文章编号:1004-0609(2010)S1-s0784-05

Ti-1023合金铸锭的铁偏析

王孟光,周洪强,姜建伟

(中国船舶重工集团公司,洛阳 471039)

摘 要:分析了Ti-1023钛锭中铁元素偏析的原因以及改善措施,通过合理控制原材料规格、混料方式、熔炼次数及熔炼参数,采用真空自耗电弧炉熔炼出直径为400 mm的Ti-1023铸锭。成分分析显示,钛锭上端面Fe元素含量为1.67%~1.76%,最大偏差不超过0.1%;钛锭底面Fe元素含量为1.70%~1.81%,最大偏差为0.11%;钛锭侧表面上、中、下位置Fe元素含量为1.61%~1.80%;整根钛锭Fe元素含量偏差范围在0.2%以内,铸锭成分均匀性良好。

关键词:Ti-1023合金;TB6;铁偏析;大直径铸锭

中图分类号:TG146.2 文献标志码:A

Iron segregation of Ti-1023 titanium ingots

WANG Meng-guang, ZHOU Hong-qiang, JIANG Jian-wei

(Luoyang Ship Materials Research Institute, Luoyang 471039, China)

Abstract: The reasons and improvements of Fe segregation in Ti-1023 titanium ingots were analyzed and summarized, then a d 400 mm Ti-1023 ingot was manufactured with VAR through controlling the specification of raw material, mixing way, melting time and melting parameter. Component analysis shows that, the content of element Fe in the upper end is 1.67%-1.76%, the deviation does not exceed 0.1%; that in the lower end is 1.70%-1.81%, the maximum deviation is 0.11%; that on the lateral surface is 1.61%-1.80%; the content deviation of the element Fe of the whole ingot is less than 0.2%, so the component homogenization is fine.

Key words: Ti-1023 alloy; TB6; iron segregation; big diameter titanium ingot

Ti-1023钛合金中Fe元素的平衡分配常数是0.3,因此有很大的偏析倾向。在富Fe区,容易形成不含α相或α相含量很少的区域,即β斑,β斑会严重影响合金的塑性和低周疲劳寿命[1-3]。因此,对于熔炼Ti-1023钛合金尤其是大尺寸钛锭来说,最重要的是控制Fe元素的偏析。

本文作者通过合理控制钛锭熔炼的各个工序,采用真空自耗电弧炉经过3次熔炼,最终生产出满足要求的d 400 mm的Ti-1023铸锭。

1 实验

采用0级海绵钛、添加元素的中间合金以及纯Al作为原材料,按Ti-9.6V-1.8Fe-3.1Al进行配料。将原料挤压成d 150 mm电极后,再经d 220 mm、d 290 mm、d 400 mm 3次熔炼试制出Ti-1023合金钛锭。

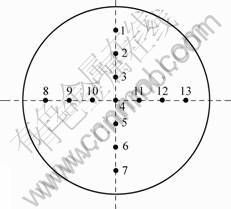

用ICP光谱仪(型号为MANGA560)检测钛锭上、中、下侧表面Fe元素含量。随后,通过超声波探伤检测顶部缩孔位置并线切割去除后检测钛锭上端面和底面Fe元素分布情况。图1为钛锭端面取样示意图。

2 结果与分析

2.1 结果

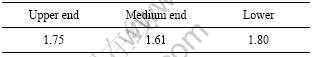

金相法测得合金β相变点为815 ℃。实验结果见表1~3。其中,表1为钛锭侧表面Fe元素含量,表2

图1 铸锭横截面取样位置示意图

Fig.1 Drawing of sampling position on cross section of ingot

和表3分别为钛锭上端面和底面Fe元素含量。

表1 钛锭侧表面Fe元素含量

Table 1 Content of Fe on side surface of ingot (mass fraction, %)

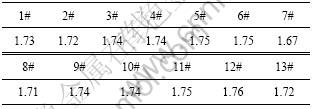

表2 钛锭上端面Fe元素含量

Table 2 Content of Fe on upper end of ingot (mass fraction, %)

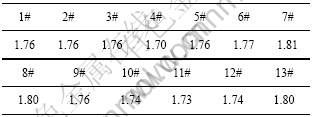

表3 钛锭底面Fe元素含量

Table 3 Content of Fe on lower end of ingot (mass fraction, %)

