采用低硅赤铁矿尾矿制备蒸压砖

赵云良,张一敏,陈铁军

(武汉理工大学 资源与环境工程学院,湖北 武汉,430070)

摘要:利用鄂西低硅赤铁矿尾矿及当地石灰石资源并掺入适量黄沙为原料制备蒸压砖,考察配方设计和搅拌工艺及成型压力对制备蒸压砖的影响,对该蒸压砖进行XRD和SEM分析。试验结果表明:在赤铁矿尾矿质量分数为70%,石灰质量分数为15%,黄沙质量分数为15%,采用2次搅拌工艺,成型压力为20 MPa,蒸汽压力为1.2 MPa,蒸压时间为6 h条件下制备的蒸压砖,其抗压强度为21.20 MPa,抗折强度为4.21 MPa;15次冻融后抗压强度为18.36 MPa,质量损失为0.72%,达到GB 11945—1999(《蒸压灰砂砖》)规定的MU20级的要求;其强度主要来源于水化反应生成的Ⅰ型水化硅酸钙、托勃莫来石和水石榴石,它们相互交织形成网络结构,并胶结赤铁矿尾矿和黄沙颗粒形成紧密和坚固的骨架。

关键词:低硅;赤铁矿尾矿;蒸压砖;制备

中图分类号:TD926.4 文献标志码:A 文章编号:1672-7207(2013)05-1760-06

Preparation of autoclaved bricks made from low-silicon hematite tailings

ZHAO Yunliang, ZHANG Yimin, CHEN Tiejun

(School of Resources and Environmental Engineering, Wuhan University of Technology, Wuhan 430070, China)

Abstract: The preparation of autoclaved bricks from low-silicon hematite tailings from western Hubei province was investigated. The results show that the optimum raw material composition is a mixture of 70% hematite tailings, 15% lime and 15% sand. The optimum forming pressure is 20 MPa. The compressive strength, flexural strength, the compressive strength and mass loss after 15 times freezing-thawing of autoclaved bricks obtained under optimum test conditions are 21.20 MPa, 4.21 MPa, 18.36 MPa and 0.72%, respectively. The performances of autoclaved brick satisfies the standard of GB 11945—1999. Calcium silicate hydrate, tobermorite and hydrogarnet make main contribution to the strength of the autoclaved brick. They form network structure and shaped compact and solid framework through cementing particles of hematite tailings and yellow sands.

Key words: low-silicon; hematite tailing; autoclaved brick; preparation

鄂西高磷赤铁矿储量巨大,如何利用分选过程产生的大量尾矿,实现鄂西铁矿尾矿的高效利用,始终是不可避免的重大课题。铁尾矿综合利用的途径一般有有价元素的再选[1]、制作建筑材料[2-3]、利用尾矿充填采空区[4]、制作功能材料[5-7]、尾矿回填与复垦等[8-9]。鄂西某选矿厂附近石灰石资源丰富且尚未开发利用,为实现该地赤铁矿尾矿和石灰石资源的综合利用,以它们为主要原料制备蒸压砖具有一定的社会效益和经济效益。目前,国内外对粉煤灰制备蒸压砖进行了大量研究[10-11],但随着粉煤灰的综合利用程度不断加深,粉煤灰价格也随之升高,粉煤灰蒸压砖的生产成本增加,以矿山尾矿为主要原料制备蒸压砖成为了重要的研究课题。本研究在铁尾矿特性分析的基础上,利用其作为骨料和硅源,以鄂西当地丰富而廉价的石灰石作为钙源,再掺配适量黄沙,制备性能较好的蒸压砖,以便为鄂西赤铁矿尾矿高效大量利用提供新的途径。

1 试验

1.1 试验原料及其特性

1.1.1 赤铁矿尾矿

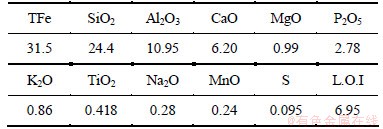

赤铁矿尾矿取自鄂西建始县某选矿厂,为强磁选尾矿。尾矿干燥后经两段颚式破碎机和一段对辊破碎机破细成粉状,作为试验用原料。以Xios advanced X线荧光光谱仪对其进行化学成分分析,结果见表1。

表1 铁尾矿化学成分(质量分数)

Table 1 Chemical compositions of hematite tailings %

由表1可知:该赤铁矿尾矿SiO2质量分数为24.4%,属低硅型铁尾矿[12]。

采用D/Max-IIIA型XRD衍射仪对其进行矿物组成分析,扫描速度为15 (°)/min,步长为0.02°,靶材为Cu靶,电压为40 kV,电流为30 mA,结果见图1。

