文章编号:1004-0609(2014)07-1707-07

基于微/纳二元结构镁合金超疏水膜层的制备

李 杰1,刘玉德 1,黄雅婷1,高东明1,张会臣2,栗苗苗1

(1. 北京工商大学 材料与机械工程学院,北京 100048;

2. 大连海事大学 交通运输装备与海洋工程学院,大连 116026)

摘 要:利用微弧氧化技术在镁合金表面制备微米级粗糙结构,采用环氧树脂溶液和纳米二氧化硅分散液对该表面进行涂覆处理,再利用全氟硅烷改性,制备得到具有超疏水性的复合膜层。采用扫描电镜、X射线衍射仪、接触角测量仪、高速摄影系统和电化学工作站评价膜层的形貌结构、润湿性和耐蚀性。结果表明:微弧氧化层所具有的微米级结构和纳米二氧化硅颗粒组成的微/纳二元粗糙结构对疏水性的提高具有重要作用;复合膜层表面的接触角随二氧化硅分散液浓度的提高呈现先增加后减小的趋势,并最终逐渐稳定在150°左右;当二氧化硅分散液溶度为10 g/L时,复合表面的接触角最大可达161°。同时该表面对水滴呈现低黏附特性。动电位极化曲线表明:与镁合金基底相比,微弧氧化层和复合膜层的耐蚀性提高2~3个数量级。

关键词:镁合金;超疏水;微弧氧化;纳米二氧化硅;微/纳二元结构;

中图分类号:O484.41 文献标志码:A

Preparation of superhydrophobic film on magnesium alloy surface based on micro-nano binary structure

LI Jie1, LIU Yu-de1, HUANG Ya-ting1, GAO Dong-ming1, ZHANG Hui-chen2, LI Miao-miao1

(1. School of Materials Science and Mechanical Engineering, Beijing Technology and Business University, Beijing 100048, China;

2. Transportation Equipments and Ocean Engineering College, Dalian Maritime University, Dalian 116026, China)

Abstract: Micron scale rough structures on magnesium alloy substrate surface were acquired by micro-arc oxidation technique. Nanoscale rough structures on the surface of micro-arc oxidation coating were prepared by painting epoxy acetone solution and silica suspension subsequently. Superhydrophobic duplex-treated film was fabricated by perfluorodecyltrichlorosilane self-assembled monolayers deposited on micro-nanostructures. Scanning electron microscope, X-ray diffractometer, contact angle measurement, high-speed camera system and electrochemical workstation were used to analyze the surface morphology, wettability and corrosion resistance of films. The results indicate that micro- and nanostructures of micro-arc oxidation and nano-silica play an important role on preparing superhydrophobic surface. The contact angles on duplex-treated film increase initially, and then reduce with increasing the concentration of silica suspension, and finally stabilize at around 150° gradually. The maximum contact angle of 161° is acquired when the concentration of silica suspension is 10 g/L. And the films possess the characteristics of low adhesion. The potentiodynamic polarization curves indicate that, comparing to the bare magnesium alloy, the corrosion resistance of micro-arc oxidation coating and duplex-treated film increases significantly by 2-3 orders of magnitude.

Key words: magnesium alloy; superhydrophobic; micro-arc oxidation; nano-silica; micro-nano binary structure

镁合金作为一种轻金属材料,被认为是21世纪的绿色工程材料。因其具有比强度高、比刚度高、热疲劳性能好、生物相容性良好、电磁屏蔽性能优异、抗震性好和可回收等优点,在交通运输、生物医学、航空航天和国防工业等领域有着广泛的应用前景[1]。然而,由于镁的化学性质十分活泼,标准电极电位低,使镁合金极易氧化生成疏松多孔的表面膜且表面呈现亲水性,导致其自身的耐蚀性很差,因此,对镁合金表面改性的研究受到人们的关注。

