宽带钢冷连轧机边降控制支持辊辊形研究

曹建国1,齐杰斌1,张 杰1,王 聪2,曾 伟2,宫贵良2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 武汉钢铁(集团)公司 冷轧薄板厂,湖北 武汉,430083)

摘 要:结合现场带钢边降控制跟踪测试和工业试验,建立辊系三维弹性变形有限元模型,分析武钢1 700 mm四辊冷连轧机组引进的常规凸度支持辊与单锥度工作辊的辊形配置方案存在板形控制能力不足、边降控制效果欠理想和波动大等问题的原因。基于有限元仿真分析和工业试验,采用工作辊和支持辊一体化辊形设计思想提出自主设计的EDW边降控制工作辊配套的VCR变接触支持辊。研究结果表明,VCR/EDW新方案与原方案相比,前者的辊缝凸度调节域扩大10.7%,辊缝横向刚度增强19.1%,辊间接触压力峰值下降21.6%;VCR变接触支持辊配合EDW边降控制工作辊经过工业轧机现场轧制,轧机凸度控制能力明显增强,弯辊力调节效率提高,带钢边降、凸度及平坦度显著提高。

关键词:冷连轧机;带钢;边降控制;辊形;有限元方法

中图分类号:TG333.71 文献标识码:A 文章编号:1672-7207(2008)05-1011-06

Backup roll contour for edge drop control technology in

tandem cold rolling mill

CAO Jian-guo1, QI Jie-bin1, ZHANG Jie1, WANG Cong2, ZENG Wei2, GONG Gui-liang2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Cold Rolling Mill, Wuhan Iron & Steel (Group) Corp., Wuhan 430083, China)

Abstract: Based on ANSYS software and industrial rolling of edge drop control, a 3-dimensional finite element model of roll stacks was built for 1 700 mm tandem cold rolling mill. Using this model, the reasons for some problems exists on the 1 700 mm tandem cold rolling mill configuration of the conventional backup roll and tapered work roll system such as the lower shape control, the poor edge drop control effect and the large fluctuation of the edge drop control were analyzed. Based on the FEM analysis and industrial experiment, the VCR (Varying contact backup rolls) matching the EDW (Edge drop control work rolls) was designed and proposed. The results show that the configuration roll system of VCR and EDW is better than the conventional backup roll and tapered work roll system, i.e. roll gap crown adjustable zone is 10.7% larger, gap stiffness characteristics 19.1% larger and pressure peak 21.6% smaller. The application of VCR matching EDW gives stronger mill crown control ability, a high performance of work roll bending force and the improved strip edge drop, crown and flatness quality.

Key words: tandem cold rolling mill; strip; edge drop control; roll contour; finite element method

边降控制(EDC,又称边部减薄控制)近年来成为板形研究与控制技术的新领域,与高度发展的凸度和平坦度控制技术相比,边降控制研究正处于起步阶段,是板形控制的薄弱环节[1-7]。近年来,为了满足用户对带钢边部板形质量的新要求,EDC日益受到重视,成为带钢边部板形控制的关键技术。为适应冷轧产品日趋苛刻的边降质量要求,主要采用以下措施:

a. 使用锥形工作辊的K-WRS技术[8]。如宝钢集团有限公司1550UCMW和武汉钢铁(集团)公司1450UCMW轧机全部5个机架锥度工作辊采用此技术[4-6];武汉钢铁(集团)公司1700冷连轧机组完成以酸轧联机为主要内容的技术改造,增加了第1和第2架利用单锥度工作辊[9]结合液压窜辊进行冷轧无取向硅钢边降控制,且改造后冷连轧机组1~5架支持辊均采用外方提供的常规凸度辊形。

