文章编号:1004-0609(2013)11-3100-07

固溶温度对7B50铝合金组织与性能的影响

刘蛟蛟1, 2,武 岳3,赖永秋1, 2,李红英1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

3. 中国航空工业集团公司 北京航空材料研究院,北京 100095)

摘 要:采用金相组织(OM)、扫描电镜(SEM)、透射电镜(TEM)以及力学性能测试研究固溶温度对7B50铝合金固溶程度、组织及力学性能的影响。结果表明:在460~480 ℃温度范围内,随着固溶温度升高,实验合金的残余第二相粒子减少,固溶程度增加,相应时效强化效应增强,再结晶程度变化不大;当固溶温度高于480 ℃后,残余第二相粒子的溶解没有明显提高,但再结晶程度加大,且合金组织发生过烧,力学性能明显恶化;当固溶温度为480 ℃时,实验合金固溶较充分,再结晶程度不高,此时合金综合力学性能最好,因此,7B50合金的最佳固溶温度为480 ℃。

关键词:7B50铝合金;固溶温度;组织;性能

中图分类号:TG166.3 文献标志码:A

Effects of solution temperature on microstructures and properties of 7B50 aluminum alloy

LIU Jiao-jiao1, 2, WU Yue3, LAI Yong-qiu1, 2, LI Hong-ying1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. Beijing Institute of Aeronautical Materials, Aviation Industry Corporation of China, Beijing 100095, China)

Abstract: The effect of solution temperature on the solid solubility, microstructure and mechanical properties of 7B50 alloy was studied by optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM) and tensile test. The results show that, with the solution temperature increasing from 460 ℃ to 480 ℃,the amount of residual phases decreases the solid solubility increases, and the recrystallization hardly changes with increasing the solution temperature. The corresponding ageing strengthening effect enhances. With the solution temperature increasing above 480 ℃, the amount of residual phases has almost no change and the recrystallization obviously increases. Alloy burnt obviously decrease the mechanical properties. Complete dissolution of the particles in the 7B50 alloy is obtained after solution treatment at 480 ℃.

Key words: 7B50 alloy; solution temperature; microstructure; properties

7B50铝合金具有密度小、加工性能好、力学性能优良、耐腐蚀性佳等优点,已广泛应用于航空航天等领域[1-3]。7B50铝合金属于Al-Zn-Mg-Cu系,是典型的时效强化合金,其发展趋势是以高合金化达到高综合性能需求,导致其加工制备困难,热处理相变难以控制[4]。目前,国内外材料工作者对7系铝合金的热处理研究主要集中在时效方面,通过开发新的时效工艺,调整合金析出相的形态、大小及分布,从而使合金性能达到预期目标[5-9]。固溶淬火后的过饱和程度显著影响合金时效析出驱动力,影响析出相的结构、形貌、性质、大小和分布状态,最终影响合金的强度、韧性等与时效析出行为相关的力学性能指标[10]。Al-Zn-Mg-Cu系合金存在η(Mg(ZnAlCu)2)、T(Al2Mg3Zn3)、S(Al2CuMg)和θ(Al2Cu)等多种相,如果这些相作为未溶相存在于固溶体中,不仅会显著降低合金的时效强化效果,而且会促进裂纹萌生和扩展,在腐蚀环境下易发生电化学腐蚀。合适的固溶工艺就是要使这些相充分固溶,获得饱和固溶体,7B50合金固溶温度范围较窄,固溶温度过低导致过饱和程度不高,致使合金时效析出动力不足,从而影响时效强化效果,固溶温度过高则会导致合金过烧,严重恶化合金性能[11],因此,采用合理的固溶温度对提高7B50合金的性能至关重要[12]。本文作者通过研究固溶温度对7B50铝合金组织性能的影响,为工业生产提供理论依据和实践指导。

