Application of direct laser metal tooling for AISI H13 tool steel

Hee-Jin JEONG1, Yoong-Ho JUNG2, Deug-Woo LEE3

1. Gyeongbuk Hybrid Technology Institute, Gyeongbuk, 770-170, Korea;

2. School of Mechanical Engineering, Pusan National University, Busan, 609-735, Korea;

3. Department of Nanosystem and Nanoprocess Engineering, Pusan National University, Busan, 609-735, Korea

Received 2 March 2009; accepted 30 May 2009

Abstract: Single carbon nanotubes (CNTs) are candidates for a number of electronics and sensing applications, provided that single CNTs can be separated from a bundle of CNTs in suspension. Dielectrophoresis has recently been demonstrated as one route for the extraction of desired CNTs. However, previous methods using dielectrophoresis have found it difficult to extract single nanotubes from bundles of CNTs in solution. Here, we show that this restriction can be overcome by using pulsed DC voltage of an electric field, instead of regular AC and DC voltages.

Key words: carbon nanotubes; dielectrophoresis; COMSOL; pulsed DC

1 Introduction

Since carbon nanotubes (CNTs) have extraordinary electrical and mechanical properties[1-3], they provide the possibility of new applications, including high-density memories, ultra-thin field emission displays, and fuel cells. In these high-technology devices, the development of suitable technology for bonding a single CNT upright on a targeted position, which is separated from a bundle of CNTs, is essential. Chemical vapor deposition[4] is used to grow a single CNT on a target as a means to bond a single CNT upright at a desired position. It is difficult to control the process and to connect with following processes, as it requires high temperatures. A magnetic manipulation[5] and a self-assembled monolayer method have also been attempted along with a chemical process. However, these methods need expensive and exclusive equipment, and may contaminate the CNTs with chemicals. The dielectrophoresis (DEP) method[1,3,5-6] has advantages of being an easy and simple method for arraying CNTs, and has the possibility of providing a route for low-cost manufacturing, since it can bond CNTs directly to a target position using the forces in the DEP process. To bond a single CNT using the DEP method, an atomic force microscope (AFM) can be used as a manipulator for moving the tip of an electrode in an AC or DC field[7]. A CNT can move in a positive or negative direction in a liquid, depending on the applied electric field. However, the DEP method needs much trial and error to bond a single CNT onto a target position, because many CNTs are attached to the wall of electrode tip. In this work, we proposed an idea for attracting a single CNT to the tip of an AFM by using a discrete pulsed DC voltage instead of a regular AC or DC voltage.

2 Dielectrophoresis

A dipole moment is induced when a polarizable object is subjected to an electric field. If the electric field is inhomogeneous, the force acting on each side of the particle will be different, causing the particle to move with respect to the medium. Depending on the polarizability of the particle compared to the polarizability of the medium, this force can push the particle towards regions of high or low electric field. The time—average force on a tube exerted by an electric field, E, is given by[1]

(1)

(1)

where r is the radius of a particle; εm is the complex permittivity of the suspending medium; E is the root mean square of electric field; and Re[K(ω)] is the real part of Clausius-Mossotti factor. When a particle is placed in a high-frequency electric field, its movement is controlled by the permittivities of the particle and the solution. Assuming that the frequency range of electric field is over 1 MHz and the particle has large slenderness ratio as CNT tube, Eq.(1) can be modified as follows:

(2)

(2)

where  is the complex permittivity of the suspending medium,

is the complex permittivity of the suspending medium,  is the complex permittivity of a particle, and l is the particle length.

is the complex permittivity of a particle, and l is the particle length.

Previous methods for arraying CNT with DEP used AC or DC field for AC-DEP and DC-DEP. When AC or DC field is applied to the solution with CNTs, the CNTs move continuously along DEF force line, finally attach to the electrode. However, this continuous movement of CNTs results in attaching a lot of CNTs to the electrode, which fails to bond a single CNT to a target position. In order to resolve this problem, we proposed a pulsed-DC DEP method that used discrete pulsed DC voltage instead of a regular AC or DC voltage, which can derive intermittent movement of few CNTs to bond a single CNT upright at a target position. In order to expect the results with previous and our method before the experiments, we simulated AC-DEP, DC-DEP, and pulsed-DC DEP with multi-physics simulation tool.

