DOI: 10.11817/j.issn.1672-7207.2019.05.001

高压辊磨超细粉碎对钒钛磁铁矿分选的影响

郭小飞1,代淑娟1,朱巨建1,李丽匣2,王洪彬3, 4

(1. 辽宁科技大学 矿业工程学院,辽宁 鞍山,114051;

2. 东北大学 资源与土木工程学院,辽宁 沈阳,110819;

3. 攀钢集团矿业有限公司设计研究院,四川 攀枝花,617063;

4. 钒钛资源综合利用国家重点实验室,四川 攀枝花,617063)

摘要:采用常规颚式破碎和高压辊磨2种不同粉碎方式,进行钒钛磁铁矿的分选试验,探究2种破碎方式对钒钛磁铁矿分选的影响,并结合粒度分析、单体解离度测试及比磁化系数分析,进一步研究高压辊磨机在钒钛磁铁矿选别中的作用机理。研究结果表明:高压辊磨机粉碎产品的粒度较小,可直接通过弱磁选将钛磁铁矿和钛铁矿分离开,进行“铁钛平行分选”;与颚式破碎机破碎产品相比,辊压产品经过一段磨矿过程就能通过相同的分选条件获得质量合格的钛磁铁矿精矿,并使钛铁矿精矿TiO2的作业回收率提高2.66%;2种破碎产品在球磨过程中的单体解离度存在差异,辊压产品中的含铁矿物能够优先实现单体解离,有利于钛磁铁矿的分选;“铁钛平行分选”能够简化磨矿过程,减少微细粒钛铁矿的生成量,提高钛铁矿强磁选的回收率,有利于钛铁矿的窄级别浮选。

关键词:高压辊磨机;钒钛磁铁矿;铁钛平行分选;单体解离度;比磁化系数

中图分类号:TD921 文献标志码:A 文章编号:1672-7207(2019)05-1013-08

Influence of ultrafine comminution by high pressure grinding rolls on separation of vanadium titanium magnetite

GUO Xiaofei1, DAI Shujuan1, ZHU Jujian1, LI Lixia2, WANG Hongbin3, 4

(1. School of Mining Engineering, University of Science and Technology Liaoning, Anshan 114051, China;

2. School of Resources & Civil Engineering, Northeastern University, Shenyang 110819, China;

3. Design and Research Institute of Pangang Group Mining Co. Ltd., Panzhihua 617063, China;

4. State Key Laboratory of Vanadium and Titanium Comprehensive Utilization, Panzhihua 617063, China)

Abstract: The separation experiments of vanadium titanium magnetite (V-Ti) crushed by conventional jaw crusher and high pressure grinding rolls (HPGR) were conducted. The influences of two different comminuting processes on separation of V-Ti magnetite were studied. Combined with the anslysis of particle size, degree of mineral liberation and specific susceptibility, the mechanism of HPGR in the separation process of V-Ti magnetite was studied. The results show that the products of HPGR are finer than those of conventional jaw crusher. Parallel separation of titanium magnetite(Fe) and ilmenite(Ti) can be realized through direct separation of Fe and Ti by low intensity magnetic separation from product crushed by HPGR. Qualified titanium magnetite can be obtained by only once grinding and other similar conditions, and the TiO2 operational recovery of ilmenite increases by 2.66%. The mineral degree of liberation in the primary grinding from this two comminuting processes become obviously different. Iron minerals of HPGR product preferentially achieve monomer dissociation, which benefits the separation of titanium magnetite. On the other hand, the parallel separation of Fe and Ti simplifies the grinding and reduces the generation of micro-fine ilmenite, which is beneficial to the high intensity magnetic separation and flotation of narrow size for ilmenite.

