文章编号:1004-0609(2011)01-0138-07

穿孔法改进泡沫铝的吸声性能

袁文文,李言祥,陈 祥

(清华大学 机械工程系,教育部先进成形制造重点实验室,北京 100084)

摘 要:利用熔体发泡技术制备不同孔径和气孔率的泡沫铝,对不同气孔率的原始状态泡沫铝以及孔径为1.1 mm的穿孔泡沫铝的吸声性能进行研究。结果表明:未设置背腔时,原始状态泡沫铝的吸声性能不高,设置背腔后,由于泡沫铝中所含通透结构的作用,泡沫铝的吸声性能明显提高;穿孔泡沫铝的穿孔率在0.5%~1.0%范围,设置60~80 mm背腔时可使降噪系数超过0.42,比原始状态泡沫铝不设置背腔时的降噪系数高2倍左右;穿孔泡沫铝设置背腔后的吸声特性符合Helmholtz共振吸声的规律,但受到穿孔结构、泡沫铝原本存在的缺陷组成的通透结构和气泡孔在穿孔过程中被打开的小开口等因素的影响。

关键词:泡沫铝;穿孔;吸声性能;Helmholtz共振

中图分类号:TG146.21 文献标志码:A

Improving sound absorption of aluminum foams by drilling holes

YUAN Wen-wen, Li Yan-xiang, CHEN Xiang

(Key Laboratory for Advanced Materials Processing Technology, Ministry of Education,

Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China

Abstract: Aluminum foams with various cell sizes and porosities were prepared by the melt foaming process. The sound absorption properties of aluminum foams with different porosities in as-received state and with drilling holes of 1.1 mm diameter were investigated. The results show that the aluminum foams in as-received state with no back cavity do not possess high sound absorbability, while setting up a back cavity behind the foam can improve the sound absorbability according to some permeable structures existing inside the aluminum foam; the noise reduction coefficients of the aluminum foams with 0.5%-1.0% holes area ratio and 60-80 mm thick back cavity are above 0.42, which are about twice more than that of the aluminum foam in as-received state with no back cavity. The sound absorption coefficients of the aluminum foams with drilling holes comply with the characteristics of Helmholtz-type resonators when a back cavity exists. But they are affected by the structure of the drilling holes, the permeable structures derived from inherent defect inside the aluminum foam and the small openings on the cells formed by drilling process.

Key words: aluminum foam; drilling holes; sound absorption; Helmholtz-type resonator

泡沫铝的气孔率、孔径、孔形等结构,以及其压缩性能、冲击能量吸收性能等特性已经被广泛研究,而对泡沫铝吸声降噪、隔热、电磁屏蔽等性能的研究较少[1]。为满足交通和航空航天高技术领域内的应用需求,泡沫铝的功能特性需要特别被关注。泡沫铝可分为开孔和闭孔两大类,在以往对泡沫铝的吸声行为研究中,对由渗流法制备的开孔泡沫铝的研究较多,而对闭孔泡沫铝的研究偏少。

赵庭良等[2]、程桂萍等[3]和郑明军等[4]对气孔率、孔径和试样厚度对开孔泡沫铝吸声性能的影响进行了实验研究。LU等[5]建立了半开孔泡沫金属的理论模型,MAYSENH?LDER等[6]用Wilson松弛模型描述了开孔泡沫铝的吸声性能。近期,何德坪研究组的刘伟伟等[7-8]应用LU的模型分析了梯度孔径和孔结构周期调制的开孔泡沫铝的吸声特性。

关于闭孔泡沫铝吸声性能的研究滞后于开孔泡沫铝,远没有达到可以建立数学模型来定量描述的状态。HAN等[9]分析了孔径在5 mm以下、气孔率在69%~86%范围内的闭孔泡沫铝的吸声特性,认为流阻 40 000 Ns/m4左右的闭孔泡沫铝吸声特性最佳。尉海军等[10-11]、LU等[12]对闭孔泡沫铝吸声性能的影响因素,如气孔率、试样厚度、压缩方式和穿孔率等进行了实验研究。从现有对闭孔泡沫铝吸声特性的研究中可以看出,泡沫铝的闭孔形态必须破坏成开孔或者半开孔,才能体现好出的吸声特性[9, 11-12]。

