文章编号:1004-0609(2008)08-1472-07

交流电压对AZ91D镁合金阳极氧化膜层的影响

王喜眉,朱立群

(北京航空航天大学 材料科学与工程学院,北京 100083)

摘 要:在含有硅酸钠和硅溶胶的氧化溶液体系中,利用工频交流电源对AZ91D镁合金材料表面进行阳极氧化处理,同时探讨氧化电压对膜层表面形貌、生长速率和耐腐蚀性能等的影响规律。结果表明:氧化过程存在一个明显的临界电压值(170 V),在电压大于170 V阳极氧化反应剧烈、氧化电流增大、试样表面出现弧光放电。当电压小于170 V时,镁合金表面则以均匀的桔黄色火花放电,获得的氧化膜层表面光滑、均匀、致密,而且膜层的生长速率和耐腐蚀性随着电压的增加而增大;当电压超过这个临界电压值时,获得的氧化膜层表面变得粗糙,其生长速率大幅提高,但膜层的耐腐蚀性能下降。

关键词:AZ91D镁合金;阳极氧化;电压;交流电源

中图分类号:TG 146.2; TG 178; TQ 153.6 文献标识码:A

Effect of AC voltage on anodic film of AZ91D magnesium alloy

WANG Xi-mei, ZHU Li-qun

(School of Materials Science and Engineering, Beihang University, Beijing 100083, China)

Abstract: The anodic films on AZ91D magnesium alloy were prepared in the electrolyte of Na2SiO3 and silica sol by AC sources. The effect of anodic voltage on the surface morphologies, growth rate and corrosion resistance of anodic films was investigated. The results show that the anodic reaction is rapid and the current increases quickly and the specimen’s surface is bestrewed with arc discharge when the anodic voltage exceeds 170 V. When the anodic voltage is less than 170 V, bisque sparks appear on the surface of magnesium alloy uniformly. The anodic films are smooth, uniformity and compact. Moreover, the growth rate and corrosion resistance of the anodic films is improved with increasing anodic voltage. When the anodic voltage is more than 170 V, the anodic films become coarse and their corrosion resistance is worse though their growth rate is extremely increased.

Key words: AZ91D magnesium alloy; anodic oxidation; voltage; AC power source

镁合金密度小,比强度和比刚度高,导电、导热性优良,易于回收,铸造、减振性能优良,在汽车、航空航天、电子、计算机等领域的应用越来越广泛[1?2]。但是镁合金的化学活性高,使用中镁合金器件表面极易受到腐蚀。因此,使用前必须对其表面进行防护处理,以提高镁合金表面的耐蚀性[3?4]。

在众多镁合金表面处理方法中[5],阳极氧化成膜技术具有一次成膜面积大、膜层与基体结合力好、膜层硬度高、膜层厚度易于控制、工艺操作简单,前处理工序少,性能价格比高,适宜于自动化生产等优点,因而成为镁合金工业化应用最广的表面处理方法[6?8]。

在镁合金的阳极氧化过程中,电参数也从某种程度上对氧化过程和膜层性能起着决定性的作用。因此,电参数也成为镁合金表面阳极氧化过程研究的热点之一[9?11]。目前,镁合金的阳极氧化研究多采用恒定电流密度。在电参数方面研究较多也是电流密度对膜层性能方面的影响[12];同时对频率、占空比的影响方面也有一些相关研究[13]。但是这些研究大多是采用微弧氧化特种电源,这种电源虽然具有电压电流值高、可稳压稳流、频率和占空比可调等优点,但是其价格昂贵、电源自身技术要求高、用于工业生产后成本高以及能量消耗高;而一般的工频交流电源,其本身电源技术要求较低、价格便宜、能耗低、用于工业生产成本低,适合于工业生产。因此,研究工频交流电源下镁合金阳极氧化的电参数具有一定的实际应用价值。

本文作者在碱性环保阳极氧化溶液的开发方面,进行了大量的研究[14?17];研制的硅酸钠+硅溶胶电解液体系,既环保膜层性能又好,有望用于工业生产。但是,前期主要采用直流电源、恒定电流密度的方式,研究了硅溶胶、硅酸钠对氧化成膜过程及氧化膜层性能的影响。从节约成本、降低能耗的角度,有必要研究工频交流电源下电参数对镁合金阳极氧化膜层性能的影响。因此,本文作者采用前期研究优选出的硅酸钠+硅溶胶电解液,采用工频交流电源对镁合金表面进行100~200 V电压范围内的阳极氧化处理,考察氧化过程中电压对氧化膜层性能的影响,为今后的工业应用打下基础。

