文章编号:1004-0609(2009)04-0639-05

应力对Al-Zn-Cu系平衡相的影响

代双贺,陈 辉,郑 涛

(沈阳建筑大学 交通与机械工程学院,沈阳 110168)

摘 要:采用99.999%分析纯的Al、Zn、Cu作原料,在外热式坩埚炉中熔制了5Cu40Zn55Al、15Cu20Zn65Al和3Cu17Zn80Al共3种合金,将其经过成分均匀化处理后,对包含亚稳相的3种合金分别进行球磨和手工锤击实验,采用X射线衍射仪分析合金平衡相组合。结果表明:合金通过球磨能得到室温平衡相,而通过手工捶击则得不到室温平衡相;能否通过应力诱发相变快速获得室温合金平衡相组织与合金应力作用产生的变形机制有关;球磨能使合金内部发生大量变形,为合金向平衡相转变提供驱动力和原子扩散通道;而手工锤击主要是使合金发生以解理为主的脆性断裂,这种变形不能为亚稳相的转变提供必要的驱动力和原子扩散通道,从而得不到合金室温下的平衡相组成。

关键词:Al-Zn-Cu三元系合金;球磨;手工捶击;应力诱发相变;平衡相

中图分类号:TG 113. 14 文献标识码: A

Effect of stress on equilibrium phases in Al-Zn-Cu alloys

DAI Shuang-he, CHEN Hui, ZHENG Tao

(Traffic and Mechanical Engineering School, Shenyang Jian Zhu University, Shenyang 110168, China)

Abstract: 5Cu40Zn55Al, 15Cu20Zn65Al and 3Cu17Zn80Al alloys were founded by using 99.999% Al, Zn and Cu as raw mater material in external-heat crucible. After uniform treatment, the alloys were then treated, respectively, by hand hammering and ball milling. The equilibrium phases of Al-Zn-Cu alloys were analyzed by XRD. The results show that the equilibrium phases of these three alloys can be obtained by ball milling at room temperature, but the result is contrary by hand hammering. So it is obtained that whether the equilibrium phase can be obtain or not by the stress at room temperature mainly depends on the feature of deformation mechanism of the alloys. During ball milling, the stress provides adequate deformation in the inner structure, which supplies enough driving force and diffuse alleyway of atom for the transformation of metastable phase. But the stress in the experiment during hand hammering only cause brittle rupture from cleavage to oriented, this can not offer enough driving force and diffuse alleyway of atom for the transformation of metastable phase, so the equilibrium phase of alloy can not be gotten at room temperature.

Key words: Al-Zn-Cu alloys; ball milling; hand hammering; stress induce phase transformation; equilibrium phase

Al-Zn-Cu三元系相图对于研究铝合金的自然时效和人工时效具有特殊的参考价值[1-2],而获得Al-Zn-Cu系合金室温平衡相组成却比较困难。在研究Al-Zn-Cu系低Cu侧的室温相图[3],Al2Zn2Cu 系200 ℃低铜侧的相平衡时[4],为保证冷却过程中组织转变进行得更充分,制定的阶梯冷却处理工艺总时间长达1 100 h。因此,如何可靠而快速获得低温平衡组织、尤其是室温平衡组织是一个比较重要的研究课题。应力诱发相变能引起合金的结构和性能的变化,许多学者在相关方面已经已经进行较多的研究[5-7]。 变形不仅使材料的外部形态发生变化,而且可以改变材料的内部组织结构,为原子的扩散提供扩散通道,从而引起材料性能的变化[8]。为了进一步多方面理解变形加工过程中材料本身结构变化特点,应力导致的结构转变成为最重要的研究课题之一[9-11] 。随着非平衡态材料和纳米材料研究的发展,球磨加工引起研究者们的广泛关 注[12]。强制冷却球磨可以在基本不改变温度的情况下向合金中引入塑变储能,进而改变原子的可动性[12-14]。为了比较快速得到Al-Zn-Cu三元系室温下的平衡相,本文作者研究了应力诱发相变对Al-Zn-Cu三元系室温相平衡关系的影响,设计了球磨加工和手工捶击两种变形方法,并从理论上进行分析讨论,得出合金在不同应力作用下组织或相组成的变化规律。

1 实验

实验熔制5Cu40Zn55Al、15Cu20Zn65Al和3Cu17Zn80Al这3个合金,实验所用的合金原料为高纯铝(99.999%)、高纯锌(99.999%)和高纯铜(99.999%),采用4 kW外热式电阻炉,在高纯刚玉坩埚中熔炼,温度为690~700 ℃,直接浇铸到钢摸中,以减少成分偏析。将熔制的合金进行成分均匀化处理,处理制度为380 ℃,100 h,然后使合金冷却到室温,用线切割将合金切割成最大尺寸为2 mm的颗粒进行球磨和手工锤击实验。

