文章编号:1004-0609(2011)11-2909-07

V型铝槽内腔微弧氧化的不均匀性

马英鹤, 巩春志, 田修波, 杨士勤

(哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001)

摘 要:采用恒压模式于硅酸盐体系中在V型内腔试件表面制备微弧氧化膜,研究V型角度对微弧氧化膜不均匀性的影响。采用数字式测厚仪、扫描电子显微镜和X射线衍射仪研究其微观结构,利用电化学分析仪进行耐蚀性的评定。结果表明:V型试件内表面的相组成无明显差别,均为γ-Al2O3,但其内表面的膜层厚度分布不同,且随着V型试件张角的增大,其内表面膜层厚度差值逐渐减小,由3.1 μm减小到0.4~0.9 μm,不均匀程度减小。此外,V型试件内表面边缘氧化膜层的耐蚀性较优,而靠近折弯处氧化膜层的耐蚀性较差,这是由于试件内表面受不同程度电力线屏蔽造成的。增大脉冲宽度对膜层不均匀性影响很小,但增加氧化处理时间后,试件内表面不均匀程度增大。

关键词:纯铝;V型槽;微弧氧化;不均匀性

中图分类号:TG174 文献标志码:A

Inhomogeneity of micro-arc oxidation of V-shaped aluminum cavity

MA Ying-he, GONG Chun-zhi, TIAN Xiu-bo, YANG Shi-qin

(State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The micro-arc oxidation (MAO) coatings were formed on the V-shaped aluminum cavity in the silicate electrolyte with constant voltage mode. The effect of the V-shaped angle on the inhomogeneity of MAO coatings was investigated. The microstructure and surface morphology were investigated using the digital coating thickness gauge, SEM and XRD, and the corrosion resistance was assessed by the electrochemistry analyzer. The results show that the phase compositions are almost γ-Al2O3, which does not demonstrate obvious difference for the inner surface of V-shaped specimen. In contrast, the thickness of the coatings on the inner surface varies substantially at different sites. With the increase of the angle of the V-shaped specimen, the thickness difference becomes slight, decreasing from 3.1 μm to 0.4-0.9 μm. A better corrosion resistance is observed near the edge of the samples and a worse corrosion resistance appears near the bent position of the samples. It may be attributed to different shielding effects of the electric field in the V-shaped cavity. The effect on the inhomogeneity by increased pulse duration is small, but with the increase of oxidation time, the inhomogeneity degree enlarges.

Key words: pure aluminum; V-shaped cavity; micro-arc oxidation; inhomogeneity

微弧氧化(Micro-arc oxidation, MAO),又称等离子体电火花沉积(Plasma electronic oxidation, PEO)[1-2]、微等离子体氧化[3](Micro-plasma oxidation, MPO),是一种能在Al、Mg和Ti等有色金属及其合金表面原位生长陶瓷膜的新技术。该技术通过电解溶液中有色金属或合金表面的微弧放电,发生复杂的等离子化学、热化学和电化学过程,从而形成致密的陶瓷氧化膜[4]。利用该技术所制备的氧化膜具有良好的耐蚀[5]、耐磨、绝缘性以及结合力强等优点[6-7], 因而得到了广泛的研究。

目前,国内外关于微弧氧化技术的研究主要集中在电参数的定性研究[8]、陶瓷层的结构和性能等方 面[9],试样一般为平面形状,而关于立体形状试样微弧氧化的研究报道很少[10]。异型试样的微弧氧化研究具有非常重要的现实意义,因为很多实际工件是异形的,这可能导致膜层结构和性能的不均匀性[11],进而严重影响微弧氧化技术的应用。本文作者以V型内腔试件微弧氧化为研究对象,探讨V型试件张角的变化对膜层厚度、结构以及耐蚀性的影响,并从电流分布的角度进行分析。