1 实验

1.1 实验材料及设备

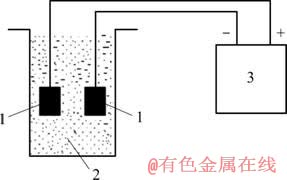

实验材料选用AZ91D镁合金,其化学成分为(质量分数):Al 8.5%~9.5%,Zn 0.5%~0.9%,Mn 0.17%~0.27%,Cu<0.01%,Ni<0.001%,Si<0.02%,Fe<0.004%,余量为镁。试样尺寸为20 mm×20 mm×5 mm,试样用铝导线连接,暴露的工作面积为20 mm×20 mm,其余部分及试样与铝导线的连接处均用氯丁橡胶密封。氧化前,试样均经180~800#水磨砂纸逐次打磨、自来水冲洗、蒸馏水冲洗、热风吹干等处理。镁合金试样阳极氧化的示意图如图1所示。

图1 阳极氧化装置示意图

Fig.1 Schematic diagram of anodic oxidation equipment: 1?Magnesium sample; 2?Electrolyte; 3?AC power apply

1.2 氧化膜层的制备

氧化膜制备工艺流程如下:前处理→阳极氧化→冷水漂洗→热风吹干。阳极氧化溶液为1 mol/L的硅酸钠+10%硅溶胶组成,溶液中不含铬、氟、磷及其它重金属离子等,属于环保型溶液。硅溶胶的制备参见文献[16]。采用由调压器控制电压的工频交流电源对镁合金表面进行恒电压氧化,阳、阴极均为AZ91D镁合金试样,温度为室温。接通电源后,缓慢升高电压,当电压升到100 V开始计时,继续缓慢升高电压大约至120 V左右时,试样表面出现密集均匀的白色细小火花放电现象,并有细微的爆破声。保持该电压几秒钟,待火花稀疏时,再缓慢升高电压直至表面重新出现密集均匀的放电火花。重复上述过程,当电压增加至设定置时,停止增大电压,直至规定的氧化时间,氧化时间为10 min。一般开始计时后,在2~3 min内可将电压加至设定值。

1.3 膜层测试

阳极氧化前后试样的质量采用分析天平(Sartorius,精度0.1 mg)称量3次取平均值;氧化膜层的厚度采用西德FISCHER公司生产的E110B涡流测厚仪,每个试样测量10次,去掉最大值和最小值后取平均值作为膜层的最终厚度;采用日立S?530型扫描电镜和配置的Link ISIS能谱仪观察膜层的表面形貌和分析膜层表面成分。

利用CHI 600 A电化学工作站,通过测试氧化膜层在5%NaCl溶液中的交流阻抗和动电位极化曲线来评价膜层的耐腐蚀性能。电化学测试采用三电极体系,工作电极为经电化学氧化后的AZ91D镁合金试样及AZ91D基材,其有效暴露面积为1 cm2,辅助电极为铂片,参比电极为饱和甘汞电极。交流阻抗测试频率范围为1×105~0.01 Hz,所用正弦激励信号幅值为10 mV,测试电位为工作电极的开路电位。动电位极化曲线测试的扫描速度为2 mV/s。