Key words: high pressure grinding rolls; vanadium titanium magnetite; parallel separation of Fe and Ti; liberation degree; specific susceptibility

高压辊磨机实施的是准静压料层粉碎,当料层受挤压时,矿石本身作为传压介质,受到巨大压力导致颗粒破碎或变形,其粉碎产品具有微裂纹多、细粒级质量分数高和单位破碎能耗低等特点[1-2],符合“多碎少磨”技术的发展趋势,已经广泛应用于矿石粉碎领域。攀西地区是我国主要的钒钛磁铁矿生产基地,主要集中分布在攀枝花、白马、红格、太和4大矿区[3]。工艺矿物学研究[3-4]表明:钛磁铁矿的嵌布粒度主要集中在0.2~3.0 mm;钛铁矿的嵌布粒度主要集中在0.2~0.8 mm,粒度小于0.2 mm的TiO2分布率为92.03%;脉石矿物以钛辉石、长石和绿泥石等为主。目前,攀枝花密地选矿厂主要采用“阶段磨矿—阶段磁选选铁、尾矿再磨—强磁—脱硫—浮选钛铁矿”的选别工艺。钛铁矿与脉石矿物实现单体解离的过程,经过了3段或以上的磨矿过程,产生了大量的微细粒钛铁矿,导致钛铁矿选别难度增大,金属流失严重[5-6]。本文作者针对攀西地区的钒钛磁铁矿矿石[7-8],采用常规颚式破碎机和高压辊磨机进行粉碎处理,对粉碎物料进行粒度特性分析,再对不同破碎方式下的钒钛磁铁矿矿石进行分选,分析不同分选产品单体解离度及钛铁矿比磁化系数,研究破碎方式对钒钛磁铁矿分选的影响机理。

1 分选试验

试验矿样为攀枝花密地选矿厂的最终破碎产品(负累积产率为95%时的粒度为15.5 mm),矿石中的主要金属矿物以钛磁铁矿和钛铁矿为主,含少量磁黄铁矿,脉石矿物主要为辉石、长石、绿泥石等。传统破碎工艺采用PEX-150×250和XPC-60×100这 2种型号的颚式破碎机及直径为3.2 mm圆孔筛组成的闭路破碎流程;超细碎工艺采用CLM-25-10型实验室高压辊磨机[7],同样采用控制粒度为3.2 mm的闭路破碎流程,高压辊磨机的辊面比压力为5.6 N/mm2,辊缝间距为4 mm,辊面速度为0.19 m/s;颚式破碎机排矿口和高压辊磨机的辊缝间距相同。

常规颚式破碎机产品(简称颚破产品)采用“阶段磨矿—阶段磁选选铁、尾矿再磨—强磁—脱硫—浮选钛铁矿”工艺进行分选试验。高压辊磨机粉碎产品(简称辊压产品)采用“铁钛平行分选”工艺进行分选试验[8],即先使用弱磁场磁选机对超细碎后的钒钛磁铁矿直接进行选别,将具有强磁性的粗精矿作为钛磁铁矿选别给矿,将磁性较弱的尾矿和钛磁矿选别后的最终尾矿混合后进行钛铁矿选别试验。

钒钛磁铁矿的弱磁选粗选采用磁感应强度分别为0.15 T和0.12 T的2种湿式鼓式弱磁选机,精选采用分选空间直径为80 mm的脉冲型电磁精选机。钛铁矿的强磁选采用CRIMM 70-200电磁夹板高梯度强磁选机(HGMS),钛铁矿的浮选在充气式单槽浮选机中进行。采用自动矿物分析仪(mineral liberation analyser,简称MLA)对试验中重要矿物的粒度和解离度进行测定,比磁化系数测定设备为Modl-7404振动样品磁强计。

2 结果与讨论

2.1 破碎产品粒度特性

对高压辊磨机以及常规颚式破碎机得到的粒度小于等于3.2 mm的闭路破碎产品进行粒度分析,结果如图1所示。

由图1可知:辊压产品中负累积产率为80%(P80)时对应的粒度为1.02 mm,粒度小于74 μm颗粒的负累积产率为21.32%;颚破产品负累积产率为80%对应的粒度为1.45 mm,粒度小于74 μm颗粒的负累积产率为15.77%。辊压产品中粒度小于74 μm颗粒的负累积产率增大5.55%,说明高压辊磨机的破碎比大,粉碎效率高。