目前,对镁合金表面进行改性处理的工艺很多,如高分子涂覆[2]、离子注入[3]、表面渗铝[4]、阳极氧化[5]等。其中,微弧氧化是近年来兴起的一种在金属表面原位生长陶瓷氧化层的新型处理工艺。研究表明,微弧氧化工艺可以提高镁合金表面的力学性能,增强耐蚀性,改善其摩擦学性能,成为镁合金改性处理的重要手段之一[6-7]。通过对材料表面进行改性,使其具有超疏水特性,可有效降低基底材料的表面自由能,改善和控制材料的润湿、黏着、润滑和磨损性能[8],在材料改性与应用方面具有巨大的应用潜力:材料基底构建超疏水涂层具有良好的抗腐蚀、流体减阻和表面自清洁性能,在舰艇船舶外壳、流体管道内壁、飞行器表面涂层、金属构件外层装饰、雷达天线和医用镁合金构件等方面具有广泛的应用前景[9-10]。

对超疏水荷叶的研究表明:表面微/纳二元粗糙结构和低表面能物质是荷叶具有超疏水自清洁效果的主要原因[11]。根据此机制,本文作者通过微弧氧化工艺构建类似于“乳突”的微米级粗糙结构,再利用纳米颗粒涂覆工艺[12-13]构建尺寸更小的纳米结构,得到具有微/纳二元粗糙结构的表面;最后利用全氟硅烷进行表面修饰,制备得到镁合金超疏水表面。该研究为改善镁合金表面特性和提高其使用性能提供了有效的手段。

1 实验

1.1 实验材料

实验使用基底材料为Mg-Mn合金系,牌号为MB8,其组分见表1,抗拉强度σb=225 MPa,屈服强度σ0.2=118 MPa,伸长率δ10=11%。纳米气相二氧化硅颗粒,直径为20~30 nm,购自Cabot公司;偶联剂为国产γ-氨丙基甲基二乙氧基硅烷,分子式为(CH3O)2CH3Si(CH2)5NH2;促进剂为国产2,4,6-三(二甲胺基甲基)苯酚;固化剂为聚酰胺树脂,购自香港;环氧树脂E-44,型号6106,购自香港。成膜分子为全氟葵烷基三氯硅烷(1H,1H,2H, 2H-Perfluorodecyltriethoxysilane,分子式为CF3(CF2)7(CH2)2SiCl3,FDTS),其纯度为97%,购自Fluka公司;溶剂为异辛烷,纯度为99%;其余试剂均为分析纯。

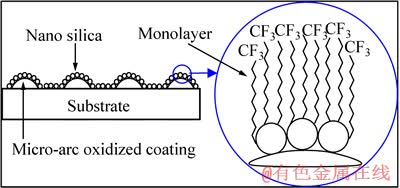

表1 镁合金的组分

Table 1 Composition of magnesium alloy

1.2 微弧氧化层的制备

将镁合金试样经800、1000、1500号砂纸研磨处理,其后依次放入丙酮、乙醇和蒸馏水中超声清洗2 min,去除表面杂质,用高纯N2吹干,然后进行微弧氧化加工。微弧氧化电源为国产WH-1型微弧氧化脉冲电源,本工艺中采用恒流源模式,频率700 Hz,电流占空比设置为0.2,电流密度为2.0 A/dm2。电解液组份为硅酸钠10 g/L,氟化钾10 g/L和氢氧化钠4 g/L,辅以EDTA 。镁合金试样作为阳极,不锈钢工件为阴极,微弧氧化过程中对电解液进行不间断冷却,使电解液温度控制在35~45 ℃之间,微弧氧化时间为15 min。