2 结果与讨论

2.1 电压对氧化膜层表面形貌和成分的影响

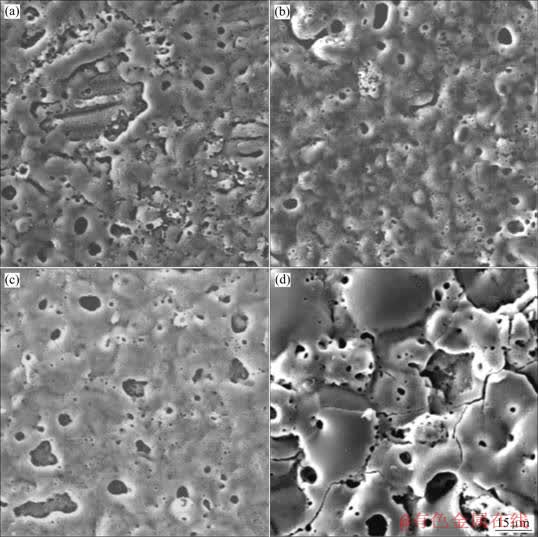

图2所示为AZ91D镁合金经不同电压氧化处理后膜层的表面形貌。氧化膜层表面是由一个个微小的、类似于“火山锥”状的物质相互结合所构成的。每个小“火山锥”中心都有一个小孔,这些小孔是溶液与基体反应的通道,同时也是火花放电产生时,熔融态的氧化物喷发出的通道。在微区火花放电作用下,膜层以小孔为中心,通过生成的氧化物不断熔化,迅速凝固并相互结合而增厚。

图2 不同电压制备的氧化膜层表面SEM形貌

Fig.2 SEM morphologies of anodic films on AZ91D magnesium alloys prepared at different voltages: (a) 130 V; (b) 150 V; (c) 170 V; (d) 178 V

由图2可知,处理电压为130、150、170 V时,氧化膜层的表面形貌与电压为178 V的氧化膜层表面形貌差异较大,178 V电压对应的膜层表面粗糙、氧化物块要大、孔洞直径变大且出现一些微裂纹。其膜层表面形貌的差异可由氧化过程中火花放电的现象来解释。

当最终的氧化电压在170 V及以下时,按1.2节的方式,当电压升高到设定值后,继续反应直到规定时间,这一过程中试样表面的火花数量随着反应的进行逐渐减少;氧化处理的后期,试样表面只有少数几处地方有火花放电现象,这时膜层生长变得很缓慢,膜层的单位面积增重及厚度也基本不再变化(见2.2节中图3所示的氧化前后试样质量增量—时间曲线和图4所示的厚度—时间曲线)。而最终电压在170 V以上时,当按1.2节逐步升高电压到设定值(如178 V,180 V)后,刚开始的2 min内其氧化过程及火花现象与170 V时没有太大的区别,而继续反应2~3 min后,试样表面的反应突然变得非常剧烈、整个试样表面布满火花且持续放电(称为弧光放电)、回路中电流急骤增大,从而会导致溶液沸腾。通过肉眼观察不同电压下氧化膜层的表面形貌可知:在氧化过程中没有发生弧光放电的试样表面膜层比产生弧光放电的膜层要光滑、均匀、致密些。而且图2不同电压下获得的膜层表面微观形貌也与宏观形貌对应。因此,说明在1 mol/L的硅酸钠+10%硅溶胶溶液中,当氧化电压超过170 V后,在镁合金表面产生的这种弧光放电对氧化膜层的表面形貌有一定的破坏作用。

根据氧化过程中,试样表面火花放电及电流急骤增大的现象,可以说存在一个临界电压,当处理电压超过此临界电压值时,反应进行一段时间后会产生弧光放电,导致电流急骤增大、反应加剧、膜层表面粗糙度和均匀度变差。

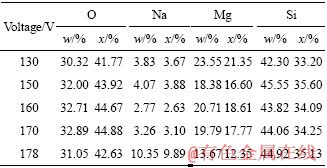

表1所列为经不同电压阳极氧化后AZ91D镁合金试样表面的能谱分析结果。结果显示:阳极氧化膜层主要由含镁、硅的氧化物组成。阳极氧化膜层中测到的Na元素,可能是由于多孔结构的阳极氧化膜孔隙中吸附了阳极氧化溶液中的钠离子所引起的。由表1还可知:随着处理电压的升高,氧化膜层表面氧和硅元素的含量基本上不变;而Na和Mg元素的含量,则当电压在130~170 V范围内时基本不变,当电压为178 V时Na元素的含量增加而Mg的含量则相对减少。这也说明临界电压的存在,且超过临界电压后的弧光放电对膜层表面成分也有一定的影响,即膜层表面粗糙化后,导致膜层孔隙中吸附的钠离子增多,而对镁合金有保护作用的含镁化合物的量减少。

