紫铜海水管焊接部位在海水中的腐蚀特征

王宏智1, 陈 君1, 周建奇2, 姚素薇1, 张卫国1

(1. 天津大学 化工学院, 天津 300072; 2. 92854部队, 湛江 524003)

摘 要: 采用金相显微镜、 X射线衍射仪、 扫描电镜结合能谱测试技术研究了紫铜海水管焊接接头部位在海水中的腐蚀特征。 结果表明: 采用黄铜焊条的接头部位为α+β双相黄铜, 在海水中发生了严重的不均匀脱锌腐蚀, 脱锌后合金表面的颜色由黄变为紫红; 腐蚀产物主要由ZnCl2和ZnSO4等锌盐和锌的氧化物ZnO2和ZnO组成, 此外还含有少量的铜绿Cu3(SO4)(OH)4; 采用白铜焊条的接头部位为Cu-Ni-Zn三元单相固溶体(α相), 在海水中浸泡前后结构未发生变化, 表面较致密、 无明显孔洞和点蚀, 与黄铜焊缝相比, 具有优异的耐海水腐蚀性能。

关键词: 铜合金; 海水管; 焊接; 腐蚀 中图分类号: TG172

文献标识码: A

Corrosion characteristics of welded joints of copper pipe in seawater

WANG Hong-zhi1, CHEN Jun1, ZHOU Jian-qi2, YAO Su-wei1, ZHANG Wei-guo1

(1. School of Chemical Engineering and Technology,

Tianjin University, Tianjin 300072, China;

2. The Unit No.92854 of the Chinese Peoples Liberation Army,

Zhanjiang 524003, China)

Abstract: The corrosion characters of the welded joints of copper pipe in seawater were analyzed by metallurgical microscope, scanning electron microscopy (SEM), X-ray diffractometry (XRD) and energy dispersive X-ray analysis(EDX). The results indicate that the metallographic structure of welded joint formed by brass welding rod is (α+β) phase brasses. The brass-welded joint was corroded seriously in seawater because of dezincification, then the surface color of the alloy changes from yellowish to purple. The XRD analysis show that the corrosion products are ZnCl2, ZnSO4, ZnO2, ZnO and a small amount of Cu3(SO4)(OH)4. And the metallographic structure of welded joint formed by cupronickel welding rod is single α-phase, which is Cu-Ni-Zn solid solution alloy. The structure has no change before and after immersing in seawater, and the surface is fine and has no holes and pitting corrosion. The corrosion resistance of cupronickel-welded joint is better than that of the brass-welded joint.

Key words: copper alloy; seawater pipe; welded joint; corrosion

铜合金具有良好的耐海水腐蚀和抗海洋生物附着能力, 同时具有足够的强度、 弹性和耐磨性, 因而铜合金在海洋工程中得到了广泛应用[1-6]。 海水管路内流过的介质是海水, 管材常用脱氧紫铜。 但在实际使用过程中发现, 在海水管路的焊接部位及如管子的弯头部位、 三通和四通部位、 加装压力表基座等处仍发生严重腐蚀。 在过去几年中, 众多学者对铜合金的腐蚀进行了大量研究, 其中不乏对黄铜合金与白铜耐蚀性的研究, 并提出了比较完善的机理来解释它们在海水中的腐蚀性能, 如先溶解机制、 溶解-再沉淀机制和空位机制等[7-11]。 但对紫铜管路中焊接接头部位黄铜和白铜在海水中的腐蚀行为的研究较少, 特别是对用微观方法研究两者腐蚀特性的报道更少。

为了获得紫铜管路中黄铜焊缝与白铜焊缝腐蚀特性的全面而深入的信息, 本文作者采用金相组织分析、 X射线衍射仪、 扫描电子显微镜及能量色散谱仪对挂海4个月后紫铜管路焊接接头部位的试样进行了测试与分析, 研究了焊接接头部位在海水中的腐蚀特性及腐蚀机理。

