不同热变形条件下Al-Zn-Mg-Cu包铝板的组织演变

来源期刊:中国有色金属学报(英文版)2017年第8期

论文作者:廖斌 吴晓东 闫昌建 刘政 纪艳丽 曹玲飞 黄光杰 刘庆

文章页码:1689 - 1697

关键词:Al-Zn-Mg-Cu合金;包铝层;热变形;回复;再结晶

Key words:Al-Zn-Mg-Cu alloy; Al cladding; hot compression; recovery; recrystallization

摘 要:利用Gleeble-3500热模拟试验机对Al-Zn-Mg-Cu包铝板进行热变形,采用EBSD和XRD对不同变形条件下的Al-Zn-Mg-Cu基体和包铝层显微结构进行表征,其变形条件为变形量70%、温度380~450 °C、应变速率0.1~30 s-1。结果表明,变形温度、道次和变形速率直接影响样品的回复和再结晶过程,从而进一步影响其显微结构。在包铝层和Al-Zn-Mg-Cu基体中回复和再结晶的程度有所区别。较高的变形温度导致较高程度的再结晶以及较大的晶粒尺寸。在多道次变形中的停留时间内会发生静态再结晶。当应变速率低于10 s-1时,随着应变速率的增大,出现较多细小的亚晶组织;然而,在30 s-1的大应变速率条件下,试样在变形温度下停留时间较短,导致动态回复及再结晶程度受限。

Abstract: Al-cladded Al-Zn-Mg-Cu sheets were compressed up to 70% reduction on a Gleeble-3500 thermo-mechanical simulator with temperatures ranging from 380 to 450 °C at strain rates between 0.1 and 30 s-1。The microstructures of the Al cladding and the Al-Zn-Mg-Cu matrix were characterized by electron back-scattered diffraction (EBSD) and X-ray diffraction (XRD). The microstructure is closely related to the level of recovery and recrystallization, which can be influenced by deformation temperature, deformation pass and deformation rate. The level of recovery and recrystallization are different in the Al cladding and the Al-Zn-Mg-Cu matrix. Higher deformation temperature results in higher degree of recrystallization and coarser grain size. Static recrystallization and recovery can happen during the interval of deformation passes. Higher strain rate leads to finer sub-grains at strain rate below 10 s-1; however, dynamic recovery and recrystallization are limited at strain rate of 30 s-1 due to shorter duration at elevated temperatures.

Trans. Nonferrous Met. Soc. China 27(2017) 1689-1697

Bin LIAO1, Xiao-dong WU1, Chang-jian YAN1, Zheng LIU1, Yan-li JI2, Ling-fei CAO1, Guang-jie HUANG1, Qing LIU1

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Suzhou Branch, Chinalco Materials Application Research Institute Co., Ltd., Suzhou 215026, China

Received 24 April 2016; accepted 23 November 2016

Abstract: Al-cladded Al-Zn-Mg-Cu sheets were compressed up to 70% reduction on a Gleeble-3500 thermo-mechanical simulator with temperatures ranging from 380 to 450 °C at strain rates between 0.1 and 30 s-1。The microstructures of the Al cladding and the Al-Zn-Mg-Cu matrix were characterized by electron back-scattered diffraction (EBSD) and X-ray diffraction (XRD). The microstructure is closely related to the level of recovery and recrystallization, which can be influenced by deformation temperature, deformation pass and deformation rate. The level of recovery and recrystallization are different in the Al cladding and the Al-Zn-Mg-Cu matrix. Higher deformation temperature results in higher degree of recrystallization and coarser grain size. Static recrystallization and recovery can happen during the interval of deformation passes. Higher strain rate leads to finer sub-grains at strain rate below 10 s-1; however, dynamic recovery and recrystallization are limited at strain rate of 30 s-1 due to shorter duration at elevated temperatures.

Key words: Al-Zn-Mg-Cu alloy; Al cladding; hot compression; recovery; recrystallization

1 Introduction

The 7xxx series alloys (Al-Zn-Mg-Cu) have been widely used in the aviation and aerospace industries due to their low density, high specific strength, good fracture toughness and corrosion resistance [1-3]. As an important structural material, the alloys are often manufactured from ingots to sheets/thick plates, among which hot deformations such as rolling, extrusion or forging are involved. Therefore, a good understanding of the hot deformation behaviour of alloys and their microstructure evolution during deformation is necessary for a better quality control.

