快速凝固铝锂合金真空除气热压的研究

来源期刊:中南大学学报(自然科学版)1991年第1期

论文作者:黄钧声 张新明 左铁镛

文章页码:86 - 91

关键词:快速凝固; 铝锂合金; 真空除气热压; 微观组织; 力学性能

Key words:rapid solidification; aluminum-lithium alloy; degas and vacuum hot press; microstructure; mechanical properties

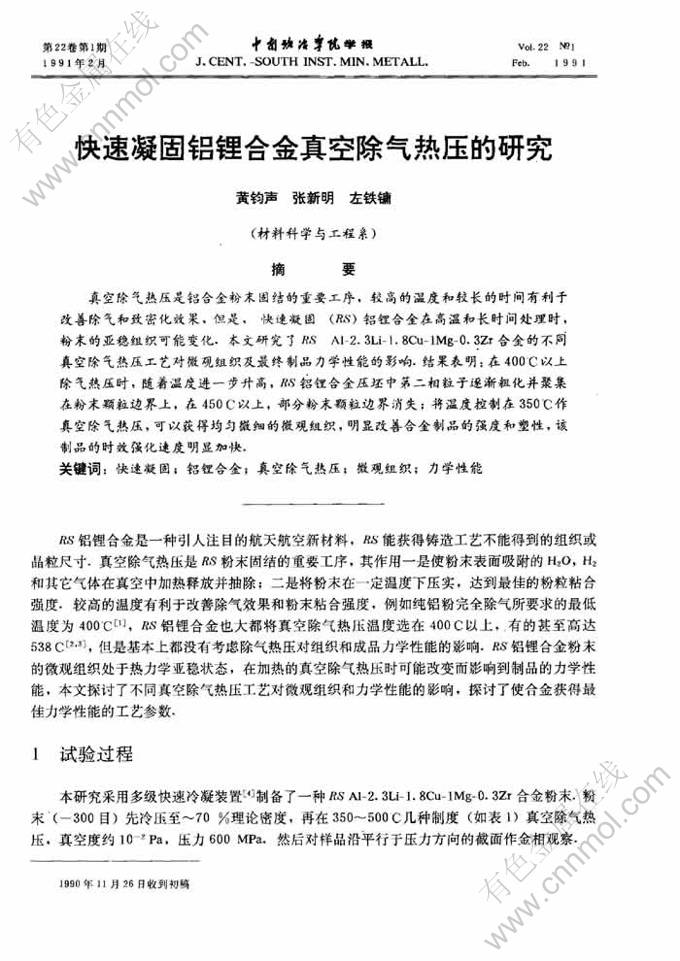

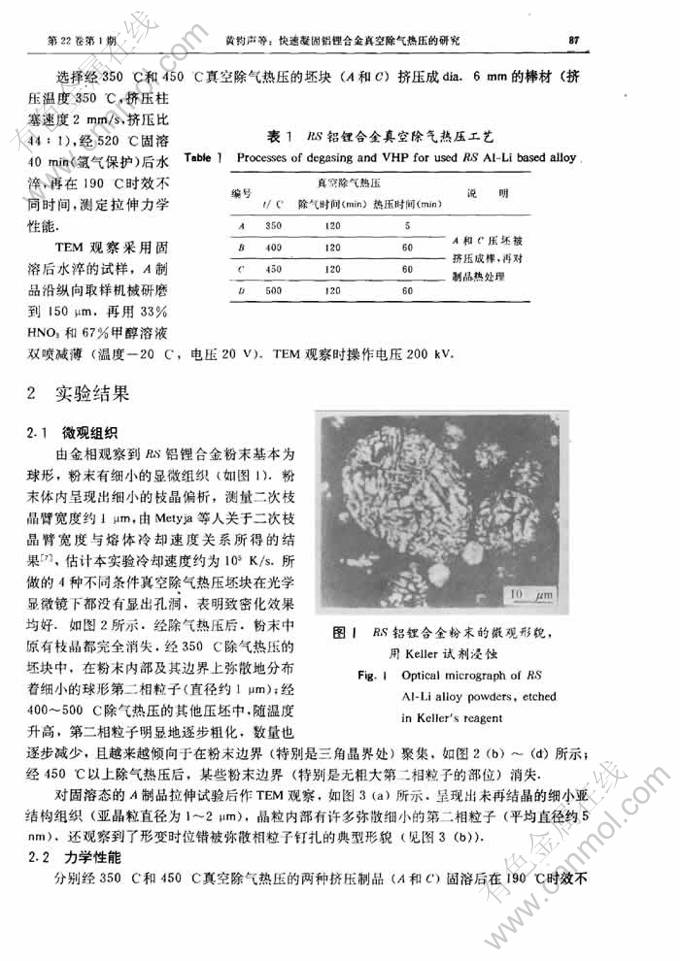

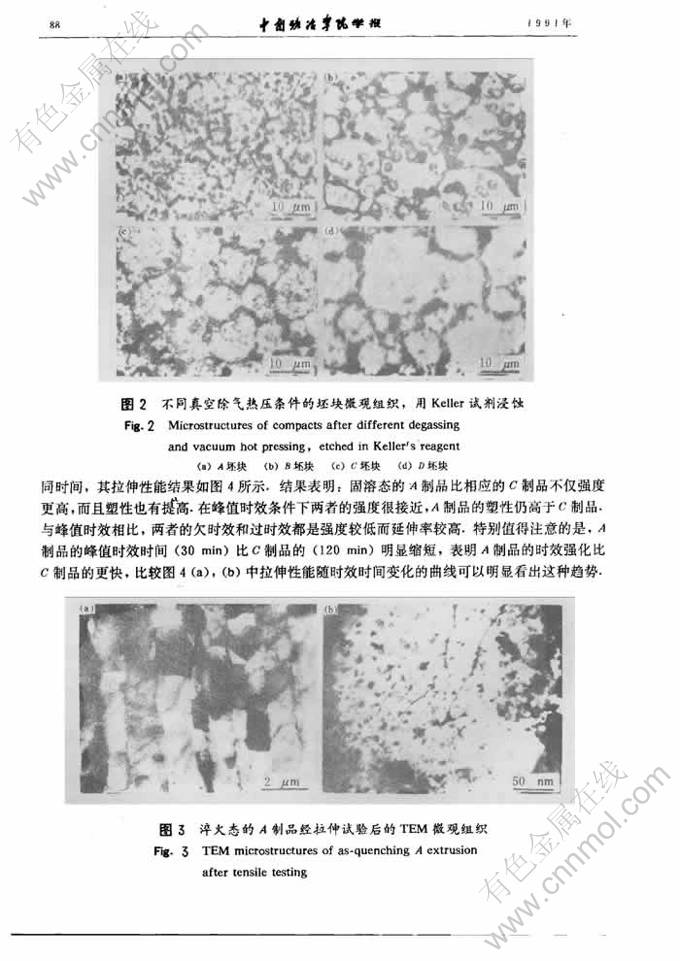

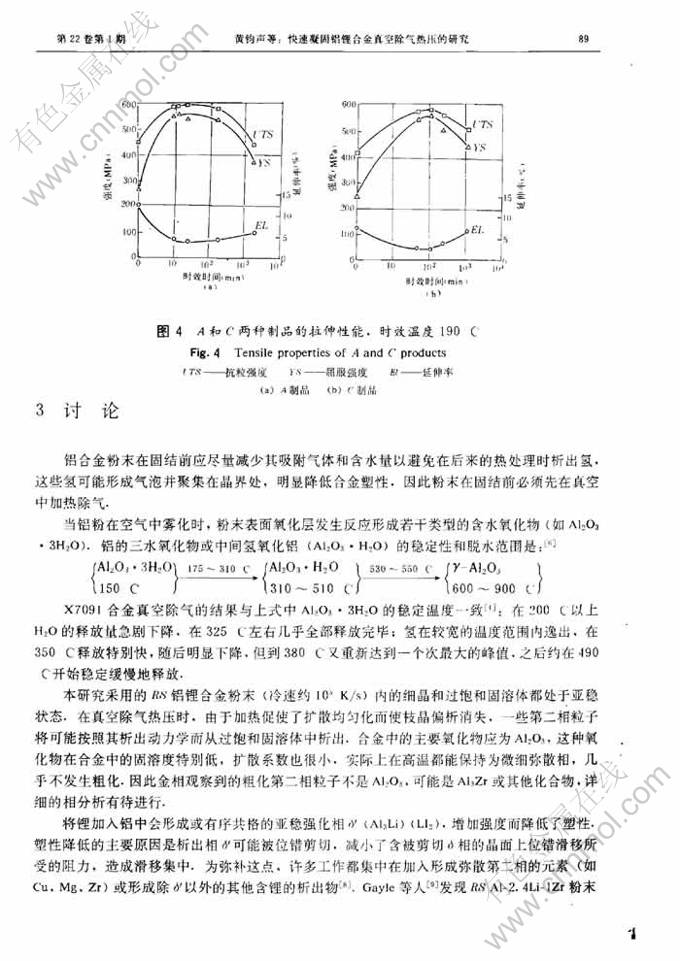

摘 要:真空除气热压是铝合金粉末固结的重要工序,较高的温度和较长的时间有利于改善除气和致密化效果,但是,快速凝固(RS)铝锂合金在高温和长时间处理时,粉末的亚稳组织可能变化。本文研究了RS Al-2.3Li-1.8Cu-1Mg-0.3Zr合金的不同真空除气热压工艺对微观组织及最终制品力学性能的影响。结果表明:在400℃以上除气热压时,随着温度进一步升高,RS铝锂合金压坯中第二相粒子逐渐粗化并聚集在粉末颗粒边界上,在450℃以上,部分粉末颗粒边界消失;将温度控制在350℃作真空除气热压,可以获得均匀微细的微观组织,明显改善合金制品的强度和塑性,该制品的时效强化速度明显加快。

Abstract: The effect of various parameters of degassing and vacuum hot pressing (VHP) for rapidly solidified (RS) Al-2. 3Li-1. 8Cu-1Mg-0. 3Zr alloy on the microstructures and mechanical properties have been investigated, When degassing and VHP are carried ont at over 400℃, the second phase particles will coarse and concentrate at powder particulate boundaries, Furthermore, a part of powder particula'te boundaries may disappear. After degassing and VHP at 350℃, fine microstructures can be achieved, which is beneficial to improve combined mechanical properties, esp., ductility; and its age strengthening appears more rapidly than that at higher temperature. Therefore, it is necessary to consider the probable variations of microstructures, and their effects on mechanical properties and the kinetics of the precipitate processes.