18R单相Mg-Y-Zn合金经773 K退火过程中14H LPSO相的析出行为

来源期刊:中国有色金属学报(英文版)2017年第1期

论文作者:刘欢 严凯 晏井利 薛烽 孙甲鹏 江静华 马爱斌

文章页码:63 - 72

关键词:Mg-Y-Zn合金;18R LPSO相;14H LPSO相;高温退火;显微组织演变

Key words:Mg-Y-Zn alloy; 18R LPSO phase; 14H LPSO phase; high-temperature annealing; microstructure evolution

摘 要:为了揭示14H相的形成机理,制备并研究了18R LPSO单相Mg-Y-Zn(简称S18)合金经773 K退火100 h的显微组织演变。结果表明:铸态S18合金主要由18R相组成(其体积分数高于93%),并含有少量的W相和α-Mg相。退火时,S18合金中的18R相保持稳定,未转变成14H LPSO结构。然而,在α-Mg相内部形成了14H层片相,其尺寸和体积分数随着退火时间的延长不断增大。TEM分析表明,14H相在α-Mg内基面堆垛层错区域独立形核。14H层片的增厚生长是界面控制过程,与基面台阶的形成密切联系。而14H层片的伸长生长属于扩散控制,与溶质元素的扩散有关。该18R单相合金中14H相的形成机理可通过反应式α-Mg''''→α-Mg + 14H表示。

Abstract: The microstructural evolution of a 18R single phase (S18) alloy during annealing at 773 K for 100 h was investigated in order to reveal the formation mechanism of 14H phase. The results showed that the as-cast S18 alloy was composed of 18R phase (its volume fraction exceeds 93%), W particles and α-Mg phase. The 18R phase in S18 alloy was thermally stable and was not transformed into 14H long period stacking ordered (LPSO) phase during annealing. However, 14H lamellas formed within tiny α-Mg slices, and their average size and volume fraction increased with prolonging annealing time. Moreover, the 14H phase is nucleated within α-Mg independently on the basis of basal stacking faults (SFs). The broadening growth of 14H lamellas is an interface-controlled process which involves ledges on basal planes, while the lengthening growth is a diffusion-controlled process and is associated with diffusion of solute atoms. The formation mechanism of 14H phase in this alloy could be explained as α-Mg′→ α-Mg+14H.

Trans. Nonferrous Met. Soc. China 27(2017) 63-72

Huan LIU1,2, Kai YAN3, Jing-li YAN4, Feng XUE4, Jia-peng SUN1, Jing-hua JIANG1,2, Ai-bin MA1,2

1. College of Mechanics and Materials, Hohai University, Nanjing 211100, China;

2. Ocean and Coastal Engineering Research Institute, Hohai University, Nantong 226300, China;

3. College of Mechanical Engineering, Yangzhou University, Yangzhou 225009, China;

4. College of Materials Science and Engineering, Southeast University, Nanjing 211189, China

Received 4 January 2016; accepted 1 September 2016

Abstract: The microstructural evolution of a 18R single phase (S18) alloy during annealing at 773 K for 100 h was investigated in order to reveal the formation mechanism of 14H phase. The results showed that the as-cast S18 alloy was composed of 18R phase (its volume fraction exceeds 93%), W particles and α-Mg phase. The 18R phase in S18 alloy was thermally stable and was not transformed into 14H long period stacking ordered (LPSO) phase during annealing. However, 14H lamellas formed within tiny α-Mg slices, and their average size and volume fraction increased with prolonging annealing time. Moreover, the 14H phase is nucleated within α-Mg independently on the basis of basal stacking faults (SFs). The broadening growth of 14H lamellas is an interface-controlled process which involves ledges on basal planes, while the lengthening growth is a diffusion-controlled process and is associated with diffusion of solute atoms. The formation mechanism of 14H phase in this alloy could be explained as α-Mg′→ α-Mg+14H.

Key words: Mg-Y-Zn alloy; 18R LPSO phase; 14H LPSO phase; high-temperature annealing; microstructure evolution

1 Introduction

In recent years, Mg-RE-Zn alloys have attracted increasing attention due to their unique microstructures and promising mechanical properties [1,2]. The novel long period stacking ordered (LPSO) phase, could strengthen the alloy remarkably when it is formed and rearranged in deformed magnesium alloys [3-5]. Among various types of LPSO phases, 18R and 14H phases are the most commonly observed, and it is reported that 18R phase could transform into 14H structure in proper heat treatments [6-8]. However, the detailed information involving this transformation process (formation of 14H phase) is still unclear and needs to be elucidated.

ITOI et al [9] first discovered that 18R LPSO phase transformed to 14H structure by annealing of Mg97Zn1Y2 (mole fraction, %) alloy at 773 K for 5 h and suggested that the 18R and 14H LPSO structures are phases at high temperature and low temperature, respectively. Similar phenomena were also observed in Mg-Dy-Zn [10,11], Mg-Ho-Zn [7], Mg-Er-Zn [12,13], Mg-Tm-Zn [7] and Mg-Y-Cu [14] alloys. In addition, although 18R phases were not observed in Mg-Gd-Zn and Mg-Tb-Zn cast alloys, the 14H lamellar structure formed when these alloys were heat-treated at temperatures above 623 K, and the structure of 14H phase in these alloys was identified the same as that appeared in Mg-Y-Zn alloys [15,16]. ZHU et al [17] examined the structures of 18R and 14H phases using high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM), and pointed out that the 18R unit cell was made up of three ABCA-type building blocks arranged in the same shear direction, while a 14H unit cell consisted of two ABCA-type building blocks with opposite shear directions. As a consequence, the transformation from 18R to 14H phase during high temperature annealing could be explained by the minimization of shear energy of the alloys, which has been accepted by most researchers [18,19].