1 实验

实验材料取自工厂生产的7B50铝合金热轧板材,在HXSG2-1200箱式电阻炉中进行固溶处理,固溶温度分别为460、470、480、490和500 ℃,保温1 h后水淬,水温≤40 ℃,淬火转移时间≤5 s,用POLYVAR MET金相显微镜观察淬火态合金显微组织。采用Sirion200场发射扫描电子显微镜观察淬火态合金未溶相的大小及分布,并用Finder1000型能谱分析仪分析未溶相种类。采用TecnaiG220型透射电子显微镜观察合金的微观组织,将试样机械减薄至80 μm以下,在MPT-1双喷电解减薄仪上双喷化学减薄,双喷电解液配比为硝酸与甲醇的体积比为3:7,温度为-30 ℃~ -20 ℃,电压为12~15 V,电流为55 mA。在不同温度固溶后进行相同的121 ℃、24 h时效处理,用CSS-44100型万能测量试验机进行常规拉伸试验,拉伸速度为2 mm/min。

2 结果与讨论

2.1 力学性能测试

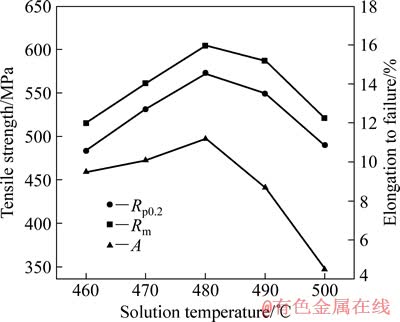

经不同温度固溶后再经121 ℃时效24 h后进行常规拉伸试验,图1所示为固溶温度对应的拉伸性能。由图1可以看出,当固溶温度由460上升至480 ℃时,时效合金的屈服强度和抗拉强度显著升高,分别提高18.6%和17.5%,伸长率由9.5%上升至11.2%。但是,当固溶温度超过480 ℃后,时效合金的屈服强度和抗拉强度急剧下降,伸长率也明显下降,固溶温度提高到500 ℃时,伸长率只有4.5%。在480 ℃固溶时,时效合金的力学性能最佳,Rm=604 MPa,Rp0.2=573 MPa,A=11.2%。

图1 固溶温度对实验合金力学性能的影响

Fig. 1 Effect of solution temperatures on tensile properties of test alloy

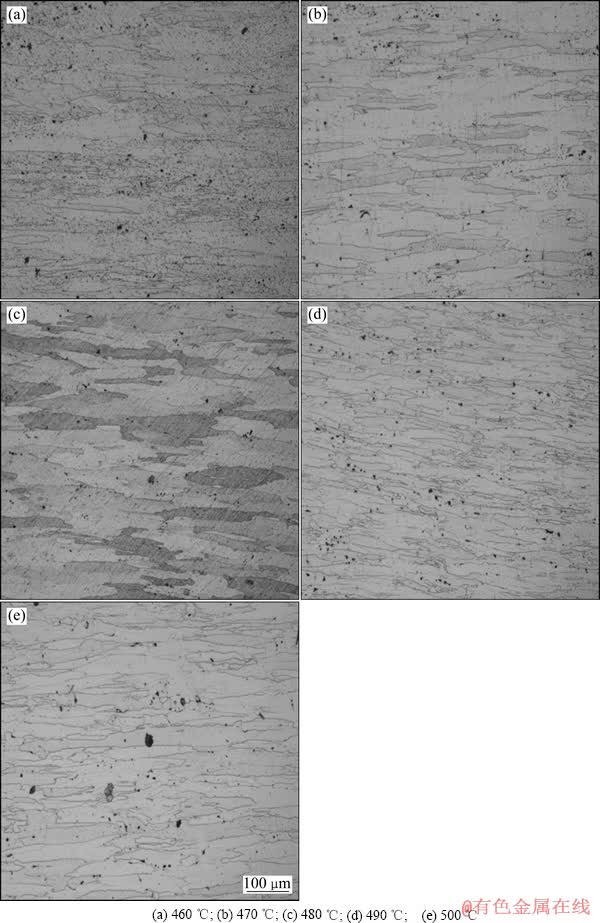

图2 在不同温度固溶保温60 min实验合金的金相组织

Fig. 2 Optical micrographs of test alloy solution-treated at different temperatures for 60 min