1 实验

试样为紫铜海水管, 分别用黄铜和白铜焊条焊接, 挂海实验4个月, 然后将试样的焊接部位分为1cm×1cm大小的测试样品。

采用PHLIPS公司的XL30ESEM环境扫描电子显微镜观测样品形貌。 结合OXFORD公司ISIS300型射线能谱仪测对样品进行成分分析。

采用荷兰PANAlytical公司生产的XPert Pro 型X-射线衍射仪分析焊条和焊接接头部位结构。 衍射角为20°~100°, 靶材为Co靶。

采用OLYMPUS BX-51金相显微镜及DP12型摄像头观测金相组织。 测试部位为黄铜焊缝与白铜焊缝的横截面, 浸蚀剂为氯化高铁盐酸溶液。

2 结果与讨论

2.1 样品腐蚀后表面形貌

紫铜海水管路在海水中浸泡4个月后, 黄铜焊缝腐蚀严重, 表面形成了厚且疏松的腐蚀产物层, 而白铜焊缝表面略有些变色, 无腐蚀裂纹、 裂缝和腐蚀孔, 只是表面黏附了一些污染物。 为考察焊缝在海水中的腐蚀特征, 采用扫描电镜对焊缝进行了形貌观察, 结果如图1~3所示。

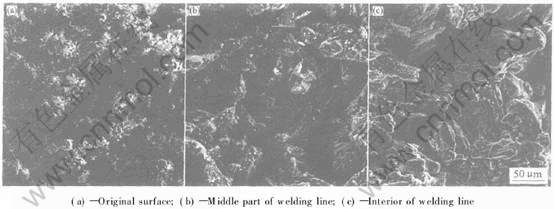

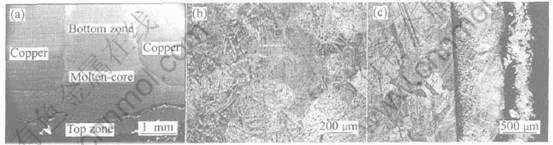

图1所示为黄铜焊缝在海水中腐蚀后的表面形貌。 图中试样分3种: 1) 原始表面 焊缝经海水浸泡后的原始表面; 2) 焊缝中部 去掉原始表面上一薄层腐蚀产物, 露出黑色多孔腐蚀层; 3) 焊缝内部 去除全部黑色多孔腐蚀层, 露出黄铜焊缝基体。 由图1可看出, 黄铜焊缝经海水浸泡后, 表面粘附了泥土等污染物, 所形成的腐蚀产物粘附力差、 易掉。 将表层的腐蚀产物除去后, 中间为多孔黑色腐蚀层(见图1(b))。 去除全部多孔腐蚀产物后, 露出黄色焊缝基体, 表面凸凹不平。 从电镜下观察形貌仍为多孔状, 与焊缝中部相比, 孔较大且深。 综上所述, 黄铜焊缝在海水中发生严重孔蚀、 沿晶腐蚀[12-14]。

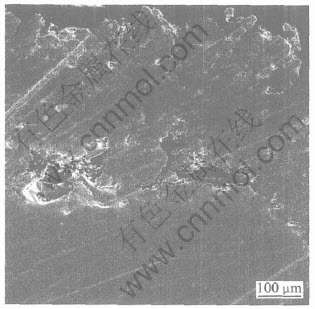

图2所示为腐蚀后黄铜焊缝纵向剖面的形貌。 由图2可以看出, 腐蚀由表面向纵深发展, 腐蚀后的焊缝表层极为疏松且有明显的孔洞, 表明焊缝发生了脱锌腐蚀, 且脱锌后合金颜色由黄变为紫红。