By now, several mechanisms concentrating on the transformation or formation details of 14H LPSO phase have been proposed. One point was established that the 14H phase could be transformed directly from other secondary phases [20,21]. WU et al [20] first reported the formation of 14H phase in as-cast Mg-Gd-Zn alloys, and found that a lamellar X-phase with 14H LPSO structure was transformed from the dendritical β phase with the FCC structure when annealed at 773 K. As for Mg-Y-Zn alloys, ZHU et al [21] suggested that 18R could transform in-situ to 14H during prolonging heat treatment at 773 K. By using HADDF-STEM, they confirmed the structural transformation from 18R to 14H involved the formation of stacking faults in 18R and cooperative gliding of Shockley partial dislocations. Another viewpoint was that the 14H could be precipitated in supersaturated α-Mg solid solution through a modulated structure-like mechanism [22]. However, ZHEN et al [23] presented that it seems to be not possible that either the direct transformation from 18R to 14H or the spinodal decomposition process could happen without other phase participated or produced since the chemical composition of 14H was different with the secondary phases or α-Mg phase. Furthermore, a recent study [24] on phase equilibria and transformations in ternary Mg-Y-Zn alloys revealed two possible invariant reactions, 18R + (Mg) → W (Mg3Y2Zn3) + 14H at 810 K and 18R → 14H + W + Y(Mg,Zn) at 756 K, but these reaction processes have not been demonstrated by experimental observations yet.

On the basis of the above considerations, it can be concluded that the formation mechanism of 14H phase in Mg-Y-Zn alloys after heat treatment remains controversial. It is well known that the mechanical properties of Mg-RE-Zn alloys are greatly influenced by types and morphologies of LPSO phases, which have already been demonstrated by many researches [25,26], it needs further investigation on the formation process of 14H. Therefore, in this work, we designed a single-phase alloy consisting of almost pure 18R phase and studied the microstructural evolutions of the alloy during high temperature annealing, in order to investigate whether 14H phase is transformed from 18R phase.

2 Experimental

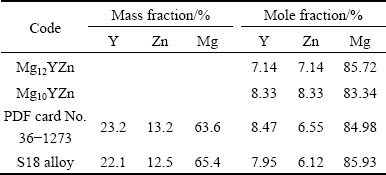

Two stoichiometric ratios, Mg12YZn and Mg10YZn, have been established to characterize 18R phase in previous studies by LUO and ZHANG [27] and ZHU et al [17], respectively. But the precise chemical formula for 18R phase is still not recognized in common. Since it is widely accepted that 18R phase is indexed by Mg12YZn when analyzed using XRD, we referred to the composition of 18R phase recommended by Mg12YZn X-ray (PDF card No. 36-1273) as the alloy composition for present investigation in order to design a single-phase alloy containing pure 18R phase, namely, S18 alloy. The composition noted by PDF card is listed in Table 1, as well as the composition of stoichiometric ratios of Mg12YZn and Mg10YZn. It can be seen that the actual composition noted by PDF card of Mg12YZn is not identical to the stoichiometric ratio of Mg12YZn, but with higher Y content and lower Zn content. The S18 alloy ingot was prepared from high pure Mg (99.90%, mass fraction), Zn (99.95%, mass fraction) and Mg-30%Y (mass fraction) master alloy by melting in an electric resistance furnace under the protection of a mixed atmosphere of CO2 and SF6. The melt was held at approximately 1023 K for 0.5 h, and then poured into a water-cooling copper mold with an inner diameter of 60 mm. The actual chemical composition of the alloy was analyzed by inductively coupled plasma (ICP), and the analyzed composition is also listed in Table 1. It is obvious that the analyzed composition of 18R is almost identical with designed composition, but with a little lower Y and Zn contents.

Table 1 Comparison of chemical compositions between S18 alloy, chemical formulas Mg12YZn and Mg10YZn, and composition noted by PDF card of 18R phase

Pieces of samples were cut from the center part of S18 cast ingot and then subjected to high temperature annealing in a resistance furnace at 773 K for various time from 0 to 100 h. With the purpose of examining the microstructures at high temperatures, the samples were quenched in cold water quickly once the heating time arrived. Phase identification of the alloy was performed with an X-ray diffractometer (XRD, D8 DISCOVER) at a scanning angle of 20°-90° and a scanning speed of 3 (°)/min with a copper target. Microstructures of the specimens were characterized by an optical microscope (OM, Olympus BHM), a scanning electron microscope (SEM, Sirion) equipped with an X-ray energy dispersive spectrometer (EDS) and a transmission electron microscope (TEM, Tecnai G2). For OM and SEM observations, the specimens were mechanically polished and then etched with 4 mL nitric acid and 96 mL ethanol. To obtain the TEM image, the specimens were thinned by twin-jet electro polishing in a solution of 5% perchloric acid and 95% ethanol. Moreover, the volume fractions of various phases were measured by using the software of Image-Pro Plus 6.0. For each state, at least three OM images were employed.

