIU Fang-kan, ZHANG Zhen-yang, GAO Qiang, LIU Liu, CUI Zhi-xiang, SHEN Dian-bang. Influence of lance arrangement on bottom-blowing bath smelting process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2393-2400.

[22] 张 军. 基于田口方法的多质量特性稳健性设计研究[D]. 上海: 上海交通大学, 2005.

ZHANG Jun. The study of multiple quality characteristics robust design based on Taguchi method[D]. Shanghai: Shanghai Jiao Tong University, 2005.

(编辑 何学锋)

基金项目:国家高技术研究发展计划资助项目(2011AA061003);中南大学自由探索计划资助项目(2011QNZT097)

收稿日期:2012-02-29;修订日期:2013-03-04

通信作者:闫红杰,教授,博士;电话:0731-88830239;E-mail:s-rfy@mail.csu.edu.cn