文章编号:1004-0609(2008)02-0266-05

剪切面显微组织及板材细晶化新工艺

周 俊,王志法,崔大田,姜国圣

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用金相显微镜和扫描电镜研究Cu-9Ni-2.3Sn(C72500)合金经剪切变形后合金切面的微观组织以及随后在550 ℃退火2 h后切面的组织变化。结果表明:经剪切变形后,切面处形成一种独特的带状变形孪晶和蜂窝状变形组织,且存在挤压、扭折等多种变形机制的作用;合金在550 ℃退火2 h后,切面出现许多再结晶晶粒,且在承受剪床切口的一边再结晶晶粒非常细小,相当于冷轧变形80%后的再结晶晶粒尺寸。根据这种现象,以异步轧制和板材连续剪切变形技术(C2S2)为基础,提出一种金属板材利用剪切变形配以适当热处理来细化晶粒的构想,有望在材料加工领域实现新的突破。

关键词:C72500合金;剪切变形;变形带;细化晶粒

中图分类号:TG 113 文献标识码:A

Microstructure of shearing plane and new method for refining grains technology in sheets

ZHOU Jun, WANG Zhi-fa, CUI Da-tian, JIANG Guo-sheng

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The shear plane microstructures of Cu-9Ni-2.3Sn(C72500) alloy after shearing deformation and then annealed at 550 ℃ for 2 h were observed by OM and SEM. The results show that some twin crystals and honeycomb structures appear in the shear plane and many kinds of deformation mechanism exist such as extruding, kinking and so on. When annealed at 550 ℃ for 2 h, the recrystal gains are observed in the shear plane. Especially the side receives the cut of guillotine, the size of recrystal grain is very thin, corresponding with the recrystal grains obtained by cold rolling at 80% deformation rate. Based on this phenomenon, associating with asynchronous rolling and confined strip shearing technology, a method was proposed to refine the grains in metal sheets by using shearing deformation and annealing sample at suitable temperature to obtain ultra fine grains. Hopefully this would prompt the development of material processing area.

Key words: C72500 alloy; shearing deformation; deformation band; refining grain

剧烈塑性变形可以细化粗晶粒成为超细(晶粒粒径为0.1~1 μm)及纳米(粒径<100 nm)晶粒[1-4],应变诱导的晶粒细化过程取决于塑性变形方式,即位错滑移及孪生等,还与晶体结构及层错能密切相关[2]。20世纪90 年代,VALIEV等[5]开始采用等通道角挤压和高压扭转工艺制备超细晶块体材料,胡兰青等[6]采用高能喷丸技术在1420铝合金上制备出纳米晶结构表层,并研究表层沿厚度方向的结构变化及硬度变化。孙文儒等[7]研究发现IN718合金冲击断口表面出现纳米化现象[7]。本文作者在对C72500合金(Cu-9Ni-2.3Sn)的研究中发现,利用剪床对板材进行剪切后,在切面会形成带状的变形组织。在随后的热处理过程中,带状组织消失,且切面的晶粒能极大的细化。随后对纯铜板剪切变形后发现切面也存在类似的变形组织。因此可以推断不同的合金板材剪切变形后,在切面均会形成变形组织,形状依据不同的原始成分有所不同,随后的热处理细化晶粒应该是一种剧烈剪切变形后的再结晶。基于此现象,本文作者提出一种合金板材依靠大剪切变形细化晶粒的工艺方案。

1 实验

按C72500质量比取Cu 3.1 kg、Ni 315 g、 Sn 80 g、Fe 10 g,另加20 g Mn作为脱氧剂,在真空熔炼炉中熔炼出铸锭。铸锭在铣床上铣面至37 mm,在热轧炉中于850 ℃保温1 h,多道次热轧至2 mm。取尺寸为100 mm×10 mm×2 mm的C72500热轧板条在马弗炉中于850 ℃固溶处理1 h后水淬,用剪床将其剪断。将切口断面研磨、抛光、腐蚀后用PLOVER-MET金相显微镜和JSM-5600LV扫描电镜观察切口的组织形貌,样品所用腐蚀剂为三氧化铁(5 g)+浓盐酸(25 mL)+水(50 mL)的三氯化铁盐酸水溶液。之后在马弗炉中550 ℃退火2 h,再观察研磨、抛光及腐蚀后的组织。