3 Results and discussion

3.1 Microstructure of as-cast S18 alloy

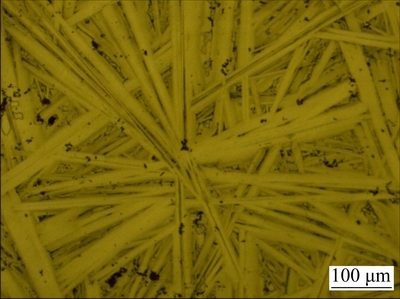

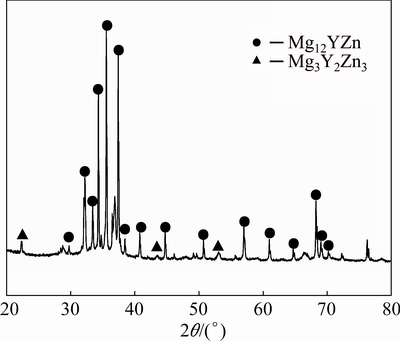

Figure 1 shows optical microstructure of as-cast S18 alloy. It can be seen that the cast S18 alloy is composed of almost all lath-shaped phases, only a few dark particles distributed separately between the laths. The average thickness of the lath-shaped phases is approximately 40 μm, and their length exceeds 300 μm. In order to identify the phase composition of S18 alloy, XRD was carried out and the result is displayed in Fig. 2. It is apparent from the XRD pattern that two phases Mg12YZn and Mg3Y2Zn3 are recognized. The Mg12YZn is usually considered as a LPSO phase with 18 folds in each period [9,27], and its structure will be demonstrated by later TEM observations in this work. The Mg3Y2Zn3 phase is a eutectic structure, which forms when the content of Zn element is high in Mg-Y-Zn ternary alloys and is usually denoted by W phase [28,29]. Based on above OM image and XRD result, it can be speculated that the laths are 18R LPSO phase, and the dark particles are W phase.

Fig. 1 OM image of as-cast S18 alloy

Fig. 2 XRD pattern of as-cast S18 alloy

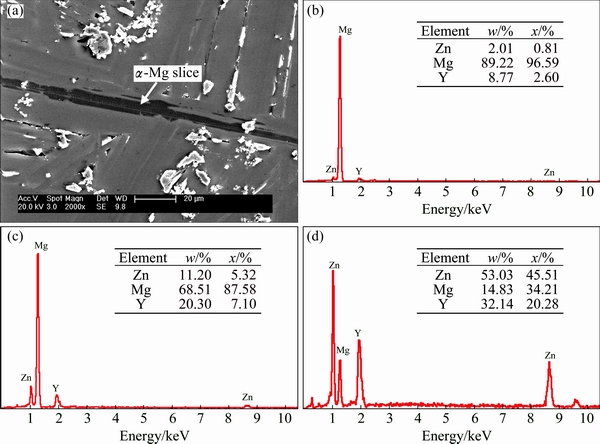

Fig. 3 SEM image of S18 alloy (a) and EDS results of slice phase (b), lath-shaped phase (c) and particle phase (d) in Fig. 3(a)

Figure 3 shows SEM images of the cast S18 alloy. It is worth noting that apart from the lath-shaped phases and particles, a slice of dark phase is observed in SEM image (as marked by white arrow in Fig. 3(a)). The slice is also present in OM image, but it is undistinguishable from boundaries of the laths due to the low magnification of optical system. To identify the slice phase, EDS analysis was conducted and the result is listed in Fig. 3(b). It is obvious that the contents of Y and Zn elements are relatively low for the slice, and Mg serves the main atom for this phase. Therefore, it is reasonable to believe that the slice is α-Mg phase, and it is not identified in XRD pattern because of its low volume fraction. Moreover, the chemical compositions of lath-shaped phase and particle phase were also analyzed by EDS, and the results are exhibited in Figs. 3(c) and (d), which further demonstrate that they are Mg12YZn phase and W phase, respectively. Considering the relatively high Y and Zn contents of S18 alloy, it can be speculated that during solidification, the primary phase is 18R, then it grows and its volume fraction increases rapidly owing to the fast cooling rate employed in this experiment. Afterwards, the rest liquid with small volume at the front interfaces of 18R dendrites begins to solidify complying with eutectic reactions to generate α-Mg phase and W phase [25,29]. Therefore, the finally generated α-Mg phase and W phase are always distributed at the intervals or boundaries of 18R coarse laths.

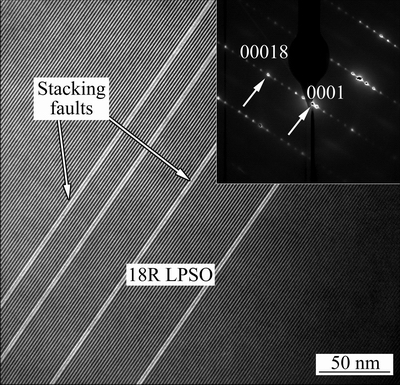

Fig. 4 TEM image of Mg12YZn phase and inset showing corresponding SAED pattern

Figure 4 shows the TEM image and corresponding SAED pattern of Mg12YZn phase (the incident electron beam is parallel to  direction). Seen from inset of Fig. 4, five extra diffraction spots occur at intervals between [0001]α and [0002]α spots, indicating that Mg12YZn phase is 18R LPSO structure [17]. In addition, it is evident from Fig. 4 that four lines with bright contrast exist within 18R phases (as marked by arrows). The existence of weak streaks between diffraction spots of SAED pattern suggests that these streaks are stacking faults [30]. Since the LPSO phase is a stacking ordered structure and its formation involves introduction of staking faults, it is rational to believe that some of stacking faults remained during growing of 18R.

direction). Seen from inset of Fig. 4, five extra diffraction spots occur at intervals between [0001]α and [0002]α spots, indicating that Mg12YZn phase is 18R LPSO structure [17]. In addition, it is evident from Fig. 4 that four lines with bright contrast exist within 18R phases (as marked by arrows). The existence of weak streaks between diffraction spots of SAED pattern suggests that these streaks are stacking faults [30]. Since the LPSO phase is a stacking ordered structure and its formation involves introduction of staking faults, it is rational to believe that some of stacking faults remained during growing of 18R.