There are many reports about hot deformation in 7xxx series aluminium alloys. For example, LI et al [4] investigated the hot compressive deformation behaviour and constitutive relationship of Al-Zn-Mg-Zr alloy with trace amounts of Sc, and found that the Al-Zn-Mg-Sc-Zr alloy is sensitive to the positive strain rate. JIA et al [5] investigated the hot deformation behaviour of spray-deposited Al-Zn-Mg-Cu alloy, and reported that the activation energy of the spray-deposited Al-Zn-Mg-Cu alloy is 135.72 kJ/mol. The activation energy obtained is lower than that of the casting alloy, though the spray-deposited Al-Zn-Mg-Cu alloy has finer grains and much higher solutes. Very recently, WU et al [6] studied the hot deformation behaviour and constitutive equation of a new type Al-Zn-Mg-Er-Zr alloy during isothermal compression. Moreover, constitutive equations for the creep of 7B04 aluminium alloys were presented by LI et al [7]. However, there are few reports about the microstructural evolution of Al-cladded Al-Zn-Mg-Cu composite sheet during hot deformation. Particularly, the information of microstructure difference between the Al layer and Al-Zn-Mg-Cu matrix during deformation is very limited. Since in the industrial practice, Al-Zn-Mg-Cu alloys are often cladded with relatively pure aluminium for a better corrosion resistance, it is important to investigate the microstructural evolution of such materials for choosing hot working process properly.

Therefore, in this work, the microstructure and texture of Al cladded Al-Zn-Mg-Cu sheet under various deformation conditions were investigated by using electron back-scattered diffraction (EBSD) and X-ray diffraction (XRD). The thermal physical simulation parameters were chosen to be close to the industrial rolling parameters.

2 Experimental

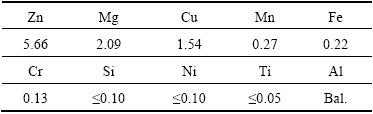

A typical high specific strength Al-cladded Al-Zn-Mg-Cu alloy was used in this work and the chemical composition of the Al-Zn-Mg-Cu matrix is shown in Table 1. Industrial pure aluminium sheets (>99.0%) were cladded with the cast Al-Zn-Mg-Cu matrix by multi-pass hot rolling at the temperature around 400 °C. Cylindrical sample with 10 mm in diameter and 15 mm in height was machined from the as-received hot rolling plates. Of the 15 mm in thickness, the Al cladding is about 0.34 mm in thickness and the rest is Al-Zn-Mg-Cu matrix. Compression tests were carried out on a Gleeble-3500 thermal-simulation machine at three different passes (1, 2 and 3 passes, the interval between each pass is 30 s), three different deformation temperatures (380, 410 and 450 °C) and four different strain rates (0.1, 1, 10 and 30 s-1). The samples were heated to the deformation temperature at the rate of 2.5 °C/s and held for 3 min so as to achieve the uniform starting temperature. The sample temperature was measured by using thermocouples welded at both ends of the sample. The sample was then compressed with a reduction of height from 25% to 70%, and was water quenched immediately after hot compression. After compression, the reduction ratio of the Al cladding is higher than that of the matrix because the Al cladding is much softer. Since the Al cladding is very thin, the reduction ratio of the matrix is very close to the nominal reduction ratio, for example, when the total reduction ratio is 70%, the reduction ratio of the matrix is about 69.8%, and that of the Al cladding is about 77%. The hot working conditions within our studied ranges did not significantly affect the reduction ratio of the Al cladding and the matrix. EBSD experiments were carried out on a TESCAN MIRI 3 scanning electron microscope. The EBSD of the Al cladding was sampled near the surface, and the EBSD of the Al-Zn-Mg-Cu matrix was taken from the 1/2 thickness place of the sheet. Texture was measured with a Rigaku D/max 2500PC X-ray diffractometer.

Table 1 Chemical composition of Al-Zn-Mg-Cu alloy used in this work (mass fraction, %)