图1 赤铁矿尾矿XRD图

Fig.1 XRD pattern of hematite tailings

从图1可知:该赤铁矿尾矿的矿物组成主要成分是赤铁矿和石英,次要矿物为绿泥石和方解石等。

用筛分分析法对其进行粒度分析,结果见图2。

图2 铁尾矿粒度特性曲线

Fig.2 Particle size distribution of hematite tailings

从图2可见:铁矿尾矿粒度较小,粒径小于0.044 mm的占50.44%,小于0.074 mm的占82.14%,故铁尾矿颗粒有较大的比表面积,有利于其硅质成分在蒸压过程中与氢氧化钙充分反应。同时,铁尾矿颗粒中存在部分较粗颗粒,在复合体系中起到骨料的作用。

1.1.2 石灰

石灰为蒸压反应提供钙源,与复合体系中的硅质材料反应生成各种水化产物,使制品获得一定强度;另一方面石灰消化时可产生大量热量,加强了水分子的热运动,提高成型物料的塑性。试验所用石灰为自制煅烧石灰。石灰石取自鄂西建始县某选矿厂附近,在煅烧温度为1 150 ℃、恒温时间为30 min条件下,所制得石灰的CaO质量分数为88.26%,消化温度为99 ℃,消化时间为280 s,满足JC/T 621—1996(《硅酸盐建筑制品用生石灰》)一等品技术要求。

1.1.3 黄沙

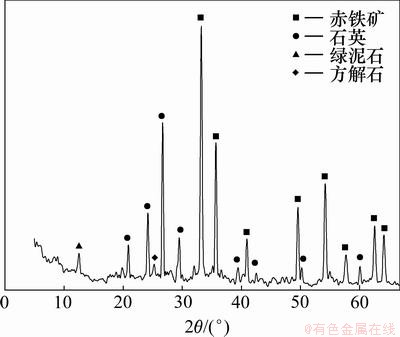

由于所用铁尾矿为低硅型铁尾矿,为满足制备蒸压砖一定的钙硅比和颗粒级配,掺入适量的硅质材料——黄沙,试验用黄沙粒度为0.9~1.6 mm,其化学成分见表2。

由表2可知:黄沙中SiO2的质量分数为90.60%。黄沙的掺入直接影响蒸压砖的性能,表现在以下2个方面:(1) 提供硅源。黄沙中的SiO2多以游离的石英态存在,在水热条件下能更为迅速的溶解于Ca(OH)2饱和溶液,生成水化硅酸钙,提高蒸压砖性能;(2) 改善粒级。黄沙在复合体系中充当粗骨料,在加压成型

表2 黄沙化学成分(质量分数)

Table 2 Chemical compositions of yellow sands %

中,起到了传递压力作用,克服较小铁尾矿颗粒所造成的密度不匀、憋气分层等现象,并提高了制品的强度[13]。

1.2 试件制备及检测

将石灰石在一定温度下经XZ-13电阻炉恒温煅烧30 min,制得生石灰,冷却后将其放入GJ-Ⅱ型密封式化验制样机中粉磨备用。

将赤铁矿尾矿、石灰、黄沙和石膏按比例称量后,在JJ-5型水泥胶砂搅拌机中混合均匀(混合料含水率为15%),消化后装入直径为50 mm的模具中,模具放置在YES-100数显式液压压力试验机中以20 MPa的压力成型,即制得砖坯。

砖坯在YZF-2A型蒸压釜中进行蒸汽养护,国外学者研究表明在饱和蒸汽正常的条件下恒压时间和压力的乘积为70~75 kg/(cm2·h)就能获得良好的制品[14],故试验蒸汽选用压力为1.2 MPa,蒸压时间为6 h。砖坯出釜后,即得赤铁矿尾矿蒸压砖。