From above microstructure observations, it is apparent that the as-cast S18 alloy is composed of 18R laths (matrix), W particles and α-Mg slices. Since the volume fractions of W phase and α-Mg phase are extremely small in this alloy, it is reasonable to consider the S18 alloy as a single-18R-LPSO-phase alloy (the volume fraction of 18R exceeds 93%), which mainly meets the expectation of alloy designing.

3.2 Microstructure evolution of S18 alloy during annealing

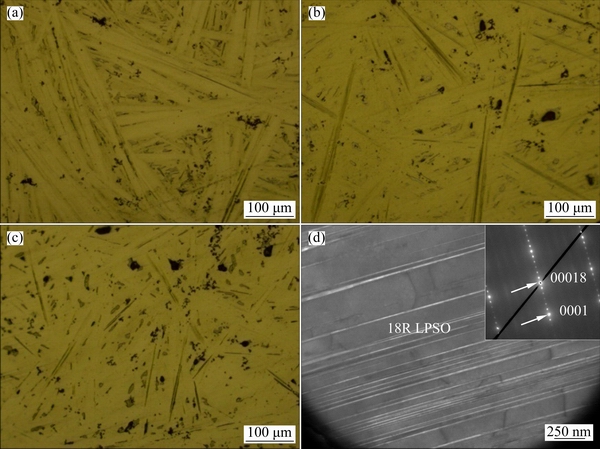

Figures 5(a)-(c) show the optical microstructure evolutions of S18 alloy after being annealed at 773 K for different time. No obvious difference is detected from OM images with different annealing time from 1 to 100 h. The morphologies of various phases (lath matrix, W particles and α-Mg slices) remain nearly unchanged, although their volume fractions may change a little. In order to investigate whether the structure of 18R phase transforms, TEM analysis was carried out on lath-shaped matrix in annealed samples with various annealing time. And the result (shown in Fig. 5(d)) indicates that the TEM image and corresponding SAED patterns are identical to those shown in Fig. 4, suggesting that the 18R phase in S18 alloy is thermal stable and is not transformed to 14H LPSO structure at 773 K. These results seem to run counter to previous reports [6,7] that 18R transforms to 14H phase during heat treatment above 623 K. However, when observed by SEM, there are some lamellar phases newly generated within the slice-shaped α-Mg grains.

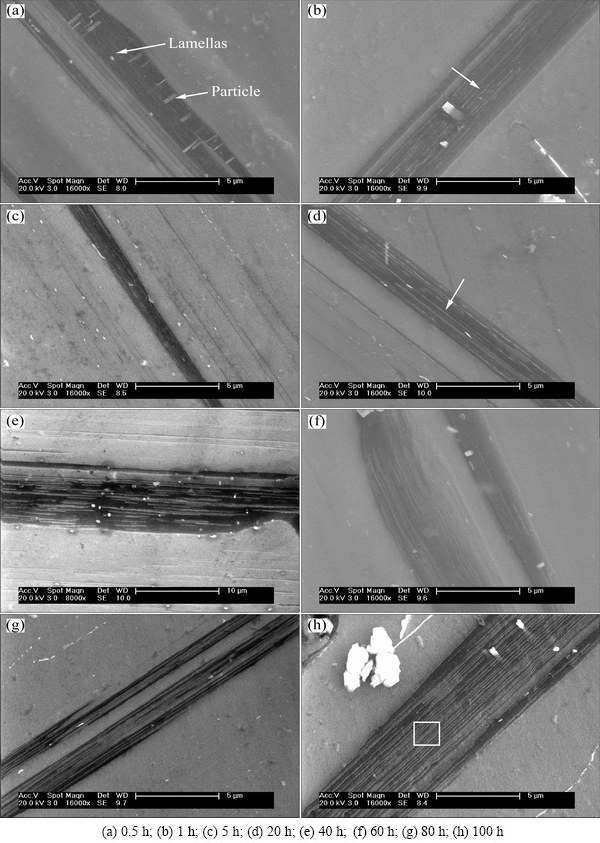

Figure 6 shows SEM images of α-Mg slices during high temperature annealing with prolonging time. Seen from Fig. 3(a), there is no phase existing within α-Mg slice in as-cast state. However, after annealing for 0.5 h (Fig. 6(a)), a kind of fuzzy lamellar contrasts can be observed in the inner of α-Mg slice. When annealing time increases to 1 and 5 h, it is obvious from Figs. 6(b) and (c) that these lamellas are parallel to the long axis of α-Mg slice. With further increase of annealing time, the lamellar phases grow, especially in broadening direction (shown in Figs. 6(d) and (e)), but they are not connected continuously in the length direction. When annealing time is prolonged to 60 and 80 h (Figs. 6(f) and (g)), the density of lamellar phase increases observably and the length of lamellas is also increased markedly, suggesting that the growth rate of lamellas in length direction is accelerated during this period. As shown in Fig. 6(h) with the longest annealing time of 100 h, the morphology of lamellar phase within α-Mg is almost the same as that annealed for 80 h.

Fig. 5 OM images of S18 alloy after being annealed at 773 K for 1 h (a), 20 h (b), 100 h (c), TEM image of lath-shaped matrix in sample annealed for 100 h (d), and inset of Fig. 5(d) showing corresponding SAED pattern

In addition, as can be seen from Fig. 6(a), some rod or cubic particles can be observed within the α-Mg slice. EDS analyses indicate their compositions are Mg-58.5Y-8.0Zn (mass fraction, %), suggesting that these particles are Y-rich phases, which is consistent with previous report [31] that Y-rich particles could form when the content of Y element is relatively high in Mg-Y-Zn alloys. Furthermore, it is apparent from Fig. 6 that the amount of Y-rich phase seems to be decreased with increasing annealing time, which could be explained by the dissolution of metastable phase during high temperature annealing.