运用R-R方程(Rosin-Rammler)[9-11]对2种破碎产品的粒度特性进行分析:

R=exp(-bd n)×100% (1)

式中:R为粒度大于d的颗粒负累积产率,%;d为颗粒粒度,mm;b为与产物粒度相关的参数;n为均匀性系数,n越小,粒度分布越均匀。

图1 不同破碎方式下闭路破碎产品粒度分布

Fig. 1 Particle size distributions of products in closed-circuit using different crushing processes

利用式(1)对图1中2种粉碎产品粒度曲线进行拟合分析,结果如表1所示(其中r为拟合相关系数)。由表1可以看出:辊压产品较颚破产品的粒度更小,均匀性系数n降低,粒度分布更加均匀。

2.2 钛磁铁矿选别试验

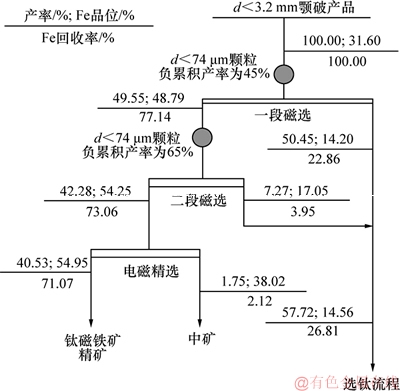

采用“铁钛平行分选”工艺对辊压产品进行钛磁铁矿选别,1段磁选的磁感应强度为0.15 T,2段磁选的磁感应强度为0.12 T,辊压产品开路选制钛磁铁矿的数量-质量流程图如图2所示。

表1 不同粉碎产品R-R方程拟合分析结果

Table 1 Fitting results of R-R equation for different crushing products

由图2可以看出:一段磁选精矿TFe品位可达41.28%,球磨至粒度小于0.18 mm的颗粒负积累产率为95%(相当于粒度小于74 μm颗粒负累积产率为45%);进行二段磁选后,精矿TFe品位可达54.24%,精选后钛磁铁矿精矿TFe品位为55.05%,回收率为70.64%。一段磁选尾矿和钛磁铁矿选别的最终尾矿混合后进入钛铁矿选别流程。

采用“阶段磨矿—阶段磁选”工艺对颚破产品进行钛磁铁矿选别,2段磨矿粒度小于74 μm的颗粒负累积产率分别为45%和65%(参考密地选矿厂两段磨矿的细度)[3],其他试验条件不变,开路试验结果如图3所示。

由图2和图3可以看出:2种破碎产品经过选别得到的钛磁铁矿精矿品位相差不大,颚破产品的钛磁铁矿回收率较前者高0.43%。辊压产品采用“铁钛平行分选工艺”时,通过一段磨矿就能达到与常规颚式破碎机产品TFe品位相近的钛磁铁矿选别指标,简化了钛磁铁矿选别工艺,能够大幅度节约磨矿能耗。

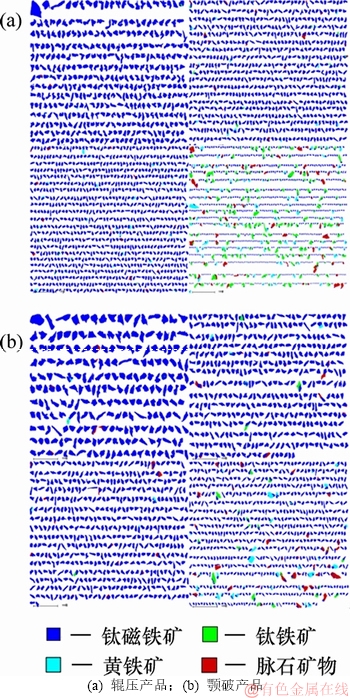

对2种破碎方式下的磨矿产品(粒度小于74 μm颗粒负累积产率为45%)进行粒度特性分析和MLA单体解离度分析[11-12],结果分别如图4和图5所示。

图2 辊压产品开路选铁试验数量-质量流程图

Fig. 2 Quantity-quality flow-sheet of open-circuit test for iron separation from products crushed by HPGR