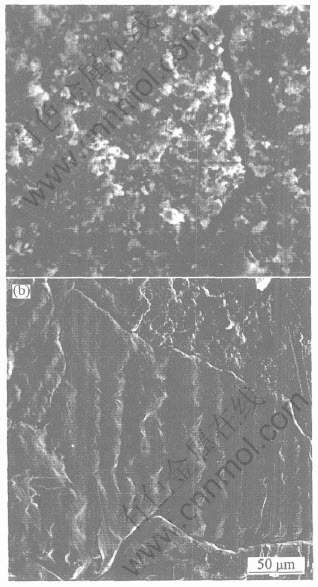

与黄铜焊缝和基体紫铜相比, 白铜焊缝挂海实验后表面无多大变化。 图3所示为紫铜基体和白铜焊缝在海水中腐蚀后的表面形貌。 由图3可看出, 白铜焊缝经海水4个月浸泡后, 表面较致密、 无明显孔洞和点蚀, 且耐腐蚀性能最佳。

2.2 金相组织与成分分析

2.2.1 黄铜焊缝

图4所示为黄铜焊缝截面的形貌及金相照片。 为确定焊缝的组织结构, 对黄铜焊缝各特征部位的

图1 黄铜焊缝经海水浸泡后的SEM像

Fig.1 SEM images of brass welding line after corroded in seawater

图2 黄铜焊缝纵剖面的形貌

Fig.2 Morphology of lognitudinal cross-sections of brass welding line

图3 紫铜基体和白铜焊缝在海水中腐蚀后的表面形貌

Fig.3 Morphologies of surfaces of copper(a) and cupronickel welding line(b) after corroded in seawater

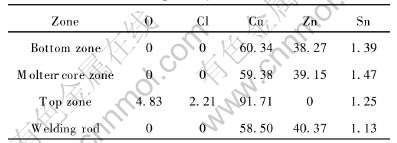

进行能谱分析, 结果列于表1。 测试结果表明, 黄铜焊缝中除焊缝顶部外, 熔核与黄铜焊条均含有Cu、 Zn、 Sn 3种元素, 但含量不同。 结合图4可知, 黄铜焊缝的金相组织为α+β双相[15]。 焊接熔池的形成过程是一个结晶过程, 由于该过程为非稳态过程, 固相线与液相线的成分存在差异, 且各成份在固相与液相中的扩散速率不等, 导致熔池内各元素分布出现差异[16]。 由表1可知, 焊缝顶部含有O、 Cl、 Cu和Sn, 但是没有含Zn元素。 成分分析证明, 黄铜焊缝在海水中浸泡4个月后, 表层发生严重脱锌腐蚀。 图4(c)中的左侧为过热区, 组织为α单相固溶体; 中间为焊缝, 组织为α+β相; 右侧为黄铜焊缝顶部的紫铜层, 为α单相固溶体, 该层疏松多孔, 进一步说明黄铜焊缝发生严重的脱锌腐蚀。

表1 黄铜焊条及黄铜焊缝不同部位成分分析

Table 1 Component analyses of brass welding rod and different zones of brass welding line(mass fraction, %)

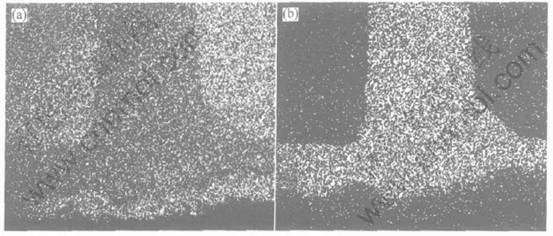

为进一步验证黄铜焊缝脱锌腐蚀, 对图4(a)所示的焊缝截面部位作Cu和Zn元素成分面扫描测试, 结果如图5所示。 图中亮点越密、 分布越均匀, 表明元素在此区域含量高、 分布均匀。 由图5可看出, Zn元素在焊缝底部和熔核区域分布较为均匀, 而在焊缝顶部分布很稀疏, 几乎没有, 证实黄铜焊缝在海水中发生层状脱锌腐蚀。