In order to identify the structure of lamellar phase, TEM analyses were employed and the corresponding micrographs and SAED patterns of lamellar phases in annealed S18 alloy are shown in Fig. 7. It can be seen from Fig. 7(a) that, after a short annealing time, the lamellar phases exhibit low density, and their average width is less than 20 nm. From the corresponding SAED pattern shown in inset of Fig. 7(a), it can be seen that weak diffraction spots (or streaks) emerge between [0001]α and [0002]α spots. As a result of the weak intensity of the diffraction spots, the structure of the lamellar phases cannot be confirmed. Figure 7(b) displays the morphology of lamellar phases after being annealed for 100 h. It is evident that the density of lamellas increases and their average width reaches approximately 200 nm. In addition, as shown in the corresponding SAED pattern of Fig. 7(b), 13 diffraction spots are detected between [0001]α and [0002]α spots, indicating that these lamellar phases are 14H structure [17]. Therefore, the thinner lamellas that formed at earlier stage can be regarded as segments or incomplete 14H phase.

3.3 Formation mechanism of 14H LPSO phase in annealed alloy

From above microstructure evolutions of S18 alloy during high temperature annealing, it can be concluded that 18R phase is thermally stable, which is not transformed into 14H structure. Moreover, although the volume fraction of α-Mg slices in S18 alloy is extremely small, the 14H LPSO phase forms only within these tiny α-Mg slices. These results clearly indicate that the formation process of 14H phase is more associated with α-Mg than 18R phase in Mg-Y-Zn alloys.

Fig. 6 SEM images of α-Mg grains in annealed S18 alloy with different annealing time

Fig. 7 TEM images and corresponding SAED patterns of lamellar phases in α-Mg slice of S18 alloy after being annealed for 0.5 h (a) and 100 h (b)

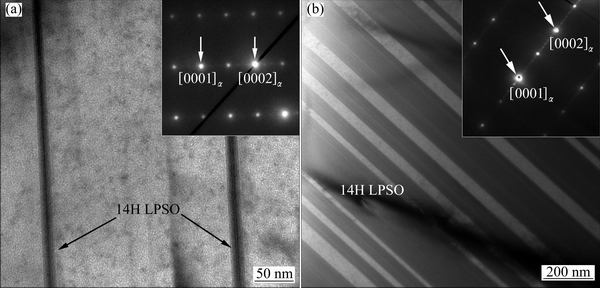

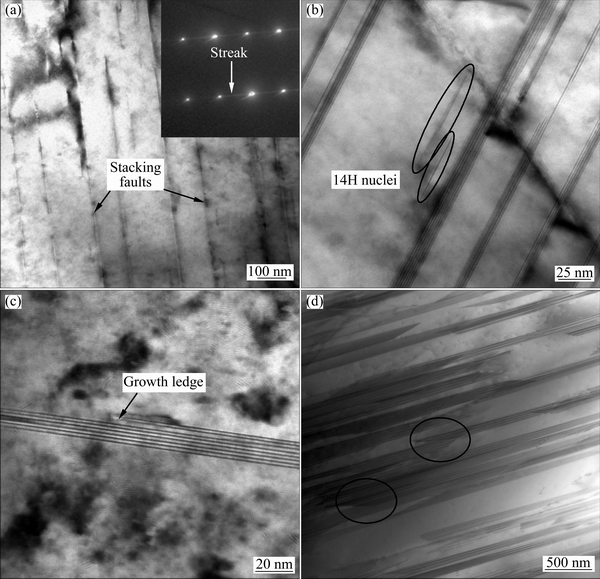

Fig. 8 TEM images of α-Mg grain in as-cast S18 alloys (a), 14H nuclei (b), growth ledge of 14H structure in S18 alloy annealed for 0.5 h (c) and connections of 14H lamellas in S18 alloy annealed for 40 h (d)

ABE et al [32] have suggested that the construction of LPSO structure involves two procedures, introducing stacking faults periodically and supplying solute elements to and adjacent to the faulted layers. Since LPSO is a stacking ordered structure, the existence of stacking faults becomes an essential requirement for formation of 14H structure. Figure 8(a) shows the TEM image of α-Mg slice in as-cast S18 alloy. It can be seen that some straight-line contrasts are present, and the continuous diffraction streaks observed between diffraction spots of the corresponding SAED pattern prove the existence of stacking faults (SFs) on basal plane of α-Mg. The appearance of SFs is in accordance with the report in Ref. [33] that simultaneous addition of Y and Zn elements could decrease the stacking fault energy of α-Mg grain on (0001)α basal plane. However, the density of SFs formed in S18 alloy is much lower compared with that observed in Mg95.5Y3Zn1.5 [3] or Mg94Y4Zn2 (mole fraction, %) alloys [19], which may be attributed to the smaller volume fraction of α-Mg grains in S18 alloy and that most solute elements are enriched in 18R and W phases (shown in Fig. 3). Since the requirement of SFs is already satisfied for the alloy, it needs only diffusion of Y and Zn atoms into the faulted layers to form 14H structure.

Figure 8(b) shows TEM image of 14H lamellas in the early stage of annealing. Apart from several 14H, lamellas with widths of 10-20 nm are observed, and two tiny 14H nuclei are detected, as marked by oval frames in Fig. 8(b). It can be confirmed that the 14H nuclei are separately generated within α-Mg grains where the 18R phases are absent, suggesting that the formation or nucleation of 14H phase in this work has no direct correlation with 18R phase. Therefore, the formation of 14H within α-Mg here is closer to a precipitation process which may follow a reaction similar to α'-Mg→ α-Mg + 14H, where α'-Mg refers to a supersaturated solid solution and α-Mg refers to a solid solution close to the equilibrium state.