2.2 分析

由表1可见,钛锭侧表面Fe元素含量为1.61%~1.80%,最大偏差为0.19%。

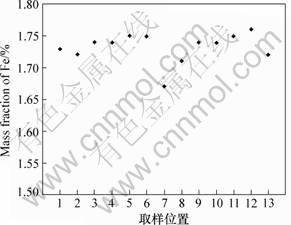

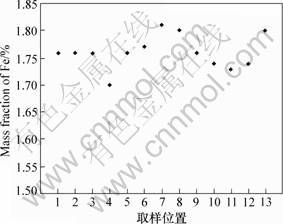

钛锭上端面和底面Fe元素含量分布如图2~3所示。钛锭上端面Fe元素含量为1.67%~1.76%,最大偏差不超过0.1%,无偏析现象,成分均匀性较好。钛锭底面Fe元素含量为1.70%~1.81%,最大偏差为0.11%。下端面Fe元素含量分布并不是像文献报道的边缘含量低,中心含量高。这是因为在熔炼初期,坩埚底部冷却速度大,合金熔化后结晶较快,因此Fe元素含量分布规律不明显。

图2 钛锭上端面Fe元素分布

Fig.2 Distribution of Fe content on upper end of ingot

图3 钛锭底面Fe元素含量分布

Fig.3 Distribution of Fe content on lower end of ingot

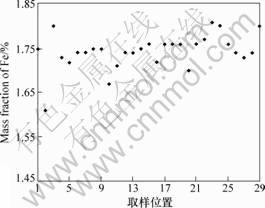

图4所示为整根钛锭Fe元素含量分布图。由图4可见,整根钛锭Fe元素含量由1.61%至1.81%,最大偏差为0.2%。

铸锭各部位Fe含量测定结果的标准偏差σ=[(0.0546/29)1/2]%=0.0434%。

综上所述,钛锭的成分均匀性很好。

图4 整根钛锭Fe元素含量分布

Fig.4 Distribution of Fe content of whole ingot

3 讨论

3.1 引起钛锭成分不均匀的原因

在工业生产中影响Fe元素偏析的主要因素有:合金化方式、熔化电流、熔化制度、熔炼次数及锭型等。Ti-1023合金铸锭内Fe组元偏析主要是由结晶偏析引起的,偏析产生的危险区域是等轴区域,特别是缩孔周围区域最为严重[4-5]。

结晶偏析的大小与溶质在固液相中的分配有关。而这个平衡分配常数(K0)直接受物质凝固速度的影响,并随温度不同而异。K0为平衡时固液两相中溶质浓度比,即

式中:ωs为溶质在固相中的浓度;ωl为溶质在液相中的浓度;K0也称为偏析度,K0>1称为负偏析,K0<1称为正偏析。而偏析系数为1-K0=(ωl-ωs)/ωl,偏析系数越大,偏析程度越大。不同元素在固体钛中的溶解度不同,溶解度大的元素偏析小,溶解度小的元素偏析大。

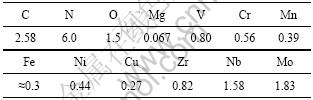

钛锭中各元素K0值见表4。可知,Fe为偏析倾向很大的正偏析元素。

表4 钛锭中各元素K0值

Table 4 K0 of some elements in titanium alloy

3.2 控制偏析的措施

针对Fe偏析的原因,控制Fe元素偏析通常有以下几条措施[6]。

3.2.1 原材料及材料含量设计

中间合金和海绵钛颗粒度大小必须严格控制,使二者的大小相匹配,这样有利于混料的均匀性。如果中间合金颗粒过大,则易造成夹杂和成分偏析。一般海绵钛粒度范围为0.83~12.7 mm,而中间合金的粒度范围为0.83~5 mm[6]。

中间合金的加入方式主要有:1) V-Al二元中间合金,Fe以单质形式(铁粉、铁丝、铁块等)加入;2) V-Al二元中间合金,Fe以V-Fe-Al三元中间合金形式加入;3) V-Fe-Al三元中间合金形式加入。以上3种方法中,铁粉按照反偏析布料,即有意在铸锭头部的电极处降低铁粉含量,则可以很好地控制Fe成分的偏析,但此种方法不易于工业化生产。

本实验选择0级海绵钛,中间合金、纯Al作为原材料,并合理设计原料的尺寸,按Ti-9.6V-1.8Fe-3.1Al进行配料。从试验结果看,本实验的合金化方式效果很好,便于工业化生产。

3.2.2 熔炼次数

熔炼次数对偏析程度的影响也是说法不一。孟祥炜等[7]认为1次熔炼对铁偏析无明显影响,2次熔炼偏析程度较3次熔炼小的,对于直径为370 mm、质量为600 kg的中型锭不宜采用3次熔炼。鲍如强[8]则认为3次熔炼效果更佳。