穿孔处理是一种常用的闭孔泡沫铝开孔方式,一些研究者测试过不同商品闭孔泡沫铝穿孔后的吸声性能。KOVACIK等[13]在厚8.9 mm的Alulight泡沫铝上加工直径为1.5 mm、穿孔率为1.4%的小孔,与质量和穿孔条件均相同的实心铝板(1.5 mm厚)相比,Alulight泡沫铝的吸收峰增高、增宽,吸声峰值频率降低。MCRAE等[14]的研究结果表明,在Cymat泡沫铝产品上加工穿孔率为2.4%和2.5%的小孔时,孔径为1.0和1.5 mm泡沫铝的的吸声效果相当,而且与穿孔率为5.6%的泡沫铝相比,其吸声平均值、峰值和低频值均提高,并且吸声峰值频率降低,对中低频吸收有利 。LU等[12]在20 mm厚Alporas泡沫铝样品上加工直径为1 mm或者2 mm的小孔,依据其在直径100 mm试样上每隔2或3个气孔进行穿孔,计算其穿孔率不超过4%;与未穿孔的泡沫铝相比,穿孔后的泡沫铝能显著提高吸声效果,在1 200~1 600 Hz范围内,几乎可以吸收所有的声音。尽管有上述研究结果可参考,工程人员仍然难从中获取有效的设计参数,包括如何选择穿孔直径、穿孔率和背腔厚度等,而且对泡沫铝穿孔后的吸声机制还缺乏足够的认识。

由于高频噪音(2 000 Hz以上)随着传播距离的增加或遭遇障碍物能够迅速衰减,而低频噪音递减得很慢,并能轻易穿越障碍物直入人耳,危害更大。因此,本文作者针对2 000 Hz以下的中低频声音,在研究原始状态闭孔泡沫铝吸声特性基础上,系统分析穿孔对闭孔泡沫铝吸声性能的影响,并结合其吸声规律探讨其吸声机制。

1 实验

1.1 材料制备及处理

以纯铝为原材料,采用熔体发泡法,通过改变加钙量和氢化钛量制备了气孔率分别为75.0%、83.2%和85.2%,对应孔径分别2.7、3.7和4.5mm的泡沫铝材料,工艺原理参见文献[15]。不同气孔率的泡沫铝试样被从制备的大块泡沫体上切割下来,后经电火花线切割成测试吸声性能的圆柱形试样。

用机械钻床在泡沫铝上加工直径为1.1 mm的穿孔。穿孔方式是在同一个试样上逐步增加孔数目,以获得需要的穿孔率。在加工过程中,尽量使各穿孔排成间距相等的方格。穿孔率p(%)和穿孔间距b (mm)之间满足如下关系:p=95.0/b2。

1.2 吸声性能测试

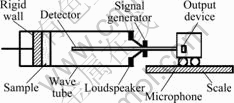

利用驻波管装置测量泡沫铝的垂直入射吸声系数,装置示意图如图1所示。刚性壁是活动的,可以调节泡沫铝试样背后所留的背腔厚度。为了避免边缘效应及考虑泡沫铝结构的不均匀性,泡沫铝被线切割成直径为98.5 mm的圆形样品。声音信号为纯声1/3倍频程,在200~1 600 Hz范围内。测量中读出1~3组(630 Hz及以上读3组)声压极大值Pmax和声压极小值Pmin,利用下式计算声压差 :

:

(1)

(1)

吸声系数则为[16]

(2)

(2)

工程中将250、500、1 000、2 000 Hz这4个频率的吸声系数的算术平均值称为“降噪系数”,来粗略比较和选择吸声材料。本研究中用1 600 Hz的吸声系数代替2 000 Hz时的值来计算降噪系数,用NRC′表示。

图1 驻波管装置示意图

Fig.1 Schematic diagram of standing wave tube

2 实验结果

2.1 原始状态泡沫铝的吸声性能

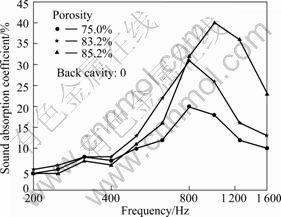

图2所示为不同气孔率的10 mm厚原始状态泡沫铝紧贴刚性壁时的吸声特性。由图2可知,其吸声性能随着气孔率的增加而提高,但是原始状态泡沫铝的吸声性能不高。例如气孔率为83.2%的泡沫铝,其NRC'为0.15,吸声峰值仅为0.31;即使气孔率达到85.2%,其NRC'和吸声峰值也只有0.2和0.4。