3个合金在室温(20 ℃)等温截面相图中的位置如图1所示。 这3个合金在平衡冷却处理后处于同一个三相区[3],合金平衡相组成均为T ′ +α+β,但在通常的缓冷处理时,合金元素由于扩散不充分,室温时这3个合金均含有亚稳相。

图1 球磨实验和手工锤击用合金在室温等温截面中的位置

Fig.1 Positions of alloys by ball milling and hand hampering in Al-Zn-Cu system at 20 ℃ (a—5Cu40Zn55Al; b— 15Cu20Zn65Al; c: 3Cu17Zn80Al

球磨实验中,球磨机为GN-1型高能球磨机。球磨过程中,球磨罐内的真空度为10-2 Pa,并且始终对罐体进行强制风冷。在每次球磨约70 min时,停止球磨20 min,同时一直保持风冷。环境温度为16~20 ℃,球磨每一循环测得的球磨罐内温度均为30 ℃以下,达到控制温度的要求,减少升温对相变的影响。

制作球磨罐、球磨球、金属钵和金属锤的材料均为GCr15,处理状态为球化退火。金属锤头部直径为5 cm,锤质量为1.5 kg。与球磨实验相比较,手工锤击锤头质量大,一次锤击的力量约为70~100 N,锤击的频率约为每分钟80~100次。

结构分析使用日本理学D/Max-Ya X射线衍射仪进行,采用Cu Kα,电压为40 kV,电流为40 mA,利用Ni滤波片,步进扫描速度为40/min,金相显微观察采用Philips XL-30FEG扫描电子显微镜。

2 结果及分析

2.1 15Cu20Zn65Al、5Cu40Zn55Al合金球磨实验

2.1.1 球磨合金显微组织变化

图2所示为熔制15Cu20Zn65Al和5Cu40Zn55Al合金铸态组织。由图2可以看出,熔制合金成分比较均匀。球磨21 h后,15Cu20Zn65Al颗粒状的合金很快破碎细化,因此,没有做金相观察;5Cu40Zn55Al颗粒状的合金经球磨得到的合金粉末很少,撞击后多数颗粒因黏结而长大(粒径最大可达4 mm)。球磨长大的颗粒可以用牙托粉镶嵌制作成金相试样进行组织观察,其扫描照片如图3所示。结合能谱分析可以认为:图3中白亮块为富Zn相(β相),黑色的基体则是富Al相(α相),而在富Zn相外边包围的环形带则是T ′ 相和富Al相的混合物。

图2 球磨用合金的铸态组织

Fig.2 Microstructures of as-cast alloy for ball milling: (a) 5Cu40Zn55Al ; (b) 15Cu20Zn65Al

图3 球磨21 h后5Cu40Zn55Al的微观组织

Fig.3 Microstructures of 5Cu40Zn55Al alloy after ball milling for 21 h: (a) SEM image; (b) SBSE image

2.1.2 球磨合金相结构变化

图4和5所示分别为15Cu20Zn65Al 和5Cu40Zn55Al合金样品球磨不同时间后的XRD谱。

图4 球磨不同时间后15Cu20Zn65Al的XRD谱

Fig.4 XRD patterns of 15Cu20Zn65Al alloy for different times

图5 球磨不同时间后5Cu40Zn55Al的XRD谱

Fig.5 XRD patterns of 5Cu40Zn55Al alloy after ball milling for different times

从图4和5可以看出,15Cu20Zn65Al和5Cu40Zn55Al两合金在成分均匀化处理后,其组成相分别为样品T ′+α+β?+θ和T ′+α+β+ε相?。其中的θ相?为Al2Cu相,ε相为CuZn4相,此两相均是亚稳相。样品球磨后的XRD分析表明,样品中的亚稳相θ和ε?相全部消失,两合金中的相组成与两合金所处平衡相区平衡相的组成一致,即T ′+α+β?。当15Cu20Zn65Al球磨到12 h后,α相、β?相和T ′相的衍射峰都出现宽化现象,并伴随有低角度的漫散射包出现,说明合金在球磨后有向非晶态转变的趋势;当球磨到40 h后,α相、β?相和T ′相的衍射峰宽化更加明显。而5Cu40Zn55Al合金球磨16 h和21 h后的XRD谱几乎没有差别。