3 Results and discussion

3.1 Influence of deformation temperature on microstructure

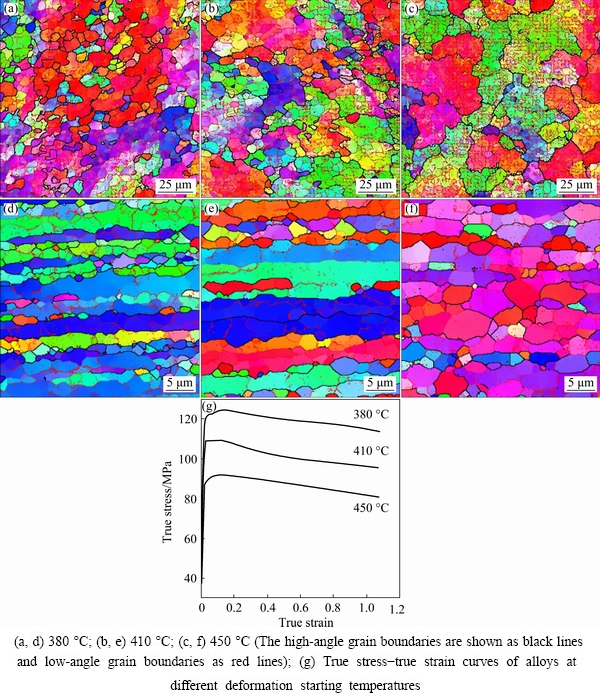

In order to understand the evolution of the microstructure during hot compress, the microstructures of sample before thermal compression, i.e., after 3 min holding at deformation temperature, were characterized by EBSD, as shown in Fig. 1. The microstructure of the Al clad (Figs. 1(a)-(c)) shows fully crystallized structure. There is no significant difference in the grain size though the samples were held at different temperatures. This maybe because the holding time was only 3 min. The Al-Zn-Mg-Cu matrix shows typical rolling structure (Figs. 1(d)-(f)) after 3 min holding at elevated temperature. It is hard to observe recrystallization at 380 °C, while partial recrystallization can be observed at 410 and 450 °C.

Figure 2 shows the EBSD maps of Al cladding and Al-Zn-Mg-Cu matrix after compression at 1 s-1 with a reduction of height to 70% under different starting temperatures. The structure of Al cladding consists of many low-angle grain boundaries and some high-angle grain boundaries. Many randomly distributed sub-grains and few high-angle grain boundaries are observed in Al cladding after compression at 380 °C (Fig. 2(a)). More low-angle grain boundaries are observed in Al cladding with the increase of compression temperature (Figs. 2(b) and (c)). Different phenomena are observed in the matrix. Some elongated grains perpendicular to the compression direction and fine grains can also be observed in the Al-Zn-Mg-Cu matrix (Fig. 2(d)), and the volume fraction of fine grains/sub-grains increases with the compression temperature (Fig. 2(e)). In the sample compressed at 450 °C, elongated grains are hard to be observed, instead recrystallized grains with straight grain boundaries are the typical feature of the microstructure (Fig. 2(f)). The true stress-strain curves (Fig. 2(g)) show that the alloy becomes softer with the increase of deformation temperature (maximum stress over 120 MPa at 380 °C in comparison to 90 MPa at 450 °C). This can be attributed to more dynamic recrystallization and dynamic recovery at higher deformation temperature.

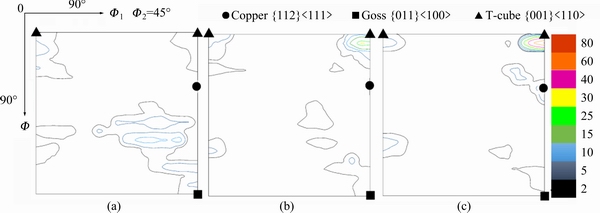

The macro-texture changes of the above samples are obtained by using XRD, as illustrated in Fig. 3. It seems that in the sample compressed at 380 °C , some cube texture and Goss texture are observed from the orientation distribution function (ODF) map (Fig. 3(a)). As cube texture belongs to recrystallization texture and Goss texture is deformation texture, the intensity of different textures can be an indicator of recrystallization process. When the compression temperature goes up to 410 °C, the intensity of cube texture raises, indicating that the degree of recrystallization is increased with elevating compression temperature. After further increase of the compression temperature, the level of cube texture is improved to 85 (Fig. 3(c)), which means that the sample is almost full recrystallized. Such microstructure changes are well consistent with the information as shown in Fig. 2.

Fig. 1 EBSD maps of Al clad (a, b and c) and Al-Zn-Mg-Cu matrix (d, e and f) after holding for 3 min at various starting temperatures

It is well-known that higher temperature provides more energy for the microstructural transformation such as dynamic recovery and dynamic recrystallization [8]. When the sample is compressed at 380 °C, the compression temperature is relatively low and the energy is not enough for a significant dynamic recrystallization. When the compression temperature is increased to 410 °C, there is more energy for the growth of sub-grains and nucleation of new grains, which results in the recrystallization increment. More energy was provided at 450 °C for microstructural transformation. In addition, it will be easier for dislocations to climb or slide during compression at high temperatures. Such dislocation migration may also result in the merging of sub-grains and transformation of low-angle grain boundaries to high-angle boundaries. Thus, a higher percentage of recrystallized grains was observed at higher deformation temperature. Considering that the strain rate is 1 s-1 during compression, the whole deformation is finished under 1 pass within about 1.2 s. Therefore, there is insufficient time for a fully recrystallization, and dispersoids may also hinder the development of recrystallization and recovery [9], as a result many sub-grain can also be observed in Fig. 2.