1.3 纳米颗粒涂覆与全氟硅烷修饰

将5.0 g环氧树脂、1.0 g固化剂和0.1 g促化剂溶于50 ml丙酮中制成环氧树脂溶液;将二氧化硅颗粒与偶联剂按照质量比为2:1置于乙醇烧杯中,采用超声振荡实现二氧化硅颗粒与偶联剂充分接触混合的方法制备出一系列不同浓度的二氧化硅分散液;将环氧树脂溶液滴涂在微弧氧化层表面,室温下风干30 min后将不同浓度的二氧化硅分散液分别滴涂到上述表面,置于100 ℃干燥箱中3 h固化;将体积浓度为1.5%的FDTS乙醇溶液滴涂到上述经固化处理试样表面,并置于100 ℃干燥箱中固化1 h。

1.4 形貌表征与性能测试

利用HITACHI-TM3000型和FEI-QUANTA200F型扫描电子显微镜对微弧氧化层和二氧化硅颗粒涂覆层形貌进行表征;试样组织结构利用X射线衍射仪(D/MAX-Ultima+型,日本Rigaku Corporation 公司生产)进行分析,采用Cu Kα辐射,λ=0.15406 nm,管电压40 kV,管电流20 mA,扫描速度 1(°)/min,扫描角分辨率 0.02°,入射角度2°。;用德国产的Easy-Drop型接触角测量仪测量试样的水接触角;利用NAC-HS512SC高速摄影系统采集记录水滴在试样表面的滚动过程;利用EG&G-VMP3多通道电化学工作站采集3.5% NaCl水溶液动电位极化曲线,对试样耐腐性进行测试评价,采用三电极体系,饱和甘汞电极为参比电极,Pt为辅助电极,试样测试面积为1 cm2,动电位扫描速率为1 mV/s,在室温条件进行。

2 结果与讨论

2.1 微弧氧化层形貌表征与物相分析

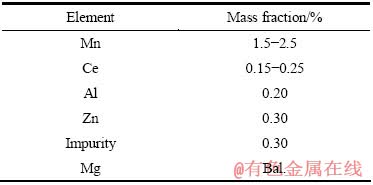

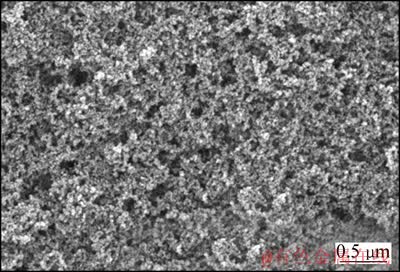

图1所示为镁合金试样经微弧氧化处理后的表面形貌。由图1可见,微弧氧化层表面分布许多微孔,孔径多在5 μm以内,较为均匀地分布在整个试样表面,微孔周围分布着突起物,部分突起物上分布有数量较少的微裂纹。研究认为,微弧氧化层微观形貌与形成机制[14]相关:微弧等离子放电总是发生在薄弱膜层的位置,膜层在放电击穿后局部电流密度剧增,镁合金与电解液反应生成物快速生成,微弧持续放电造成生成物不断生成而形成叠加,造成局部突起,由此形成粗糙不平的表面形貌;微孔是由于微弧等离子放电击穿膜层,高温熔融态氧化物在电解液快速冷却过程中形成的喷发通道;微裂纹的存在是微弧氧化过程中瞬时热能在快速冷凝过程中引发热应力集中造成的[15]。

图1 微弧氧化层的表面形貌

Fig. 1 Surface morphology of micro-arc oxidized coating

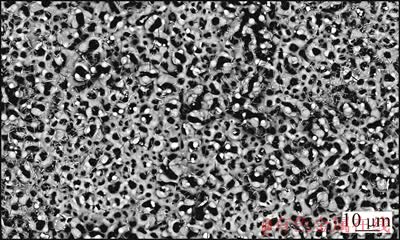

图2所示为镁合金表面微弧氧化层的XRD谱。由图2可见,微弧氧化层主要物相是由MgO、Mg和Mg2SiO4组成的。MgO相是微弧等离子放电过程中镁合金基底在高温作用下发生氧化反应的生成物;Mg2SiO4相的存在则证实了电解液参与微弧氧化反应,电解液中的SiO32-离子通过放电通道与镁合金基底中的Mg相发生反应后生成了Mg2SiO4相;由于XRD测试采用X射线低掠射角入射(2°),X射线的有效穿透深度较浅,此时微弧氧化层中Mg相的出现主要是由于微弧氧化过程中镁合金基体中的Mg相没有被完全氧化,部分处于熔融态的Mg相被冷凝的熔融态氧化物包覆在一起。