蒸压砖的抗压强度检测按照GB/T 2542—2003 (《砌墙砖试验方法》)的试验规程进行。

2 结果分析及讨论

2.1 配方设计

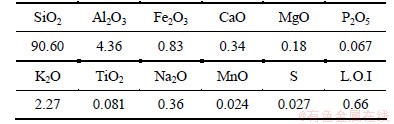

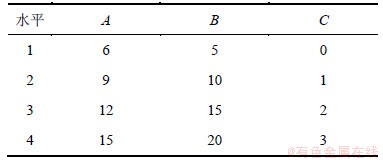

试验所用原料赤铁矿尾矿、石灰、黄沙和石膏之间存在化学反应,在复合体系中是相互影响、相互制约,故试验采用3因素4水平的正交试验进行配方设计。

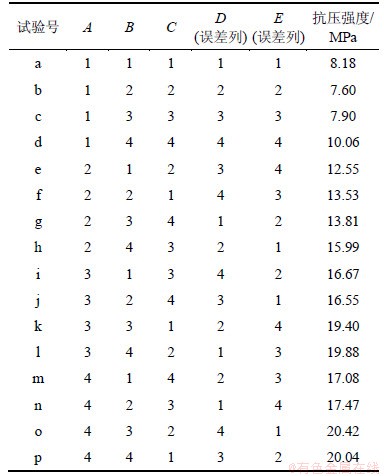

选取石灰、黄沙和石膏掺量为考察因素,以抗压强度为评价指标进行正交试验,寻求最佳的配方,选用4水平的L16(45)正交表所设计的试验方案进行试验。试验所用的因素水平表见表3,正交试验结果和极差分析分别如表4和表5所示。

由表4和表5结果可知:影响赤铁矿尾矿蒸压砖的抗压强度从大到小的顺序为石灰(A)、黄沙(B)和石膏(C),即A>B>C。综合考虑赤铁矿尾矿的利用率、原料成本和蒸压砖性能,配方的适宜组合为A4B3C1,即石灰质量分数为15%,黄沙质量分数为15%,不掺入石膏,此时赤铁矿尾矿的质量分数为70%。

表3 因素水平表(质量分数)

Table 3 Levels of factors %

表4 正交试验结果

Table 4 Results of orthogonal experiments

表5 正交试验的极差分析

Table 5 Range analysis of orthogonal experiment

2.2 搅拌工艺的影响

在一般情况下,传统混凝土物料采用一次搅拌,即可达到技术要求[15]。但是,由于本试验所用石灰为自烧石灰,在加水搅拌时石灰开始消化,为提高石灰消化扩散和成型物料塑性,考虑采用预搅拌和终搅拌的2次搅拌工艺,即增加预搅拌工序。

在赤铁矿尾矿质量分数为70%,石灰质量分数为15%,黄沙质量分数为15%条件下,以未经预搅拌和经预搅拌的2种搅拌工艺分别制得赤铁矿尾矿蒸压砖,并对蒸压砖的抗压强度进行测试,结果见图3。

图3 不同搅拌工艺对塑性和抗压强度的影响

Fig.3 Effect of different stirring processes on plasticity and compressive strength

由图3可知:经一次搅拌工艺的成型物料塑性指标为2.1 cm·kg,蒸压砖抗压强度为18.58 MPa;经2次搅拌工艺的成型物料塑性指标为2.5 cm·kg,蒸压砖抗压强度为21.20 MPa,均高于一次搅拌,并将制品级别提高,从MU15提高到MU20。这是因为石灰在消化过程中会部分结块形成假性颗粒,导致成型坯体不密实,而2次搅拌工艺能很好地对消化物料起到粉碎作用。另外,第二次搅拌时加入少量水,并将这部分水均匀分布在尚未形成良好水膜的固体颗粒表面,有效地提高了成型物料的塑性和蒸压砖的抗压强度。

后续试验全部采用2次搅拌工艺,工艺参数为:一次搅拌加水10%(质量分数),二次搅拌加水5%。

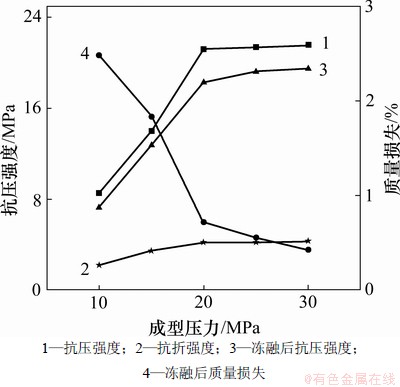

2.3 成型压力的影响

压制成型使硅源颗粒与钙源颗粒紧密接触以保证颗粒间的反应高效进行,同时为砖坯提供初始强度。在赤铁矿尾矿质量分数为70%,石灰质量分数为15%,黄沙质量分数为15%,采用2次搅拌工艺不变的条件下改变成型压力,分别为10,15,20,25和30 MPa,考察成型压力对蒸压砖制品的影响,结果见图4。