3.2 Influence of compression passes on microstructure

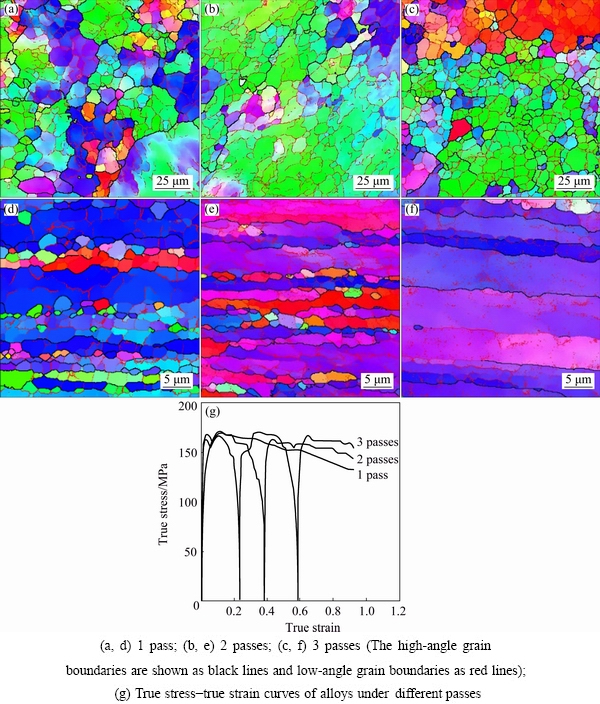

The influence of the compression pass on the microstructure is quite different for the Al cladding and the Al-Zn-Mg-Cu matrix. The grain size of Al cladding is much larger than that of matrix. For the sample, compressed with single pass, equiaxed grains with size about 50 μm are observed in the Al cladding (Fig. 4(a)), while elongated grains are observed in the matrix (Fig. 4(d)). Many low-angle boundaries and clear sub- grains can be seen inside the grains. For the sample compressed with multiple passes (Figs. 4(b) and (c)), the original grain of Al cladding grows to larger than 100 μm, while sub-grains coarsening and small amount of new grains along the original grain boundaries can also be observed. More sub-grains are observed in Fig. 4(c) (three passes) than in Fig. 4(b) (two passes). While for the matrix, many clear sub-grains are observed in the sample compressed with two passes (Fig. 4(e)). However, unlike in Al cladding, the matrix of the sample compressed with 3 passes shows very low density of sub-grains and low-angle grain boundaries (Fig. 4(f)). Figure 4(g) shows the true stress-true strain curves during compression with different passes. The flow softening is very significant when compressed with single pass, and weakens with the increase of the number of passes.

Fig. 2 EBSD maps of Al cladding (a, b and c) and Al-Zn-Mg-Cu matrix (d, e and f) after hot compression with strain rate of 1 s-1 at various starting temperatures

Fig. 3 Orientation distribution functions (ODFs) maps of Al-Zn-Mg-Cu alloy after hot compression at 1 s-1 with reduction of height to 70% at 380 °C (a), 410 °C (b) and 450 °C (c)

Fig. 4 EBSD maps of Al cladding (a, b and c ) and Al-Zn-Mg-Cu matrix (d, e and f) after hot compression to 70% of original height at 410 °C with strain rate of 30 s-1 under different passes