图2 微弧氧化层的XRD谱

Fig. 2 XRD pattern of micro-arc oxidized coating

2.2 二氧化硅颗粒涂覆与有机硅烷修饰

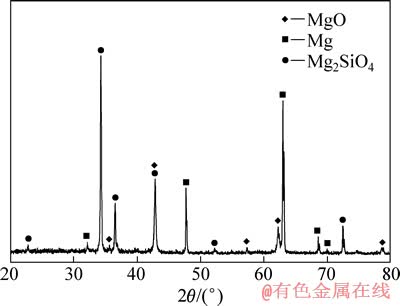

二氧化硅颗粒作为构建微纳二元粗糙结构的重要组成部分,其参与制备过程如下:由于气相纳米二氧化硅颗粒表面富含羟基,其表面羟基与偶联剂上的硅氧甲基发生醇解、脱水、缩合反应[16],从而在二氧化硅表面接枝有机硅烷链条;环氧树脂在偶联剂上氨基作用下发生开环反应,开环后形成的羟基也与偶联剂上的硅氧甲基反应;在偶联剂的作用下,纳米二氧化硅颗粒参与环氧树脂的固化过程,同时将二氧化硅颗粒植入到试样表面。在环氧树脂固化完成后,环氧树脂剩余羟基、二氧化硅表面未发生缩合反应的羟基均能与FDTS发生缩合反应,在其表面接枝形成碳氟长链,从而形成有序致密的分子排布,最终制备得到具有微/纳二元粗糙结构的复合膜层,该膜层的制备示意图如图3所示。图4所示为二氧化硅分散液浓度为10 g/L条件下制备的二氧化硅涂覆层表面形貌,二氧化硅颗粒多以微小团簇的形式存在试样表面,团簇直径多在数十纳米,极少数团簇的直径达到100 nm,这些团簇较为均匀地分散在涂层表面,团簇之间存在明显的间隙。

2.3 润湿性研究

接触角是表征固体表面润湿性的重要参数。镁合金基底表面的水接触角为50°~60°之间,呈现亲水性。

图3 微/纳二元复合膜层结构制备示意图

Fig. 3 Schematic diagram of preparation of micro- and nanostructure duplex-treated coating

图4 纳米二氧化硅涂覆层的表面形貌

Fig. 4 Morphograph of coating embedded by nano-silica

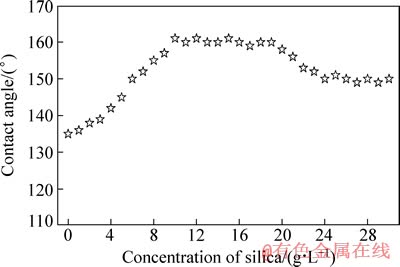

水滴在微弧氧化层表面几乎完全铺展,其静态接触角接近于0°,表现为超亲水性,分析认为微弧氧化层表现超亲水性的原因是:1) 微弧氧化过程中释放的能量部分扩散到微弧氧化层中,诱使其表面自由能增大,据相似相溶原理[17],具有较高表面自由能的氧化膜层对同样具有较高自由能的水分子具有极强的相容性,因此诱发水分子的扩散铺展;2) 镁合金微弧氧化层表面形貌凹凸不平,微结构的存在使毛细吸附力[18]增大,微结构与水分子之间的范德瓦耳斯力得到增强[19],诱使水分子吸附铺展。水滴在未经FDTS修饰的二氧化硅复合膜层上的接触角在110°左右,分析认为—CH3和—NH2具有一定的疏水性,未参加环氧树脂开环反应的氨基和环氧树脂中的甲基对该表面疏水性的提高起到一定的作用。因此,该微/纳二元粗糙表面在未经低表面能FDTS修饰的情况下,依然呈现疏水性。在光滑基底表面涂覆不同浓度的二氧化硅纳米颗粒,经FDTS修饰后,其接触角在120°~145°之间,依然达不到超疏水性。图5所示为不同二氧化硅分散液浓度下制备得到经FDTS修饰后的微/纳二元粗糙表面的接触角。