1 实验

实验材料为工业纯铝,试件形状见图1,V型试件每页均是正方形,边长为50 mm。将V型试件每页均分为A、B、C和D 4个样条,每个样条长50 mm,宽12.5 mm,且每个样条中心离整个试件中心折线的距离分别为6.25、18.75、31.25和43.75 mm。采用自行研制的15 kW微弧氧化设备于硅酸盐系电解液中对试件进行微弧氧化处理,装置包括高压直流脉冲电源、方形不锈钢工作槽和冷却系统。试件置于不锈钢槽中心位置,处理过程中通过冷却系统的作用使电解液温度保持在40 ℃左右。微弧氧化工艺采用恒压模式,电压为450 V,固定频率为200 Hz,反向脉冲宽度为 100 μs。

图1 试件形状示意图

Fig.1 Schematic diagram of specimen

采用基于涡流原理的图层测厚仪(TT240,北京时代公司制造)对膜层厚度进行测量。 采用FEI-SEM (QUANTA 200F)电子显微镜和D/MAX-rB旋转阳极X射线衍射仪(XRD)对陶瓷膜(V型试件内表面a、b、c和d 4处,见图1)的表面形貌及相组成进行分析。采用CHI604C型(上海华辰公司制造)电化学分析仪(三电极体系)在3.5%NaCl溶液中对膜层的抗腐蚀性能进行检测,以测试试件为工作电极,铂片为辅助电极,饱和甘汞电极为参比电极。通过示波器(型号TDS1012B-SC,Tektronix公司制造)记录图1中A、B、C和D 4个样条的电流波形。为了分析微弧过程,对上述A、B、C和D 4个样条进行彼此绝缘处理,然后连接导线,用以检测每个样条流过的电流及其随时间的变化规律。示波器经USB接口连接U盘用于波形存储和数据处理。

2 结果与分析

将V型试件放入电解液中,通电后表面立即生成一层很薄的氧化膜,同时有气体放出。随着电压的升高,电解液中溶质粒子在电场作用下向阳极移动加快,同时气泡增多。继续升高氧化电压,当电压超过某一临界值时,氧化膜的薄弱部分被击穿,发生微弧放电现象,试件表面出现无数快速移动的细小火花,火花放电能够在氧化膜中留下大量的放电微孔[12],且伴随大量气体的析出。微区电弧放电使局部区域温度高达1 000 ℃[13],膜层受到高温作用瞬间熔融,熔融物由于电解液的冷凝作用很快凝结在孔中央及周围,大孔洞被阻塞,留下很小的放电微孔,氧化过程得以继续进行。氧化膜上进行着孔的生成与填塞、膜层的溶解与沉积过程,最终达到一种平衡状态,形成一种表面多孔、内部致密的陶瓷氧化膜,随着微弧氧化的进行,膜层逐渐变厚。

2.1 V型试件表面形貌的不均匀性

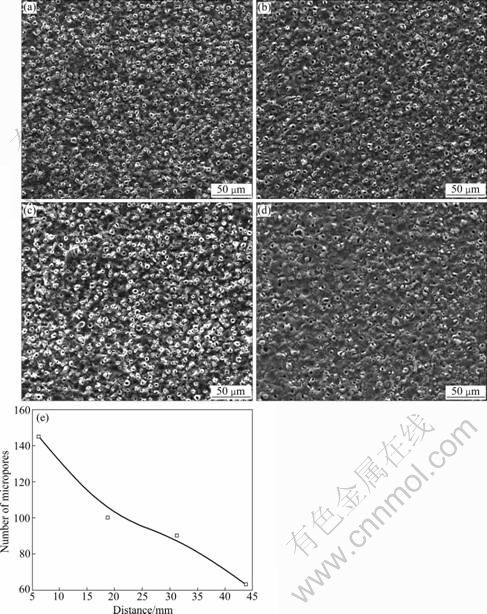

图2(a)~(d)所示分别为V型试件90°张角时经微弧氧化处理后所得到的a、b、c和d 4处陶瓷层的表面形貌。由图2可知,表面微孔基本上呈现“火山口”结构,且V型试件内表面区域a~d的微孔孔径逐渐增大,熔融物颗粒变大,粗糙程度增大,且微孔数量逐渐减小。图2(e)所示为试件不同位置表面形貌图中固定一小区域微孔的数量分布。由图2(e)可知,从试件折线到边缘,微孔数量由145个逐渐减小到63个。不同张角V型试件得到相似的变化趋势。