2.2 金相组织分析

图2所示为经过不同温度固溶保温60 min后的金相组织,分别为在460、470、480、490和500 ℃保温1 h后的金相组织,均为不完全再结晶组织,存在沿变形方向被拉长的板条状和扁平状晶粒组织。由图2(a)~(c)可以看出,经460 ℃固溶处理后,基体中仍存在数量较多的未溶相,表明合金固溶尚不充分,随着固溶温度的升高,合金的固溶程度明显加大,未溶相逐渐溶解,在460~480 ℃温度范围内,固溶组织出现了少量的等轴晶粒,表明实验合金发生了轻微再结晶。由图2(d)可观察到少量复熔球,表明在490 ℃固溶的实验合金已经发生过烧,因此,实验合金的过烧温度在480~490 ℃之间。由图2(e)可以看出,合金中黑色复熔球尺寸变大,出现晶界融化等明显过烧现象,合金晶粒明显粗化,说明在500 ℃固溶时,实验合金严重过烧。

第二相溶解属于扩散过程,所有影响元素扩散速率的因素都会最终影响合金的固溶效果。根据菲克第一定律[13],当浓度梯度一定时,扩散系数D越大,则在单位时间内通过垂直于扩散方向的单位截面积的扩散物质流量J越大,如式(1)所示:

(1)

(1)

式中:J为扩散通量, 为浓度梯度,D为扩散系数。根据扩散过程的空位机制原理,扩散系数与温度的关系可表示为

为浓度梯度,D为扩散系数。根据扩散过程的空位机制原理,扩散系数与温度的关系可表示为

(2)

(2)

式中:D0为扩散常数;Q为扩散激活能;R为摩尔气体常数;T为温度。

由式(2)可以看出,D与T呈指数关系,随温度升高,扩散系数急剧增大,一方面,随着温度升高,借助热起伏获得足够能量而越过势垒的原子数量增大;另一方面,温度升高引起空位浓度增大,有利于扩散。

实验合金在460 ℃固溶后,时效合金的强度和韧性都相对较低,这是因为该温度下合金固溶不够充分,致使固溶体的过饱和程度较低,时效析出驱动力不强,第二相析出数量不多,对时效合金的最终性能产生不利影响。当固溶温度达到480 ℃时,未溶相明显减少,这是因为较高的固溶温度可促进溶质原子溶入基体,增大固溶体的过饱和度,提高时效析出的驱动力,与此同时,固溶体的过饱和空位浓度随着固溶温度的提高而增加,促使溶质原子在基体中扩散,促进溶质原子脱溶,增加时效析出相数量,使合金拥有较好的最终性能。但是,当固溶温度过高时,出现过烧现象会严重恶化合金组织和性能,导致时效合金的力学性能指标明显下降。

