DOI: 10.11817/j.issn.1672-7207.2020.05.014

再生陶粒混凝土吸音板的制备与声学性能

栾皓翔1,吴瑾1,朱万旭2, 3,潘佳玉3, 4,张瑞东3,周红梅3

(1. 南京航空航天大学 土木工程系,江苏 南京,210016;

2. 桂林理工大学 土木与建筑工程学院,广西 桂林,541004;

3. 广西科技大学 土木与建筑工程学院,广西 柳州,545006;

4. 江苏华江建设集团有限公司 建筑设计分公司,江苏 南京,210009)

摘要:通过以建筑垃圾为主要原料,掺入激发剂,黏结剂等外加剂,采用免烧结制备工艺,进行建筑垃圾再生料吸音陶粒的制备。将吸音陶粒作为主要骨料,掺入减水剂调节水灰比和水泥用量,进行吸音陶粒混凝土的配合比正交试验。为满足实际工程应用要求,以抗压强度作为指标确定吸音陶粒混凝土的配合比,其孔隙率为20.5%,抗压强度为12.76 MPa。结合轨道交通现场实际,设计模板尺寸浇筑陶粒混凝土吸音板,并采用混响室法对吸音板进行声学性能测试。研究结果表明:孔隙率是影响吸音陶粒混凝土吸声性能和抗压强度的主要因素。陶粒混凝土吸音板的平均吸声系数为0.74,降噪系数为0.8,满足实际轨道交通工程中的吸音降噪要求。

关键词:建筑垃圾;陶粒制备;混凝土吸音板;声学性能

中图分类号:TU528 文献标志码:A

文章编号:1672-7207(2020)05-1299-10

Preparation and acoustic performance of recycled ceramsiteconcrete noise-absorbing plate

LUAN Haoxiang1, WU Jin1, ZHU Wanxu2, 3, PAN Jiayu3, 4, ZHANG Ruidong3, ZHOU Hongmei3

(1. Department of Civil Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. College of Civil Engineering and Architecture, Guilin University of Technology, Guilin 541004, China;

3. College of Civil Engineering and Architecture, Guangxi University of Science and Technology, Liuzhou 545006, China;

4. Jiangsu Huajiang Construction Group Co., Ltd., Architectural Design Branch, Nanjing 210009, China)

Abstract: Taking the construction wastes as one of the raw materials, incorporating activator, binder and other admixtures, the recycled noise-absorbing ceramsite was prepared with non-sintering process. Utilizing noise-absorbing ceramsite as main aggregate, water-reducing agent was mixed in to adjust water cement ratio and cement dosage. The orthogonal experiment was conducted on the mixture proportion. The mixture proportion was determined after taking the compressive strength as the basic index for practical engineering application with its porosity 20.5%, and compressive strength 12.76 MPa. Referring to the rail traffic site conditions, the mold was designed and the ceramsite concrete was poured. Acoustics performance of the ceramsite concrete was tested in the reverberation chamber. The results show that the porosity is the major factor affecting the noise-absorbing performance and compressive strength of noise-absorbing ceramsite concrete, and the average noise-absorbing and noise-reduction coefficient are 0.74 and 0.8, respectively, according to reverberation chamber test results, which would achieve obvious noise-absorbing effect in rail traffic noise-reduction projects.

Key words: construction waste; ceramsite preparation; concrete noise-absorbing plate; acoustic performance