2.2 V型试件张角对膜层厚度均匀性的影响

图3(a)所示为V型试件30°张角时内表面一页的膜层厚度分布云图。试验参数如下:电压450 V,频率200 Hz,反向脉冲宽度100 μs,正向脉冲宽度200 μs,时间20 min,处理后由试件中心折线向边缘进行膜层厚度测试。由图3(a)可以看出,试件靠近折线处膜层厚度较小,而边缘膜层厚度较大,平均膜层厚度从4.0 μm增加到7.0 μm,膜层厚度增加了3 μm,且表面膜层厚度分布基本是对称的。图3(b)所示为V型试件不同张角时内表面中心膜层厚度分布。膜层厚度测试沿表面中心线进行,方向由折线到边缘。由图3(b)可知,由折线到边缘膜层厚度大致呈上升趋势,膜层厚度差值最大为3.1 μm。且随着张角的增大,表面膜层厚度增大,但从折线到边缘膜层厚度上升趋势减小,膜层厚度差值减小,膜层厚度差值最大为0.4~0.9 μm。

图2 90°张角时样品内表面不同位置微弧氧化膜层的表面形貌及微孔数量

Fig.2 Surface morphologies of coatings on different sites of V-shaped cavity with angle of 90°: (a) 6.25 mm; (b) 18.75 mm; (c) 31.25 mm; (d) 43.75 mm; (e) Number of micropores at different sites

图3 30°张角时V型试件内表面膜层厚度分布图及不同张角时V型试件内表面中心膜层厚度分布

Fig.3 Thickness contour of MAO coatings at different sites of V-shaped cavities (a) and thickness of MAO coatings along central line with different angles

图4(a)所示为30°张角时(氧化时间t1为40 min,其他参数不变)内表面一页的膜层厚度分布云图。由图4(a)可以看出,氧化处理时间40 min时得到的陶瓷膜层厚度与20 min时得到的相比有所提高,平均提高3 μm左右。试件靠近折线处膜层厚度较小而边缘膜层厚度较大,平均膜层厚度从5.9 μm增加到10.4 μm,膜层厚度增加了4.5 μm。图4(b)所示为试件张角分别为30°、90°和150°时其中心线膜层厚度分布(氧化时间为40 min,其他参数不变)。由图4(b)可以看出,随着张角的增大,从折线到边缘的膜层厚度差值由4.6 μm减小到2.2 μm。

图4(c)所示为30°张角时(脉冲宽度t2为400 μs,其他参数不变)内表面一页的膜层厚度分布云图。由图4(c)可以看出,试件靠近折线处膜层厚度较小而边缘膜层厚度较大,平均膜层厚度从7.5 μm增加到10.6 μm,膜层厚度增加了3.1 μm。图4(d)所示为试件张角分别为30°、90°和150°时其中心线膜层厚度分布(脉冲宽度为400 μs,其他参数不变)。由图4(d)可以看出,随着张角的增大,从折线到边缘的膜层厚度差值由2.8 μm减小到1.4 μm。

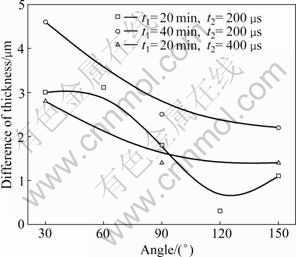

图5所示为不同参数下膜层厚度差值(试件边缘与折线处)与试件张角的变化关系。由图5可以看出,当脉冲宽度不变时,与氧化处理时间为20 min时相比,氧化处理时间为40 min时膜层厚度差值增大,不均匀性增大。而当氧化处理时间恒定、脉冲宽度增大时,不均匀性并未明显受到影响。但不同参数下,膜层厚度差值随着试件张角的增加而下降,不均匀性提高。