表1 阳极氧化膜层表面的化学成分

Tabel 1 Chemical composition of surface of anodic films

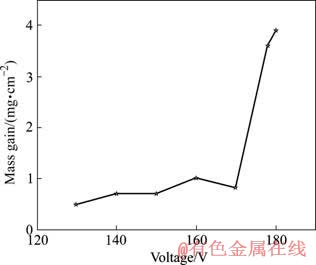

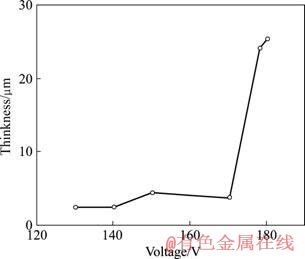

2.2 电压对氧化膜层生长速率的影响

图3和图4所示为阳极氧化处理10 min后,氧化膜层单位面积质量增量、氧化膜层厚度与处理电压的关系。可以看出,随着阳极氧化电压的增加,氧化膜单位面积质量增量和厚度基本上呈增加趋势,也即氧化膜的生长速率与电压成正比。而且,也证实了2.1节中所分析的确实存在着一个电压临界值,使得氧化膜层的单位面积质量增量和膜层厚度不是呈单一线性增加的。在临界电压以下时(如130 V到170 V),氧化膜层的单位面积质量增量的增加量和厚度随着电压升高而小幅度增加。而一旦电压超过临界电压值(如170 V)后,氧化膜层的单位面积质量增量的增加量和厚度则大幅度提高。即存在一临界电压170 V,使得氧化膜层的生长速率迅速增加。

图3 氧化膜层单位面积质量增量与电压的关系

Fig.3 Relationship between mass gain and voltage for anodic films

图4 氧化膜层厚度与电压的关系

Fig.4 Relationship between thickness and voltage for anodic films

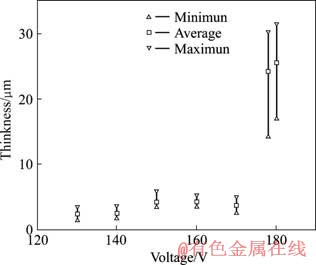

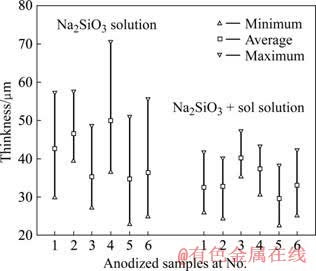

不同电压处理后的AZ91D镁合金表面氧化膜的厚度分布如图5所示。当氧化电压在130~170 V范围内时,氧化膜层的厚度分散度较小(即厚度最大值和最小值相差不大),说明膜层表面比较均匀;而当氧化电压超过170 V后,氧化膜层的厚度大幅增加的同时,其厚度的分散度也明显变大,说明膜层表面变得不均匀、粗糙。与图2中试样的表面形貌一致。

图5 氧化膜层表面厚度分布与处理电压的关系

Fig.5 Relationship between thickness distribution and voltage for anodic films

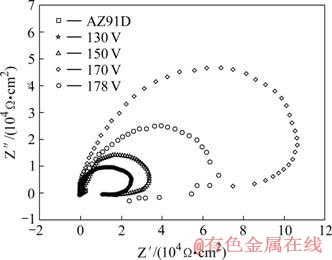

2.3 电压对氧化膜层耐腐蚀性的影响

图6所示为AZ91D镁合金试样及其在不同电压阳极氧化处理后的试样在5%NaCl中的电化学阻抗谱。经不同电压阳极氧化处理后,膜层的容抗弧的直径均明显增大,传递电阻提高,耐腐蚀性能得到改善。在临界电压以下时,阳极氧化膜的容抗弧直径随着电压的升高而增大,而当处理电压高于临界电压后,氧化膜的容抗弧直径反而有所减小。

图6 AZ91D镁合金及不同电压阳极氧化处理试样在5%NaCl中的交流阻抗谱

Fig.6 EIS patterns of AZ91D magnesium alloys and anodic films treated at different voltages in 5% NaCl solutions