3 Simulation with COMSOL

While Maxwell 2D/3D[8] and COSMOS[9] are used for electromagnetic analysis, multi-physics tool is used for analyzing CNT arraying since electromagnetic fluidics is necessary. In our simulation, we used the COMSOL multiphysics v.3.2 software package[10] to simulate the CNTs’ motion, which was subjected to the DEP force by the electric field and electromagnetic fluidics of the liquid.

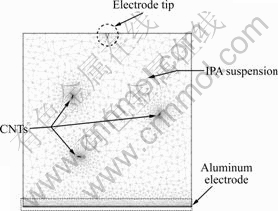

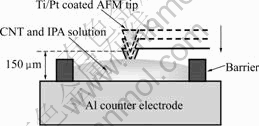

In order to attach a single CNT to target position, we downed a sharp tip to IPA suspension with CNTs while inducing electric field to both electrodes, which derived CNTs’ motion to the tip by DEP force. For this analysis we generated finite element model with boundary conditions for the simulation as shown in Fig.1.

Fig.1 Geometric modeling for DEP simulation

With the geometric modeling and Eq.(2), we simulated the DEP force behavior for the movement of a CNT in three types of electric fields, including an AC voltage, a DC voltage, and our proposed pulse-type DC voltage. Figs.2-4 show the results for each type of electric field. Fig.2 and Fig.3 show that the lines of the DEP force are distributed over all the electrode walls for both the regular AC and DC voltage cases. This means that it is difficult to separate a single CNT to attach to the electrode tip because many CNTs are attracted to the electrode wall. In contrast, Fig.4(a) shows that lines of DEP force concentrate on the electrode tip with a gap at the tip. Fig.4(b) shows that the electric field strength near the tip is smaller than other cases, which means that a few CNTs can be gathered at the tip while a lot of CNTs can be gathered with the other cases. As a result, we presume that a pulse-type DC voltage offers a higher possibility to bond a single CNT onto a target position.

Fig.2 DEP simulation result for AC case (5 MHz, ±5 V): (a) DEP force lines; (b) Electric field

Fig.3 DEP simulation result for DC case (5 V): (a) DEP force lines; (b) Electric field

Fig.4 DEP simulation result for pulsed-DC case (5 V): (a) DEP force lines; (b) Electric field

4 Experimental

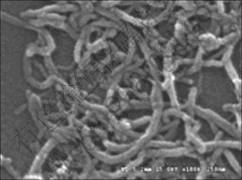

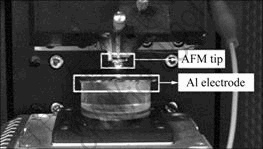

To verify the simulations, we carried out experiments on bonding CNTs using the same electric field conditions as in the simulations. In our experiments, we used purified CNTs in an isopropyl alcohol (IPA) suspension with a mole ratio of 2 to 1 of H2O to IPA as shown in Fig.5. In order to attach CNTs to a tip’s apex by DEP, we needed to control the vertical displacement of the tip in nanoscale. For this purpose, we used a Ti/Pt coated AFM tip for manipulation of the electrode tip, which has precise displacement control in nanoscale as shown in Fig.6. Then, after putting 100 ?L of IPA suspension with CNT on aluminum counter electrode as shown in Fig.7, we slowly lowered the AFM tip to the IPA suspension while applying three kinds of electric fields for 40 s in the simulations. For the pulsed DC voltage, we used 20 ns at 5 V using a frequency of 5 MHz.