图4 成型压力对制品性能的影响

Fig.4 Effect of different forming pressures on performance of autoclaved bricks

由图4可知:制品的抗压强度和冻融后抗压强度随着成型压力的增加先快速增加,当成型压力达到20 MPa后趋于平缓;抗折强度随着成型压力的增加并不太明显,当成型压力分别为5 MPa和10 MPa时,冻融后质量损失在1%以上,当成型压力大于20 MPa时,冻融后质量损失明显降低并趋于缓和。这是由于在成型压力低于一定值时,物料的孔隙率很大,颗粒间的内摩擦力小,成型压力的增加能显著地提高物料颗粒的紧密程度,有利于蒸压反应的充分进行和砖坯的初始强度提高;但当压力达到一定值时,颗粒间摩擦力增大,同时,颗粒间未排出的气体压缩导致反膨胀力增大,此时,成型压力的增加并不能有效地提高颗粒间的致密度。故试验选取20 MPa作为适宜的成型压力。

2.4 优化试验

将上述各试验所得结果组合成优化试验方案制备一批赤铁矿尾矿蒸压砖,并参照GB 11945—1999(《蒸压灰砂砖》)标准进行检测,优化试验方案及抗压强度检测结果见表6。

从表6可知:在优化试验方案条件下制备的蒸压砖抗压强度达到GB 11945—1999(《蒸压灰砂砖》)规定的MU20级的要求,这说明利用鄂西赤铁矿尾矿及当地石灰石资源并掺入适量黄沙,制备性能较好的赤铁矿尾矿蒸压砖是可行的。

表6 优化试验方案及蒸压砖性能

Table 6 Optimization experiment and performance of autoclaved brick

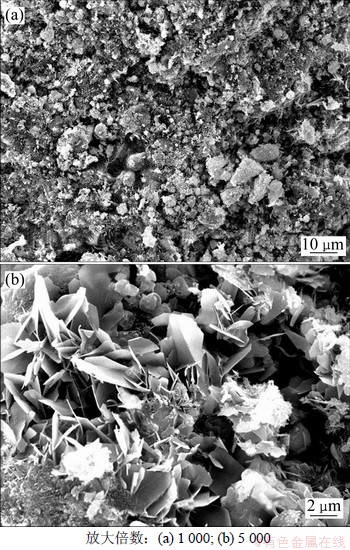

3 制品表征

为研究制备的蒸压砖的强度形成机理,对在赤铁矿尾矿质量分数为70%,石灰质量分数为15%,黄沙质量分数为15%,采用2次搅拌工艺,成型压力为20 MPa,蒸汽压力为1.2 MPa,蒸压时间为6 h条件下制备的蒸压砖进行XRD和SEM分析,结果分别见图5和图6。

从图5可以看出:蒸压砖的主要物相有赤铁矿、石英、方解石、水石榴石、托勃莫来石和Ⅰ型水化硅酸钙。这说明在1.2 MPa的蒸汽养护条件下,赤铁矿尾矿和黄沙中的SiO2溶解,并与Ca(OH)2发生水化反应生成了Ⅰ型水化硅酸钙、托勃莫来石和水石榴石,这些水化产物填充在骨架的孔隙中,赋予蒸压砖强度,尤其是托勃莫来石具有良好的物理力学性能,为蒸压砖的高强度提供了保证。

由图6(a)看到:蒸压砖的结构致密,孔隙少且小,颗粒级配合适,颗粒之间的连接紧密,水化产物很好地包覆在赤铁矿尾矿及黄沙颗粒表面,蜂窝状的水化硅酸钙交织填充在孔隙中,这为蒸压砖强度的发挥提供了很好的条件。图6(b)中,薄片状的托勃莫来石,纤维状的Ⅰ型水化硅酸钙以及未分解完全的水石榴石聚集在一起,相互交织形成网络结构,同时水化产物在颗粒上附着,并胶结赤铁矿尾矿和黄沙颗粒形成紧密和坚固的骨架,使整个复合体系结构更加致密,孔隙率降低,从而使蒸压砖具有较高的强度。

图5 蒸压砖的X线衍射谱

Fig.5 XRD pattern of autoclaved brick

图6 蒸压砖的SEM形貌图

Fig.6 SEM morphologies of autoclaved brick

4 结论

(1) 利用鄂西赤铁矿尾矿及当地石灰石资源并掺入适量黄沙为原料制备蒸压砖。在赤铁矿尾矿质量分数为70%,石灰质量分数为15%,黄沙质量分数为15%,采用2次搅拌工艺,成型压力为20 MPa,蒸汽压力为1.2 MPa,蒸压时间为6 h条件下制备的蒸压砖达到GB 11945—1999(《蒸压灰砂砖》)规定的MU20级的要求。

(2) 赤铁矿尾矿蒸压砖强度主要来源于水化反应生成的Ⅰ型水化硅酸钙、托勃莫来石和水石榴石,它们相互交织形成网络结构,并胶结赤铁矿尾矿和黄沙颗粒,形成紧密和坚固的骨架。

参考文献:

[1] LI Chao, SUN Henghu, BAI Jing, et al. Innovative methodology for compressive utilization of iron ore tailings. Part 1: The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting[J]. Journal of Hazardous Materials, 2010, 174(1): 71-77.