本实验对直径为400 mm的中型锭采用3次熔炼工艺。实验结果表明,本实验的熔炼次数对合金的均匀化效果很好。

3.2.3 熔炼电流及熔炼电压

采用较小的熔化电流,使熔池深度和熔化速度减小,熔池形状由漏斗形变为扁平形,同时,逐级降低电流,可以使熔池深度基本保持恒定,获得化学成分和组织均匀的铸锭,可以有效控制铁偏析[4, 9-12]。

对于熔炼电压,由于钛及钛合金一般采用短弧熔炼,电压一般为28~40 V。铸锭规格大,电流大则电压接近上限;铸锭规格小,电流小则电压接近下限。电压对于成分均匀性并无明显影响。

3.2.4 磁场

熔炼过程中,主要有以下两个电流磁场。

熔炼电流产生水平磁场,它对电弧的作用体现 在[13]:1) 对弧柱内的电子有一个径向的分拉力,具有将偏离电弧轴线运动的带电粒子拉回到轴线方向的趋势,有利于电弧稳定;2) 电弧受到水平磁场对其径向的分拉力,使弧柱断面被压缩,熔池的受热面积向中心部位集中,熔池边沿温度降低,从而增大了熔池径向冷却梯度,导致结晶条件的恶化,促使成分偏析、疏松及铸锭表面质量变差。

稳弧电流产生的纵向磁场,生产实践中,为了使电弧工作稳定,通常在坩埚外加稳弧线圈。稳弧线圈的作用是当通入直流或交流电时产生纵向磁场,减少边弧,稳定电弧。应选用合适的稳弧电流。电流过小稳弧作用不明显;电流过大则由于电弧被压缩得严重而导致熄灭,而且,过大的电流产生过大的磁场,使电弧过分聚集。因此,熔池的受热面积更加向中心部位集中,增大熔池深度。稳弧磁场一直沿着一个方向流动,凝固时,晶粒会在某一方向优先长大,对锻造不利。在实际生产中,可每隔几秒将直流电极转换或采用交流稳弧,补偿熔池固有的旋转[4]。

为了减小Fe元素偏析,熔炼过程中应减小熔炼电流和使用合适的稳弧电流。

3.2.5 热封顶

热封顶的目的是减少铸锭头部的缩孔和偏析,减少铸锭的切头量,提高铸锭的成品率。对于最后一次熔炼,当电极消耗到90%以上时,应逐级降低电流,使熔池凝固不形成有害的缺陷,并以较快的凝固速度及较大的温度梯度结晶,可防止Fe元素偏析[14]。

由于偏析产生的危险区域在等轴晶区,特别是缩孔周围。因此,采取合理的热封顶工艺及特殊的控制方法,可以有效地控制铸锭顶部的V型凝固区域的凝固方式,以缩小等轴晶区域,防止Fe元素发生 偏析[5]。

针对不同直径的铸锭采用不同的熔炼电流和熔炼电压,并选择合适的磁场以及热封顶等工艺3次熔炼,可以熔炼出性能及成分满足要求的d400 mm钛锭。

4 结论

1) 采用合适的原材料、布料方式、成分设计可以从源头控制Fe元素偏析;熔炼过程中针对不同的铸锭直径选择合适的电流和电压,合适的磁场以及热封顶等工艺3次熔炼,可以熔炼出性能及成分满足要求的d400 mm钛锭。

2) 钛锭上端面Fe元素含量为1.67%~1.76%,最大偏差不超过0.1%;钛锭底面Fe元素为1.70%~1.81%,最大偏差为0.11%;钛锭侧表面上、中、下Fe元素含量为1.61%~1.80%;整根钛锭Fe元素为1.61%~1.81%,最大偏差为0.2%,铸锭成分均匀性良好。

REFERENCES

[1] ZENG Wei-dong, ZHOU Yi-gang. Effect of beta flecks on mechanical properties of Ti-10V-2Fe-3Al alloy[J]. Materials Science and Engineering A, 1999, 260: 203-208.

[2] 俞汉清, 曾卫东, 胡鲜红, 周义刚. 钛合金中的β斑点及其研究方法[J]. 稀有金属材料与工程, 1995, 24(5): 23.

YU Han-qing, ZENG Wei-dong, HU Xian-hong, ZHOU Yi-gang. β-fleck in titanium and its investigation method[J]. Rare Metal Materials and Engineering, 1995, 24(5): 23.