2.3 扫描电镜观察分析

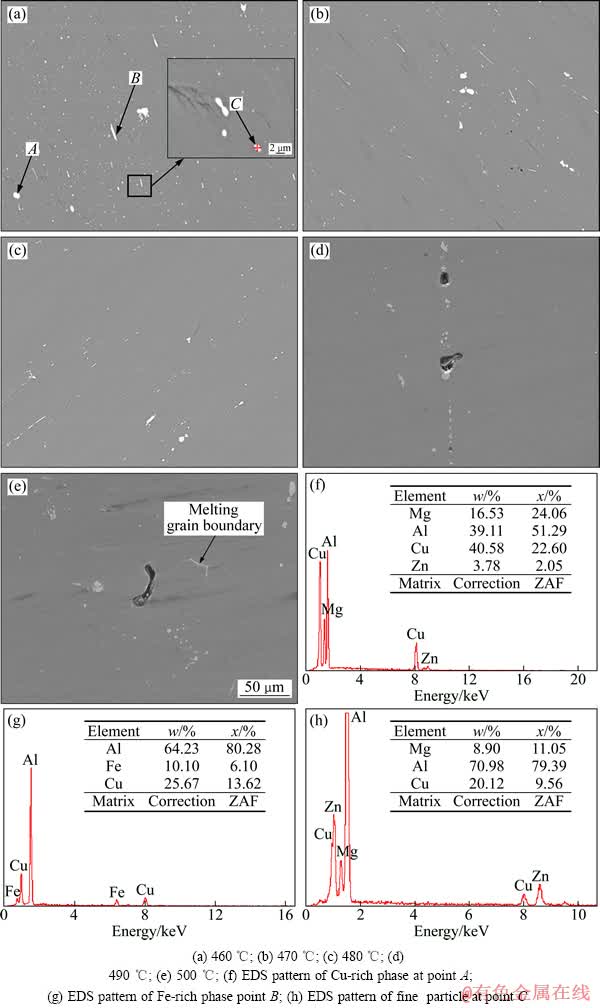

图3所示为不同温度固溶合金的SEM像,图3(a)中标出了3种典型的残余相粒子,其EDS分析结果如图3(f)~(g)所示。根据能谱分析结果,大块状的第二相主要为富Cu的AlZnMgCu相,小尺寸的第二相为Al2CuMg相,条状第二相为含Fe的杂质相。7B50合金中小尺寸的Mg(Zn,Al,Cu)2相为易溶相,在固溶过程中能很快溶入基体,因此,在固溶后的SEM组织中难以发现这种第二相粒子残留,大块状的富Cu相为难溶相,只有达到一定的固溶温度并保温较长时间后才会开始溶解,含Fe杂质相为不溶相,在固溶过程中不会发生明显变化。

图3 实验合金在不同温度固溶后的SEM像及EDS分析结果

Fig. 3 SEM images of test alloy solution-treated at different temperatures and EDS analysis

由图3(a)~(c)可以看出,随着固溶温度的升高,未溶相的数量明显减少。当固溶温度较低时,首先溶入基体的是小尺寸易溶相,随着固溶温度的提高,大块状难溶相才能逐渐溶入基体。当固溶温度为460 ℃时,只有小尺寸的易溶相得以减少,合金中存在大量未溶相,说明固溶尚不充分。适当提高固溶温度,可促进粗大未溶相熔入基体,由图3(b)可以看出,当固溶温度升高至470 ℃时,小尺寸易溶相的数量大幅度降低,大块状的含Cu相数量有所减少,尺寸明显减小,而条状含Fe相的尺寸及数量都没有发生明显变化。当固溶温度达到480 ℃时,含Mg相及含Cu相基本溶解,残留的第二相基本为含Fe杂质相。由图3(d)~(e)可以看出,当固溶温度高于480 ℃后,提高固溶温度对减少粗大杂质相的作用不大,对于提高固溶体的过饱和程度没有太大作用;而当温度升高至490 ℃以上时,不仅不能促进未溶相的溶解,反而发生过烧,恶化了合金的组织性能,在图3(d)和(e)中可以观察到低熔点共晶相熔化后留下的孔洞,当固溶温度提高到500 ℃时,由图3(e)还可观察到晶界熔化等显著过烧现象,过烧程度明显加大。

2.4 透射电镜观察分析

图4所示为实验合金在不同温度固溶1 h后的TEM像。由图4可看出,经过460 ℃、1 h固溶后,大部分晶粒呈扁平状,出现了回复组织,尺寸为3~5 μm;随着固溶温度的升高,亚晶组织开始长大,尺寸为5~7 μm,部分晶界变得平直;当固溶温度达到480 ℃时,亚晶开始合并,出现了细小的再结晶组织;当固溶温度在480 ℃以上时,再结晶程度明显加大。