在我国城市化快速发展过程中,城市建设在不断加速,然而建设中产生的建筑垃圾数量也在逐年剧增。建筑垃圾的产生速度与城市的建设速度成正比,我国的建筑垃圾占到城市垃圾总量的30%~40%,数据显示,2011年我国建筑垃圾现存量已超过20亿t,每年会有超过数亿吨的建筑垃圾产生,到2020年建筑垃圾累积量预计将达到50亿t左右[1]。建筑垃圾作为一种常见的固体废弃物,在过去的几十年里持续、快速增长,具有数量大、普遍性和污染性等特点,由于对建筑垃圾的管理不到位以及处理不合理等原因,造成了严重的生态环境和资源浪费等一系列问题[2]。同时,噪声污染也是当前面临的另一个环境问题。噪声不仅影响人们的正常工作、生活,而且噪声强度在85 dB以上时,除了损伤听力以外,还会诱发人体多种疾病,对人体的健康造成了严重的影响。随着城市轨道交通网络的不断完善,城市地铁、轻轨和高速铁路建设里程逐年增加,轨道交通产生的噪声污染成为影响居民生活质量的重要污染源之一。轨道交通噪声对人们的影响也越来越凸显,并且投诉事件也时有发生[3],因此备受轨道交通部门以及沿线居民的高度关注。陶粒由于自身内部的微孔、多孔结构,形态均一等特点,使陶粒具有轻质高强、防火抗冻、耐化学腐蚀、保温隔热效果好、施工适应性强等良好性能,被作为建筑材料广泛应用于建筑行业,同时在园艺林园和工业过滤方面有很多应用[4-5]。以陶粒为骨料制成的多孔水泥基材料,属于一种特殊的吸声型陶粒混凝土,具有十分理想的吸声降噪性能,将其应用于轨道交通噪声治理方面具有一定的工程实际意义,也能够产生很好的经济效益。经过免烧结粉煤灰陶粒的试验研究,掌握了制备免烧型陶粒的基本工艺和理论方法。在此基础上,本文作者以建筑垃圾再生微粉料、粉煤灰和水泥等作为原材料,辅以激发剂,研制出免烧型建筑垃圾再生料吸音陶粒,实现建筑垃圾的再生资源化利用。并以自制建筑垃圾陶粒为主要骨料进行吸声型陶粒混凝土配合比设计,制备出陶粒混凝土吸声材料,通过混响室法进行陶粒混凝土吸声性能测试,以满足轨道交通噪声治理工程应用要求。

1 试验

1.1 试验原材料

1.1.1 建筑垃圾

本研究所使用的建筑垃圾是以废混凝土为主,含有少量烧结黏土砖和废瓷砖碎片,经过分拣、破碎、筛分等工艺得到试验用建筑垃圾再生微粉料。建筑垃圾再生微粉料的制备工艺流程如图1所示。

图1 再生微粉料的制备工艺流程

Fig. 1 Preparation process of renewable powder material

根据制备流程,先采用颚式破碎机进行初次破碎,经筛分得到粒径≤2 mm再生细料,再利用行星式球磨机进行球磨,筛分得到粒径≤0.075 mm作为试验用再生微粉料。试验用建筑垃圾再生微粉的烧失量为12.5%,建筑垃圾再生微粉的粒径分布如图2所示,物相组成XRD图谱分析如图3所示。从图3可以看出:再生微粉中的主要成分是SiO2,CaCO3和Al2O3。

图2 建筑垃圾再生微粉的粒度分布

Fig. 2 Particle size distribution of C&D powder

图3 建筑垃圾再生微粉的XRD图谱

Fig. 3 XRD pattern of C&D powder

1.1.2 粉煤灰

本试验选用的Ⅰ级粉煤灰,密度为2 240 kg/m3,比表面积为423 m2/kg,45 μm筛余量8.6%,需水量比为92%,强度活性指数为87%,其化学成分如表1所示,各项性能指标均满足GB/T 1596—2017中有关用于水泥和混凝土中的粉煤灰的要求[6]。

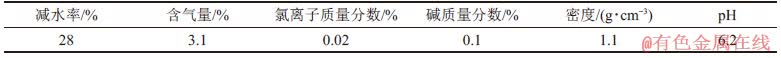

表1 粉煤灰的主要化学组成(质量分数)

Table 1 Main chemical composition of fly ash %

1.1.3 水泥

本试验选用42.5级普通硅酸盐水泥,其主要的物理性能指标如表2所示,各项性能均满足GB 175—2007中对于通用硅酸盐水泥的要求[7]。

1.1.4 激发剂

本试验中选用生石灰和石膏粉作为陶粒制备过程中的主要激发剂。由于建筑垃圾再生微粉料和粉煤灰都属于固体废弃物,其自身的活性玻璃体SiO2和Al2O3必须在一定的碱性条件下通过水化反应才能够形成硅酸盐和铝酸盐等凝胶体,采用激发剂有利于在陶粒制备过程中缩短成球时间和提高成球质量[8]。