图3所示为气孔率为83.2%的10 mm厚泡沫铝在设置不同厚度背腔后的吸声特性。由图3可知,随着背腔厚度增加,其吸声峰值先增加而后趋于平稳,达到0.8左右;峰值频率随背腔厚度增加而逐渐降低,

图2 原始状态泡沫铝紧贴刚性壁时的吸声特性

Fig.2 Sound absorption properties of aluminum foams in as-received state with no back cavity

图3 原始状态泡沫铝设置不同厚度背腔后的吸声特性

Fig.3 Sound absorption properties of aluminum foams in as-received state with different thickness of back cavity

增强了低频时的吸声效果。在设置80 mm背腔时,其吸声峰值为0.82,NRC'为0.31,均比不设置背腔时增加1倍左右。

2.2 穿孔泡沫铝的吸声性能

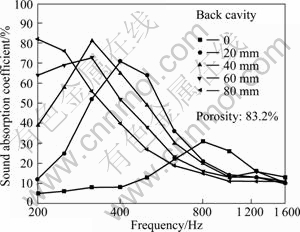

图4所示为在气孔率83.2%的10 mm厚穿孔泡沫铝的吸声特性。图4(a)所示为未穿孔和不同穿孔率条件的泡沫铝紧贴刚性壁时的吸声特性;图4(b)所示为在这些泡沫铝后面设置60 mm厚背腔时的吸声特性;图4(c)所示为穿孔率为0.5%留有不同厚度背腔时的吸声特性;图4(d) 所示为穿孔率1.0%留有不同厚度背腔时的吸声特性。

由图4(a)可知,在未设置背腔时,穿孔泡沫铝的吸声系数随穿孔率的提高而逐渐提高。与图4(b)中设置60 mm厚背腔时的泡沫铝相比,无背腔时泡沫铝的吸声峰值应该在高于1 600 Hz的频率出现,并且峰值频率似乎是随着穿孔率的提高而逐渐提高。

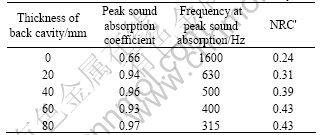

由图4(b)可知,留60 mm厚背腔时,不同穿孔率下的吸声峰值、峰值频率和降噪系数见表1。随穿孔率逐渐增加,吸声峰值先升高后减小,在穿孔率为1.0%时达到最大值0.99;峰值频率逐渐增大;NRC'体现了和峰值同样的特性先增大后减小,穿孔率为0.5%和1.0%时分别达到最大值0.43和0.42。因此,在穿孔率为0.5%~1.0%时,穿孔泡沫铝可以获得更优的吸声效果,NRC'和吸声峰值比原始状态泡沫铝不留背腔时的高2倍左右。

由图4(c)可知,改变背腔厚度时,其吸声峰值基本不变;峰值频率随背腔厚度增大而逐渐降低;NRC'先增加后维持在0.43,见表2。如果使背腔厚度大于80 mm,会提高低频段的吸声效果,但会牺牲中频段的吸声效果,而NRC'会先保持不变而后逐渐降低。

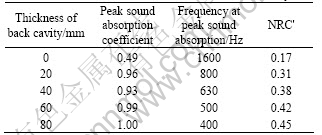

穿孔率分别为0.5%和1.0%时的两种泡沫铝的吸声特性具有同样的变化特征,见图4(d)和表3。因此,为提高整个中低频范围的吸声特性,泡沫铝的穿孔率

表1 设置60 mm背腔时不同穿孔率泡沫铝的吸声特性

Table 1 Sound absorption properties of aluminum foams with different holes area ratios and 60-mm-thick back cavity

图4 穿孔泡沫铝的吸声特性

Fig.4 Sound absorption properties of aluminum foams after drilling holes: (a) With different holes area ratios and no back cavity; (b) With different holes area ratios and 60-mm-thick back cavity; (c) With 0.5% holes area ratio and different thickness of back cavity; (d) With 1.0% holes area ratio and different thickness of back cavity

表2 设置不同厚度背腔时穿孔率0.5%泡沫铝的吸声特性

Table 2 Sound absorption properties of aluminum foams with 0.5% holes area ratio and different thickness of back cavity

表3设置不同厚度背腔时穿孔率1.0%泡沫铝的吸声特性

Table 3 Sound absorption properties of aluminum foams with 1.0% holes area ratio and different thickness of back cavity