根据金相组织和TEM分析结果,合金在460~480 ℃固溶后,均为不完全再结晶组织,晶粒沿变形方向呈板条状和扁平状。这是由于合金中添加了少量Zr元素,形成了均匀弥散的Al3Zr粒子,在轧制过程中,Al3Zr粒子沿轧向成带状分布, Al3Zr粒子的存在阻碍了大角度晶界的迁移,抑制再结晶核心的生长,使再结晶受阻[14-15],而且使再结晶晶粒倾向于沿着轧向生长。在不同固溶温度对应的高倍TEM像中均发现了Al3Zr粒子,由图4(b)、(d)和(f)可以看出,合金在460~480 ℃固溶后,均可观察到大量Al3Zr粒子钉扎在晶界上,因此,实验合金的再结晶程度没有明显变化。当固溶温度高于480℃后,晶界处Al3Zr粒子数量明显减少,由图4(h)和(j)可观察到晶界脱钉现象,大角度晶界开始扫过Al3Zr粒子继续向外迁移,说明温度升高使晶界克服了Al3Zr粒子的钉扎作用,随着晶界的迁移加剧,实验合金再结晶程度提高,晶粒明显长大并开始发生等轴化。

7系铝合金为时效强化铝合金,对其强度产生贡献的因素可分为几个部分,如式(3)所示[16]:

σ=σm+σss+σp+σg (3)

式中:σm为铝基体的强度,σss为固溶强化效应,σp为析出强化效应,σg为晶粒结构及织构等因素的强化效应。其中析出强化效应对于时效强化合金的强度贡献最大,任何影响时效析出行为的因素,都会对合金的强度、韧性等与时效析出行为有关的力学性能指标产生影响。

再结晶程度的变化会影响时效析出行为,间接影响合金强度。一般来说,合金中保留的未再结晶组织越多,合金的强度越高,这是由于未再结晶组织中存在大量亚结构,在时效过程中,第二相倾向于在亚晶界上析出,时效效果优于完全再结晶组织的。此外,未完全再结晶组织中存在的亚晶界可与位错以及强化相发生相互作用,位错迁移时需要克服较大的阻力,在一定程度上提高了组织结构的稳定性。因此,在保证合金固溶度的前提下,减少再结晶程度可提高实验合金的析出强化效应。

由上述分析可知,实验合金低于480 ℃固溶后,虽然再结晶程度较低,但未能充分固溶化,降低了后续时效析出驱动力,影响了实验合金的时效析出效果。当固溶温度达到480 ℃时,合金的再结晶程度没有明显增大,基体得到充分固溶,时效析出效果最好;当固溶温度高于480 ℃时,实验合金的固溶度变化不大,而再结晶程度明显增大,并且发生局部过烧,影响时效合金综合力学性能。因此,综合力学性能测试和组织分析结果,确定实验合金的理想固溶温度为480 ℃。

图4 实验合金在不同温度固溶60 min后的微观组织

Fig. 4 Microstructures of test alloy solution-treated at different temperatures for 60 min

3 结论

1) 当固溶温度较低时,Mg(Zn,Al,Cu)2易溶相首先回溶,提高固溶温度可以促进含Cu难溶相溶解,但不能促进含Fe杂质相的溶解。当固溶温度达到480 ℃后,可溶相几乎完全溶入基体,当温度高于480 ℃后,升温对于提高固溶体的过饱和程度没有太大作用。

2) 在460~480 ℃固溶时,由于Al3Zr粒子的钉扎作用,提高温度对实验合金的再结晶程度影响不大,当固溶温度高于480 ℃后,升温促进晶界克服Al3Zr粒子的钉扎作用,再结晶程度明显增加。

3) 在460~480 ℃固溶时,随着固溶程度的增加,实验合金的强度和韧性均随温度的提高而上升,当固溶温度超过490 ℃时,实验合金发生过烧,强度和韧性均迅速下降。当固溶温度为480 ℃时,实验合金固溶较充分,再结晶程度不高,综合力学性能最好,因此,7B50合金的最佳固溶温度为480 ℃。

REFERENCES

[1] 刘静安. 研制超高强铝合金材料的新技术及其发展趋势[J]. 铝加工, 2004, 154(1): 9-13.