图3 颚破产品开路选铁试验数量-质量流程

Fig. 3 Quantity-quality flow-sheet of open-circuit test for iron separation from products crushed by jaw crusher

由图4可知:当磨矿产品中粒度小于74 μm的颗粒负累积产率为45%时,辊压产品中各粒级颗粒的负累积产率比颚破产品中相同粒级颗粒的负累积产率略高。由图5可知:辊压产品的单体解离度为84.94%,颚破产品为83.02%,辊压产品较颚破产品高1.92%。辊压产品及颚破产品中铁氧化物的质量分数分别为81.59%和77.61%,辊压产品较颚破产品高3.98%,说明含铁矿物在高压辊磨机粉碎过程中能够优先实现单体解离。在该磨矿细度条件下,采用弱磁选工艺对辊压产品进行分选,即可获得钛磁铁矿精矿。

图4 不同粉碎产品的粒度分布

Fig. 4 Particle size distribution of different crushed products

图5 不同产品中130≤d<170 μm颗粒MLA单体解离度分析

Fig. 5 Liberation degree of 130≤d<170 μm particles by MLA in different products

2.3 钛铁矿选别试验

2.3.1 钛铁矿强磁选试验

辊压产品“铁钛平行分选”的选钛给矿TiO2品位为11.47%,粒度小于74 μm的颗粒负累积产率为44.5%。颚破产品“阶段磨矿—阶段选别”的选钛给矿TiO2品位为11.66%,粒度小于74 μm的颗粒负累积产率为53.5%[8]。分别将2种选钛给矿球磨至粒度小于74 μm的颗粒负累积产率约为80%,采用磁感应强度为0.12 T的湿式鼓式磁选机将磨矿过程中解离出的强磁性矿物预先选出,在背景磁感应强度为0.3 T时采用电磁夹板强磁选机进行强磁选钛试验[13-14],结果如表2所示。

表2 不同破碎方式下钛铁矿强磁选试验结果

Table 2 Separation results of ilmenite using HGMS by different crushing processes

由表2可见:与颚破产品“阶段磨矿—阶段分选”获得的强磁精矿相比,辊压产品“铁钛平行分选”获得的强磁精矿中TiO2品位降低0.25%,但TiO2回收率增加4.18%。对球磨后的2种产品进行MLA单体解离度分析[11],其中,不同产品中颗粒(11≤d<19 μm) MLA单体解离度分析结果如图6所示。

颚破产品的选钛给矿中粒度小于74 μm颗粒的负累积产率比辊压产品的高9%;当2种破碎产品中粒度小于74 μm的颗粒负累积产率达80%时,辊压产品的单体解离度为91.25%,颚破产品的单体解离度为90.72%;辊压产品(11≤d<19 μm)及颚破产品中铁氧化物的质量分数分别为90.66%和91.91%;辊压产品选钛给矿的单体解离度较颚破产品高0.53%,但辊压产品11≤d<19 μm粒级中铁氧化物的质量分数比颚破产品的低1.25%,说明颚破产品中铁氧化物泥化更加严重,这是辊压产品“铁钛平行分选”的强磁精矿中TiO2回收率升高的主要原因。分别对2种分选工艺得到的强磁精矿和尾矿中粒度小于19 μm颗粒的TiO2负累积产率进行分析,结果如图7所示。

由图7可以看出:与颚破产品的“阶段磨矿—阶段分选”工艺相比,在高压辊磨超细碎产品的“铁钛平行分选”过程中,强磁精矿中粒度小于19 μm的颗粒的TiO2负累积产率降低2.15%,强磁尾矿中粒度小于19 μm的颗粒的TiO2负累积产率也降低6.95%,由此可见微细粒级钛铁矿负累积产率的变化直接影响了钛铁矿后续的分选效果。

图6 不同破碎产品中颗粒(11≤d<19 μm)MLA单体解离度分析

Fig. 6 Liberation degree of particles (11≤d<19 μm) by MLA in different crushed products