图5 不同浓度二氧化硅溶液制备的复合表面的接触角

Fig. 5 Contact angles on surfaces of micro-arc oxidized coating with different concentrations of silica suspension

与其他几种工艺处理表面的接触角相比,此类表面的静态接触角明显增大,部分表面呈现出超疏水性。分析认为,FDTS末端官能团—CF3相比—CH3、—NH2具有更低的表面自由能[20],制备得到的FDTS在微弧氧化层与纳米二氧化硅颗粒组成的微/纳二元粗糙表面上具有致密有序的分子排布,且有效降低原基底表面自由能。由图5可见,随着二氧化硅分散液浓度的增加,试样表面接触角在初期呈现增大的趋势,在10 g/L时达到极值161°,浓度在10~20 g/L之间没有明显地变化,随后在二氧化硅浓度继续增加的情况下接触角逐渐减小,在浓度达到25 g/L之后,接触角逐渐稳定在150°。分析认为,接触角的变化与经不同浓度二氧化硅分散液制备得到复合表面的微结构存在一定的差异相关。根据Cassie-Baxter模型[21],水滴在具有微细粗糙结构疏水性表面上的接触是一种复合接触,水滴不仅与固体表面相接触,而且与微结构中存在的“气垫”相互作用,所以这种表观上的固液接触面实际上是由固液接触面和气液接触面共同组成的,此时的接触角满足如下关系:

(1)

(1)

式中:f1和f2分别为空气和固体占整个接触面积的百分数;θ1和θ2分别为空气和固体表面的本征接触角,θ为表观接触角。

由于θ1=180°,f1+f2=1,因此,式(1)可写为

(2)

(2)

由式(2)可见,表观接触角θ与固体面积百分数f2成反比,与空气面积百分数f1成正比。

在本研究中,对二氧化硅分散液浓度较低时制备的复合表面,其附着在微弧氧化层上的二氧化硅颗粒较少,复合膜层形貌结构以微弧氧化层基底为主,此时的固体面积百分数数值较大,因而接触角小于150°,但由于微弧氧化层上具有的微米级粗糙结构和低表面能FDTS的作用使其接触角在140°左右;随着二氧化硅分散液浓度逐渐增大,制备得到的复合膜层表面的二氧化硅颗粒逐渐增多,二氧化硅颗粒以纳米级团簇的形式分布在微弧氧化层上,从而形成类似于荷叶的微/纳二元粗糙结构[11],在水滴接触到此类复合表面时,微弧氧化层中的微米级孔洞和二氧化硅团簇之间存在的纳米级空隙会增大“气垫”的存留,进而增大了空气面积百分数,因此,其接触角进一步增大,达到超疏水性;但随着在二氧化硅浓度的逐渐增大,二氧化硅团簇之间的空气会相对减少并逐渐趋于稳定,而微弧氧化层中的微孔会逐渐被二氧化硅颗粒填充,从而减少了该表面与水滴在接触过程中的空气百分数,因此,接触角逐渐减小并趋于稳定,此时的空气百分数依然可以满足超疏水表面的获得。