1.1.5 黏结剂

本试验中选用固体粉末硅酸钠作为黏结剂。硅酸钠是一种水溶性硅酸盐,固体硅酸钠具有良好的黏结力。在制备陶粒的物料中加入一定掺量的硅酸钠,能够增强物料的团聚,使松散物料形成密实核心,从而提高陶粒物料的塑性。

1.1.6 减水剂

本试验中减水剂选用上海钦和化工有限公司聚羧酸高效减水剂,该减水剂为白色粉末,其主要性能参数指标如表3所示。加入减水剂可以减少单位用水量从而降低水灰比使吸音陶粒混凝土具有良好的孔性结构,也可以减少单位水泥用量。

1.1.7 拌合水

本试验中使用的拌合水都是普通自来水。

表2 水泥的主要物理性能指标

Table 2 Main physical performance indexes of cement

表3 减水剂的主要性能指标

Table 3 Water reducing agent performance indexes

1.2 试验方法

1.2.1 吸音陶粒制作原理及方法

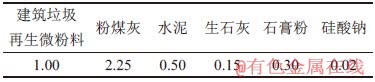

建筑垃圾再生料吸音陶粒制作过程是先将建筑垃圾进行机械破碎粉磨后,同粉煤灰、水泥、外加剂等混合搅拌均匀后得到陶粒制备的混合物料,再利用圆盘造粒机将物料成球造粒,用雾化水对物料进行喷淋,将制备的陶粒保湿自然养护3 d,待达到一定强度后进行筛分再自然养护至龄期。表4所示为陶粒制作原材料的基本配合比。

表4 陶粒基本配合比

Table 4 Mixture proportion of ceramsite kg/cm3

本试验所用的圆盘造粒机圆盘直径为0.5 m,盘高为0.16 m,刮料板距离盘底面3 mm,圆盘转速为34 r/min,通过多次试验后将圆盘的倾斜角调整到35°左右为宜,物料成球率在90%以上。在制备陶粒过程中,第一步是物料团聚成粒,即粉料的成核阶段。在均匀的向物料表面喷淋雾化水时,固体粉粒表面产生一层吸附水,随着物料被润湿,水分含量不断增加,激发剂水化后产生的凝胶体以及黏结剂的水溶液在粉粒表面形成一层具有黏性的薄膜水,在薄膜水表面张力的作用下吸附粉粒,继续加水使得粉料进一步被润湿,粉粒之间产生毛细管水,在毛细管压力的作用下吸附更多粉粒,从而产生团聚效应。此时,粉体与粉体颗粒之间的黏性液体起到一个液体架桥作用,会使得粉体团聚更加紧密,部分粉体起到填充作用,同时控制用水量,使粉体间的黏结液固结形成固体桥架,从而使粉体黏结成核[9]。物料成核过程如图4所示。

图4 物料成核过程

Fig. 4 Material nucleation process

圆盘造粒机在制备陶粒过程中起到为物料成球提供一个机械外力的作用,主要包括摩擦力、离心力、重力和刮料板的阻力。物料成球制粒过程主要分为粉料成核、球粒长大和增长密实3个阶段。在粉料成核阶段,粉料在盘内主要受到摩擦力和刮料板的阻力,使物料均匀分布,受水均匀,提高粉料成核质量。在粉料成核后,出现的小球粒处于长大阶段。小球粒受到的机械力明显增大,随着球粒的不断长大出现分级现象,不同粒径的球粒按照不规则的螺旋线运动。造粒密实阶段即强度形成阶段,此过程须控制好水含量,在离心力的作用下球粒运动速度很快,球粒内部多余的水分逐渐析出,内部结构逐渐密实,强度增大。球粒外层不断包裹粉料,粒径增大达到目标粒径时即可完成[10]。利用造粒机制备陶粒的原理以及陶粒的运动轨迹如图5所示。