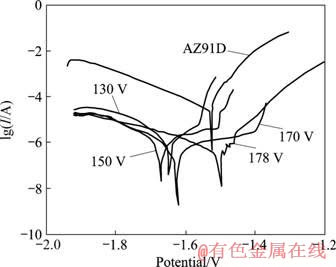

图7所示为AZ91D镁合金试样及其不同电压阳极氧化处理后试样的动电位极化曲线。经不同电压阳极氧化处理后的镁合金试样,尽管130~170 V的氧化膜层的腐蚀电位比AZ91D空白试样的腐蚀电位(?1.528 V)负,但其腐蚀电流均呈数量级降低,说明阳极氧化膜层提高了镁合金表面的耐腐蚀性能。另外,电压为178 V时氧化膜层的腐蚀电流比电压为170 V时氧化膜层的腐蚀电流有所增加。

图7 AZ91D镁合金及不同电压阳极氧化处理试样在5%NaCl中的动电位极化曲线

Fig.7 Potentiodynamic polarization curves of AZ91D magnesium alloys and anodic films treated at different voltages in 5% NaCl solutions

结合图4可知,氧化膜层耐腐蚀性能的提高并不严格与氧化膜的厚度增加成正比。当电压低于170 V时,镁合金表面主要形成致密的微火花氧化膜层;在此临界电压以下时,膜层厚度随着电压的增加而小幅度增加,耐腐蚀性也随着电压的增加而相应提高。当电压高于临界电压170 V后,镁合金电极上的当前处理电压超出表面生成膜层所需的击穿电压值较多,因此,击穿放电能在整个试样表面长期进行,表现为在镁合金表面长时间的火花放电。这种在镁合金整个表面上的长时间放电,使得镁合金表面上的放电通道数量大量增加而且放电通道保持的时间较长,从而导致回路中电流迅速增长,溶液和膜层内部的温度均升高,新形成的氧化膜层在溶液中的冷却速度降低,导致氧化膜层变得粗糙、孔隙大且有微裂纹出现。因此,氧化电压超过临界电压170 V后,镁合金氧化膜层厚度大幅增加,但氧化膜层的微观缺陷增多(见图2中178 V电压处理的试样表面形貌),因而膜层的耐腐蚀性反而下降。另外,针对临界电压产生弧光放电这一现象,在单独的硅酸钠溶液(不加硅溶胶)中也进行了相关的实验研究;结果表明在硅酸钠溶液中也存在一个临界的氧化电压值105 V,在此临界电压时试样表面的反应变得剧烈、电流迅速增大、在整个镁合金试样的表面产生弧光放电,获得的氧化膜层表面比没有弧光放电的表面要粗糙。因此,可推断出超过临界电压后出现的弧光放电可大大增加膜层的厚度、破坏膜层的表面的光滑、致密性、降低膜层表面的耐腐蚀性。

2.4 硅溶胶对弧光放电临界电压及膜层厚度和均匀性的影响

在1 mol/L硅酸钠溶液中,产生弧光放电的临界电压值为105 V;而在1 mol/L硅酸钠+10%硅溶胶溶液中,氧化时产生弧光放电的临界电压值为170 V。硅溶胶加入后,氧化过程中镁合金表面的火花现象也不一样,在硅酸钠溶液中的火花为桔黄色且尺寸较大;而在添加了硅溶胶的溶液中,表面的火花细小、颜色偏白,比在单独硅酸钠溶液中试样表面的火花尺寸要小的多。

当产生弧光放电时,在硅酸钠溶液中氧化电流会迅速升高至1.4~1.8 A/cm2;而在添加硅溶胶的溶液中氧化电流只在0.4~0.7 A/cm2,但反应也同样较剧烈且溶液会沸腾。当电压在临界电压值以下时,硅溶胶+硅酸钠溶液中的氧化电流值整体上要比硅酸钠溶液中的氧化电流值低。

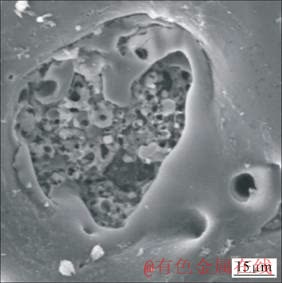

图8所示为在有无硅溶胶的溶液中产生弧光放电条件下获得的氧化膜层厚度分布(6个平行试样、氧化10 min)。图9所示为在1 mol/L硅酸钠溶液中弧光放电条件下(氧化电压105 V),在镁合金表面获得的氧化膜层的表面形貌。由图8、9和图2(d)可知,在硅酸钠溶液中氧化膜层平均厚度要稍微比加硅溶胶后的氧化膜层厚,但是硅酸钠溶液中氧化膜层表面厚度的分散度大,氧化膜层不如加硅溶胶后的氧化膜层表面均匀、光滑。