以在0.5%~1.0%之间为宜,而相应的背腔厚度在60~80 mm范围内最合适。

3 讨论

3.1 原始状态泡沫铝的吸声机制

由于泡沫铝的金属骨架本身阻尼性能很低,所以材料自身振动对吸声的作用有限。从图3可以看出,泡沫铝背后加背腔体现了明显的Helmholtz共振吸声特性。因此,可以推断泡沫铝虽是闭孔结构,但其中含有一定量的通透结构,否则泡沫铝的吸声性能仅由表面孔形态决定,与背腔无关。通透结构是在泡沫铝制备中产生的,其形式是裂纹或穿孔等缺陷。这样在原始状态泡沫铝不设置背腔时,其吸声性能主要由通透结构产生的粘滞和热效应决定。当泡沫铝的气孔率提高时,依据泡沫铝的制备工艺,增加了泡沫铝中含有通透结构的几率,所以表现出吸声特性会随气孔率提高而增加。而在泡沫铝留背腔时吸声特性主要由通透结构引起的Helmholtz共振决定。

3.2 穿孔泡沫铝的吸声机制

在泡沫铝上钻孔,会形成如图5所示的穿孔形态。依据气泡与所穿的孔位置不同,气泡上被打开的孔口大小不一。如果形成了微米级的开口,如图5中数字1标明的小开口,那么由于粘滞作用声波穿透该开口会损失较大的声能。这就是泡沫铝穿孔之后在未留背腔时吸声性能比未穿孔前有大幅提高的原因。气泡上的小开口与气泡本身也会形成Helmholtz共振,该共振频率由下式计算

(3)

(3)

式中:c为声音在介质中的传播速度;s为气泡孔上开口的截面积;l为开口的颈长;V是气泡孔的体积。因为气泡孔的直径均小于10 mm,所以共振频率的值远超过20 kHz,可以不考虑该结构对吸声的影响。

图5 泡沫铝穿孔处理后气泡孔开口状态示意图

Fig.5 Schematic diagram of openings on cells formed by drilling process: 1—Small openings; 2, 3—Large openings

如果在泡沫铝背后设置背腔,沿泡沫板厚度方向的穿孔会与背腔形成Helmholtz共振。可以应用微穿孔理论[17-18]来描述这种共振的效果,如式(4)、(5)和(6)。

(4)

(4)

(5)

(5)

(6)

(6)

式(4)~(6)中相关参数可用下列各式表达:

式中: c为声音在介质中的传播速度,取340 m/s;d为穿孔直径,mm;p为穿孔率,%;t为穿孔板的厚度,mm;D为背腔厚度,mm;f为声音频率,kHz。式(4)给出了微穿孔板的吸声系数α的表达式,式(5)和式(6)分别是由式(4)导出的吸声峰值αmax和共振频率f0的表达式。如果穿孔直径不是比板厚小得多,这3个公式适用于任何材料的微穿孔板。

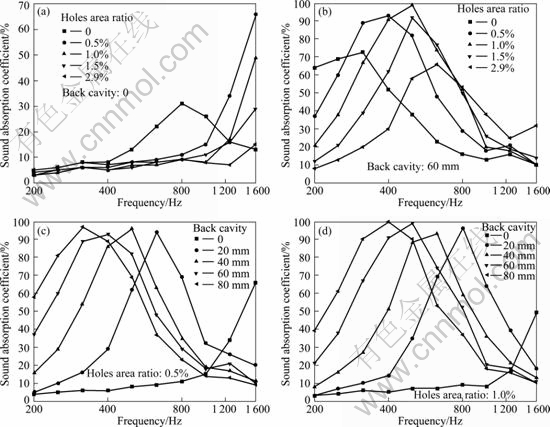

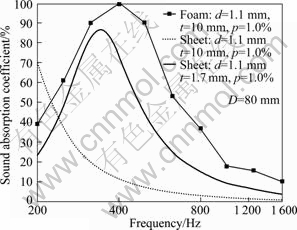

式(4)~(6)描述的Helmholtz共振可以解释这样的吸声规律:1) 随着穿孔率的增加,吸声峰值先增加后减小,峰值频率逐渐增加;2) 随着背腔厚度的增加,吸声峰值不变,峰值频率逐渐降低。但是正如比较图6中穿孔泡沫铝和穿孔实心铝板的吸声特性可知,简单化的Helmholtz共振机制不能完全反映穿孔泡沫铝设置背腔后的吸声特点。图6所示为穿孔直径为1.1 mm、穿孔率为1.0%、厚度为10 mm的泡沫铝设置有80 mm背腔时的吸声曲线。与同样穿孔直径、同样穿孔率、同样板厚的实心板(图6中虚线所示)和同样穿孔直径、同样穿孔率、同样质量(厚1.7 mm)的实心板(图6中实线所示)的吸声特性相比,穿孔泡沫铝的降噪系数、吸声峰值、峰值频率、峰的半高宽均更大。