图5 圆盘造粒机的制备陶粒原理

Fig. 5 Schematic diagram of ceramsite preparation by disc pelleter

1.2.2 吸音陶粒物理性能试验

参照GB/T 17341.2—2010“轻集料及其试验方法第2部分:轻集料试验方法”对制备而成的粒径1~8 mm的陶粒进行筒压强度、堆积密度、表观密度和吸水率进行测试[11]。采用环氧树脂灌孔法进行吸音陶粒的有效孔隙率测试[12]。具体原理方法为:依靠环氧树脂的高流动性和渗透性,将圆柱体吸声试件装入钢模中,密封底部,将环氧树脂和固化剂按比例配制,搅拌均匀后灌入钢模中,使环氧树脂充分填充试件孔隙,待完全固化后拆除钢模即可得到材料的有效孔隙率。

1.2.3 吸音陶粒微观试验

1) 吸音陶粒的X线衍射分析。单色X线照射到物质晶体上形成的X线衍射图,采用粉末法将待测材料试样破碎、磨细放入到样品框内置于X线衍射仪中,根据衍射峰的峰位、峰强度来进行材料物相的定性分析和定量分析。

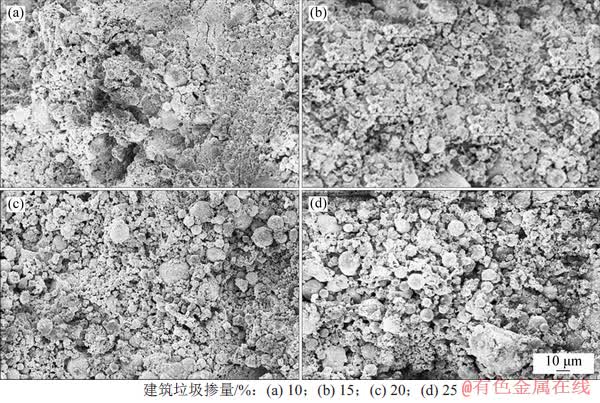

2) 吸音陶粒的扫描电镜分析。将不同配比物料的陶粒制品破碎后的块状试样进行喷金处理,再通过SEM扫描电镜对建筑垃圾掺量分别为10%,15%,20%和25%的陶粒内部结构和水化产物形貌进行观察分析。

1.3 陶粒混凝土吸音板

陶粒混凝土吸音板主要是由陶粒作为骨料、水泥作为凝胶材料、水和外加剂等拌和而成的新型水泥基复合材料。陶粒颗粒表面仅仅包裹一薄层的水泥净浆作为胶结层,将骨料颗粒彼此黏结起来使内部形成大量相互贯通的孔隙,这些多孔结构细密均匀,彼此互通并且延伸到外部表面,属于一种特殊的多孔结构混凝土。由于内部的多孔结构使陶粒混凝土吸音板具有吸音降噪的特性,因为在声能传播过程中引起孔隙内部空气振动,空气与孔隙间固体筋络发生摩擦,由于黏滞性和热传导效应,声能被不断转化为热能而消耗掉,从而使声波衰减,声压级降低,从而达到吸音降噪的效果[13]。多孔性吸音陶粒混凝土结构模型如图6所示。

图6 多孔性吸音陶粒混凝土结构模型

Fig. 6 Structure model of porous noise-absorbing ceramsite concrete

1.3.1 陶粒混凝土吸音板配合比正交试验

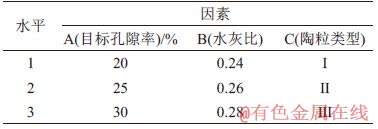

利用正交试验法确定吸音陶粒混凝土配合比。正交试验选择目标孔隙率、水灰比和陶粒级配类型为影响因素,进行配合比的三水平三因素正交试验[14-15]。选用的陶粒骨料粒径范围为1~8 mm,分别由陶粒ⅰ(1~3 mm)、陶粒ii[3~5 mm)和陶粒iii[5~8 mm)不同范围粒径的陶粒通过不同比例进行混合得到3种级配陶粒Ι、陶粒Ⅱ和陶粒Ⅲ,陶粒类型如表5所示,试验因素水平表见表6所示,正交试验配合比方案见表7所示。