Once the 14H cores are nucleated, they begin to grow with the diffusion of Y and Zn elements. As seen from Fig. 8(b), both the length and width of different 14H lamellas vary distinctly, indicating that the growth rate for 14 lamellas is different. This could be ascribed to the non-uniform distribution of solute atoms in α-Mg slice. In areas where Y and Zn atoms are enriched, the growth of 14H would be accelerated. In addition, the evolution of Y-rich particles also influences the formation of 14H. Since these particles have much higher Y content than α-Mg, they are inclined to dissolve during annealing, which could accelerate the formation of 14H by offering sufficient solute atoms.

Figure 8(c) displays a growth ledge observed on basal plane of 14H phase, which suggests that the growth of 14H phase on broadening direction is associated with the formation of ledges. The appearance of ledges was also confirmed by ZHU et al [21], and they proposed that the heights of growth ledges for 18R and 14H phases are 1.563 and 1.824 nm, respectively, which are approximately identical to the measured spaces (1.6 nm and 1.8 nm) between fringes of 18R and 14H structures when observed in high-magnification TEM images [17,27]. Ledge growing mechanism is usually adopted for the broadening of lamellar phase which exhibits a coherent or semi-coherent interface with adjacent matrix [21]. For 14H phase, its growth involves two processes, broadening vertical to (0001)α basal plane and lengthening along the basal plane. As indicated by previous studies [3,17] and SAED patterns in Fig. 7(d), the 14H phase exhibits coherent interface with α-Mg phase on (0001)α basal plane. Therefore, the broadening growth of 14H phase is an interface controlled process, which is dominated by the formation rate of ledges. Once a ledge is formed on basal planes, lengthening growth of 14H activates with the diffusion of Y and Zn elements. Moreover, it should be noted that the broadening growth could be accelerated when adjacent 14H lamellas are contacted and connected with the increase of annealing time. For adjacent 14H lamellas, the growth ledges at the interfaces move towards each other, as a result, the sandwiched α-Mg slice between them becomes thinner. When the basal growth ledges of two 14H lamellas are encountered, the α-Mg slice between them disappears and hence the two 14H lamellas are combined into a thicker lamella. As can be seen from Fig. 8(d), several encounters of growth ledges of 14H lamellas are marked by ellipses in the sample annealed for 40 h.

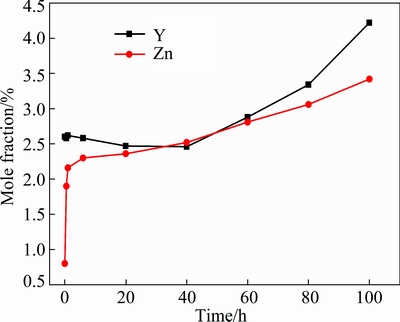

As shown in Figs. 6 and 7, it is apparent that the newly precipitated 14H lamellas are arranged alternately with α-Mg phases, forming a sandwich structure. Figure 9 shows the variations of contents of Y and Zn elements in the sandwich structure with the prolonging of annealing time. The schematic test area for EDS is shown and marked by a square in Fig. 6(h). At the start of annealing, the content of Zn increases significantly from 0.8% to 2.2% (mole fraction), while Y content remains relatively stable. Taking into consideration of microstructure evolutions, this period (0-5 h) corresponds to the abundant nucleation process of 14H phase. Therefore, it can be inferred that Zn may play an important role in promoting generation of 14H nuclei. When annealing time is in the range of 5-40 h, the contents of Y and Zn elements in the sandwich structure change less. Afterwards, their contents increase steadily with increasing annealing time, especially for Y element. During the annealing period of 5-40 h, it is apparent that the width of 14H phase increases obviously. This is because the diffusion distance of solute atoms required for broadening growth is much shorter than lengthening growth of 14H phase, and it must take enough time for atoms diffusing to the target location. Therefore, since the annealing time in this period is insufficient for solute atoms to diffuse a long distance, the broadening growth of 14H phase becomes dominated. Thereafter, the lengthening growth of 14H phase is promoted remarkably due to the increased diffusion distances of Y and Zn with increasing time.

Fig. 9 Content variations of Y and Zn elements in α-Mg slice with annealing time

Based on the above observations and discussion, it can be inferred that the formation of 14H in this single-18R-LPSO-phase alloy is more associated with α-Mg phase than 18R structure, and may be explained as a precipitation process similar to α'-Mg→ α-Mg + 14H. Furthermore, the nucleation of 14H nuclei is mainly associated with the formation of SFs, and the growth of 14H involves generation of ledges and migrations of ledges, which corresponds to the broadening and lengthening of lamellas.

4 Conclusions

1) The microstructure of as-cast S18 alloy is composed of most 18R laths (its volume fraction exceeds 93%), a few W particles and tiny α-Mg slices.

2) During high temperature annealing at 773 K, the 18R phase is thermally stable and is not transformed into 14H phase. Lamellar 14H phase forms only within the α-Mg slices, and their average size and volume fraction increase with prolonging annealing time.

3) 14H lamellas are nucleated within α-Mg independently on the basis of basal SFs. The broadening growth of 14H phase is an interface-controlled process which involves the generation of basal ledges, while the lengthening growth is a diffusion-controlled process and is associated with diffusion of solute atoms. The formation of 14H phase in this alloy is not transformed from 18R phase, and its formation mechanism could be explained as α'-Mg→α-Mg + 14H.