穿孔泡沫铝中除了穿孔这种主要结构特征,原本存在的缺陷组成的通透结构引起Helmholtz共振、气泡孔上被打开的小开口引起的粘滞效应和热效应,均会增加泡沫铝的整体吸声性能。另外,即使对穿孔特征而言,由于大多数穿孔会穿过气泡,而不是穿过孔棱边界,所以穿孔的孔型不是圆形,并且穿孔的实际

图6 设置有80 mm背腔时穿孔泡沫铝和穿孔实心铝板的吸声特性

Fig.6 Sound absorption properties of aluminum foam and aluminum solid sheets after drilling holes with 80-mm-thick back cavity (Curves of solid sheets are calculated according to Eqn.(4))

长度会发生变化。这三方面因素即是穿孔泡沫铝有优于同等条件穿孔实心铝板吸声性能的原因。

4 结论

1) 原始状态泡沫铝中所含有的一定量通透结构决定了其吸声性能。背后未设置背腔时,通透结构起粘滞和热效应作用;设置背腔后通透结构与背腔组成Helmholtz共振结构,泡沫铝的吸声峰值和降噪系数可以明显提高。

2) 穿孔泡沫铝设置背腔后的吸声特性符合Helmholtz共振吸声规律,即随穿孔率的增加,吸声峰值先增加而后减小,峰值频率逐渐增加;随背腔厚度的增加,吸声峰值不变,峰值频率逐渐降低。在泡沫铝上加工直径1.1 mm,穿孔率0.5%~1.0%的穿孔,设置60~80 mm厚的背腔可使吸声峰值接近1,降噪系数超过0.42,比原始状态泡沫铝不设置背腔时的降噪系数高2倍左右。

3) 简单化的Helmholtz共振机制不能完全反映穿孔泡沫铝设置背腔后的吸声特点。它的吸声特性受到穿孔结构、泡沫铝原本存在的缺陷组成的通透结构和气泡孔在穿孔过程中被打开的小口等三方面因素的影响。

致谢:

本项研究得到浙江省科技研究计划的支持(2009C31049),泡沫铝制备在杭州龙邦合金科技有限公司完成,特此致谢!

REFERENCES

[1] BANHART J. Manufacture, characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 559-632.

[2] 赵庭良, 徐连棠, 李道韫, 战松江, 吴林美, 周 为. 泡沫铝的吸声特性[J]. 内燃机工程, 1995, 16(2): 55-59.

ZHAO Ting-liang, XU Lian-tang, LI Dao-yun, ZHAN Song-jiang, WU Lin-mei, ZHOU Wei. Study on sound absorption properties of aluminum alloy foam[J]. Chinese Internal Combustion Engine Engineering, 1995, 16(2): 55-59.

[3] 程桂萍, 陈宏灯, 何德坪, 舒光冀. 孔结构对多孔铝吸声性能的影响[J]. 机械工程材料, 1999, 23(5): 30-32.

CHENG Gui-ping, CHEN Hong-deng, HE De-ping, SHU Guang-ji. Effect of pore structure on acoustic properties of porous aluminum[J]. Materials of Mechanical Engineering, 1999, 23(5): 30-32.

[4] 郑明军, 陈 锋, 何德坪. 孔结构对多孔铝空气声吸收性能的影响[J]. 机械工程材料, 2006, 30(2): 39-41.

ZHENG Ming-jun, CHEN Feng, HE De-ping. Air sound absorption property of porous aluminum[J]. Materials of Mechanical Engineering, 2006, 30(2): 39-41.

[5] LU T J, CHEN F, HE D P. Sound absorption of cellular metals with semiopen cells[J]. Journal of the Acoustical Society of America, 2000, 108(4): 1697-1709.

[6] MAYSENH?LDER W, BERG A, LEISTNER P. Acoustic properties of aluminium foams—Measurements and modeling[C]// Proceedings of CFA/DAGA’04. Strasbourg: Fraunhofer-Institut of Bauphysik(IBP), 2004: 995-996.