表5 陶粒级配组成

Table 5 Grading composition of ceramsite

表6 配合比正交试验因素水平表

Table 6 Factor levels of proportion of mixture for orthogomal experiment

表7 吸音陶粒混凝土配合比方案

Table 7 Sound-absorbing ceramsite concrete mixture proportion

1.3.2 陶粒混凝土吸音板试件浇筑

本试验中的陶粒混凝土吸音板设计时结合实际工程轨道下部尺寸,确定吸音板的长×宽×高为0.55 m×0.55 m×0.2 m,试验所用特制钢模具,由侧面板、盖板和连接螺栓3部分组成[16]。侧面板通过连接螺栓进行固定,盖板主要用来压制成型,控制试件的高度和密实程度,模具如图7所示。由于试件的凝结强度较低,在拆除侧模时,应该防止用力过大使模具碰撞到试件边角。完全拆除侧模后,应该立即用养护薄膜覆盖试件,进行保湿养护,保证试件的早期强度。试件养护示意图如图8所示。

图7 组装式钢模具

Fig. 7 Composited steel mold

图8 吸音板试件养护

Fig. 8 Specimens under curing

1.3.3 陶粒混凝土吸音板吸音性能试验

参照GB/T 20247—2006“声学 混响室吸声测量”进行陶粒吸音板试件吸声系数测试[17]。混响时间的测量应按中心频率的1/3倍频程序列进行测量,测量频率为:100,125,160,200,250,315,400,500,630,800,1 000,1 250,1 600,2 000,2 500,3 150,4 000和5 000 Hz,共18个中心频率。先连接设备,然后进行测点布置,每个传声器测点的位置离声源、被测试件和边界面的距离的最小值分别为2 m,1 m和1 m,再测量混响时间T60-1,将30块陶粒混凝土吸音板紧密整齐拼接,避免板间产生过大空隙,保证测试数据的精确度。同时,为了避免测量误差并结合实际工程应用环境,对试件的边界采用表面光滑的非吸声材料进行围合处理,然后进行混响时间T60-2的测试,测试试件布置如图9所示。

图9 陶粒混凝土吸音板混响室法声学性能试验

Fig. 9 Acoustic performance test of ceramsite concrete noise-absorbing plate by reverberation chamber method

2 结果与讨论

2.1 吸音陶粒的物理性能测试结果

将粒径范围为1~8 mm的陶粒进行基本物理性能测试,其中粒径范围为(1~3) mm的筒压强度约为6.4 MPa,粒径逐渐增大,筒压强度也逐渐提高。粒径为[3~5) mm和[5~8) mm的陶粒的筒压强度分别为6.8 MPa和7.5 MPa,堆积密度为900 kg/m3左右,表观密度为1 639 kg/m3,平均孔隙率为45.6%,吸水率为17.5%,结果表明陶粒的基本物理性能指标达到了人造高强轻集料的标准要求[18]。

2.2 吸音陶粒的微观试验结果

2.2.1 X线衍射(XRD)分析

为了进一步了解利用建筑垃圾再生微粉料制备陶粒的水化产物组成情况,对陶粒样品经烘干、研磨等处理后进行XRD分析,分析图谱如图10所示。

由XRD峰匹配结果可以看出:CaCO3的峰值最强且分布比较广,其主要化学成分是方解石,为陶粒提供了主要强度。其中还有一定的SiO2和CaMg(CO3)2,表明样品中有较多的二氧化硅和白云石,也能够为陶粒提供一定的强度。以上结果说明建筑垃圾微粉中的方解石和白云石为陶粒提供了较好的强度基础,以建筑垃圾再生料进行陶粒的制备对其强度指标是有利的。

2.2.2 扫描电镜(SEM)结果分析

为了进一步了解建筑垃圾再生微粉料对陶粒内部结构的影响,通过扫描电子显微镜对建筑垃圾掺量分别为10%,15%,20%和25%的情况下所制备的陶粒样品进行微观形貌观察,如图11所示。