LIU Jing-an. Study on the new technology of super-high strength aluminum alloy materials and its development trends[J]. Aluminum Fabrication, 2004, 154(1): 9-13.

[2] 曾周亮, 宁康琪, 彭北山. 高强铝合金第二相强化及其机理[J]. 冶金丛刊, 2008(4): 5-7.

ZENG Zhou-liang, NING Kang-qi, PENG Bei-san. Mechanism and second phase strengthening of high strength aluminum alloy[J]. Metallurgical Collections, 2008(4): 5-7.

[3] 刘志义, 李云涛, 刘延斌, 夏卿坤. Al-Cu-Mg-Ag合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

LIU Zhi-yi, LI Yun-tao, LIU Yan-bin, XIA Qing-kun. Development of Al-Cu-Mg-Ag alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1905-1915.

[4] SONG R G, ZHANG Q Z. Heat treatment technique optimization for 7175 aluminum alloy by an artificial neural network and a genetic algorithm[J]. Joural of Material Processing Technology. 2001, 117: 84-88.

[5] MACCHI C E, SOMOZA A, LUMLEY A J, DUPASQUIER A. Secondary precipitation in Al-Zn-Mg-(Ag) alloys[J]. Acta Material, 2003, 51: 5151-5158.

[6] LUMLEY R N, POLMEAR I J, MORTON A J. Interrupted aging and secondary precipitation in aluminum alloys[J]. Materials Science and Technology, 2003, 19(11): 1483-1490.

[7] DUPASQUIER A, SOMOZA A, LUMLEY A J. Studies of secondary ageing in aluminum alloys[J]. Materials Forum, 2004, 28: 85-95.

[8] OLIVERA A F J, de BARROS M C, CARDOSO K R. The effect of RRA on the stress corrosion cracking and SCC resistance on AA7050 and AA7150 aluminum alloys[J]. Materials Science and Engineering A, 2004, 379: 321-326.

[9] WALLACE W, BEDDOES J C, DE MALHERBE M C. New approach to the problem of stress corrosion cracking in 7075-T6 aluminum[J]. Canadian Aeronautics and Space Journal, 1981, 27(3): 222-232.

[10] CHEN Kang-hua, LIU Hong-wei, LI Yun-zhong. Effect of temperature incremental solution heat treatment on the microstructure and mechanical properties of Al-Zn-Mg-Cu alloy[J]. J Central South Univ Technol, 2000, 31: 339-341.

[11] 秦 建, 卢锦德. 固溶温度对高强度铝合金组织和性能的影响[J]. 现代机械, 1999(4): 60-61.

QIN Jian, LU Jin-de. Effect of solution temperature on microstructure and mechanical property of high strength aluminum alloy[J]. Modern Machinery, 1999(4): 60-61.

[12] KIM J D, PARK J K. Effect of stretching on the precipitation kinetics of an Al-2.0Li-2.8Cu-0.5Mg(0.13Zr) alloy[J]. Metall Trans A, 1993, 24(12): 2613-2621.

[13] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 74-477.

ZHENG Zi-qiao. Foundations of materials science and engineering[M]. Changsha: Central South University Press, 2005: 74-477.

[14] 孙立明, 于化顺, 闵光辉. Zr对Al-Zn-Mg-Cu合金组织和性能的影响[J]. 特种铸造及有色合金, 2007, 27(5): 380-381.

SUN Li-ming, YU Hua-shun, MIN Guang-hui. Effects of Zr on microstructure and properties of Al-Zn-Mg-Cu alloy[J]. Special Casting & Nonferrous Alloys, 2007, 27(5): 380-381.

[15] Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena[M]. New York: Elsevier Science Inc, 1995.

[16] STARINK M J, WANG S C. A model of the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51: 5131-5150.

(编辑 龙怀中)

基金项目:长沙市科技计划资助项目(K1303013-11)

收稿日期:2013-05-16;修订日期:2013-06-30

通信作者:李红英,教授,博士;电话:0731-88836328;E-mail:lhying@ csu.edu.cn