The compression rate is as high as 30 s-1 in Fig. 4, therefore compression time is only about 0.04 s for a reduction of 70%. Within such short time, dynamic recovery and recrystallization cannot happen during the compression. For the sample compressed with multiple passes, there is an interval of 30 s at elevated temperature between each pass. There are not many alloying elements in the Al cladding, therefore there are not many precipitates to hinder the growth of the grains and sub-grains, the grains and sub-grains can readily grow during the interval of the passes at 410 °C. While in the Al-Zn-Mg-Cu matrix, there are many precipitates, the grain and sub-grains need higher driving force and longer time to grow at 410 °C. Therefore, the grain size in the Al cladding is much larger than that in the matrix, and in the sample compressed with multiple passes significant grain growth is observed in the Al cladding, while the grain growth is not obvious in the matrix. At the interval between deformation passes, static recovery or recrystallization driven by the stored deformation energy could happen [10] through the merge of sub-grains, which result in the sub-grain coarsening or formation of new grains to lower down the interfacial energy [11-16], just as observed in Figs. 4(b)-(c). More sub-grains and new grains in Fig. 4(c) than that in Fig. 4(b) can be attributed to the longer stay at 410 °C. It is interesting to notice that the microstructure of the matrix of the sample compressed with 3 passes (Fig. 4(f)) is quite different with that of the sample compressed with 2 passes. This could be explained by the less reduction per pass, which results in less stored energy and cell structure. During the following interval, the stored energy is partly released by the annihilation and re-arrangement of dislocations, and moreover the motion of the sub-grains boundaries in the Al-Zn-Mg-Cu matrix is obstacled by higher pinning force, consequently there are not many sub-grain boundaries observed in the matrix of the sample compressed with 3 passes.

Flow softening is a common characteristic of many alloys deformed at elevated temperatures. It is related to the thermal softening and microstructural softening [17]. The thermal softening is ascribed to deformation heating, whereas the microstructural softening consists of dynamic recovery, dynamic recrystallization and the coarsening of dynamic precipitation [18-20]. The microstructural softening can hardly happen in short compression time due to fast compression rate, therefore thermal softening is the main mechanism for the observed flow softening in Fig. 4(g). The experimental records also show that the rise of sample temperature can be up to 40 °C during single pass heating, and only 15 °C during three passes. During multiple passes compression,the compression time is shorter at each pass and the sample cools down to environmental temperature at the 30 s interval between each pass, consequently the temperature rise due to deformation heating is lower during the multiple passes compression compared with the single pass compression. As a consequence, the flow softening is less prominent during multiple passes compression.

3.3 Influence of deformation strain rate on microstructure

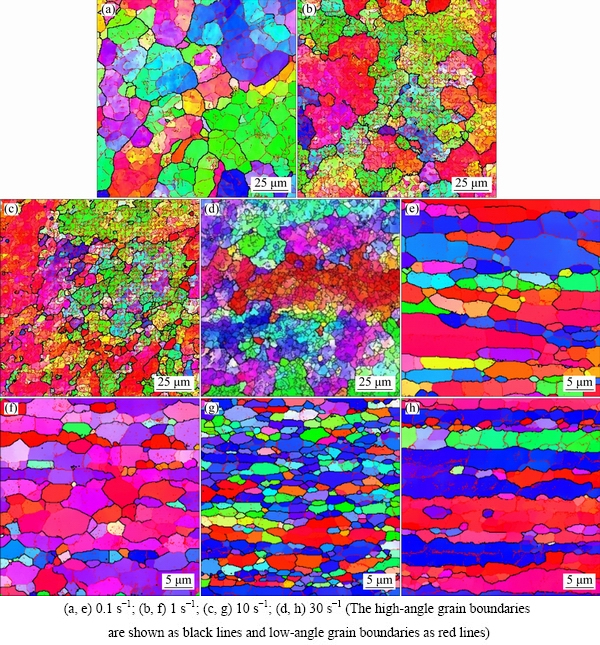

Figure 5 shows the microstructure evolution of Al- cladded Al-Zn-Mg-Cu samples deformed at different strain rates. It is clear that in the Al layer, the density of sub-structures increases at higher strain rates from 0.1 to 10 s-1 (Figs. 5(a)-(c)), as indicated by the increment of low-angle boundaries. When the strain rate increases to 30 s-1 (Fig. 5(d)), the compression time is only about 0.04 s for a reduction of 70%, so there is not enough time for dislocation migration and the visualized amount of low-angle boundaries seems not higher than that in Fig. 5(c). For the Al-Zn-Mg-Cu matrix (Figs. 5(e)–(h)), all deformed grains elongate along the direction vertical to the compression direction. At lower strain rate (0.1 s-1), sub-grains get sufficient time to grow up and larger grains appear in Fig. 5(e). At higher strain rates, the deformation energy increases, but the deformation time is shortened when compression to the same reduction level. Therefore, deformation brings more dislocations, while the time for dislocation re- arrangement or annihilation is not enough. The existence of high density sub-structures restrains the growth of grains, so dynamic recrystallization happens during hot deformation but the grain size is refined as shown in Figs. 5(f) and (g). When the strain rate is too high (30 s-1), EBSD observation shows that the grains are still somehow elongated. The high-angle grain boundaries (black lines) distribute vertical to the compressive direction, and many low-angle grain boundaries (red lines) penetrate the deformed grains. Although a few small recrystallized grains (indicated by arrows in Fig. 5(h)) are observed, grain refinement in general is not effective (Fig. 5(h)). Obviously, dynamic recovery and dynamic recrystallization are limited. WU et al [21] observed similar phenomenon at a low strain rate (20 s-1) in 7050 alloys. This is because the deformation time (only 0.04 s for 70% reduction) is too short at such high strain rate. Within such short deformation time, the dynamic recovery and recrystallization become hard to take place [22], even though the deformation heating causes a temperature rise of about 30 K.