[3] 周义刚, 俞汉清, 张恒毕, 徐好义. Ti-10V-2Fe-3Al合金中β斑点的研究[J]. 西北工业大学学报, 1990, 8(4): 425.

ZHOU Yi-gang, YU Han-qing, ZHANG Heng-bi, XU Hao-yi. On beta fleck of Ti-10V-2Fe-3Al alloy[J]. Journal of Northwestern Polytechnical University, 1990, 8(4): 425.

[4] 莫 畏. 钛[M]. 北京: 冶金工业出版社, 2008: 364-367.

MO Wei. Titanium[M]. Beijing: Metallurgical Industry Press, 2008: 364-367.

[5] 陈战乾, 高 颀, 刘 新, 张金波, 王韦琪, 王立平, 窦永庆. Ti-1023合金铸锭铁偏析控制[J]. 钛工业进展, 2003, 20(4/5): 57.

CHEN Zhan-qian, GAO Qi, LIU Xin, ZHANG Jin-bo, WANG Wei-qi, WANG Li-ping, DOU Yong-qing. Control of iron segregation in Ti-1023 titanium alloy[J]. Titanium Industry Progress, 2003, 20(4/5): 57.

[6] 安 红, 刘俊玲, 范丽颖. 真空自耗电弧炉熔炼钛铸锭的质量控制[J]. 世界有色金属, 2007(8): 26-27.

AN Hong, LIU Jun-ling, FAN Li-ying. Quality control in smelting titanium ingots in vacuum arc-melting furnace[J]. World Nonferrous Metals, 2007(8): 26-27.

[7] 孟祥炜, 薛祥义, 付宝全. Ti-10V-2Fe-3Al合金铸锭Fe元素宏观偏析行为[J]. 稀有金属材料与工程, 2008, 37(S3): 124.

MENG Xiang-wei, XUE Xiang-yi, FU Bao-quan. The macrosegregation behavior of Fe element in Ti-10V-2Fe-3Al ingot[J]. Rare Metal Materials and Engineering, 2008, 37(S3): 124.

[8] 鲍如强. Ti-1023合金热工艺、组织和性能研究[D]. 北京: 北京科技大学, 2004: 3.

BAO Ru-qiang. Research of thermal processing, structure and properties in Ti-1023 titanium alloy[D]. Beijing: University of Science & Technology Beijing, 2004: 3.

[9] 潘 峰, 张少卿. 热处理对铸造Ti-10V-2Fe-3Al合金微观组织的影响[J]. 稀有金属, 1989, 13(2): 159-162.

PAN Feng, ZHANG Shao-qing. Influence of heat treatment to as-cast Ti-10V-2Fe-3Al titanium alloy microstructure[J]. Chinese Journal of Rare Metals, 1989, 13(2): 159-162.

[10] 王 哲. 飞机结构应用Ti-1023钛合金应注意的问题[J]. 钛工业进展, 2000(3): 27.

WANG Zhe. Issues need to attention in Ti-1023 titanium alloy used in aeroplane structure[J]. Titanium Industry Progress, 2000(3): 27.

[11] 《中国航空材料手册》编辑委员会. 中国航空材料手册: 第4卷[M]. 北京: 中国标准出版社, 2002: 254.

China Aeronautical Materials Handbook. Edition Committee. China aeronautical materials handbook: The 4th Volume[M]. Beijing: Standards Press of China, 2002: 254.

[12] 杨 昭. 熔炼工艺对Ti-1023合金中Fe的均匀性影响[J]. 上海钢研, 2006(4): 11-12.

YANG Zhao. Influence of melting progress on the uniformity of iron in Ti-1023 alloy[J]. Journal of Shanghai Iron & Steel Research, 2006(4): 11-12.

[13] 邹 伟, 陈占乾, 高 颀, 郭廷中, 刘会英. VAR炉熔炼过程中磁场作用的分析[J]. 金属学报, 2002, 38(S): 331-333.

ZOU Wei, CHEN Zhan-qian, GAO Qi, GUO Ting-zhong, LIU Hui-ying. Analysis of magnetic field action in vacuum arc remelting[J]. Acta Metallurgica Sinica, 2002, 38(S): 331-333.

[14] 吕逸帆, 孟祥军, 李士凯. TB6合金β斑研究概述[J]. 稀有金属材料与工程, 2008, 37(S3): 546.

L? Yi-fan, MENG Xiang-jun, LI Shi-kai. An overview of β fleck in TB6 alloy[J]. Rare Metal Materials and Engineering, 2008, 37(S3): 546.

(编辑 陈卫萍)

通信作者:王孟光;E-mail:jzyfb@725.com.cn