2.2 3Cu17Zn80Al和5Cu40Zn55Al手工锤击合金变形实验

2.2.1 手工锤击合金的显微组织

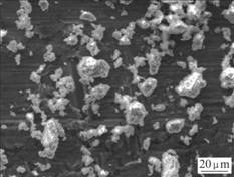

图6和7所示分别为合金经手工锤击实验后得到合金粉末的扫描电镜二次电子像。由图6和7可看出,两合金经过手工锤击后破碎得很细小,达到通过手工锤击快速细化合金颗粒的使其发生大变形的目的,颗粒尺寸由锤击前的粒径小于2 mm细化至5~15 μm,进一步锤击时,锤击能量基本被金属钵所吸收,颗粒继续细化变形已比较困难。

图6 手工锤击20 h后3Cu17Zn80Al的SEM像

Fig.6 SEM image of 3Cu17Zn80Al alloy after hand hammering for 20 h

图7 手工锤击15 h后5Cu40Zn55Al的SEM像

Fig.7 SEM image of 5Cu40Zn55Al l alloy hammering by hand for 15 h

2.2.2 手工锤击实验合金相结构变化分析

图8和9所示分别为3Cu17Zn80Al 和5Cu40Zn55Al经手工锤击后的XRD谱。从图8和9中可以看出,在成分均匀化和手工锤击的各个不同阶段,3Cu17Zn80Al合金中的亚稳相Al2Cu(θ)以及5Cu40Zn55Al中的亚稳相CuZn4(ε)的衍射峰几乎没有变化,说明Al2Cu(θ)和CuZn4(ε)相均没有消失,且其它各相的衍射峰变化也不明显,这说明手工锤击实验不能使3Cu17Zn80Al和5Cu40Zn55Al中的亚稳相消失,即通过手工锤击得不到3Cu17Zn80Al和5Cu40Zn55Al 合金室温下平衡相的组成。

图8 手工锤击不同时间后3Cu17Zn80Al的XRD谱

Fig.8 XRD patterns of 3Cu17Zn80Al alloy after hand hammering for different times

图9 手工锤击不同时间后5Cu40Zn55Al的XRD谱

Fig.9 XRD patterns of 5Cu40Zn55Al alloy after hand hammering for different times

2 讨论

球磨能使合金得到室温下平衡相的组成[13],主要原因是由于球磨合金时合金的变形机制决定的。一方面,在球磨过程中,合金颗粒受力较小,但频度很高,在长时间的反复作用下,合金内部发生大量的塑性变形,该塑性变形可以在基本不改变温度的情况下向合金中引入塑变储能,进而改变原子的可动性,增加原子的扩散能力,为亚稳相向稳定相的转变提供足够大的驱动力;另一方面,球磨过程中,合金在变形的同时组织内部产生大量的缺陷,这些缺陷为原子的扩散提供了大量的快速扩散通道,使得亚稳相在向稳定态转变时原子的扩散更加容易,促进了亚稳相向平衡相的转变。

在手工锤击实验中,颗粒明显细化,但却并不能使其中的亚稳相消失,得不到室温下的平衡相组成。其原因主要是由于手工锤击时撞击力较大,合金颗粒得到的能量主要是用来使合金发生脆性断裂(以解理为主),而其内部既不能累积足够的变形储能为亚稳相的转变提供驱动力,也不能在微观结构中积累很多的缺陷。另外,有研究表明,球磨可以影响物相的形成温度,认为研磨除了可以使物相结构发生畸变外,还可以通过引入晶种,有效地降低物相转变温度[15]。

当应力作用于合金时,可以使合金发生变形,引起合金的外部形态和内部组织结构发生变化。但并不是每一种应力作用于合金时都会得到合金的相平衡,这主要取决于应力作用的方式。作用方式不同的应力会向合金引入不同类型的变形储能,从而会使合金发生不同的变形,最终影响合金的亚稳相转变。

3 结论

1) 室温下,应力诱发相变能否实现合金的相平衡,与应力作用于合金时所产生的变形机制有关。

2) 若希望通过应力诱发相变来快速得到合金室温下的平衡相组成,作用于合金的应力必须能使合金发生大量变形,为亚稳相向平衡相转变提供足够大的驱动力和原子扩散通道。

REFERENCES

[1] LEGENDRE B, FEUTELAIS Y, SAN JUAN J M, HURTADO I. Enthalpy of formation of the ternary T ′ phase in the Al-Cu-Zn system[J]. Journal of Alloys and Compounds, 2003, 308(1): 216-220.