2.2.2 白铜焊缝

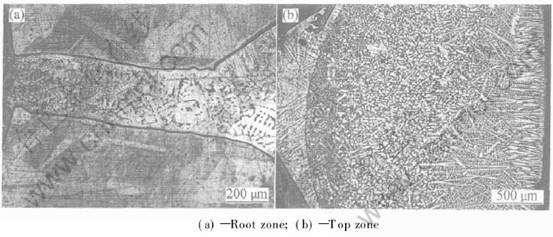

图6所示为白铜焊缝的金相照片。 图6(a)所示为焊缝的下半部分, 包括熔池根部和熔合区。 图6(b)所示为焊缝的上半部分, 即整个熔池的全貌。

白铜焊缝的一次组织具有晶体结构。 在焊缝顶部, 晶体粗大, 组织为明显的柱状晶, 在横截面中, 这些晶体具有等轴形状, 而在纵截面中, 则沿焊缝轴向稍许伸长; 在焊缝中部, 最常见的是横晶结构, 此处的晶体具有伸长的形状, 枝状结构表现得不明显; 而在焊缝下部, 在焊缝根部及靠近未熔化基体的金属晶体则细小。 图6(a)中所示的上侧和下侧为基体紫铜过热区, 组织为α单相固溶体, 中间[CM(22]为焊缝。 对图6中的白铜焊缝成分进行面分析, 结

图4 黄铜焊缝截面形貌及溶体中心和顶部区域的金相照片

Fig.4 Morphology of cross-section(a) and metallography of molten-core(b) and top zone(c) in brass welding line

图5 图4(a)中黄铜焊缝Cu、 Zn元素成分的面分布

Fig.5 Area distributions of Cu(a) and Zn(b) in brass welding line shown in Fig.4(a)

图6 白铜焊缝不同区域的金相照片

Fig.6 Metallographies of cupronickel welding line in different zones

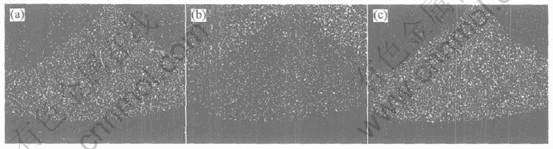

果如图7所示。 由图7可以看出, 白铜焊缝中Cu、 Ni、 Zn的含量分布很均匀, 含量分别为49.6%、 10.0%和40.4%。 经成分分析验证, 对照Cu-Ni-Zn三元平衡图室温截图[15], 得知白铜焊缝组织为α单相固溶体。

锌能大量固溶于Cu-Ni合金的α相中, 锌的加入不仅使合金得到了固溶强化, 且合金的耐蚀性也进一步提高了。 当显微组织为α单相时, 在此成分范围内可适当降低镍的含量, 增加锌成分以降低成本, 减少质量。 所以实验中采用的白铜焊条中锌含量已达40%左右, 镍含量的10%左右, 组织仍保持α单相组织。 黄铜焊缝组织为α+β双相组织, 双相

