一水硬铝石型铝土矿焙烧-碱浸脱硅新工艺(Ⅰ)

来源期刊:中国有色金属学报2000年第4期

论文作者:姜涛 李光辉 范晓慧 黄柱成 邱冠周

文章页码:534 - 538

关键词:一水硬铝石型铝土矿; 化学选矿; 脱硅

Key words:diasporic bauxite; chemical processing; desiliconization

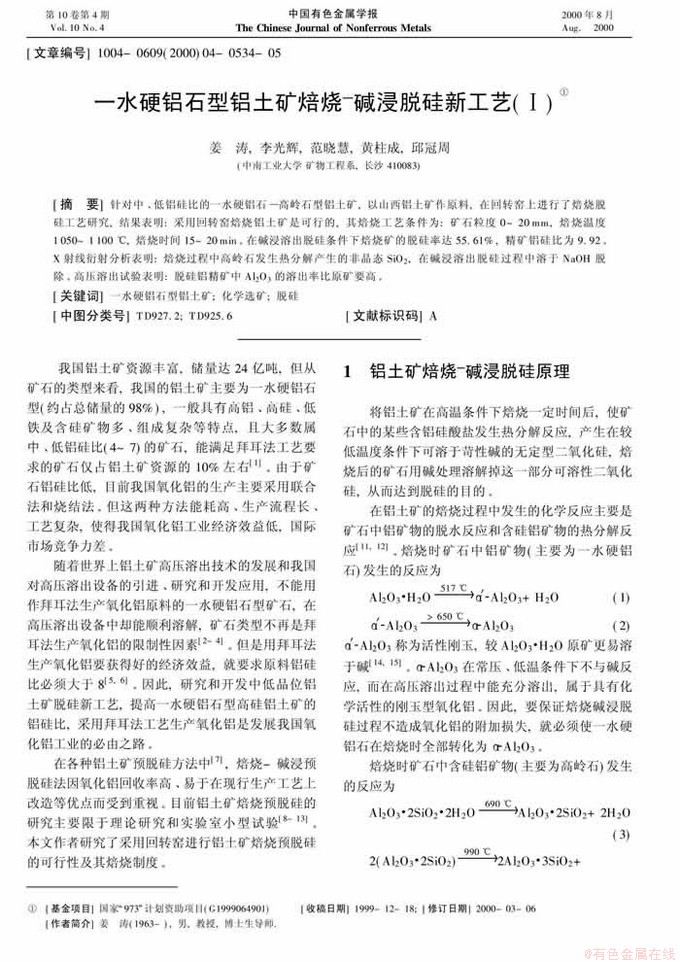

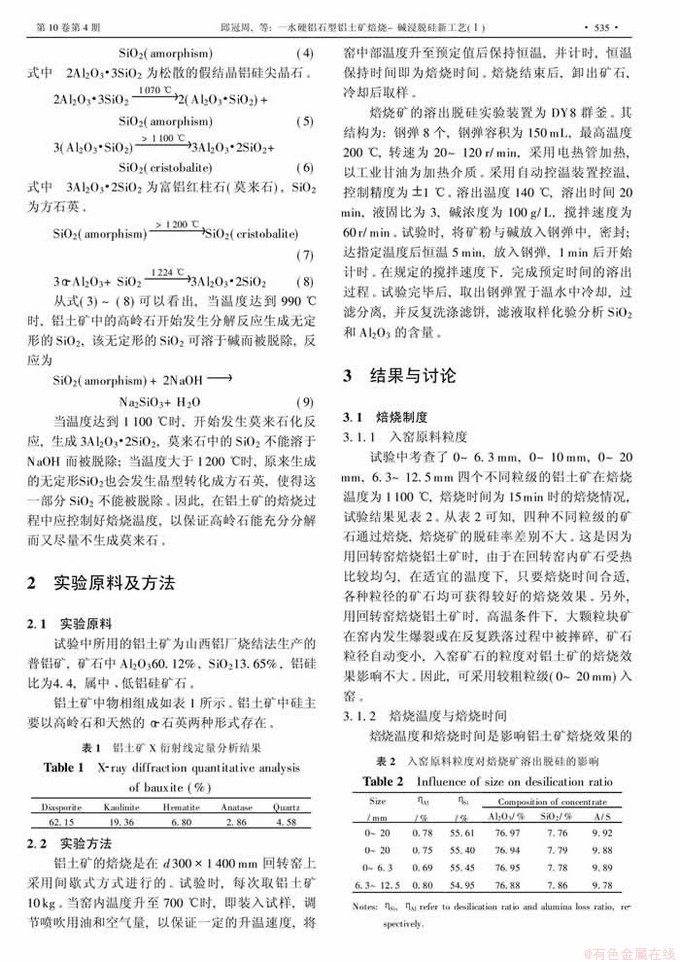

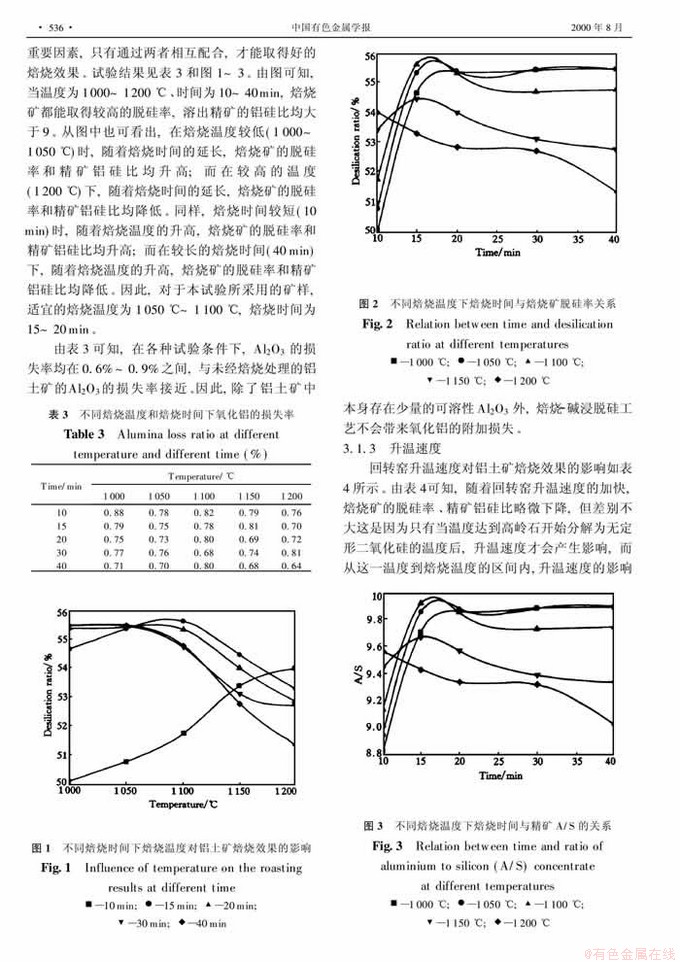

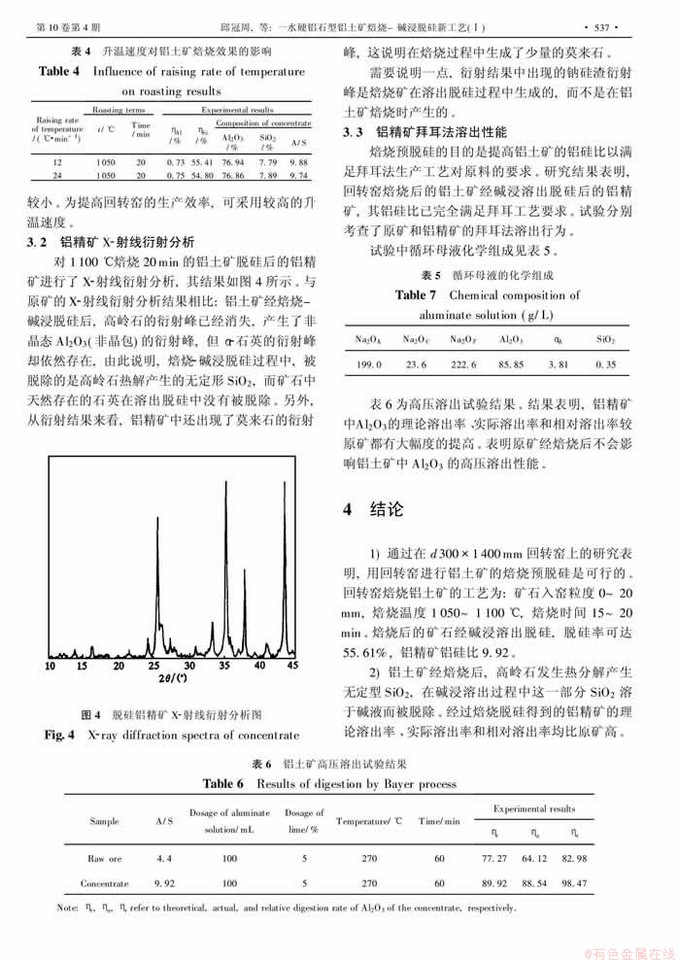

摘 要:针对中、 低铝硅比的一水硬铝石—高岭石型铝土矿, 以山西铝土矿作原料, 在回转窑上进行了焙烧脱硅工艺研究,结果表明: 采用回转窑焙烧铝土矿是可行的, 其焙烧工艺条件为: 矿石粒度0~20 mm, 焙烧温度 1 050 ~1 100 ℃,焙烧时间15~20 min。 在碱浸溶出脱硅条件下焙烧矿的脱硅率达55.61%, 精矿铝硅比为9.92。 X射 线衍射分析表明: 焙烧过程中高岭石发生热分解产生的非晶态SiO2, 在碱浸溶出脱硅过程中溶于NaOH脱除。 高压溶出试验表明: 脱硅铝精矿中Al2O3的溶出率比原矿要高。

Abstract: Using the ore from Sanxi province, the roasting process of the desilication from the diasporic bauxite was studied. It was shown that using rotary kiln as the roasting apparatus is practicable, and the optimum roasting parameters are: grain size 0~20 mm, roasting temperature 1 050~1100 ℃, roasting time 15~20 min. The alkali leaching results, rate of desilication55.61% and ratio between aluminium and silicon of the concentrate 9.92, were obtained. By means of XRD analysis, the following conclusions were reached: only Si, existed in kaolinite, could be changed into noncrystalline silica; during the leaching, this kind of silica isdissolved by NaOH solution, but α silica does not dissolve, so it is not contributive todesilication. The digestion of the concentrate by Bayer process also showed that the digestion ratio of Al2O3 of the concentrate is higher than that of raw ore.