2.4 黏附性能与耐蚀性分析

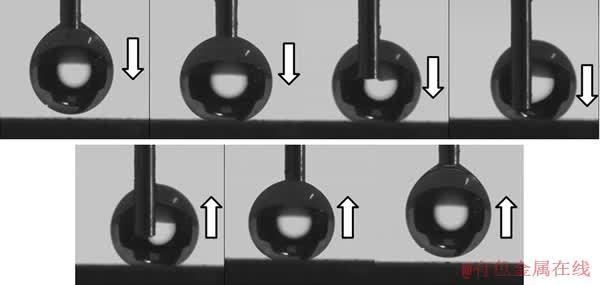

超疏水表面黏附性是近年来的研究热点。基于GAO等[22]提出的黏附性测试方法,本文作者利用接触角测量仪和高速摄影机对制备得到的复合表面黏附性进行测试表征。图6所示为超疏水镁合金表面逐渐挤压悬挂于针头的4 μL水滴的光学图片,图中箭头所指方向为针头的运动方向。在超疏水表面与水滴接触的过程中,无论超疏水表面如何挤压接触水滴,水滴始终保持近乎球形,且无法被超疏水表面拉落脱离针头,水滴与表面接触后,无任何液体残留复合表面。此过程表明此复合表面具有优良的表面低黏附性。

图6 4 μL水滴在复合表面上悬挂于针头的照片

Fig. 6 Sequential photographs of 4 μL water droplet contacted with superhydrophobic surface

图7所示为高速摄影系统采集的水滴在超疏水镁合金表面上处于稳定滚动状态下的光学图片。为了使水滴能够脱离针头的吸附,在重力作用下脱落到超疏水表面,该过程中水滴大小约为8 μL。此时超疏水表面与水平线夹角小于3°,高速摄影系统取帧频率为500 帧/s,选取图中记录水滴在连续16 ms内的滚动过程。由图7可见,任意时刻任意位置上,水滴在超疏水镁合金表面上的接触角均在150°以上,且呈规则球形。此过程进一步证实了超疏水镁合金表面对水滴呈现低黏附特性,且其滚动接触角在3°以内。

图7 8 μL水滴在复合表面上动态过程的照片

Fig. 7 Sequential photographs of 8 μL water droplet slipping on superhydrophobic surface by high-speed camera system

图8所示为镁基底、微弧氧化层和复合膜层3种试样在3.5%NaCl(质量分数)溶液中测得的动电位极化曲线。其中腐蚀电位(φcorr)、腐蚀电流密度(Jcorr)、阳/阴极Tafel常数(βa和βc)通过回归电位-电流密度(φ-J)曲线获得,并依据Stern–Geary公式[23]计算得到腐蚀阻抗RP,即RP=(βaβc)/[2.303Jcorr(βa+βc)],由此得到3种试样在3.5% NaCl溶液中的动电位极化电化学参数,如表2所列。

由表中各参数可知,与镁合金基底的腐蚀电流密度Jcorr=4.16×10-5 A/cm2相比,微弧氧化处理后试样Jcorr降低了2个数量级,达到7.69×10-7 A/cm2,而试样经复合处理后Jcorr进一步降低了3个数量级,其值为9.31×10-8 A/cm2;与镁合金基底相比,微弧氧化处理和复合处理后试样的腐蚀阻抗提高了2~3个数量级。这表明镁合金基底在经微弧氧化后,试样表面的腐蚀倾向减小,耐蚀性得到了明显地提高,这与现有的研究相一致[24];复合处理后的试样耐蚀性在微弧氧化层的基础上得到了进一步的提高,其原因在于:1) 制备得到的超疏水复合表面具有微/纳米分级结构,这种微结构可以有效地捕获空气,这些空气气垫的存在可以有效地阻隔腐蚀液与复合表面之间的接触,减缓腐蚀过程的发生;2) 复合膜层表面的纳米颗粒与环氧树脂以化学键的形式与基体结合,结合强度高,该膜层不易脱落,从而增强了基体的耐蚀性[25];3) 复合膜层与微弧氧化层的共同作用在一定程度上能够阻隔试样表面的离子和电子转移,减缓镁合金的腐蚀倾向,因此,其耐蚀性得到提高。