2 结果与讨论

2.1 剪切变形后切面组织分析

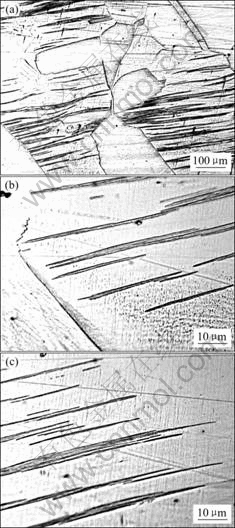

对固溶淬火后样品经剪切的切面用金相显微镜观察后发现;在粗大的固溶体晶粒中形成黑色的带状组织,有的在晶界处形成,向晶粒中伸长;有的直接在晶粒中出现,如图1所示。

图1 剪切变形后形成的带状组织

Fig.1 Band structure formed by shearing deformation microstructure: (a) Low magnification; (b), (c) High magnification

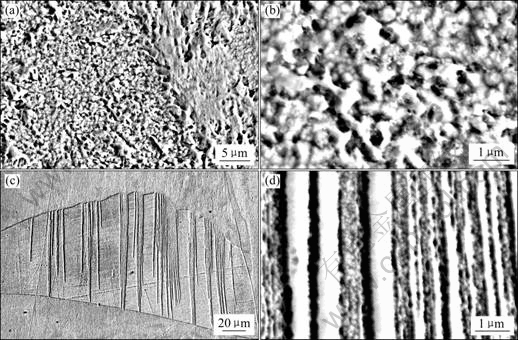

目前许多研究发现各种金属、岩土和高分子材料等在遭受爆炸、高速碰撞、高速切削和高速磨损等涉及高应变率载荷的高速变形过程中会形成绝热剪切 带[8-9]。但本实验是在普通剪床上完成的,并不符合绝热剪切带形成的条件,所以认为这种带状的变形组织是在剪切变形时形成的形变孪晶。在面心立方晶系中,由于其滑移系较多,因而滑移是其变形的主要方式,一般情况下较难生成孪晶。但在剪床切口处剪切变形下,切面受到较大剪切应力作用,位错密度迅速增加,许多位错相互缠结在一起,阻碍部分滑移系的启动,单靠滑移并不能满足其变形,因而出现孪生现象。对切面做高倍扫描电镜分析表明,在样品承受剪床切口的一面,看不到晶界,形成许多蜂窝状组织。对图1中出现的孪晶分析发现孪晶带中也出现少量该组织,如图2所示。本文作者认为,这种组织的形成是多种变形综合的结果:首先在变形初期,形成变形孪晶和不稳定的亚晶,接着在大应力变形的挤压下造成晶格严重畸变,孪晶和亚晶破碎,碎晶粒互相挤压、扭折,大量的晶体缺陷缠结在一起,会聚较高的畸变能,腐蚀以后呈现出图中的黑处。

图2 剪切变形微观组织

Fig.2 Shearing deformational microstructures: (a) Microstructure received cut of guillotine; (b) Microscopic structure of (a); (c) Deformed twin crystal microstructure; (d) Microscopic structure of (c)

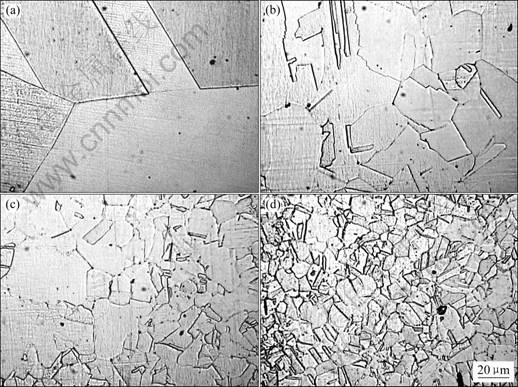

2.2 热处理对剪切变形样品组织的影响

剪切变形的样品在马弗炉中于550 ℃退火2 h后,剪切变形后样品的切面变形组织消失,形成许多微小的细晶粒,比固溶处理后的晶粒细很多,但其晶粒大小不一致,在承受剪床切口一边的再结晶晶粒最细小密集,远离切口的一边再结晶晶粒较粗,样品中间为粗细再结晶晶粒过渡区,如图3所示。在剪切变形过程中,在原始晶粒中产生高密度位错,位错相互缠结堵塞,发展成为胞状组织。且随着变形量的继续增大,位错胞数量增加,尺寸减少,胞壁的位错密度提高,不断向晶界运动。最终胞壁位错缠结不断集聚,胞状结构崩塌,形成小角度的织构界面,晶内出现大量亚微米量级的亚结构。在剪切应力作用下,小角度织构发生旋转,发展成为亚晶粒。在退火回复作用下,亚晶逐渐粗化,形成晶界清晰、具有大角度晶界的亚晶,这种亚晶也就作为再结晶的晶核而继续长大。从图3中可以看到,切面两边晶粒大小不一样,这与图2(a),(b)中观察的组织形貌相吻合。在承受剪床切口的一边由于晶体缺陷密度高(图2(a),(b)中的黑点处),在再结晶退火中为晶粒的形核提供十分有利的条件,因而再结晶晶粒较另一边更多更细,相当于冷轧变形80%后的再结晶晶粒尺寸。