2.3 电化学腐蚀的不均匀性

图6(a)所示为V型试件60°张角及基体的极化曲线。由图6a)可以看出,从试件折线到边缘膜层的耐蚀性增强,且耐蚀性均强于基体的。图6(b)所示为V型试件张角分别为60°、90°、120°和150°时区域a(见图1)及基体腐蚀电流与腐蚀电位的关系。由图6(b)可以看出,随着张角的增大,膜层的耐蚀性增强,且基体的耐蚀性得到很大改善,经微弧氧化处理后,其膜层的腐蚀电流约降低2个数量级。

图4 不同参数时内表面膜层厚度分布

Fig.4 Thickness contour ((a), (c)) of MAO coatings at different sites with oxidation time of 40 min ((a), (b)) and with pulse duration of 400 μs ((c), (d)) for sample with angle of 30° and thickness ((b), (d)) of MAO coatings along central line with angles of 30°, 90° and 150°, respectively

图5 不同参数下膜层厚度差值随试件张角的变化关系

Fig.5 Dependence of difference of thickness on angles at different parameters

图6 微弧氧化膜层的耐蚀性

Fig.6 Corrosion resistance of MAO coatings: (a) Electrochemical curves of substrate and MAO coatings with angle of 60°; (b) Dependence of corrosion potential and corrosion current on angles of V-shaped cavity

2.4 陶瓷层的相结构变化

采用X射线衍射仪分别对a、b、c和d 4处所制备陶瓷膜的相组成进行分析,结果如图7所示。由图7可知,V型试件内部不同部位的陶瓷相组成基本相同,陶瓷膜层主要由γ-Al2O3相组成,产生Al的衍射峰可能是膜层较薄,且具有多孔结构使X射线能够有效穿透膜层,直达基体造成的。V型试件内表面受到电场的屏蔽作用,从折线处到边缘其膜层厚度、表面形貌以及耐腐蚀性均发生变化,但膜层的相组成差别不大。

图7 微弧氧化膜层内表面不同位置(图1)的XRD谱

Fig.7 XRD patterns of coatings at different sites of inner cavity shown in Fig.1: (a) Zone a; (b) Zone b; (c) Zone c; (d) Zone d

2.5 电流密度分布

图8(a)所示为V型试件60?张角时A、B、C和D(见图1) 4个样条的波形图。由图8(a)可以看出,从V型试件内表面折线到边缘,脉冲电流呈逐渐上升趋势,这说明V型试件内部受到了电场屏蔽作 用[14],因而电场强度大小不同。折线处受到的电场屏蔽作用较大,因而脉冲电流较小;边缘处受到的电场屏蔽作用较弱,因而脉冲电流较大。

图8(b)~(d)所示为不同张角的V型试件分别处理60、360和660 s得到的脉冲电流积分值曲线。可以看出,氧化处理一段时间以后,试件整体脉冲电流积分值下降,而试件内表面不同位置的脉冲电流差值减小。随着微弧氧化处理时间的延长,试件整体膜层厚度增加,而恒压模式下膜层厚度增加必然导致放电阻力[3]增加,所以脉冲电流减小。而V型试件内表面边缘处能量较高,因此,在微弧氧化初期,膜层生长较快,而靠近折线处能量较低,导致膜层生长较慢,此时脉冲电流差值较大。当边缘处膜层厚度达到临界值时,膜层电击穿变得困难;相反,V型试件内表面靠近折线处,由于氧化初期膜层较薄,因而在后期膜层电击穿变得相对容易,膜层生长加快。因此,试件内表面不同位置的脉冲电流差值减小。

图8 V型试样60°张角内表面不同位置的电流波形及其积分值曲线

Fig.8 Current waveforms at different sites on inner surface of V-shaped cavities with angle of 60° (a) and integral values of current for MAO time of 60 s (b), 360 s (c) and 660 s (d)