图8 有无硅溶胶时弧光放电下获得的氧化膜层的表面厚度分布

Fig.8 Thickness distribution of anodic films formed by arc-discharge in electrolytes containing sol or not

图9 硅酸钠溶液中弧光放电下获得的氧化膜层的表面形貌

Fig.9 Surface morphology of anodic film formed by arc-discharge in 1.0 mol/L Na2SiO3

硅溶胶的加入使得氧化过程中产生弧光放电的临界电压值增加、氧化过程中火花变得更细小致密、膜层表面更均匀,但膜层厚度略减小。硅溶胶加入后,溶液的电导率减小,从而发生弧光放电的电压值增大;这与在硅酸钠溶液中添加溶胶后,会使火花放电的击穿电压值增加的原理相同[15?16]。在氧化过程中,硅溶胶粒子吸附在试样表面,能有效地填充火花放电击穿后在试样表面留下的孔洞,使得试样表面更均匀,因而会使随后的火花击穿在试样表面更均匀地进行、火花尺寸也较小,从而得到比在硅酸钠溶液中更均匀的氧化膜层。在整个阳极氧化过程中,添加硅溶胶的硅酸钠溶液中,其氧化电流比较小,膜层的生长速度可能会变小,因而添加了硅溶胶后获得的氧化膜层厚度较小。

3 结论

1) 在1 mol/L的硅酸钠+10%硅溶胶的溶液体系中,采用工频交流电源进行镁合金表面阳极氧化时,存在一个临界电压值,在本实验条件下为170 V。当电压超过此临界电压时,反应加剧、回路中电流急骤增大、试样整个表面产生弧光放电;导致膜层的表面变得粗糙、孔洞直径变大、表面微裂纹增多。

2) 随着电压的升高,氧化膜层单位面积增重和厚度均增加,即氧化膜生长速率增大。尤其当两极间的电压超过临界电压170 V时,膜层的生长速率会大幅度提高。

3) 经130~170 V电压处理后的镁合金表面氧化膜层的耐蚀性均大大提高。在临界电压170 V以下时,随着电压的增加,膜层的容抗弧直径增大、传递电阻提高、腐蚀电流减小,耐蚀性提高;当电压高于临界电压时,膜层的容抗弧直径反而有所减小、腐蚀电流也小幅增加,膜层的耐蚀性下降。

4) 在单独的硅酸钠溶液中氧化时,其产生弧光放电的临界电压值为105 V;硅溶胶的加入会提高弧光放电产生的临界电压值、获得更均匀的氧化膜层。

REFERENCES

[1] 师昌绪, 李恒德, 王淀佐, 李依依, 左铁镛. 加速我国金属镁工业发展的建议[J]. 材料导报, 2001, 15(4): 5?6.

SHI Chang-xu, LI Heng-de, WANG Dian-zuo, LI Yi-yi, ZUO Tie-yong. A proposal on accelerating development of metallic magnesium industry in China[J]. Materials Review, 2001, 15(4): 5?6.

[2] 袁序弟. 镁合金在汽车工业的应用前景[J]. 汽车技术, 2002(3): 1?3.

YUAN Xu-di. Prospects of magnesium alloy used for automotive industry[J]. Automobile Science and Technology, 2002(3): 1?3.

[3] 李卫平, 朱立群. 镁及其合金表面防护性涂层国外研究进展[J]. 材料保护, 2005, 38(2): 41?46.

LI Wei-ping, ZHU Li-qun. Recent progress in research of protective coatings on magnesium and its alloys[J]. Materials Protection, 2005, 38(2): 41?46.

[4] 余 刚, 刘跃龙, 李 瑛, 叶立元, 郭小华, 赵 亮. Mg合金的腐蚀与防护[J]. 中国有色金属学报, 2002, 12(6): 1087?1098.

YU Gang, LIU Yue-long, LI Ying, YE Li-yuan, GUO Xiao-hua, ZHAO Liang. Corrosion and protection of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1087?1098.