Strain rate and deformation temperature are two key factors to influence the microstructure of deformed materials. The temperature corrected strain rate Zener- Hollomon parameter (Z) can be expressed as

(1)

(1)

where  is the strain rate, Q is the activation energy of hot deformation, R is the mole gas constant, and T is the deformation temperature, A, n and α are constants, and σ is the stress [24]. Taking logarithm of Eq. (1) gives as follows:

is the strain rate, Q is the activation energy of hot deformation, R is the mole gas constant, and T is the deformation temperature, A, n and α are constants, and σ is the stress [24]. Taking logarithm of Eq. (1) gives as follows:

(2)

(2)

At fixed temperature, n can be obtained by differentiating Eq. (2):

(3)

(3)

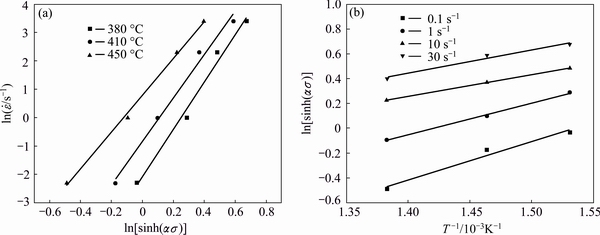

Therefore, n can be obtained from the slopes of the  -ln[sinh(ασ)] plots, as shown in Fig. 6(a). The average n value is 7.34.

-ln[sinh(ασ)] plots, as shown in Fig. 6(a). The average n value is 7.34.

Fig. 5 EBSD maps of Al cladding (a, b, c and d ) and Al-Zn-Mg-Cu matrix (e, f, g and h) after hot compression under 1 pass with 70% reduction at 450 °C at different strain rates

Fig. 6 Variation of strain rate with saturation flow stress (a) and saturation flow stress with deformation temperature (b) for Al cladded Al-Zn-Mg-Cu alloy

For a given strain rate, after differentiating Eq. (2), there is

(4)

(4)

So, the value of Q can be easily derived from the slopes in the ln[sinh(ασ)]-1/T plot, as shown in Fig. 6(b). The hot deformation activation energy Q of the experimental alloy is 144.4 kJ/mol, which is close to the homogenized Al-Zn-Mg-Cu alloy (160.3 kJ/mol) [24] and higher than extruded Al-Zn-Mg-Cu alloy (122 kJ/mol) [21], but much lower than that of solution treated Al-Zn-Mg-Cu alloy (256.6 kJ/mol) [25]. The hot deformation activation energy Q can have great differences, even for the similar or same composition alloys. This is because that the deformation activation energy Q is sensitive to the initial microstructures (e.g., grain size, the presence of precipitates) and heat treatment conditions in the alloys. The current alloy was hot rolled before the thermal simulation tests, and the grain size is not fine, the precipitate size is relatively large. Therefore, the deformation activation energy Q is relatively low.

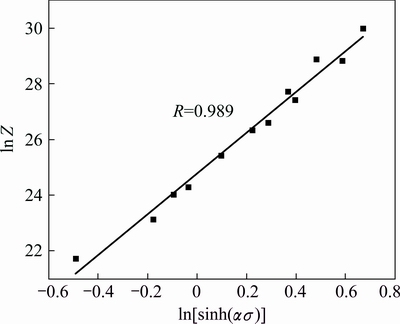

Z value is calculated according to Eq. (1). A linear relationship between ln Z and the saturation flow stress is observed, as shown in Fig. 7. The correlation coefficient is 0.989, suggesting that Eq. (1) is relatively accurate for describing the hot deformation behavior of the experimental alloys.