图7 白铜焊缝Ni、 Cu、 Zn元素成分面分布

Fig.7 Area distributions of Ni(a), Cu(b) and Zn(c) in cupronickel welding line

组织的黄铜在海水中耐蚀性最差, 易发生脱锌腐蚀、 孔蚀等, 从而使材料损坏, 使用寿命降低。 由此可知, 白铜焊缝在海水中的耐蚀性明显优于黄铜焊缝的。

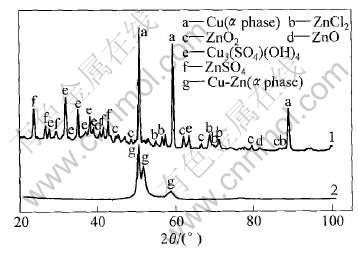

2.3 X射线衍射分析

图8所示为黄铜焊条和在海水中浸泡后黄铜焊缝的X射线衍射谱。 由图8可看出, 焊条在49.53°、 50.81°、 57.67°处出现3个强衍射峰, 该3个强衍射峰对应Cu-Zn合金α相(面心立方结构)的{111}、 {200}、 {220}晶面族。 黄铜焊缝在海水中浸泡后, 腐蚀产物种类较多。 在50.85°、 59.34°、 88.84°出现了Cu的衍射峰, 未出现Cu-Zn合金的衍射峰, 再次证明黄铜焊缝在海水中发生了脱锌腐蚀。 此外, 在X射线衍射谱中还出现了ZnCl2、 ZnSO4、 ZnO2、 ZnO和Cu3(SO4)(OH)4的衍射峰。 综上所述, 黄铜焊缝在海水中浸泡后, 发生严重脱锌腐蚀, 腐蚀产物主要由ZnCl2、 ZnSO4等锌盐和锌的氧化物ZnO2、 ZnO组成, 此外还有少量的铜绿Cu3(SO4)(OH)4[17]。

图8 黄铜焊缝在海水中浸泡后和黄铜焊条的X射线衍射谱

Fig.8 XRD patterns of brass welding line in corroded seawater(1) and brass welding rod (2)

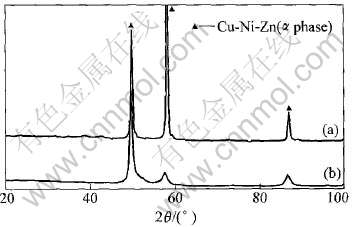

图9所示为白铜焊条和在海水中浸泡后白铜焊缝的X射线衍射谱。 由图9可知, 焊条和焊缝的X射线衍射峰出现的位置相同, Cu-Ni-Zn为α共溶相。 表明白铜焊缝在海水中浸泡前后结构未发生变化。

图9 白铜焊缝在海水中浸泡后和白铜焊条的X射线衍射谱

Fig.9 XRD patterns of cupronickel welding line corroded in seawater(a) and cupronickel welding rod(b)

3 结论

1) 黄铜焊缝经海水浸泡后, 表层为黑色多孔疏松腐蚀层, 并有腐蚀产物的颗粒附着于孔洞内部。 腐蚀层底部腐蚀严重, 出现沿晶腐蚀形貌。 剖面分析及成分面扫描结果表明: 黄铜焊缝发生严重层状脱锌腐蚀, 脱锌后颜色由黄变为紫红。 X射线衍射结果表明, 腐蚀产物主要由ZnCl2、 ZnSO4等锌盐和锌的氧化物ZnO2、 ZnO组成, 此外还含有少量的铜绿Cu3(SO4)(OH)4。

2) 采用白铜焊条的接头部位为Cu-Ni-Zn三元合金, 焊缝中Cu、 Ni、 Zn含量分布均匀, 含量分别为49.6%、 10%、 40.4%, 成分分析验证焊缝为α单相固溶体。 白铜焊缝在海水中浸泡前后, 结构未发生变化, 表面较致密、 无明显孔洞和点蚀, 与黄铜焊缝相比, 具有优异的耐海水腐蚀性能。

REFERENCES

[1]朱相容, 王相润. 金属材料的海洋腐蚀与防护[M]. 北京: 国防工业出版社, 1999. 174-175.

ZHU Xiang-rong, WANG Xiang-run. Corrosion and Protection of Metallic Materials in Seawater[M]. Beijing: National Defence Industry Press, 1999. 174-175.

[2]夏炳仁. 船舶及海洋工程结构物的腐蚀与防护[M]. 大连: 大连海运学院出版社, 1993. 51-55.

XIA Bing-ren. Corrosion and Protection of the Oceanics Structure Materials and Shipping[M]. Dalian: Dalian Ocean Shipping Institute Press, 1993. 51-55.

[3]Ravichandran R, Rajendran N. Electrochemical behaviour of brass in artificial seawater: effect of organic inhibitors[J]. Applied Surface Science, 2005, 241(3-4): 449-458.

[4]Nunez L, Reguera E, Corvo F, et al. Corrosion of copper in seawater and its aerosols in a tropical island[J]. Corrosion Science, 2005, 47(2): 461-484.