图7 不同分选工艺下强磁选产品 (d<19 μm)的TiO2负累积产率

Fig. 7 Negative cumulative yield of TiO2 in products (d<19 μm) obtained by HGMS using different seperation processes

微细粒钛铁矿比磁化系数及其在高梯度磁选中受力特性的变化[8, 15-16]是“铁钛平行分选”工艺中强磁选精矿TiO2回收率发生变化的根本原因。为分析钛铁矿在强磁选中的磁选行为,采用Modl-7404振动样品磁强计测试不同粒级钛铁矿的磁化曲线,背景磁感应强度为0.3 T时的钛铁矿比磁化系数如图8所示。

图8 不同粒级钛铁矿比磁化系数

Fig. 8 Specific susceptibility of ilmenite with different sizes

由图8可见:随着钛铁矿粒度减小,各粒级钛铁矿的比磁化系数逐渐变小,当矿石粒度小于19 μm时,比磁化系数小于1.657 cm3/kg。矿石颗粒在磁选过程中所受的比磁力Fm为

(2)

(2)

式中:μ0为真空磁导率,μ0=4π×10-7 H/m;χ0为钛铁矿的比磁化系数,m3/kg;H0gradH0为磁场力,A2/m3。

钛铁矿颗粒沿磁力方向运动时受到的比阻力FR为

(3)

(3)

式中:m为颗粒的质量,kg;δ为颗粒的密度,kg/m3;η为矿浆黏滞系数,取1.25×10-6 m2/s(矿浆质量分数为20%);v为钛铁矿进入分选区时速度,取0.05 m/s。

随着矿物颗粒粒度减小,强磁选过程中矿浆对矿物颗粒产生的比阻力增大,弱磁性矿物颗粒被磁场捕获所需的比磁力也增大。比磁力取决于矿物颗粒的比磁化系数和磁选机的磁场特性。根据式(2)和(3),计算不同粒度钛铁矿颗粒在强磁选过程中所受到的比阻力和比磁力,结果如图9所示。

图9 不同粒级钛铁矿在强磁场中的受力分析

Fig. 9 Force analysis of ilmenite with different sizes in high intensity magnetic field

由图9可知不同粒度钛铁矿所受比阻力的变化规律可以分为3个阶段[8]:当38≤d<106 μm时,钛铁矿受到的比阻力缓慢增大;当19≤d<38 μm时,钛铁矿受到的比阻力迅速增大;当d<19 μm时,钛铁矿受到的比阻力急剧增大。当钛铁矿粒度由106 μm减小到7 μm时,钛铁矿所受到的比阻力增大约660倍,回收钛铁矿所需的比磁力却降低约12%。在磁选条件一定的情况下,当粒度降低时,钛铁矿被磁场捕获的难度急剧增加。这也进一步说明了微细粒钛铁矿的增加将导致强磁选难度的增加,尤其是粒度小于 19 μm的颗粒的增加将会导致强磁选过程中钛铁矿回收率降低。

2.3.2 钛铁矿浮选试验

采用相同浮选条件对不同破碎方式下的钒钛磁铁矿进行钛铁矿选别试验[3, 5],辊压产品选钛闭路试验的数量-质量流程如图10所示。由图10可知:最终得到的钛铁矿精矿TiO2品位为47.78%,TiO2作业回收率为35.16%,浮钛尾矿的TiO2品位为10.94%,选钛总尾矿的TiO2品位为7.85%。

颚式破碎机破碎产品选钛试验获得钛精矿的TiO2品位为47.85%,回收率为32.50%,浮钛尾矿的TiO2品位为11.30%,选钛总尾矿的TiO2品位为8.34%。辊压产品选别出的钛精矿品位较颚破产品低0.08%,但作业回收率提高2.66%,浮选尾矿和总尾矿的TiO2品位分别降低0.36%和0.49%。

图10 辊压产品选钛闭路试验数量-质量流程图

Fig.10 Quantity-quality flow-sheet of closed-circuit test of titanium separation of products crushed by HPGR