由于V型试件内部受到屏蔽作用,因此,试件内部的电场强度分布不均匀。由于V型试件内表面边缘电场强度较高,所以微弧氧化反应过程的驱动力较 大[15],能量较高,因而放电通道冷却凝固后形成的微孔孔径较大,微区电弧放电形成的熔融物较多,使得熔融物颗粒较大,而越向折线处电场强度越低,能量越低,所以微孔孔径越小,微孔的数量越多。

试件边缘处电流较高,膜层生长较快,而越靠近折线处电流越小,膜层生长较缓慢。从实验中可以观察到氧化处理初期火花多出现在V型试件内表面边缘处,边缘的微弧亮度高且较密集,而靠近折线处火花较少,内部的火花较暗且较稀疏,膜层熔融物在V型试件内表面边缘凝结较多,而在折线处凝结较少,从而导致了表面膜层厚度的差别(见图3~5)。 随着张角的增大,V型试件受到电力线屏蔽的作用减弱,导致边缘电流和靠近折线处的电流差值减小,所以,膜层厚度差值减小。试件表面膜层厚度存在差异,导致其耐蚀性不同[16]。膜层厚度越大,其耐腐蚀性能越强。此外,随着张角的增大,试件的膜层厚度增大,因此其耐蚀性增强。

3 结论

1) V型试件表面膜层厚度呈不均匀分布,且随着V型试件张角的增大,其内表面膜层厚度差值逐渐减小,不均匀程度降低,张角越大,差值越小。但总体来说,V型试件内表面边缘膜层厚度较大,而靠近折线处膜层厚度较小。表面形貌显示,V型试件内表面边缘微孔数量较少,微孔孔径较大,而越靠近内表面折线处,微孔数量越少,微孔孔径越小。

2) V型试件内表面边缘氧化膜层的耐蚀性较好,而靠近折线处氧化膜层的耐蚀性较差。与基体相比,微弧氧化膜层耐腐蚀能力均有提高。

3) 微弧氧化处理时,脉冲宽度增大1倍,膜层厚度差并未出现明显变化,但将处理时间延长1倍时,膜层厚度差增大,不均匀程度增大。同时,随着V型试件张角的增大,其内表面膜层厚度差值逐渐减小,不均匀程度减小。

REFERENCES

[1] PARFENOV E V, YEROKHIN A L, MATTHEWS A. Impedance spectroscopy characterisation of PEO process and coatings on aluminium[J]. Thin Solid Film, 2007, 516(2/4): 428-432.

[2] YEROKHIN A L, SHATROV A, SAMSONOV V, SHASHKOV P, PILKINGTON A, LEYLAND A, MATTHEWS A. Oxide ceramic coatings on aluminium alloys produced by a pulsed bipolar plasma electrolytic oxidation process[J]. Surface and Coating Technology, 2005, 199(2/3): 150-157.

[3] YAO Zhong-ping, JIANG Zhao-hua, WU Xiao-hong, SUN Xue-tong, WU Zhen-dong. Effects of ceramic coating by micro-plasma oxidation on the corrosion resistance of Ti-6Al-4V alloy[J]. Surface and Coating Technology, 2005, 200(7): 2445-2450.

[4] 吕维玲, 马 颖, 陈体军, 徐卫军, 杨 健, 郝 远. 氧化时间对AZ91D镁合金微弧氧化膜微观组织和性能的影响[J]. 中国有色金属学报, 2009, 19(8): 1385-1391.

L? Wei-ling, MA Ying, CHEN Ti-jun, XU Wei-jun, YANG Jian, HAO Yuan. Effects of oxidation time on microstructures and properties of micro-arc oxidation coatings of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(8): 1385-1391.

[5] BARIK R C, WHARTON J A, WOODA R J K, STOKES K R, JONES R L. Corrosion, erosion and erosion–corrosion performance of plasma electrolytic oxidation (PEO) deposited Al2O3 coatings[J]. Surface and Coating Technology, 2005, 199(2/3): 158-167.