图10 建筑垃圾再生料免烧陶粒的XRD图谱

Fig. 10 XRD pattern of non-sintering ceramsite of C&D waste renewable materials

图11 不同建筑垃圾掺量的免烧陶粒的微观形貌结构

Fig. 11 Morphology and structure of non-sintering ceramsite with different dosage of C&D waste

从SEM形貌分析结果可以看出:当建筑垃圾掺量为10%时,陶粒内部形貌结构相对比较平整密实,没有明显的孔隙结构,如图11(a)所示。这说明了在建筑垃圾掺量较少的情况下,陶粒中的水泥和粉煤灰的水化凝结成度比较高,在机械力成球作用下制成的陶粒密实度较高,所以陶粒的单颗粒强度很高,同时也会使陶粒的密度增大。当建筑垃圾掺量为15%时,陶粒结构内部呈现出一定的孔隙结构,表面略微粗糙,如图11(b)所示。在此掺量下,陶粒的单颗粒强度变化不大,密度有所下降。当建筑垃圾掺量分别为20%和25%时,内部结构形貌如图11(c)和(d)所示。可以看出陶粒内部都有明显的圆球形颗粒结构,球形颗粒排列比较紧密,但是粗糙度比较大,形成比较明显的孔隙结构。其中图11(d)中孔隙相对更加明显,而单颗粒的强度有略微下降,但密度降低了很多。

这种现象是由于建筑垃圾的再利用,含有的水泥的水化程度已经较高,会提高陶粒的强度,而在制备陶粒的过程中再生微粉的水化程度略低,主要依靠水泥和粉煤灰的水化凝胶作用形成团聚机制。以上结果表明:建筑垃圾掺量在20%~25%时能够保证陶粒具有足够的强度和较好的孔隙结构。

2.3 吸音陶粒混凝土配合比正交试验结果

按照正交设计换算得到的9组配合比试验方案,以材料的平均吸声系数和28 d抗压强度为指标确定吸音陶粒混凝土配合比。正交试验方案及结果如表8所示,极差分析如表9所示。

表8 正交试验方案及结果

Table 8 Orthogonal test programs and results

表9 正交试验极差分析表

Table 9 Range analysis of orthogonal test

由表9的极差计算结果可以得出:影响吸音陶粒混凝土吸声性能和抗压强度的因素主次顺序依次为:目标孔隙率,陶粒类型,水灰比。这说明孔隙率是影响水泥基多孔陶粒混凝土吸声性能的主要因素,陶粒类型较水灰比对陶粒混凝土吸声性能的影响更显著,说明陶粒骨料的颗粒级配对吸音陶粒混凝土吸声性能影响更大。同时从T-1到T-9的9组强度试验结果可以看到:吸音陶粒混凝土抗压强度的最大值为试验编号T-3,抗压强度为12.76 MPa;最小值是试验编号T-8,为8.74 MPa。吸音陶粒混凝土抗压强度与普通混凝土的强度相比要小很多,这也充分说明了吸音降噪型陶粒混凝土内部结构的多孔性是影响其强度的主要因素。同时水灰比的变化对吸音陶粒混凝土的强度影响并不明显,但是陶粒骨料类型对于强度影响比较大,这说明了陶粒的颗粒级配更能影响吸音陶粒混凝土的强度。由正交试验结果可知,相同条件下,小粒径陶粒比例较大时,吸音陶粒混凝土的强度相对较高。

当以抗压强度作为考察指标进行配合比最优组合确定时,由表9的正交试验极差计算结果可以看出,抗压强度均值k越大说明材料的强度越高,更能满足实际应用要求,即能得出最优组合方案为A1B3C3,此方案为正交试验组的T-3,抗压强度为12.76 MPa,由此可得吸音陶粒混凝土配合比如表10所示。