b. 轧辊沿板带宽度方向产生适当的温度分布,产生热凸度的EDC冷却系统。

c. 在板带边部区域配置对轧辊进行弱化的EDC辊,如Thyssen Krupp冷轧厂、武汉钢铁(集团)公司2180冷连轧机和邯钢新建的5机架6辊轧机的每个机架上均配置EDC辊系统[7]。由于EDC辊系统加工、应用维护成本较高,随着1700冷连轧机国内合作自主开发的EDW辊取得显著边降控制工业应用实绩,2180冷连轧机于2008年5月应用EDC辊。

d. 使用工作辊既可交叉又可横移的T-WRS&C技术,如宝钢集团有限公司益昌1 220 mm 5机架冷连轧机组改造的第1架采用T-WRS&C冷轧机[10-11]。需指出的是,目前,生产实践中冷连轧机边降控制大多采用新建六辊轧机机型,利用工作辊边降控制手段、小直径工作辊和中间辊窜动消除辊间有害接触区等可有效提高边部板形控制能力,但存在投资、生产应用成本和维护成本高等缺点。而四辊冷轧机是宽带钢冷连轧机的主力机型之一,具有易实现高速、大扭矩稳定轧制,辊系简单,可靠性好的特点,但目前,国内外关于四辊冷连轧机进行带钢边降控制的理论研究和实践很少。在此,本文作者对四辊冷轧机边降控制新技术进行研究。

1 EDW边降控制工作辊工业应用效果及分析

在工业轧制试验中,采用VAI提供的单锥度工作辊常规配辊方案结合工作辊液压窜辊、弯辊技术进行带钢边降控制新技术,冷轧无取向硅钢平均边降低于10 μm的比率由29.2%提高到62.5%,但在调试过程中,若控制不当则极易出现剪边、辊面粘结和边降控制效果不对称等问题,甚至出现“断带”导致停产[9]。目前,这项引进的板形控制新技术在1 700 mm冷连轧生产线一直未能投入应用。本文作者在边降控制调试、单锥度工作辊辊形及窜辊模型研究的基础上,自主设计了VCR/EDW(变接触支持辊/边降控制工作辊)一体化配辊方案。

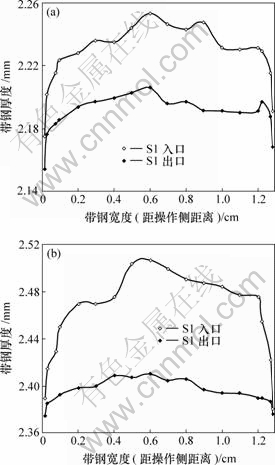

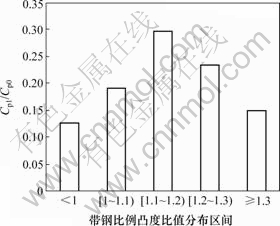

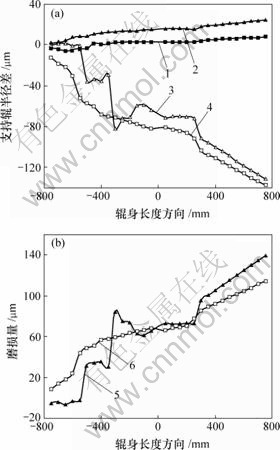

EDW工作辊已投入稳定工业应用,应用后边降平均值在10 μm以内的比率由外方提供边降控制技术调试的62.5%提高到EDW工业应用的91.3%。图1所示为EDW辊使用前后的带钢在线取样实测结果。带钢同卷之内和不同卷之间边降波动均较大,工业试验结果表明,同卷内边降波动幅值大于5 μm的比例达到75%。宽带钢热连轧机-冷连轧机工业轧制跟踪实验结果表明,该1700冷连轧机组对凸度的控制能力不足。图2所示为连续轧制47卷冷轧带钢成品比例凸度Cp1(指出口带钢凸度与厚度之比)与原料比例凸度Cp0(指入口带钢凸度与厚度之比)的比值Cp1/ Cp0的分布情况。可见,成品比例凸度与来料比例凸度的比值平均值为1.2,需要在门户机架加强凸度控制能 力[12-15]。采用原常规凸度支持辊下机后存在辊面粗糙甚至剥落等问题。图3所示为常规凸度支持辊与EDW配辊方案下轧辊编号为106号和865号支持辊在不同服役时期的实际磨损状况。