图8 试样在3.5%NaCl溶液中的动电位极化曲线

Fig. 8 Potentiodynamic polarization curves of different treated films on substrates in 3.5% NaCl solution

表2 3种试样在在3.5%的NaCl溶液中的动电位极化参数

Table 2 Potentiodynamic polarization parameters of three substrates in 3.5% NaCl solution

3 结论

1) 镁合金试样经微弧氧化处理后得到具有微米级粗糙结构的表面,该表面是由高温烧结相MgO、Mg和Mg2SiO4三相组成,其对水静态接触角接近于0°,呈现超亲水特性。

2) 微弧氧化层与纳米二氧化硅颗粒组成的微/纳二元粗糙结构与低表面能物质FDTS的共同作用使制备得到的复合表面具有超疏水特性;接触角测量仪和高速摄影系统采集记录的光学图片证实制备得到的超疏水镁合金表面呈现小滚动角和低黏附性能。

3) 利用微弧氧化与纳米颗粒涂覆技术制备得到的复合膜层具有良好的耐蚀性,同镁合金基底相比,在3.5% NaCl溶液中的动电位极化腐蚀电流密度降低了3个数量级,腐蚀阻抗提高了3个数量级,复合膜层明显提高了镁合金基底的耐蚀性。

REFERENCES

[1] Mordike B L, Ebert T. Magnesium properties— applications—potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] Thiago F, Scharnagl N, Dietzel W, Kainer K U. Corrosion protectionofmagnesium AZ31 alloy using poly(ether imide)[PEI]coatings preparedby thedip coating method:Influenceofsolventand substrate pre-treatment[J]. Corrosion Science, 2011, 53(1): 338-346.

[3] Gu C, Lian J, He J, Jiang Z, Jiang Q. High corrosion-resistance nanocrystalline Ni coatingonAZ91D magnesium alloy[J]. Surface and Coatings Technology, 2006, 200(18/19): 5413-5418.

[4] Huo H, Li Y, Wang F. Improvement on the corrosion resistance of AZ91D magnesium alloy by aluminum diffusion coating[J]. Journal of Materials Science&Technology, 2007, 23(3): 379-382.

[5] 张荣发, 单大勇, 韩恩厚, 曾志良. 镁合金阳极氧化的研究进展与展望[J]. 中国有色金属学报, 2006, 16(7): 1136-1148.

ZHANG Rong-fa, SHAN Da-yong, HAN Hou-en, ZENG Zhi-lian. Status and prospect of anodization on magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1136-1148.

[6] Cai Q, Wang L, We B, Liu Q. Electrochemical performance of microarc oxidation films formed on AZ91D magnesium alloy in silicate and phosphate electrolytes[J]. Surface and Coatings Technology, 2006, 200(12/13): 3727-3733.

[7] Ma Y, Hu H, NORTHWOOD D, NIE X. Optimization of the electrolytic plasma oxidation processes for corrosion protection of magnesium alloy AM50 using the Taguchi method[J]. Journal of materials processing, 2007, 182(1/3): 58-64.

[8] Bhushan B. Nanotribology and nanomechanics of MEMS/NEMS and BioMEMS/BioNEMS materials and devices[J]. Microelectronic Engineering, 2007, 84(3): 387-412.

[9] Cui Jing, Li Wei-zhong, LAM Wei-haur. Numerical investigation on drag reduction with superhydrophobic surfaces by lattice-Boltzmann method[J]. Computers & Mathematics with Applications, 2011, 61(12): 3678-3689.

[10] Zhang X, Shi F, Niu J, Jiang Y, Wang Z. Superhydrophobic surfaces: from structural control to functional application[J]. Journal of Materials Chemistry, 2008, 18(16): 621-633.