图3 原始晶粒与剪切变形后的再结晶组织

Fig.3 Original grains and recrystallization grains after shearing deformation: (a) Grains gained by solution treatment; (b) Recrystal grains far away from cut of guillotine; (c) Recrystal grains in middle area; (d) Recrystal grains received cut of guillotine

2.3 金属板材利用剪切变形细化晶粒的方案

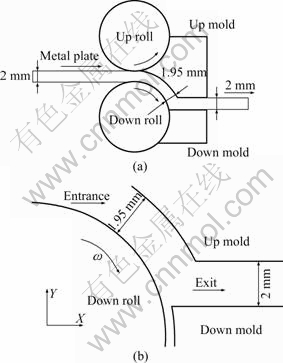

根据这种现象可以认为,大剪切变形配以适当的热处理可以细化晶粒。有研究报道,等径弯角挤压(ECAE)技术可以在不改变坯料的横截面形状和截面面积条件下,实现对材料的剧烈剪切变形, 而且通过多次挤压可使单次应变不断得到累积, 最终得到很大的剪切应变量, 从而达到细化晶粒、有效改善材料性能的目的[10-12]。但在挤压过程中会造成高温试样表层温度的急剧下降而导致表层出现裂纹或严重的整体断裂,常常导致挤压的失败[13]。且等径弯角挤压技术受模具形状条件限制,多用于小圆棒料的挤压,其中还存在一些问题,因而目前尚处于实验研究阶段。同时对于板材很难实现这种等径弯角挤压。所以如何让金属板材产生如等径弯角挤压那种剪切应力,从而在热处理过程中极大细化晶粒,已成为材料加工领域研究的热门方向。板材连续剪切变形技术(C2S2)[14-15]是近年来提出的最新技术,其工作原理示意图和变形区详细构造如图4所示,上下辊轮相对运动带动板料进入模腔,板料在模腔转角处发生剧烈的剪切变形后从模腔一侧挤出。因为板材连续剪切变形技术具有使变形体变形后不改变其外观尺寸形状的特点,这样就使得变形可以在一套模具内循环进行,最后得到非常大的应变,从而大幅度降低材料的晶粒尺寸,制备出细晶的板材。

图4 C2S2法工作原理示意图和变形区结构示意图

Fig.4 Schematic diagram of operating principle and deformation area structure of C2S2 technology: (a) Schematic diagram of C2S2; (b) Structure of deformation area

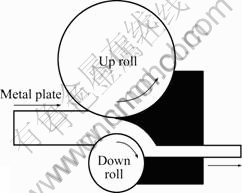

但C2S2技术仍然是基于挤压的基础之上,利用的纯剪切变形。因此本文作者以异步轧制和C2S2技术为基础,提出另一种方案的构想,其结构示意图如图5所示。

图5 变形工艺示意图

Fig.5 Schematic diagram of deformation processing

以异步轧制为基础,上下辊径不一样,上辊的线速度v1要大于下辊的线速度v2,这样在板材的轧制过程中45?方向会产生剪切应变,使出来的板材的头部要略向下弯曲,工程上叫“翘头”,这在异步轧制过程中是需要避免的[16]。但本方案恰要利用这一特点,在异步轧辊之后,由于上下模的限制,在拐角处产生剧烈的剪切变形。考虑到快辊侧和慢辊侧组织可能不同,再一次翻面进行轧制,甚至多次翻面进行轧制。这样出来的板材经过轧制变形和剪切变形两种效果的叠加,在随后的再结晶退火中应该能生成极细小的等轴晶,势必能极大的提高板材的强度。同时也发挥了异步轧制的轧制力小、少道次、大压下量的优点。

该方案的现实意义在于:1) 对于塑性较好的面心立方金属,如铜合金、铝合金等,在加工过程中实现轧制变形和剪切变形两种效果叠加,对于要求同一厚度的板材来讲,比单纯的轧制效果要好的多;2) 对于塑性较差的六方晶系金属,如镁合金等。由于其滑移面很少,塑性较差,此时异步轧辊可相当于送料辊,只让板材承受剪切变形,其效果等同于C2S2技术。

3 结论

1) C72500合金在剪床剪切变形后切面会生成形变孪晶,在承受剪床切口的一边存在挤压、扭折等多种变形机制的叠加,在扫描电镜下呈现蜂窝状结构。

2) 在550 ℃退火2 h后,剪切面生成再结晶细晶粒,在承受剪床切口的一边晶粒更加细小,相当于冷轧变形80%后的再结晶晶粒尺寸。

3) 根据异步轧制和板材连续剪切变形技术提出了金属板材细化晶粒方案构想,有较好的现实研究意义。

REFERENCES

[1] LU K, LU J. Surface nanocrystallization (SNC) of metallic materials—Presentation of the concept behind a new approach[J]. J Mater Sci Technol, 1999, 15(2): 193-197.