[2] LIANG H, CHANG Y A. A thermodynamic description for the Al2Zn2Cu system[J]. Journal of Phase Equilibria, 1998, 19(1): 25-37.

[3] 陈 辉, 信 昕, 董丹阳, 郝士明. Al2Zn2Cu系室温低Cu侧的相平衡关系[J]. 东北大学学报(自然科学版), 2004, 5(S5): 416-419.

CHEN H, XIN X, DONG D Y, HAO S M. The phase transformation in the Al2-Zn2-Cu alloys containing low Cu[J]. Journal of Northeast University (Natural Science Version), 2004, 5(S5): 269-273.

[4] 陈 辉, 信 昕, 任玉平, 郝士明, 李洪晓. Al2Zn2Cu系200 ℃低铜侧的相平衡[J]. 中国有色金属学报, 2004, 14(6): 912-916.

CHEN H, XIN X, REN Y P, HAO S M, LI H X. The equilibrium phases in low Cu side of Al2Zn2Cu system at two hundreds degree centigrade[J]. The Chinese Journal of Nonferrous Metal, 2004, 14(6): 912-916.

[5] 徐祖耀. 应力对钢中贝氏体相变的影响[J]. 金属学报, 2004, 16(S2): 113-119.

XU Zu-yao. The effection of stress to phase transformation bainite in steel[J]. Journal of Metal, 2004, 16(S2): 113-119.

[6] 刘春成, 姚可夫, 高国峰, 刘 庄. 应力应变对马氏体相变动力学及相变塑性影响的研究[J]. 金属学报, 1999, 11(S11): 1125-1129.

LIU C C, YAO K F, GAO G F, LIU Z. The study of the effection of stress-strain to martensite phase transformation dynamics and transformation plasticity[J]. Journal of Metal, 1999, 11(S11): 1125-1129.

[7] 陆荣林, 方如华. 应力引起的镍钛单晶形状记忆合金相变的实验研究[J]. 力学季刊, 2005, 12: 589-594.

LU Rong-lin, FANG Ru-hua. The study of the phase transformation of Ti-Ni unit crystal shape memory alloys induced by stress[J]. Seasons Journal of Mechanical, 2005, 12: 589-594.

[8] REN Y P, DING H, HAO S M. Abnormal refining of stepped-annealing microstructure in an Al alloy containing low copper and high Zinc[J]. Journal of Materials Science Letters, 2003, 22: 433-436.

[9] ZHU Y H. Milling induced microstructural change in furnace cooled eutectoid Zn-Al alloy[J]. Journal of Materials Processing Technology, 1997, 63: 624-627.

[10] ZHU Y H. Structural evolution in mechanically milled eutectoid Zn-Al based alloy[J]. Z Metallkde, 1997, 88: 934-937.

[11] QIAO Zhi-xia, LIU Yong-chang, WANG Dong-ai, NING Bao-qun, LI Zong-min. Mechanism of stress induced γ→ε martensite transformation in an Fe2Mn2Si shape memory alloy[J]. Journal of Materials Science & Engineering, 2007, 11: 528-529.

[12] 陈 辉, 罗继曼, 韩泽光, 许溪沙. AL-Zn-Cu系合金室温球磨中相变行为研究[J]. 沈阳建筑大学学报(自然科学版), 2007, 23(4): 672 -675.

CHENG Hui, LUO Ji-man, HAO Ze-guang, XU Xi-sha. Study on milling induced structural transformation[J]. Journal of Shenyan Jianzhu University (Natural Science Version), 2007, 23(4): 672-675.

[13] ZHU Y H, OROZCO E, TORRES J. Tensile creep deformation and microstructure change in cast Zn-Al alloy[J].Materials Transactions, 1997(6): 521-526.

[14] ZHE Y H. Milling induced Zn-Al alloy[J]. Journal of Materials Processing Technology, 1997, 63: 624-630.

[15] 陈 玮, 尹周谰, 李晋峰. 影响γAl2O3→αAl2O3物相的转变的因素研究[J]. 轻金属, 2006(3): 12-15.

CHEN Wei, YIN Zhou-lan, LI Jin-feng. Study of influence factor of γAl2O3→αAl2O3 phase transformation process[J]. Light Metal, 2006(3): 12-15.

基金项目:国家自然科学基金资助项目(50171019);辽宁省自然科学基金资助项目(20072007);沈阳市科学技术基金资助项目(1063293)

收稿日期:2008-04-07;修订日期:2008-12-22

通讯作者:陈 辉,教授,博士;电话:024-24692159;E-mail: chenhui@sjzu.edu.cn

(编辑 龙怀中)