表10 吸音陶粒混凝土配合比

Table 10 Mix proportion of noise-absorbing ceramsite concrete

2.4 陶粒混凝土吸音板吸声试验结果

通过混响室法测试出陶粒混凝土吸音板在1/3倍频程下各中心频率的吸声系数,吸声系数曲线如图12所示。从陶粒混凝土吸音板的吸声系数曲线可以看出:在60~200 Hz的低频段,材料的吸声系数相对较低,吸声系数在0.5以下。在200~1 000 Hz的中频段,材料的吸声系数波动比较大,而且在频率250 Hz处出现峰值吸声系数为0.99。在1 000~5 000 Hz的中高频段,材料的吸声系数有略微上升的趋势但相对比较平稳。在混响室法测量下的150,250,500,1 000,2 000和4 000 Hz这6个频率吸声系数的算术平均值为0.74,达到了理想的吸声材料性能要求[14]。

图12 吸音板吸声系数曲线

Fig. 12 Sound absorption coefficient curve of noise-absorbing plate

对于材料的吸声性能评价主要是根据材料的降噪系数(noise reduction coefficient, NRC)分级进行评估,参照GB/T 16731—1997“建筑吸声产品的吸声性能分级”[19],根据陶粒吸音板各频率的吸声系数计算出250,500,1 000和2 000 Hz频率下4个倍频带的实用吸声系数αp1,αp2,αp3和αp4,按照下式计算,可得出4个倍频带实用吸声系数的算术平均值即可的到降噪系数,计算值保留两位小数点且以0.05为最小倍数。

(1)

(1)

式中:i=1,2,3,4。由式(1)可以得到4个倍频带的实用吸声系数αpi分别为0.93,0.76,0.78和0.75,再根据实用吸声系数可以得到吸音陶粒混凝土材料的降噪系数:

(2)

(2)

通过计算得到的吸音陶粒混凝土材料的降噪系数为0.80,达到了标准中吸声性能分级的Ⅰ级标准,在实际的工程应用中将会达到很好的降噪效果。

3 结论

1) 以建筑垃圾为主要原材料,辅以激发剂和黏结剂等外加剂制备出免烧结再生吸音陶粒的强度等物理性能指标完全满足国家标准规范对人造高强轻集料的要求,当建筑垃圾掺量为20%~25%时制备出的吸音陶粒有足够的强度和较好的孔隙结构。

2) 影响吸音陶粒混凝土吸声性能和抗压强度的因素主次顺序依次为目标孔隙率、陶粒类型、水灰比。根据实际工程应用要求,以抗压强度作为指标确定吸音陶粒混凝土的配合比,混凝土的有效孔隙率为20.5%,抗压强度为12.76 MPa。

3) 水泥基吸音陶粒混凝土材料的平均吸声系数为0.74,降噪系数为0.80,是一种理想的吸音降噪材料,用于轨道交通噪声治理工程中将会起到显著的吸音降噪的效果。

参考文献:

[1] DUAN Huabo, LI Jinhui. Construction and demolition waste management: China′s lessons[J].Waste Management and Research, 2016, 34(5): 397-398.

[2] LU Weisheng, YUAN Hongping. Exploring critical success factors for waste management in construction projects of China[J]. Resources, Conservation and Recycling, 2010, 55(2): 201-208.

[3] 储益萍. 地铁引起的结构振动与噪声及其相关性分析[J]. 噪声与振动控制, 2011, 31(4): 85-88.

CHU Yiping. Measurement and correlation analysis of ground-borne vibration and noise induced by underground railway[J]. Noise and Vibration Control, 2011, 31(4): 85-88.

[4] 崔守远. 高强页岩陶粒混凝土在芥园西道立交桥中的应用[J]. 铁道建筑, 2009(4): 113-116.

CUI Shouyuan. Application of high strength shale ceramsite concrete in mustard garden west road overpass[J]. Railway Engineering, 2009(4): 113-116.

[5] 黄丽华. 壳核型免烧陶粒的研制与生产[J]. 墙材革新与建筑节能, 2015(2): 43-45.

HUANG Lihua. Development and production of shell-core sinterless ceramsite[J]. Wall Materials Innovation and Energy Saving in Buildings, 2015(2): 43-45.

[6] GB/T 1596—2017, 用于水泥和混凝土中的粉煤灰[S].

GB/T 1596—2017, Fly ash used for cement and concrete[S].

[7] GB 175—2007, 通用硅酸盐水泥[S].

GB 175—2007, Common Portland Cement[S].