(a) EDW投入使用前;(b) EDW投入使用后

图1 EDW投入使用前后带钢在线取样对比

Fig.1 Comparison of strip profile before and after using EDW(Edge drop control work rolls)

图2 1 700 mm冷连轧机常规支持辊方案的带钢成品比例凸度与原料比例凸度的比值分布

Fig.2 Distribution of rations for relative strip crown between final products and raw products with conventional backup rolls in 1 700 mm tandem cold rolling mill

1—上辊(106号)上机前辊形;2—上辊(106号)下机后辊形;3—下辊(865号)上机前辊形;4—下辊(865号)下机后辊形;5—上辊(106号)磨损曲线;6—下辊(865号)磨损曲线

图3 1 700 mm冷连轧机常规支持辊与EDW配辊下的支持辊磨损(第1架)

Fig.3 Backup roll wear contour with configuration of conventional backup roll and EDW in 1 700 mm tandem cold rolling mill (Stand 1)

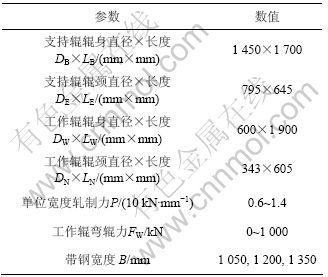

2 辊系弹性变形有限元模型

为分析EDW工作辊与常规凸度支持辊配辊方案以及存在的问题,并进一步提高冷连轧机边降控制能力,提高机组运行稳定性和降低支持辊辊耗等,采用大型通用有限元软件ANSYS建立辊系三维变形有限元模型,用于对辊系力学行为进行分析。选取Solid45(八节点六面体)等参单元作为主要单元。同时,为增加辊缝的计算精度,在与带钢接触的小区域内采用Solid95(二十节点六面体)高阶等参单元。为兼顾计算精度和计算速度,在轧辊内部,单元划分较粗,越靠近轧辊表层,单元划分越细。同时,在辊间接触区、工作辊与带钢接触区,将单元细分。工作辊与支持辊之间的接触属于柔-柔接触;为减少计算时间,仅在辊间一部分可能发生接触的表面上附加接触单元,并将支持辊表面指定为目标面,使用的单元号为TARGET170,工作辊表面指定为接触面,使用的单元号为CONTACT173。具体建模参数如表1所示。

表1 辊系有限元模型的建模参数

Table 1 Parameters of finite element model of roll stacks

3 VCR变接触支持辊性能分析

VCR支持辊是根据变接触轧制思想[14-20],依据辊系弹性变形特性,使辊系在轧制力作用下辊间接触长度能自动与带钢宽度相适应,以减小或消除辊间有害接触区,减小辊缝区的挠曲变形,达到降低辊缝凸度、增大辊缝刚度、提高弯辊力调控范围和调节效率、增大辊缝调节柔性的效果。

由于边降控制工作辊EDW为非对称辊形且反对称布置,因此,辊系呈非对称分布,从理论上设计了第1架和第2架与EDW边降控制工作辊配套的上下辊形反对称的VCR支持辊,同时,为兼顾支持辊换辊周期内轧制普板时其与常规凸度工作辊配辊的生产实际情况,满足支持辊在第1架和第2架间的互换性,确定了现场实际应用的VCR支持辊辊形,并比较分析常规凸度支持辊和VCR支持辊配辊方案的力学行为和板形控制性能。