Fig. 7 Variation of ln Z with saturation flow stress

Z value has a great effect on the sub-grain and recrystallization structures. In general, with the increase of Z (i.e., the strain rate increases or deformation temperature decreases), the size of sub-grains is reduced as well as that of recrystallization grains (Fig. 5). The driving force for recrystallization comes from the distortion energy between grain boundaries. At lower Z value,the dislocations collect into more widely spaced and less dense tangles. The sub-grain diameter increases with more clearly defined sub-boundaries containing dislocations in an orderly manner (Figs. 5(a) and (e)). At a higher Z value, the dislocation proliferation and pileup become more significant for a given strain, and dislocations do not have enough time to rearrange or merge themselves. Therefore, there are more sites for nucleation and higher driving force for recrystallization. There is also limited time for the growth of recrystallized grains, so the grains get refined. At a very high Z value, the recrystallization and recovery is restricted due to short stay at elevated temperatures although the driving force for recrystallization and recovery is high (Figs. 5(d) and (h)).

4 Conclusions

1) The degree of crystallization and grain size increase with the increase of deformation temperature.

2) Static recovery and recrystallization happens during the interval of compression passes when the sample is compressed with multiple passes.

3) The levels of recovery and recrystallization are different in the Al cladding and Al-Zn-Mg-Cu matrix due to the difference in the content of the additional elements.

4) The deformation heating is significant at higher strain rate, which can cause thermal softening.

5) Higher strain rate leads to finer sub-grains at strain rate below 10 s-1. At strain rate of 30 s-1, dynamic recovery and recrystallization is limited due to short duration at elevated temperature.

References

[1] HEINZ A, HASZLER A, KEIDEL A, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280: 102-107.

[2] DUMONT D, DESCHAMPS A, BRECHET Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy [J]. Materials Science and Engineering A, 2003, 356(1-2): 326-336.

[3] WILLIAMS J C, STARKE E A Jr. Progress in structural materials for aerospace systems [J]. Acta Materialia, 2003, 51(19): 5775-5799.

[4] LI Bo, PAN Qing-lin, LI Chen, ZHANG Zhi-ye, YIN Zhi-ming. Hot compressive deformation behavior and constitutive relationship of Al-Zn-Mg-Zr alloy with trace amounts of Sc [J]. Journal of Central South University, 2013, 20 (11): 2939-2946.

[5] JIA Yan-dong, CAO Fu-yang, GUO Shu, MA Pan, LIU Jing-shun, SUN Jian-fei. Hot deformation behavior of spray-deposited Al-Zn-Mg-Cu alloy [J]. Materials and Design, 2014, 53: 79-85.

[6] WU H, WEN S P, HUANG H, WU X L , GAO K Y, WANG W, NIE Z R. Hot deformation behavior and constitutive equation of a new type Al-Zn-Mg-Er-Zr alloy during isothermal compression [J]. Materials Science and Engineering A, 2016, 651: 415-424.

[7] LI Chao, WAN Min, WU Xiang-dong, HUANH Lin. Constitutive equations in creep of 7B04 aluminum alloys [J]. Materials Science and Engineering A, 2010, 527(16-17): 3623-3629.

[8] YAN Ming-liang, SHEN Jian, LI Zhou-bing, LI Jun-peng. Effect of deformation temperature on microstructure and mechanical properties of 7055 aluminum alloy after heat treatment [J]. Transactions of Nonferrous Metals Society of China , 2013, 23(3): 625-630.

[9] EZATPOUR H R, CHAICHI A, SAJJADI S. A. The effect of Al2O3-nanoparticles as the reinforcement additive on the hot deformation behavior of 7075 aluminum alloy [J]. Materials and Design, 2015, 88: 1049-1056.

[10] YAN Ming-liang, SHEN Jian, LI Zhou-bing, LI Jun-peng. Multi-pass hot rolling simulation of Al-Zn-Mg-Cu-Zr alloy [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1013-1018. (in Chinese)

[11] KIM H W, KANG S B, TSUJI N, MINAMINO Y. Elongation increase in ultra-fine grained Al-Fe-Si alloy sheets [J]. Acta Materialia, 2005, 53 (6): 1737-1749.

[12] DING H, HIRAI K, KAMADO S. Microstructure characteristics during the multi-pass hot rolling and their effect on the mechanical properties of AM50 magnesium alloy sheet [J]. Materials Science and Engineering A, 2010, 527(15): 3379-3385.