References

[1] HUANG Xue-fei, ZHANG Wen-zheng, WANG Jing-feng, WEI Wen-wen. Long-period stacking ordered structures in Mg-3Cu- 1Mn-2Zn-1Y damping alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1947-1953.

[2] HU Mao-liang, WANG Qu-dong, JI Ze-sheng, XU Hong-yu, XIN Ming-de, MA Guo-rui. Wear behavior of Mg-10Y-4Gd-1.5Zn- 0.4Zr alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 406-413.

[3] LIU Huan, XUE Feng, BAI Jing, SUN Yang-shan. Effect of heat treatments on the microstructure and mechanical properties of an extruded Mg95.5Y3Zn1.5 alloy [J]. Materials Science and Engineering A, 2013, 585: 261-267.

[4] ZHANG Jin-shan, XIN Chao, CHENG Wei-li, BIAN Li-ping, WANG Hong-xia, XU Chun-xiang. Research on long-period- stacking-ordered phase in Mg-Zn-Dy-Zr alloy [J]. Journal of Alloys and Compounds, 2013, 558: 195-202.

[5] WANG Jing-feng, SONG Peng-fei, ZHOU Xiao-en, PAN Fu-sheng. A study of the microstructure, phase composition, and mechanical properties of extruded Mg-9Er-6Y-xZn-0.6Zr magnesium alloys [J]. Journal of Materials Science, 2012, 47(18): 6716-6723.

[6] YOSHIMOTO S, YAMASAKI M, KAWAMURA Y. Microstructure and mechanical properties of extruded Mg-Zn-Y alloys with 14H long period ordered structure [J]. Materials Transactions, 2006, 47(4): 959-965.

[7] KAWAMURA Y, YAMASAKI M. Formation and mechanical properties of Mg97Zn1RE2 alloys with long-period stacking ordered structure [J]. Materials Transactions, 2007, 48(11): 2986-2992.

[8] LIU Huan, BAI Jing, YAN Kai, YAN Jing-li, MA Ai-bin, JIANG Jing-hua. Comparative studies on evolution behaviors of 14H LPSO precipitates in as-cast and as-extruded Mg-Y-Zn alloys during annealing at 773 K [J]. Materials & Design, 2016, 93: 9-18.

[9] ITOI T, SEIMIYA T, KAWAMURA Y, HIROHASHI M. Long period stacking structures observed in Mg97Zn1Y2 alloy [J]. Scripta Materialia, 2004, 51(2): 107-111.

[10] BI Guang-li, FANG Da-qing, ZHAO Lei, ZHANG Qing-xin, LIAN Jian-she, JIANG Qing, JIANG Zhong-hao. Double-peak ageing behavior of Mg-2Dy-0.5Zn alloy [J]. Journal of Alloys and Compounds, 2011, 509(32) 8268-8275.

[11] LUO Xiao-mei, BI Guang-li, JIANG Jing, LI Ming, LI Rong-guang, LI Yuan-dong, MA Ying, HAO Yuan. Compressive anisotropy of extruded Mg-Dy-Zn alloy sheet [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 390-397.

[12] ZHANG Li, ZHANG Jing-huai, LENG Zhe, LIU Shu-juan, YANG Qiang, WU Rui-zhi, ZHANG Mi-lin. Microstructure and mechanical properties of high-performance Mg-Y-Er-Zn extruded alloy [J]. Materials & Design, 2014, 54: 256-263.

[13] ZHANG Xiao-long, WANG Zhao-hui, DU Wen-bo, LIU Ke, LI Shu-bo. Microstructures and mechanical properties of Mg-13Gd- 5Er-1Zn-0.3Zr alloy [J]. Materials & Design, 2014, 58: 277-283.

[14] KAWAMURA Y, KASAHARA T, IZUMI S, YAMASAKI M. Elevated temperature Mg97Y2Cu1 alloy with long period ordered structure [J]. Scripta Materialia, 2006, 55(5): 453-456.

[15] WU Y J, PENG L M, ZENG X Q, LIN D L, DING W J, PENG Y H. A high-strength extruded Mg-Gd-Zn-Zr alloy with superplasticity [J]. Journal of Materials Research, 2009, 24(12): 3596-3602.

[16] CAO Li-jie, WU Yu-juan, PENG Li-ming, WANG Qu-dong, Ding Wen-jiang. Microstructure and tribological behavior of Mg-Gd- Zn-Zr alloy with LPSO structure [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(12): 3785-3791.

[17] ZHU Y M, MORTON A J, NIE J F. The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys [J]. Acta Materialia, 2010, 58(8): 2936-2947.

[18] ZHANG Jin-shan, CHEN Chang-jiu, QUE Zhong-ping, CHENG Wei-li, XU Ji-dong, KANG Jing-jing. 18R and 14H long-period stacking ordered structures in the Mg93.96Zn2Y4Sr0.04 alloy and the modification effect of Sr on X-phase [J]. Materials Science and Engineering A, 2012, 552: 81-88.

[19] LIU Huan, XUE Feng, BAI Jing, ZHOU Jian, SUN Yang-shan. Effects of heat treatments on microstructures and precipitation behaviour of Mg94Y4Zn2 extruded alloy [J]. Journal of Materials Science & Technology, 2014, 30(2): 128-133.

[20] WU Y J, ZENG X Q, LIN D L, PENG L M, DING W J. The microstructure evolution with lamellar 14H-type LPSO structure in an Mg96.5Gd2.5Zn1 alloy during solid solution heat treatment at 773 K [J]. Journal of Alloys and Compounds, 2009, 477(1-2): 193-197.