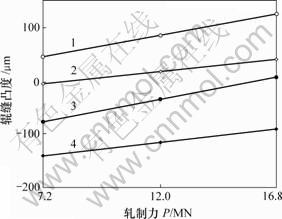

3.1 辊缝横向刚度和凸度调节域

在相同窜辊量作用下,改变轧制力P和弯辊力,通过计算分析可得辊缝横向刚度特性,结果如图4所示。由图4可知,应用VCR支持辊配合EDW工作辊后,辊缝横向刚度为148 kN/μm,比常规凸度支持辊配辊时的横向刚度124 kN/μm提高了19.1%,明显增加了辊缝控制的稳定性。

1—常规弯辊力为0;2—VCR弯辊力为0;3—常规弯辊力为0.5 MN;4—VCR弯辊力为0.5 MN

图4 VCR变接触支持辊和常规支持辊与EDW边降控制工作辊不同配辊方案的辊缝横向刚度特性

Fig.4 Gap stiffness characteristics of EDW with VCR and conventional backup rolls

VCR变接触支持辊配辊方案的辊缝凸度调节域为133.1 μm,比常规凸度支持辊配辊方案的辊缝凸度调节域120.2 μm提高10.7%,不仅表示门户机架轧机凸度干预控制能力增强,而且弯辊的边降调节能力增强,有助于减轻工作辊通过EDW连续可变锥形段窜辊进行边降控制的负担,减轻带钢非边降区进入EDW工作辊边降控制曲线段导致带钢该区域超厚的现 象,以保证自第5架轧出的成品具有良好的横截面形状和理想的表观平坦度。

3.2 辊间接触压力分析

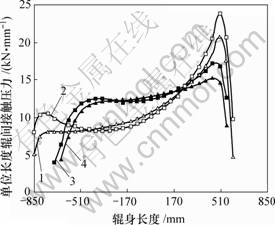

采用前述建立的有限元模型进行仿真,得到辊系不同弯辊力条件的辊间接触压力分布,见图5。

1—常规弯辊力为0.5 MN;2—常规弯辊力为1 MN;3—VCR弯辊力为0.5 MN;4—VCR弯辊力为1 MN

图5 VCR变接触支持辊和常规支持辊与EDW边降控制工作辊不同配辊方案的单位长度辊间压力分布对比

Fig.5 Comparison of contact pressure distribution between rolls of EDW with VCR and conventional backup rolls

由图5可知,采用原有辊形配置方案,带钢宽度以外的辊间有害接触区明显存在,辊间接触压力分布不均性严重,EDW工作辊锥度侧辊间接触压力大且存在明显压力尖峰,弯辊力越大,压力尖峰越明显。这不仅引起轧制过程中所出现的上述问题,而且将引起弯辊力板形调控效率下降,支持辊容易产生严重不均匀磨损甚至剥落,缩短换辊周期,增加轧辊辊耗。研究结果表明,四辊轧机带钢宽度以外的辊间有害接触区是造成带钢边降的主要原因之一,带钢越薄,这种影响越大。采用VCR支持辊与EDW单锥度工作辊进行配辊时,大大降低了有害接触区的辊间接触压力,增强了辊间接触压力的均匀性,减弱了辊身端部的接触压力尖峰,辊间压力峰值下降幅度达21.6%以上。

4 现场试验及应用

北京科技大学和武汉钢铁(集团)公司合作开发的变接触长度支持辊首先应用于武汉钢铁(集团)公司1700冷连轧机第1机架,后推广应用于宝钢集团有限公司2030冷连轧机、武汉钢铁(集团)公司1700热连轧机、2250热连轧机,并在多套中厚板轧机、平整机组得到广泛应用[14-20]。1700冷连轧机完成改造后,本课题组自主设计的EDW边降控制工作辊已投入工业应用,并在1700冷连轧机上进行了VCR变接触支持辊辊形配置方案的工业轧制试验。VCR支持辊与EDW工作辊在第1架和第2架上机,取得明显效果,并已投入工业应用。