[13] LI Chen, LI Zhi-hui, HUANG Shu-hui, LI Xi-wu, YAN Hong-wei, LIU Hong-wei, ZHANG Yong-an, XIONG Bai-qing. Microstructure evolution of 7055 aluminum alloy during multi-pass hot deformation and solution treatment process [J]. Transactions of Materials and Heat Treatment, 2015, 36(12): 55-60. (in Chinese)

[14] WANG Xin, CHEN Wen-zhen, HU Lian-xi, WANG Guo-jun, WANG Er-de. Microstructure refining and property improvement of ZK60 magnesium alloy by hot rolling [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: s242-s246.

[15] MURTY S V S, NAYAN N, KUMAR P, NARAYANAN P R, SHARMA S C, GEORGE K M. Microstructure–texture–mechanical properties relationship in multi-pass warm rolled Ti-6Al-4V Alloy [J]. Materials Science & Engineering A, 2014, 589: 174-181.

[16] LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bai-ping, YAN Ming-liang. Recrystallization behavior of 7050 aluminum alloy during multi-pass hot compression process [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1754-1758. (in Chinese)

[17] LEE B H, REDDY N S, YEOM J T, LEE C S. Flow softening behavior during high temperature deformation of AZ31Mg alloy [J]. Journal of Materials Processing Technology, 2007, 187-188: 766-769.

[18] BHATTACHARYA R, B P WYNNE, W M RAINFORTH. Flow softening behavior during dynamic recrystallization in Mg-3Al-1Zn magnesium alloy [J]. Scripta Materialia, 2012, 67(3): 277-280.

[19] LI Luo-xiong, WANG Guan, LIU Jie, YAO Zao-qi. Flow softening behavior and microstructure evolution of Al-5Zn-2Mg aluminum alloy during dynamic recovery [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 42-48.

[20] QUAN Guo-zheng, LIU Ke-wei, ZHOU Jie, CHEN Bin. Dynamic softening behaviors of 7075 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(S3): 537-541.

[21] Wu B, Li M Q, Ma D W. The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy [J]. Materials Science and Engineering A ,2012, 542: 79-87.

[22] Myshlyaev M M, McQeen H J, Mwembela A, Konopleva E, Twinning, dynamic recovery and recrystallization in hot worked [J]. Materials Science and Engineering A, 2002, 337(1-2): 121-133.

[23] MIRZADEH H. Simple physically-based constitutive equations for hot deformation of 2024 and 7075 aluminum alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1614-1618.

[24] Deng Ying, Yin Zhi-min, Huang Ji-wu. Hot Deformation behavior and microstructural evolution of homogenized 7050 aluminum alloy during compression at elevated temperature[J]. Materials Science and Engineering A, 2011, 528: 1780-1786.

[25] Hu H E, Zhen L, Shao W Z, Zhang B Y. Deformation behavior and microstructure evolution of 7050 aluminum alloy during high temperature deformation [J]. Materials Science and Engineering A, 2008, 488: 64-71.

廖 斌1,吴晓东1,闫昌建1,刘 政1,纪艳丽2,曹玲飞1,黄光杰1,刘 庆1

1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 中铝材料应用研究院有限公司 苏州分公司,苏州 215026

摘 要:利用Gleeble-3500热模拟试验机对Al-Zn-Mg-Cu包铝板进行热变形,采用EBSD和XRD对不同变形条件下的Al-Zn-Mg-Cu基体和包铝层显微结构进行表征,其变形条件为变形量70%、温度380~450 °C、应变速率0.1~30 s-1。结果表明,变形温度、道次和变形速率直接影响样品的回复和再结晶过程,从而进一步影响其显微结构。在包铝层和Al-Zn-Mg-Cu基体中回复和再结晶的程度有所区别。较高的变形温度导致较高程度的再结晶以及较大的晶粒尺寸。在多道次变形中的停留时间内会发生静态再结晶。当应变速率低于10 s-1时,随着应变速率的增大,出现较多细小的亚晶组织;然而,在30 s-1的大应变速率条件下,试样在变形温度下停留时间较短,导致动态回复及再结晶程度受限。

关键词:Al-Zn-Mg-Cu合金;包铝层;热变形;回复;再结晶

(Edited by Xiang-qun LI)

Foundation item: Projects (2016YFB0300901, 2016YFB0700401) supported by the National Key Research and Development Program of China; Projects (106112015CDJXY130003, 106112015CDJXZ138803) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: Xiao-dong WU; Tel: +86-23-65102017; E-mail: xiaodongwu@cqu.edu.cn

DOI: 10.1016/S1003-6326(17)60191-2