[5]朱小龙. 铜合金在海水环境中的腐蚀规律及主要影响因素[J]. 中国有色金属学报, 1998, 8(9): 210-217.

ZHU Xiao-long. Corrosion of copper alloys in natural seawater and main influence factors[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(9): 210-217.

[6]林乐耘, 严宇民, 煮小龙, 等. 铜合金实海暴露腐蚀与抗污行为的研究[J]. 腐蚀科学与防护技术, 1995, 7(3): 241-243.

LIN Le-yun, YAN Yu-min, ZHU Xiao-long, et al. Study of marine corrosion and antifouling behavior of corrosion alloys[J]. Corrosion Science and Protection Technique, 1995, 7(3): 241-243.

[7]Alkharafi F M, Ateya B G. Selective dissolution of brass in salt water[J]. Applied Electrochemistry, 2004, 24(1): 47-53.

[8]Proyer M J, Fister J C. The Mechanism of dealloying of copper solid solutions and intermetallic phases[J]. Electrochem Soc, 1984, 131(6): 1230-1235.

[9]Kleber C, Schreiner M. Multianalytical in-situ investigations of the early stages of corrosion of copper, zinc and binary copper/zinc alloys[J]. Corrosion Science, 2003, 45(12): 2851-2866.

[10]Seungman S, Tak K. The effects of tin and nickel on the corrosion behavior of 60Cu-40Zn alloys[J]. Journal of Alloys and Compounds, 2002, 335(1-2): 281-289.

[11]LU Hong, GAO Ke-wei, CHU Wu-yang. Determination of tensile stress induced by dezincification layer during corrosion for brass[J]. Corrosion Science, 1998, 39(9): 0552-0569.

[12]Kondrashin V Y. To the theory of anticorrosion alloying of brasses[J]. Protection of Metals, 2005, 41(2): 138-145.

[13]王晓华, 林乐耘, 刘安生. HSn62-1铜合金海水腐蚀行为特征的扫描电镜研究[J]. 稀有金属, 1998, 22(6): 410-413.

WANG Xiao-hua, LIN Le-yun, LIU An-sheng. Study on scanning electron microscope of corrosion characteristics of HSN62-1 Cu alloy in seawater[J]. Rare Metals, 1998, 22(6): 410-413.

[14]黄桂桥, 王相润, 林乐耘. 青岛海域铜合金脱成分腐蚀特征研究[J]. 腐蚀科学与防护技术, 1995, 7(3): 237-240.

HUANG Gui-qiao, WANG Xiang-run, LIN Le-yun. Study on dealloying corrosion character of copper alloys exposed in Qingdao sea area[J]. Corrosion Science and Protection Technique, 1995, 7(3): 237-240.

[15]洛阳铜加工厂中心实验室金相组编. 铜及铜合金金相图谱[M]. 北京: 冶金工业出版社, 1983.

Compiled by Center Laboratory of Luoyang Manufactory. The Metallurgical Photos of Copper and Copper Alloys[M]. Beijing: Metallurgical Industry Press, 1983.

[16]刘以宽, 魏馥铭. 金相组织解说[M]. 周莲, 译. 上海科学技术出版社, 1985. 50-82.

LIU Yi-kuan, WEI Fu-ming. Interpretation of Metallographic Structures[M]. ZHOU Lian, transl. Shanghai Science and Technology Press, 1985. 50-82.

[17]张吉刚, 王振尧, 魏立营, 等. 铜合金及其复合材料在氯化钠盐雾中的腐蚀行为[J]. 中国有色金属学报, 2004, 14(5): 836-841.

ZHANG Ji-gang, WANG Zhen-yao, WEI Li-ying, et al. Corrosion behavior of copper alloys and its composites in NaCl spray[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 836-841.

(编辑李艳红)

收稿日期: 2005-08-09; 修订日期: 2005-12-15

通讯作者: 王宏智, 副教授; 电话: 022-27401794; 传真: 022-27402018; E-mail: wanghz@tju.edu.cn