[8] 周栋梁, 潘志华. 新型水泥基泡沫吸声材料的研制[J]. 噪声与振动控制, 2010, 30(4): 58-60.

ZHOU Dongliang, PAN Zhihua. Research and development of a new type cellular concrete based sound absorption material[J]. Noise and Vibration Control, 2010, 30(4): 58-60.

[9] 邱珊, 黄旭, 刘子述, 等. 秸秆灰为添加剂的粉煤灰免烧陶粒的试制[J]. 哈尔滨工业大学学报, 2013, 45(2): 36-40.

QIU Shan, HUANG Xu, LIU Zishu, et al. Utilization of straw ash as an additive for making unburned fly ash ceramsite[J]. Journal of Harbin Institute of Technology, 2013, 45(2): 36-40.

[10] 朱万旭, 酆磊, 周红梅, 等. 新型免烧粉煤灰陶粒的研制及应用浅析[J]. 混凝土, 2017(5): 59-62.

ZHU Wanxu, FENG Lei, ZHOU Hongmei, et al. Analysis on the development and application of a new type of ash haydite [J]. Concrete, 2017(5): 59-62.

[11] GB/T 17431.2—2010, 轻集料及其试验方法—第2部分: 轻集料试验方法[S].

GB/T 17431.2—2010, Lightweight aggregates and its test methods—Part 2: test methods for lightweight aggregates[S].

[12] 黄英. 玻璃纤维层合板孔隙率的测定研究[J]. 玻璃纤维, 2012(6): 10-12.

HUANG Ying. Study on porosity test for fiberglass laminates[J]. Fiber Glass, 2012(6): 10-12.

[13] 钟祥璋. 建筑吸声材料与隔声材料[M]. 北京: 化学工业出版社, 2012: 177-187.

ZHONG Xiangzhang. Building sound absorbing materials and sound insulation materials[M]. Beijing: Chemical Industry Press, 2012: 177-187.

[14] 韩建国, 阎培渝. 系统化的高性能混凝土配合比设计方法[J]. 硅酸盐学报, 2006, 34(8): 1026-1030.

HAN Jianguo,YAN Peiyu. Mix proportion design method for systematical high performance concrete[J]. Journal of the Chinese Ceramic Society, 2006, 34(8): 1026-1030.

[15] 徐淑红, 马春燕, 张静文, 等. 正交设计与回归分析在底泥陶粒松散容重研究中的应用[J]. 中国陶瓷, 2008, 44(9): 54-57.

XU Shuhong, MA Chunyan, ZHANG Jingwen, et al. The application of orthogonal design and regression analysis on the study of losse bulk density of ceramsite[J]. China Ceramics, 2008, 44(9): 54-57.

[16] 栾皓翔, 朱万旭, 周红梅, 等. 新型轨道吸声板工程适用性优化改进研究[J]. 新型建筑材料, 2016, 43(7): 120-124.

LUAN Haoxiang, ZHU Wanxu, ZHOU Hongmei, et al. The studies on the applicability improvement and the optimization of new tracks sound-absorbing boards[J]. New Building Materials, 2016, 43(7): 120-124.

[17] GB/T 20247—2006, 声学-混响室吸声测量标准[S].

GB/T 20247—2006, Acoustics-measurement of sound absorption in a reverberation room[S].

[18] GB/T 17431. 2—2010, 轻集料及其试验方法—第1部分: 轻集料[S].

GB/T 17431.2—2010, Lightweight aggregates and its test methods—Part 1: lightweight aggregates[S].

[19] GB/T 16731—1997, 建筑吸声产品的吸声性能分级[S].

GB/T 16731—1997, The gradation of sound absorption property for absorbent products[S].

(编辑 杨幼平)

收稿日期: 2019 -07 -18; 修回日期: 2019 -09 -05

基金项目(Foundation item):国家自然科学基金资助项目(51768014) (Project(51768014) supported by the National Natural Science Foundation of China)

通信作者:朱万旭,博士,教授,从事新型吸音降噪材料和预应力拉索等研究;E-mail:zhuwanxu@vip.163.com