微细粒钛铁矿增加会导致钛铁矿浮选回收率降低 [6, 17]。与颚式破碎机破碎产品采用“阶段磨矿—阶段磁选选铁、选铁尾矿再磨—强磁抛尾—脱硫—浮钛”工艺相比,高压辊磨机超细碎钒钛磁铁矿采用的“铁钛平行分选”工艺在一段湿式粗粒磁选之后,能够将部分钛铁矿分离出来,进行钛磁铁矿和钛铁矿同时分选,一方面使钛磁铁矿和钛铁矿的分选更有针对性,另一方面,传统工艺中的钛铁矿选别经过了3段磨矿,而“铁钛平行分选”工艺缩短了磨矿过程,能够减少磨矿产品中微细颗粒的生成量,为钛铁矿的选别提供窄级别的给矿条件,从而提高钛铁矿在后续选别过程中的分选效率,提高钛铁矿的回收率。同时,辊压产品的“铁钛平行分选”也可简化钒钛磁铁矿选别的工艺,节约系统能耗,降低生产成本,提高选别指标。

3 结论

1) 与颚式破碎相比,高压辊磨破碎方法具有细粒级粉碎产品负累积产率高、粒度分布均匀、易实现单体解离等特点,高压辊磨机超细碎后的钒钛磁铁矿可经过弱磁选将强磁性的钛磁铁矿和弱磁性的钛铁矿在一定程度上分离,进行“铁钛平行分选”。

2) 辊压产品中的含铁矿物在磨矿过程中可实现优先单体解离,经过一段磨矿过程,就能通过相同的分选条件获得与颚破产品TFe品位相近的钛磁铁矿精矿;随着磨矿粒度减小,辊压产品较颚破产品单体解离度的增加幅度逐渐减小,但颚破产品中铁氧化物的泥化更加严重。

3) 当钛铁矿的粒度小于19 μm时,其在强磁选过程中所受的比阻力迅速增加,比磁力却迅速减小,导致强磁选的难度增加。高压辊磨机超细碎的钒钛磁铁矿在分选中能够降低微细粒钛铁矿的新生成量,提高钛铁矿强磁选的精矿回收率,为钛铁矿浮选提供了窄级别的入浮给矿,从而减少了钛铁矿的流失。

参考文献:

[1] 刘建远, 黄瑛彩. 高压辊磨机在矿物加工领域的应用[J]. 金属矿山, 2010(6): 1-8.

LIU Jianyuan, HUANG Yingcai. Applications of high-pressure grinding rolls in mineral processing[J]. Metal Mine, 2010(6): 1-8.

[2] LIU Lei, TAN Qi, LIU Lu, et al. Comparison of different comminution flowsheets in terms of minerals liberation and separation properties[J]. Minerals Engineering, 2018, 125: 26-33

[3] 朱俊士. 钒钛磁铁矿选矿[M]. 北京: 冶金工业出版社, 1996: 3-64.

ZHU Junshi. Separation of vanadium titanium magnetite[M]. Beijing: Metallurgical Industry Press, 1996: 3-64.

[4] 李亮, 罗建林. 攀枝花地区某钒钛磁铁矿工艺矿物学研究[J]. 金属矿山, 2010(4): 89-93.

LI Liang, LUO Jianlin. Process mineralogy studies on V-Ti magnetite in Panzhihua[J]. Metal Mine, 2010(4): 89-93.

[5] 王洪彬, 李丽匣, 申帅平, 等. 微细粒级钛铁矿预富集工艺研究[J]. 矿冶工程, 2016, 36(5): 37-40.

WANG Hongbin, LI Lixia, SHEN Shuaiping, et al. Optimization of preconcentration process to reclaim microfine ilmenite[J]. Mining and Metallurgical Engineering, 2016, 36(5): 37-40.

[6] ZHU Yangge, ZHANG Guofan, FENG Qiming, et al. Effect of surface dissolution on flotation separation of fine ilmenite from titanaugite[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 1149-1154.

[7] 袁致涛, 郭小飞, 严洋, 等. 攀西钒钛磁铁矿高压辊磨的产品特性[J]. 东北大学学报(自然科学版), 2012, 33(1) : 124-128.