4.1 轧机板形控制能力

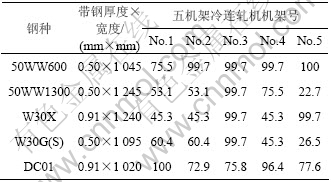

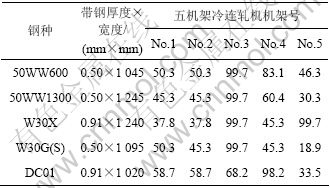

采用原辊形配置方案时,第1架和第2架弯辊力常达到最大值,轧机板形控制能力不足。先后投入使用EDW边降控制工作辊和VCR变接触支持辊后,轧机板形控制能力增强,正弯辊降低。表2和表3所示为采用上述2种方案时,轧制的实际正弯辊力与最大正弯辊力(1 320 kN)之比。其中,No.1~No.5表示1700冷连轧机第1~5机架。表中数据为正弯辊率,即实际正弯辊力与最大正弯辊力(1 320 kN)的比值。

表2 采用常规凸度支持辊方案时轧制的正弯辊力与最大正弯辊力之比

Table 2 Rates of the actual to the maximum positive bending force with conventional backup rolls %

表3 VCR支持辊方案时轧制的正弯辊力与最大正弯辊力之比

Table 3 Rates of the actual to the maximum positive bending force with VCR %

对比表2和表3可见,第1架和第2架在VCR支持辊上机之后,正弯辊明显减小,弯辊的调控范围得到有效增大;第3架和第4架正弯辊略降低;第5架弯辊由于板形自动控制,其弯辊力自动变化。

4.2 带钢板形实物质量

在第1架和第2架应用VCR支持辊和EDW工作辊及其相关配套工艺控制策略时,轧机凸度控制能力明显增强,板形实物质量明显提高。连续跟踪63卷带钢实测数据发现:带钢凸度比由1.20降至1.05,有效控制了带钢凸度;板形平坦度由原来的15 IU降低至9~10 IU。

应用VAI提供的常规凸度支持辊和单锥度工作辊,工业试验冷轧无取向硅钢平均边降10 μm以内的比率提高到62.5%,但由于前述原因未能投入工业应用。本课题组自主研制的EDW边降控制工作辊投入工业应用后,连续跟踪采集151卷带钢横向厚度分布,结果表明:边降平均值在10 μm以内的比率为91.3%;应用EDW/VCR新方案后,连续跟踪采集63卷带钢的边降平均值在10 μm以内的比率为100%,按照武汉钢铁(集团)公司根据市场确定的新控制目标,边降平均值在7 μm以内的比率同样达到100%。2007年7月现场工业应用连续轧制厚度×宽度分别为0.5 mm×1 150 mm,0.5 mm×1 195 mm和0.5 mm×1 240 mm等规格1 121卷计23 266 t电工钢板统计数据,结果表明:边降平均值≤10 ?m的比率达到100%,根据武汉钢铁(集团)公司边降控制新要求(边降平均值≤7 ?m的比率达到98.22%,且同板差即同一卷带钢沿长度方向各处横截面上最大厚度和最小厚度差≤10 ?m的比率达到97.25%),达到2006年4月新建的1450UCMW六辊冷连轧机的同期控制水平(采用相同热轧来料的冷轧成品其同板差≤10 ?m的比率为96.31%),满足了冷轧硅钢片的边降质量,增强了市场竞争力。

5 结 论

a. 建立了辊系弹性变形三维有限元仿真模型,分析揭示了常规凸度辊形方案的轧机板形控制能力不足是冷轧带钢尤其是电工钢边降控制效果欠理想和波动大等的根本原因。

b. 采用辊系弹性变形有限元分析并结合生产实验提出了一体化边降控制工作辊/变接触支持辊辊形方案,新方案辊缝凸度调节域扩大10.7%,辊缝横向刚度提高19.1%,辊间接触压力峰值下降21.6%,有利于改善支持辊磨损状况,明显增强了轧机的板形控制能力。

c. 1700四辊冷连轧机形辊形配置方案投入工业应用,不仅在保证板形平坦度由15 IU降到9~10 IU,且增强轧机凸度控制能力保证带钢凸度比由1.20降至1.05的前提下,不同品种规格第1架和第2架弯辊力下降7%~49%,而且取得了边降平均值≤7 ?m的比率达到98.22%,同板差≤10 ?m的比率达到97.25%的显著生产实绩,达到新建六辊冷连轧机同期控制水平,有助于四辊冷连轧机改造和新建四辊或六辊冷连轧机边降控制新技术推广应用。