Fig.5 Purified CNTs in IPA suspension

Fig.6 Experimental setup with AFM

Fig.7 AFM tip motion

5 Results and discussion

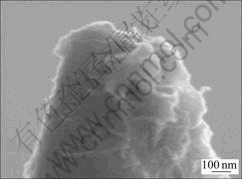

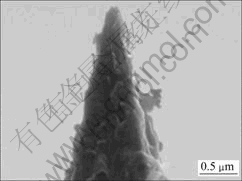

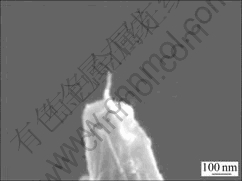

Figs.8-10 show photographs of the CNTs near to the tip of the electrode, magnified in the FE-SEM. Fig.8 shows the result when 5 V AC at 5 MHz is applied to the electrode and the AFM tip for 40 s. The magnified image of CNTs near AFM tip is shown in Fig.8, which has a lot of CNTs on all over the AFM tip wall. Fig.9 shows the result when regular 5 V DC is applied to the electrode and the AFM tip is in the same period. Even this case has smaller number of CNTs on the AFM tip wall than AC case, it still fails to attach single CNT to target position. In contrast, Fig.10 shows that a single CNT is attached upright on the tip’s apex, while a few CNTs are attached to the tip wall. This means that our proposed method of discrete DC voltage of an electric field can increase the possibility of being able to bond a single CNT upright at a desired position.

Fig.8 CNTs at AFM tip with AC (5 MHz, ±5 V)

Fig.9 CNTs at AFM tip with DC (5 V)

Fig.10 Single CNT at AFM tip with pulsed-DC (5 V)

6 Conclusions

We proposed a method of applying a pulsed-DC voltage of an electric field for bonding a single CNT upright at a target position using the DEP technique. The proposed technique shows a higher possibility for bonding single CNTs than previous AC and DC voltage methods from simulations and experiments. Thus, this method should find broad applicability.

Acknowledgement

This work is financially supported by the Ministry of Education, Science Technology (MEST) and Korea Institute for Advancement of Technology (KIAT) through the Human Resource Training Project for Regional Innovation and by grants-in-aid for the National Core Research Center Program from MOST/KOSEF (R15-2006-022-03002-0).

References

[1] SEO H W, HAN C S, CHOI D G, KIM K S, LEE Y H. Controlled assembly of single SWNTs bundle using dielectrophoresis[J]. Microelectronic Engineering, 2005, 81: 83-89.

[2] DRESSELHAUS M S, DRESSELHAUS G, AVOURIS P H. Carbon nanotubes-synthesis, structure, properties and applications (Springer Topics in Applied Physics no 80)[M]. Berlin: Springer, 2001: 1-7, 147-68, 287-325.

[3] HONE J, WHITNEY M, ZETTLE A. Thermal conductivity of single-walled carbon nanotubes[J]. Synthetic Metals, 1999, 103: 2498-2499.

[4] LEE C J, et al. Synthesis of aligned carbon nanotubes using thermal chemical vapor deposition[J]. Chemical Physics Letters, 1999, 312(5/6): 461-468.

[5] PARK B Y, MADOU M J. 3-D electrode designs for flow-through dielectrophoretic systems[J]. Electrophoresis, 2005, 26: 3745-3757.

[6] KADAKSHAM J, SINGH P, AUBRY N. Manipulation of particles using dielectrophoresis[J]. Mechanics Research Communications, 2006, 33: 108-122.

[7] LEE H W, KIM S H, KWAK Y K, LEE E S, HAN C S. The effect of the shape of a tip’s apex on the fabrication of an AFM tip with an attached single carbon nanotube[J]. Sensors and Actuators, 2005, 125: 41-49.

[8] http://www.ansoft.com/products/em/max2d/

[9] http://www.cimlogic.com/

[10] http://comsol.com/products/multiphysics/

(Edited by CHEN Wei-ping)

Corresponding author: Yoong-Ho JUNG; Tel: +82-10-2447-2469; E-mail: yhj@pusan.ac.kr