[7] 刘伟伟, 黄 可, 何思渊, 何德坪. 梯度孔径通孔多孔铝合金的空气吸声性能[J]. 机械工程材料, 2007, 31(12): 72-75.

LIU Wei-wei, HUANG Ke, HE Si-yuan, HE De-ping. Sound absorption of open-celled gradual porous aluminum alloy[J]. Materials of Mechanical Engineering, 2007, 31(12): 72-75.

[8] 刘伟伟, 何思渊, 黄 可, 何德坪. 孔结构周期调制通孔多孔铝合金及其吸声性能[J]. 材料研究学报, 2009, 23(2): 171-174.

LIU Wei-wei, HE Si-yuan, HUANG Ke, HE De-ping. Sound absorption of periodic porous aluminum with controlled pore structures[J]. Chinese Journal of Materials Research, 2009, 23(2): 171-174.

[9] HAN Fus-heng, ZHU Zheng-gang, LIU Chang-song. Acoustic absorption characteristics of foamed aluminum[J]. Acta Physica Sinica: Overseas Edition, 1998, 7(2): 134-142.

[10] 尉海军, 姚广春, 王晓林, 李 兵, 尹 铫. 铝硅闭孔泡沫铝吸声性能研究[J]. 功能材料, 2006, 37(12): 2014-2018.

YU Hai-jun, YAO Guang-chun, WANG Xiao-lin, LI Bing, YIN Yao. Research on sound absorption property of Al-Si closed-cell aluminum foam[J]. Journal of Function Materials, 2006, 37(12): 2014-2018.

[11] 尉海军, 姚广春, 成 艳, 朱 磊, 简旭宇, 王 忠, 褚 颖, 蒋利军. 闭孔泡沫铝吸声性能的影响因素[J]. 中国有色金属学报, 2008, 18(8): 1487-1491.

YU Hai-jun, YAO Guang-chun, CHENG Yan, ZHU Lei, JIAN Xu-yu, WANG Zhong, CHU Ying, JIANG Li-jun. Influence factors of sound absorption properties of closed-cell aluminum foam[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1487-1491.

[12] LU T J, HESS A, ASHBY M F. Sound absorption in metallic foams[J]. Journal of Applied Physics, 1999, 85(11): 7528-7539.

[13] KOVACIK J, TOBOLKA P, SIMANCIK F. Noise attenuation using aluminum foams[C]//Banhart J, Ashby M F, Fleck N A. Metal Foams and Porous Metal Structures. Bremen: Verlag MIT Publishing, 1999: 405-408.

[14] MCRAE J, NAGUIB H E, ATALLA N. Acoustic performance and compression behaviour of perforated aluminium foam[C]//DAPINO M J, QUNAIES Z. Behavior and Mechanics of Multifunctional and Composite Materials 2008. Bellingham WA: SPIE Vol. 6929, 69290W, 2008: 1-8.

[15] 袁文文, 陈 祥, 刘 源, 李言祥. 熔体发泡法批量制备泡沫铝板材关键技术的研究[J]. 稀有金属材料与工程, 2009, 38(增刊3): 306-310.

YUAN Wen-wen, CHEN Xiang, LIU Yuan, LI Yan-xiang. Research on key technologies for batch preparation of aluminum foam slabs by melt foaming process[J]. Rare Metal Materials and Engineering, 2009, 38(Supple. 3): 306-310.

[16] GB/T 18696.1—2004. 阻抗管中吸声系数和声阻抗的测量(第1部分):驻波比法[S].

GB/T 18696.1—2004. Determination of sound absorption coefficient and impedance in impedance tubes(Part 1): Method using standing wave ratio[S].

[17] 马大猷. 微穿孔板吸声结构的理论和设计[J]. 中国科学: A辑, 1975, 5(1): 38-50.

MA Da-you. Theory and design of microperforated panel constructions for sound absorption[J]. Scientia Sinica: Series A, 1975, 5(1): 38-50.

[18] 马大猷. 微穿孔板结构的设计[J]. 声学学报, 1988, 13(3): 174-180.

MA Da-you. Design of microperforated panel constructions[J]. Acta Acustica, 1988, 13(3): 174-180.

(编辑 何学锋)

基金项目:浙江省科技研究计划资助项目(2009C31049)

收稿日期:2010-03-04;修订日期:2010-04-15

通信作者:李言祥,教授,博士;电话: 010-62773640; E-mail: yanxiang@tsinghua.edu.cn