参考文献:

[1] Campas J J, Terreaux S, Roches L V D, et al. New on-line gage for edge drop measurement and effect of tapered work rolls[J]. Iron and Steel Engineer, 1995, 72(12): 27-32.

[2] Hiruta T, Akagi I, Mizushima N. Development of advanced transverse thickness profile control of thin hard steel strips at tandem cold rolling mill[J]. Kawasaki Steel Technical Report, 1997, 37(10): 19-24.

[3] 许健勇. 薄板冷轧厚度与板形高精度控制技术[J]. 钢铁, 2002, 37(1): 73-77.

XU Jian-yong. High precision thickness and shape control technology for thin strip rolling[J]. Iron and Steel, 2002, 37(1): 73-77.

[4] 李 丹, 李 林. 硅钢轧制中的边缘降控制技术[J]. 轧钢, 2001, 18(4): 18-19.

LI Dan, LI Lin. Edge drop control technology in silicon strip rolling[J]. Steel Rolling, 2001, 18(4): 18-19.

[5] 吴 平, 张清东, 林秀贞, 等. 板形控制的新领域——边降控制[J]. 北京科技大学学报, 2003, 25(S6): 107-110.

WU Ping, ZHANG Qing-dong, LIN Xiu-zhen, et al. The frontier of shape control—edge drop control[J]. Journal of University of Science and Technology Beijing, 2003, 25(S6): 107-110.

[6] 朱简如, 徐耀寰. 边缘降控制技术的应用[J]. 宝钢技术, 2001, 19(5): 10-13.

ZHU Jian-ru, XU Yao-huan. Edge drop control technology[J]. Bao Steel Technology, 2001, 19(5): 10-13.

[7] 池文茂, 高 巍, 吴 滨, 等. 冷轧带钢轧制中的新技术——边降控制[J]. 矿冶, 2003, 12(2): 91-94.

CHI Wen-mao, GAO Wei, WU Bin, et al. New technique for cold rolling-edge drop control[J]. Mining and Metallurgy, 2003, 12(2): 91-94.

[8] 蛭田敏树. 片テ}パきワ}クロ}ルシワト压延方法によゐ高精度エヅツジドロツプ制御システム[J]. CAMP-ISIJ, 1999, 39(12): 996-999.

Toshiki H. Advanced transverse thickness profile control system by applying one-side tapered work roll shifting method[J]. CAMP-ISIJ, 1999, 39(12): 996-999.

[9] 鲁海涛, 曹建国, 张 杰, 等. 冷连轧机带钢单锥度辊边降控制[J]. 北京科技大学学报, 2006, 28(8): 774-777.

LU Hai-tao, CAO Jian-guo, ZHANG Jie, et al. Edge drop control of a taper roll during continuous cold rolling[J]. Journal of University of Science and Technology Beijing, 2006, 28(8): 774-777.

[10] 王军生, 赵启林, 矫志杰, 等. T-WRS&C冷轧机工作原理与应用[J]. 重型机械, 2001, 46(6): 8-11.

WANG Jun-sheng, ZHAO Qi-lin, JIAO Zhi-jie, et al. The research on the principle and application for T-WRS & C cold mill[J]. Heavy Machinery, 2001, 46(6): 8-11.

[11] 王军生, 赵启林, 矫志杰, 等. 宝钢益昌冷连轧机组改造新技术[J]. 材料与冶金学报, 2002, 1(2): 136-142.