[2] Das S K, Kumar S, Ramachandrarao P. Exploitation of iron ore tailing for the development of ceramic tiles[J]. Waste Management, 2000, 20(8): 725-729.

[3] LIU Yangsheng, DU Fang, YUAN Li, et al. Production of lightweight ceramist from iron ore tailings and its performance investigation in a biological aerated filter(BAF) reactor[J]. Journal of Hazardous Materials, 2010, 178(3): 999-1006.

[4] 赵瑞敏. 我国铁矿尾矿综合利用[J]. 金属矿山, 2009, 397(7): 158-162.

ZHAO Ruimin. Comprehensive utilization of iron tailings in China[J]. Metal Mine, 2009, 397(7): 158-162.

[5] Sakthivel R, Vasumathi N, Sahu D, et al. Synthesis of magnetite powder from iron ore tailings[J]. Powder Technology, 2010, 201(2): 187-190.

[6] LI Jing, WANG Qi, LIU Jihui, et al. Synthesis process of forsterite refractory by iron ore tailings[J]. Journal of Environmental Sciences, 2009, 21(S1): 92-95.

[7] YU Honghao, XUE Xiangxin, HUANG Dawei. Synthesis of mesoporous silica materials (MCM-41) from iron ore tailings[J]. Materials Research Bulletin, 2009, 44(11): 2112-2115.

[8] 郭涛, 杨小波, 廖香俊, 等. 海南昌江石碌铁矿尾矿库区植被调查[J]. 生态学报, 2007(2): 754-762.

GUO Tao, YANG Xiaobo, LIAO Xiaojun, et al. Investigation on the vegetation of iron tailing wasteland in Shilu, Changjiang, Hainan Province[J]. Acta Ecologica Sinica, 2007(2): 754-762.

[9] Norland M R, Veith D L. Revegetation of coarse taconite iron ore tailing using municipal solid waste compost[J]. Journal of Hazardous Materials, 1995, 41(2): 123-134.

[10] Tayfun C, Mehmet T. Lime based steam autoclaved fly ash bricks[J]. Construction and Building Materials, 2007, 21(6): 1295-1300.

[11] Chindaprasirt P, Pimraksa K. A study of fly ash-lime granule unfired brick[J]. Powder technology, 2008, 182(1): 33-44.

[12] 郭建文, 王建华, 杨国华. 我国铁尾矿资源现状及综合利用[J]. 现代矿业, 2009(10): 23-25.

GUO Jianwen, WANG Jianhua, YANG Guohua. Current situation and comprehensive utilization of iron ore tailings resources in our country[J]. Modern Mining, 2009(10): 23-25.

[13] 刘涛, 张一敏, 陈铁军, 等. 赤铁矿尾矿免烧免蒸砖的制备研究[J]. 现代矿业, 2010(2): 67-69.

LIU Tao, ZHANG Yimin, CHEN Tiejun, et al. Preparation study of low density tailings of hematite non-burned and non-autoclaved bricks[J]. Modern Mining, 2010(2): 67-69.

[14] 府坤荣. 蒸压加气混凝土养护制度的探讨[J]. 新型建筑材料, 2006(12): 72-74.

FU Kunrong. Discussion on curing system of autoclaved aerated concrete[J]. New building materials, 2006(12): 72-74.

[15] 闫振甲, 何艳君. 免烧砖生产实用技术[M]. 北京: 化学工业出版社, 2009: 153-156.

YAN Zhenjia, HE Yanjun. Production practical techniques of non-burned bricks[M]. Beijing: Chemical Industry Press, 2009: 153-156.

(编辑 何运斌)

收稿日期:2012-09-27;修回日期:2012-11-27

基金项目:“十一五”国家科技支撑计划重点项目(2007BAB15B02)

通信作者:张一敏(1954-),男,河南许昌人,教授,博士生导师,从事高效洁净矿物加工理论与工艺、二次资源利用研究;电话:027-87212127;E-mail: zym126135@126.com