[5] SONG Guang-ling. Recent progress in corrosion and protection of magnesium alloys[J]. Advanced Engineering Materials, 2005, 7(7): 563?586.

[6] 张荣发, 单大勇, 韩恩厚, 曾志良. 镁合金阳极氧化的研究进展与展望[J]. 中国有色金属学报, 2006, 16(7): 1136?1147.

ZHANG Rong-fa, SHAN Da-yong, HAN En-hou, ZENG Zhi-liang. Status and prospect of anodization on magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1136?1147.

[7] HSIAO H Y, TSUNG H C, TSAI W T. Anodization of AZ91D magnesium alloy in silicate-containing electrolytes[J]. Surface & Coatings Technology, 2005, 199: 127?134.

[8] MIZUTANI Y, KIM S J, ICHINO R, OKIDO M. Anodizing of Mg alloys in alkaline solutions[J]. Surface and Coatings Technology, 2003, 169/170: 143?146.

[9] 张荣发, 李明升, 龙小丽, 何向明, 单大勇, 韩恩厚. 电参数对镁合金阳极氧化膜性能影响的研究进展[J]. 中国有色金属学报, 2006, 16(11): 1829?1837.

ZHANG Rong-fa, LI Ming-sheng, LONG Xiao-li, HE Xiang-ming, SHAN Da-yong, HAN En-hou. Research progress in effects of electric parameters on properties of anodic coatings on magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1829?1837.

[10] VERDIER S, BOINET M, MAXIMOVITCH S, DALARD F. Formation, structure and composition of anodic films on AM60 magnesium alloy obtained by DC plasma anodising[J]. Corrosion Science, 2005, 47: 1429?1444.

[11] 邓姝皓, 易丹青, 娄 嘉, 周玲伶. 镁合金脉冲阳极氧化工艺[J]. 电镀与涂饰, 2006, 25(2): 32?35.

DENG Shu-hao, YI Dan-qing, LOU Jia, ZHOU Ling-ling. Pulsed anodizing process of magnesium alloys[J]. Electroplating & Finishing, 2006, 25(2): 32?35.

[12] SHI Zhi-ming, SONG Guang-ling, ATRENS A. Influence of anodising current on the corrosion resistance of anodised AZ91D magnesium alloy[J]. Corrosion Science, 2006, 48: 1939?1959.

[13] 郝建民, 陈 宏, 张荣军. 电参数对镁合金微弧氧化陶瓷层致密性和电化学阻抗的影响[J]. 腐蚀与防护, 2003, 24(6): 249?251.

HAO Jian-min, CHEN Hong, ZHANG Rong-jun. Effects of electric parameters on density and electrochemical impedance of ceramic layer made by micro-arc oxidization on magnesium alloy[J]. Corrosion & Protection, 2003, 24(6): 249?251.

[14] 朱立群, 刘慧丛. 溶胶成分对镁合金阳极氧化膜层的影响研究[J]. 功能材料, 2005, 36(6): 923?926.

ZHU Li-qun, LIU Hui-cong. The effect of sol ingredient to anodic oxidation film on magnesium alloys[J]. Journal of Functional Materials, 2005, 36(6): 923?926.

[15] LI Wei-ping, ZHU Li-qun, LIU Hui-cong. Effects of silicate concentration on anodic films formed on AZ91D magnesium alloy in solution containing silica sol[J]. Surface and Coatings Technology, 2006, 201(6): 2505?2511.

[16] LI Wei-ping, ZHU Li-qun, LI Yi-hong. Electrochemical oxidation characteristic of AZ91D magnesium alloy under the action of silica sol[J]. Surface and Coatings Technology, 2006, 201(3-4): 1085?1092.

[17] LI Wei-ping, ZHU Li-qun, LI Yi-hong, ZHAO Bo. Growth characterization of anodic film on AZ91D magnesium alloy in an electrolyte of Na2SiO3 and KF[J]. Journal of University of Science and Technology Beijing: Mineral, Metallurgy, Material, 2006, 13(5): 450?455.

收稿日期:2007-11-20;修订日期:2008-03-18

通讯作者:王喜眉,博士研究生;电话:010-82317113;E-mail: wangximei126@126.com

(编辑 陈爱华)