[11] Feng Lin, Li Shu-hong, Li Ying-shun, Li Huan-jun, Zhang Ling-juan, Zhai Jin, Song Yan-lin, Liu Bi-qian, Jiang Lei, Zhu Dao-ben. Super-hydrophobicsurfaces:Fromnatural to artificial[J]. Advanced Materials, 2002, 14(24): 1857-1860.

[12] Georgakilas V, Bourlinos A, Zboril R, Trapalis C. Synthesis, characterization and aspects of superhydrophobic functionalized carbon nanotubes[J]. American Chemical Society, 2008, 20(9): 2884-2886.

[13] BRAVO J, ZHAI L, WU Z,COHEN R, RUBNER M. Transparent superhydrophobic films based on silica nanoparticles[J]. Langmuir,2007, 23(13): 7293-7298.

[14] Barchuiche C, Rocca E, Hazan J. Corrosion behaviour of Sn-containing oxide layer on AZ91D alloy formed by plasma electrolytic oxidation[J]. Surface & Coatings Technology, 2008, 202(17): 4145-4152.

[15] YerokhinL A, Nie X, Leyland A, Matthews A. Plasma electrolysis for surface engineering[J]. Surface and Coatings Technology, 1999, 122(2/3): 73-93.

[16] Juvaste H, Iiskola E I, Pakkanen T T. Aminosilane as a coupling agent for cyclopentadienyl ligands on silica[J]. Journal of Organometallic Chemistry, 1999, 587(1): 38-45.

[17] Tian F, Li B, Ji B, Yang J, Zhang G., Chen Y, Luo Y. Antioxidant and antimicrobial activities of consecutive extracts from Galla chinensis: The polarity affects the bioactivities[J]. Food Chemistry, 2009, 113(1): 173-179.

[18] Honschoten J W, Brunets N, Tas N R. Capillarity at the nanoscale[J]. Chemical Society Reviews, 2010, 39(3): 1096-1114.

[19] Bico J, Tordeux C,  D. Rough wetting[J]. Europhysics Letters, 2001, 55(2): 214-220.

D. Rough wetting[J]. Europhysics Letters, 2001, 55(2): 214-220.

[20] Nishino T,Meguro M,Nakamae K, Matsushita M,Ueda Y. The lowest surface free energy based on -CF3 alignment[J]. Langmuir, 1999, 15(13): 4321-4323.

[21] Cassie A B D, Baxter. Wettability of porous surfaces[J]. Transaction Faraday Society, 1944, 44: 546-551.

[22] Gao L, McCarthy T. A Perfectly hydrophobic surface(θA/θR=180°/180°)[J]. Journal of the American Chemical Society, 2006, 128(28): 9052-9053.

[23] Stern M, Geary A. Electrochemical polarization 1: Theoretical analysis of the shape of polarization curves[J]. Journal of theElectrochemicalSociety, 1957(4): 56-63.

[24] ZHANG Rong-fa, SHAN Da-yong, HAN En-hou, GUO Shi-bo. Development of microarc oxidation process to improve corrosion resistance on AZ91HP magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S2): s685-s688.

[25] 康志新, 赖晓明, 王 芬, 龙 雁, 李元元. Mg-Mn-Ce镁合金表面超疏水复合膜层的制备及耐腐蚀性[J]. 中国有色金属学报, 2011, 21(2): 283-289.

KANG Zhi-xin, LAI Xiao-ming, WANG Fen, LONG Yan, LI Yuan-yuan. Preparation of super-hydrophobic duplex-treated film on surface of Mg-Mn-Ce magnesium alloy and its corrosion resistance[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 283-289.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51275064,50975036);国家青年科学基金资助项目(51205006);北京市优秀人才培养基金资助项目(2013D005003000011)

收稿日期:2013-09-20;修订日期:2014-02-25

通信作者:李 杰,讲师,博士;电话:010-68985535;E-mail:lijie0739@btbu.edu.cn