WANG Jun-sheng, ZHAO Qi-lin, JIAO Zhi-jie, et al. New technology for Baosteel Yichang Tandem Cold Mill modernization[J]. Journal of Materials and Metallurgy, 2002, 1(2): 136-142.

[12] 曹建国, 顾云舟, 张 杰, 等. 1 700 mm冷轧带钢轧机板形控制能力研究[J]. 钢铁研究, 2002, 30(3): 16-19.

CAO Jian-guo, GU Yun-zhou, ZHANG Jie, et al. Study on control ability of profile and flatness at 1 700 mm tandem cold rolling mill[J]. Research on Iron and Steel, 2002, 30(3): 16-19.

[13] 曹建国, 张 杰, 陈先霖, 等. 宽带钢冷连轧机选型配置[J]. 北京科技大学学报, 2003, 23(S3): 109-112.

CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Selection of mill type configuration for profile and flatness control of tandem cold rolling mill[J]. Journal of University of Science and Technology Beijing, 2003, 23(S3): 109-112.

[14] CHEN Xian-lin, YANG Quan, ZHANG Qing-dong, et al. Varying contact backup roll for improved strip flatness[M]. London: Sterling Publications Limited, 1994/95: 174-178.

[15] CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Control of roll contour for strip profile and flatness in hot rolling[C]//David L. 44th Mechanical Working and Steel Processing Conference Proceeding. Florida, 2002: 1001-1010.

[16] 杨 荃, 陈先霖, 徐耀寰, 等. 应用变接触长度支承辊提高板形综合调控能力[J]. 钢铁, 1995, 30(2): 48-51.

YANG Quan, CHEN Xian-lin, XU Yao-huan, et al. Applying VCL backup roll to raise the control level of strip shape[J]. Iron and Steel, 1995, 30(2): 48-51.

[17] 何安瑞, 曹建国, 吴庆海, 等. 热轧精轧机组变接触支持辊综合性能研究[J]. 上海金属, 2001, 23(1): 14-17.

HE An-rui, CAO Jian-guo, WU Qin-hai, et al. Study on comprehensive function of varying contact-length backup roll in finishing mill of hot rolling[J]. Shanghai Metals, 2001, 23(1): 14-17.

[18] 郝建伟, 曹建国, 张 杰, 等. 2250CVC热连轧机支持辊辊形研究[J]. 中南大学学报: 自然科学版, 2007, 38(4): 734-738.

HAO Jian-wei, CAO Jian-guo, ZHANG Jie, et al. Backup roll contour of 2250CVC hot strip mill[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 734-738.

[19] 魏立群, 陆济民, 蔡恩沛, 等. 应用变接触长度支承辊改善中厚板板形及横向同板差[J]. 钢铁研究学报, 1999, 11(1): 23-27.

WEI Li-qun, LU Ji-min, CAI En-pei, et al. Improvement on shape and transverse error of plate by backup rolls with variable contacting length[J]. Journal of Iron and Steel Research, 1999, 11(1): 23-27.

[20] 胡衍生, 程晓茹, 李虎兴, 等. 变接触长度支承辊间等接触压力时轧辊变形规律[J]. 钢铁研究, 2006, 34(3): 37-39.

HU Yan-sheng, CHENG Xiao-ru, LI Hu-xing, et al. Roll deformation rule of varying contact length back-up roll under the condition of equal contact pressure between rolls[J]. Research on Iron and Steel, 2006, 34(3): 37-39.

收稿日期:2007-12-12;修回日期:2008-03-05

基金项目:国家自然科学基金重点资助项目(59835170);北京科技大学科技发展专项基金资助项目(20050311890)

通信作者:曹建国(1971-),男,湖南衡山人,博士,副教授,从事板形控制、板带轧制技术及自动化研究;电话:010-62332835; E-mail: geocao@ me.ustb.edu.cn