[6] TILLOUS K, TOLL-DUCHANOY T, BAUER-GROSSE E, HERICHER L, GEANDIER G. Microstructure and phase composition of microarc oxidation surface layers formed on aluminium and its alloys 2214-T6 and 7050-T74[J]. Surface and Coating Technology, 2009, 203(19): 2969-2973.

[7] WU Xiang-qing, XIE Fa-qin, HU Zong-chun, WANG Li. Effects of additives on corrosion and wear resistance of micro-arc oxidation coatings on TiAl alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 1032-1036.

[8] 李淑华, 程金生, 尹玉军, 辛文彤, 杨润泽. 微弧氧化过程中电流和电压变化规律的探讨[J]. 特种铸造及有色合金, 2001(3): 4-5.

LI Shu-hua, CHENG Jin-sheng, YIN Yu-jun, XIN Wen-tong, YANG Run-ze. An approach to changing regularity of current and voltage variation during the microarc oxidation process[J]. Special Casting and Nonferrous Alloys, 2001(3): 4-5.

[9] SUNDARARAJAN G, RAMA-KRISHNA L. Mechanisms underlying the formation of thick alumina coatings through the MAO coating technology[J]. Surface and Coating Technology, 2003, 167(2/3): 269-277.

[10] GU Wei-chao, L? Guo-hua, CHEN Huan, CHEN Guang-liang, FENG Wen-ran, YANG Si-ze. PEO protective coatings on inner surface of tubes[J]. Surface and Coating Technology, 2007, 201(15): 6619-6612.

[11] 杨 巍, 蒋百灵, 沈维滇, 李 尧. 铝合金微弧氧化陶瓷层微观形貌与力学性能的不均匀性[J]. 材料科学与工程学报, 2009, 27(6): 888-891.

YANG Wei, JIANG Bai-ling, SHEN Wei-dian, LI Yao. Unhomogeneity of micro-morphology and mechanical properties of oxidation coatings on aluminum alloy[J]. Journal of Materials Science and Engineering, 2009, 27(6): 888-891.

[12] 王燕华, 王 佳, 张际标. AZ91D镁合金微弧氧化过程中的火花放电现象研究[J]. 中国腐蚀与防护学报, 2006, 26(5): 267-271.

WANG Yan-hua, WANG Jia, ZHANG Ji-biao. Spark discharges during the micro-arc oxidation of AZ91D magnesium alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2006, 26(5): 267-271.

[13] XUE Wen-bin, DENG Zhi-wei, CHEN Ru-yi, ZHANG Tong-he. Growth regularity of ceramic coatings formed by microarc oxidation on Al-Cu-Mg alloy[J]. Thin Solid Films, 2000, 372(1/2): 114-117.

[14] 赵凯华, 陈熙谋. 电磁学[M]. 北京: 高等教育出版社, 2003: 27.

ZHAO Kai-hua, CHEN Xi-mou. Electromagnetism[M]. Beijing: Higher Education Press, 2003: 27.

[15] 马 颖, 詹 华, 马跃洲, 吕维玲, 冯君艳, 高 唯. 电参数对AZ91D镁合金微弧氧化膜层微观结构及耐蚀性的影响[J]. 中国有色金属学报, 2010, 20(8): 1467-1473.

MA Ying, ZHAN Hua, MA Yue-zhou, L? Wei-ling, FENG Jun-yan, GAO Wei. Effects of electrical parameters on microstructure and corrosion resistance of micro-arc oxidation coatings on AZ91D magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 1467-1473.

[16] 陈 宏, 郝建民, 王利捷. 镁合金微弧氧化陶瓷层耐蚀性的电化学分析[J]. 腐蚀与防护, 2004, 25(9): 383-385.

CHEN Hong, HAO Jian-min, WANG Li-jie. Electrochemical analyses of corrosion resistance of magnesium alloy(MB8) treated by micro-arc oxidization[J]. Corrosion and Protection, 2004, 25(9): 383-385.

(编辑 陈卫萍)

收稿日期:2010-11-15;修订日期:2011-05-16

通信作者:田修波,教授,博士;电话:0451-86418791;E-mail: xiubotian@163.com