YUAN Zhitao, GUO Xiaofei, YAN Yang, et al. Product characteristics of vanadium-titanium magnetite from Panxi by high pressure grinding roller[J]. Journal of Northeastern University(Natural Science), 2012, 33(1) : 124-128.

[8] 郭小飞, 袁致涛, 申帅平, 等. 铁钛平行分选对微细粒钛铁矿强磁选的影响[J]. 东北大学学报(自然科学版), 2016, 37(2) : 253-257, 262.

GUO Xiaofei, YUAN Zhitao, SHEN Shuaiping, et al. Effect of parallel separation of Fe and Ti on high-intensity magnetic separation of micro-fine ilmenite[J]. Journal of Northeastern University(Natural Science), 2016, 37(2) : 253-257, 262.

[9] 侯英, 丁亚卓, 印万忠, 等.邦铺钼铜矿石高压辊磨后物料的特性[J]. 中南大学学报(自然科学版), 2013, 44(12): 4781-4786.

HOU Ying, DING Yazhuo, YIN Wanzhong, et al. Product characteristics of Mo-Cu ore from Bangpu by high pressure grinding rolls[J]. Journal of Central South University (Science and Technology), 2013, 44(12): 4781-4786.

[10] TORRES M, CASALI A. A novel approach for the modelling of high-pressure grinding rolls[J]. Minerals Engineering, 2009(22): 1137-1146.

[11] TAVARES L M. Particle weakening in high-pressure roll grinding[J]. Minerals Engineering, 2005, 18(7) : 651-657.

[12] CELIK I B, ONER M. The influence of grinding mechanism on the liberation characteristics of clinker minerals[J]. Cement and Concrete Research, 2006, 36(3): 422-427.

[13] ZENG Shanglin, ZENG Weilong, REN Liuyi, et al. Development of a high gradient permanent magnetic separator (HGPMS)[J]. Mineral Engineering, 2015, 71: 21-26.

[14] ZENG Wenqing, XIONG Dahe. The latest application of SLon vertical ring and pulsating high-gradient magnetic separator[J]. Minerals Engineering, 2003, 16(6): 563-565.

[15] 曾剑武, 陈禄政, 丁利, 等. 棒介质组合方式对脉动高梯度磁选效果的影响[J]. 金属矿山, 2015(3): 161-164.

ZENG Jianwu, CHEN Luzheng, DING Li, et al. Effect of rod matrix arrangement on pulsating high gradient magnetic separation performance[J]. Metal Mine, 2015(3): 161-164.

[16] 袁致涛, 王常任. 磁电选矿[M]. 2版. 北京: 冶金工业出版社, 2011: 16-29.

YUAN Zhitao, WANG Changren. Mineral processing by magnetoelectric[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2011: 16-29

[17] 徐翔, 章晓林, 张文彬. 攀枝花钒钛磁铁矿浮钛时磨矿细度的影响[J]. 矿山机械, 2010, 38(9): 93-96.

XU Xiang, ZHANG Xiaolin, ZHANG Wenbin. Effect of grinding fineness of ilmenite from vanadium titano-magnetite in Panzhihua district[J]. Mining & Processing Equipment, 2010, 38(9): 93-96.

(编辑 伍锦花)

收稿日期:2018-05-31;修回日期:2019-07-30

基金项目(Foundation item):“十二五”国家科技支撑计划项目(2015BAB19B01);钒钛资源综合利用国家重点实验室开放基金资助项目(2014);辽宁省教育厅项目(2017LNQN21) (Project (2015BAB19B01) supported by the National Science and Technology Pillar Program during the 12th “Five-year” Period of China; Project(2014) supported by the Open Fund for the State Key Laboratory of Vanadium and Titanium Comprehensive Utilization; Project (2017LNQN21) supported by the Education Department of Liaoning Province)

通信作者:郭小飞,博士,副教授,从事金属矿高压辊磨粉碎理论及分选技术研究;E-mail:gxf0957@126.com