[2] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation[J]. Prog Mater Sci, 2000, 45(2): 103-189.

[3] 张洪旺, 刘 刚, 卢 柯, 黑祖昆, 吕 坚. 表面机械研磨诱导AISI304不锈钢表层纳米化(Ⅱ)[J]. 金属学报, 2003, 39(4): 347-350.

ZHANG Hong-wang, LIU gang, LU Ke, HEI Zhu-kun, L? Jian. Surface nanocrystrallization of AISI 304 stainless steel induced by surface mechanical attrition treatment(Ⅱ)[J]. Acta Metallurgica Sinica, 2003, 39(4): 347-350.

[4] LU K, LU J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment[J]. Mater Sci Eng A, 2004, 375/377: 38-42.

[5] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation[J]. Progress in Materials Science, 2000, 45(2): 103-189.

[6] 胡兰青, 李茂林, 王 科, 刘 刚, 卫英慧, 许并社. 铝合金表面纳米化处理及显微结构特征[J]. 中国有色金属学报, 2004, 14(12): 2016-2019.

HU Lan-qing, LI Mao-lin, WANG Ke, LUI Gang, WEI Ying-hui, XU Bin-she. Microstructure and characterization of surface nanocrystallization of aluminum alloy[J]. The Chinese Journal of Nonferrous Matals, 2004, 14(12): 2016-2019.

[7] 孙文儒, 郭守仁, 佟百运, 卢德忠, 胡壮麒. 变形IN718 合金冲击断口表面纳米化现象及其机制[J]. 材料研究学报, 2003, 17(2): 122-126.

SUN Wen-ru, GUO Suo-ren, TONG Bai-yun, LU De-zhong, HU Zhuang-qi. Nanostructure at fracture surface of IN718 impact specimen[J]. Chinese Journal of Materials Research, 2003, 17(2): 122-126.

[8] DOBROMYSLOV A V, TALUTS N I, KAZANTSEVA N V, KOZLOV E A. Formation of adiabatic shear bands and instability of plastic flow in Zr and Zr-Nb alloys in spherical stress waves[J]. Scripta Materialia, 1999, 42(1): 61-71.

[9] RAVI-CHANDAR K. On the failure mode transitions in polycarbonate under dynamic mixed-mode loading[J]. Int J Solids Structures, 1995, 32(6/7): 925-938.

[10] MUKAI T, KAW AZOE M, H IGASH I K. Dynamic mechanical properties of a near nano aluminum alloy processed by equal channel angular extrusion[J]. Nanostructured Materials, 1998, 10 (5): 755-765.

[11] Chang J Y, Aidang S. Microstructure and mechanical properties of Al-Mg-Si alloys after equal channel angular pressing at room temperature[J]. Mater Sci Eng A, 2003, 347: 165-170.

[12] DONG H S, INYOUNG K. Shear strain accommodation during severe plastic deformation of titanium using equal channel angular pressing[J]. Mater Sci Eng A, 2003, 347: 239-24.

[13] SEMIAT IN S L, DELO D P. Equal channel angular extrusion of difficult-to-work alloys[J]. Materials & Design, 2000, 21(4): 311-322.

[14] LEE J C, SEOK H K, SUH J Y. Microstructural evolutions of the Al strip prepared by cold rolling and continuous equal channel angular pressing[J]. Acta Materialia, 2002, 50: 4005-4019.

[15] LEE J C, SEOK H K, HAN J H, CHUNG Y H. Controlling the textures of the metal strips via the continuous confined strip shearing (C2S2) process[J]. Materials Research Bulletin, 2001, 36: 997-1004.

[16] 胡衍生, 程晓茹, 李虎兴, 宋耀华. 中厚板轧制头部弯曲机理的探讨[J]. 钢铁, 2003, 38(6): 28-31.

HU Yan-sheng, CHENG Xiao-ru, LI Hu-xing, SONY Yao-hua. Discussion on front end bending during plate rolling[J]. Iron and Steel, 2003, 38(6): 28-31.

收稿日期:2007-05-15;修订日期:2007-10-22

通讯作者:王志法,教授; 电话:0731-8877698; E-mail: zhouj_81@yahoo.com.cn

(编辑 龙怀中)