[21] ZHU Y M, MORTON A J, NIE J F. Growth and transformation mechanisms of 18R and 14H in Mg-Y-Zn alloys [J]. Acta Materialia, 2012, 60(19): 6562-6572.

[22] DING W J, WU Y J, PENG L M, ZENG X Q, YUAN G Y, LIN D L. Formation of 14H-type long period stacking ordered structure in the as-cast and solid solution treated Mg-Gd-Zn-Zr alloys [J]. Journal of Materials Research, 2009, 24(5): 1842-1854.

[23] ZHEN Rui, SUN Yang-shan, XUE Feng, SUN Jing-jing, BAI Jing. Effect of heat treatment on the microstructures and mechanical properties of the extruded Mg-11Gd-1Zn alloy [J]. Journal of Alloys and Compounds, 2013, 550: 273-278.

[24]  J, KOZLOV A, FANG X Y, GENG J, NIE J F, SCHMID-FETZER R. Phase equilibria and transformations in ternary Mg-rich Mg-Y-Zn alloys [J]. Acta Materialia, 2012, 60(17): 5948-5962.

J, KOZLOV A, FANG X Y, GENG J, NIE J F, SCHMID-FETZER R. Phase equilibria and transformations in ternary Mg-rich Mg-Y-Zn alloys [J]. Acta Materialia, 2012, 60(17): 5948-5962.

[25] CHEN Bin, LIN Dong-liang, ZENG Xiao-qin, LU Chen. Effects of yttrium and zinc addition on the microstructure and mechanical properties of Mg-Y-Zn alloys [J]. Journal of Materials Science, 2010, 45(9): 2510-2517.

[26] LIU Huan, XUE Feng, BAI Jing, ZHOU Jian, SUN Yang-shan. Microstructure and mechanical properties of Mg94Zn2Y4 extruded alloy with long-period stacking ordered structure [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3598-3603.

[27] LUO Z P, ZHANG S Q. High-resolution electron microscopy on the X-Mg12ZnY phase in a high strength Mg-Zn-Zr-Y magnesium alloy [J]. Journal of Materials Science Letters, 2000, 19(9): 813-815.

[28] ZHANG S, YUAN G Y, LU C, DING W J. The relationship between (Mg,Zn)3RE phase and 14H-LPSO phase in Mg-Gd-Y-Zn-Zr alloys solidified at different cooling rates [J]. Journal of Alloys and Compounds, 2011, 509(8): 3515-3521.

[29] LIU K, ZHANG J H, LU H Y, TANG D X, ROKHLIN L L, ELKIN F M, MENG J, LU H Y. Effect of the long periodic stacking structure and W-phase on the microstructures and mechanical properties of the Mg-8Gd-xZn-0.4Zr alloys [J]. Materials & Design, 2010, 31(1): 210-219.

[30] ZHU Y M, MORTON A J, WEYLAND M, NIE J F. Characterization of planar features in Mg-Y-Zn alloys [J]. Acta Materialia, 2010, 58(2): 464-475.

[31] ZHANG Li, ZHANG Jing-huai, XU Chi, LIU Shu-juan, JIAO Yu-feng, XU Long-jiang, WANG Yan-bo, MENG Jian, WU Rui-zhi, ZHANG Mi-lin. Investigation of high-strength and superplastic Mg-Y-Gd-Zn alloy [J]. Materials & Design, 2014, 61: 168-176.

[32] ABE E, KAWAMURA Y, HAYASHI K, INOUE A. Long-period ordered structure in a high-strength nanocrystalline Mg-1%Zn-2% Y alloy studied by atomic-resolution Z-contrast STEM [J]. Acta Materialia, 2002, 50(15): 3845-3857.

[33] SUZUKI M, KIMURA T, KOIKE J, MARUYAMA K. Strengthening effect of Zn in heat resistant Mg-Y-Zn solid solution alloys [J]. Scripta Materialia, 2003, 48(8): 997-1002.

刘 欢1,2,严 凯3,晏井利4,薛 烽4,孙甲鹏1,江静华1,马爱斌1,2

1. 河海大学 力学与材料学院,南京 211100;

2. 河海大学 海洋与近海工程研究院,南通 226300;

3. 扬州大学 机械工程学院,扬州 225009;

4. 东南大学 材料科学与工程学院,南京 211189

摘 要:为了揭示14H相的形成机理,制备并研究了18R LPSO单相Mg-Y-Zn(简称S18)合金经773 K退火100 h的显微组织演变。结果表明:铸态S18合金主要由18R相组成(其体积分数高于93%),并含有少量的W相和α-Mg相。退火时,S18合金中的18R相保持稳定,未转变成14H LPSO结构。然而,在α-Mg相内部形成了14H层片相,其尺寸和体积分数随着退火时间的延长不断增大。TEM分析表明,14H相在α-Mg内基面堆垛层错区域独立形核。14H层片的增厚生长是界面控制过程,与基面台阶的形成密切联系。而14H层片的伸长生长属于扩散控制,与溶质元素的扩散有关。该18R单相合金中14H相的形成机理可通过反应式α-Mg'→α-Mg + 14H表示。

关键词:Mg-Y-Zn合金;18R LPSO相;14H LPSO相;高温退火;显微组织演变

(Edited by Wei-ping CHEN)

Foundation item: Project (BK20160869) supported by the Natural Science Foundation of Jiangsu Province, China; Project (GY12015009) supported by the Nantong Science and Technology Program, China; Project (2015B01314) supported by the Fundamental Research Funds for the Central Universities, China; Project (51501039) supported by the National Natural Science Foundation of China

Corresponding author: Huan LIU; Tel: +86-25-83787239; E-mail: liuhuanseu@hhu.edu.cn

DOI: 10.1016/S1003-6326(17)60007-4