DOI: 10.11817/j.issn.1672-7207.2017.03.011

多方向耦合振动连轧机再生颤振建模及应用

刘晓潺,臧勇,郜志英,曾令强

(北京科技大学 机械工程学院,北京,100083)

摘要:为了研究连轧机的再生颤振机理,首先综合考虑轧制过程中的轧辊弹性压扁和轧件加工硬化效应的影响以及轧机工作辊的振动所造成的轧制辊缝在垂直和水平方向的变化,建立新的动态轧制过程模型,将该模型与多方向耦合振动的轧机结构模型结合,建立单机架轧机振动模型,而后对机架间的张力耦合和轧件厚波动在机架间的有时滞传递进行表征,建立新的多方向振动耦合的连轧机再生颤振系统模型。以所建立的模型为基础,根据劳斯判据和积分值检验法分别对典型五机架冷连轧机每个单机架系统和多机架耦合的再生颤振系统进行稳定性分析。研究结果表明:所建立的再生颤振模型正确。

关键词:动态轧制过程模型;连轧机;再生颤振;时滞

中图分类号:TG331;TH113 文献标志码:A 文章编号:1672-7207(2017)03-0635-09

Multidirectional regenerative chatter model of tandem rolling mills and its application

LIU Xiaochan, ZANG Yong, GAO Zhiying, ZENG Lingqiang

(School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: To explore the regenerative chatter mechanism in rolling, a new dynamic rolling process model was established firstly. The new model considers the work roll flattening effect, the rolled piece working hardening effect and the roll gap variation generated in vertical and horizontal direction by the work roll vibration. A single stand vibration model was built by coupling the new dynamic rolling process model with multi direction mill stand model. And then the interaction factors between adjacent rolling mill stands, namely the inter-stand tension variation and strip gauge variation passed onto the next stand after a delay time, were represented in functions. Finally, a new multi direction multi stand regenerative chatter model was built. Based on the models, stabilities of each single stand vibration model and multi stand regenerative chatter model were analyzed using the Routh criterion and the integral criterion respectively. The results prove that the proposed model is correct.

Key words: dynamic rolling process model; tandem rolling mills; regenerative chatter; time delay

轧机振动严重制约了轧制速度的提高,导致轧制产品质量下降,严重时甚至造成断带或者轧制设备被损坏,是目前国内外研究的热点之一。轧机的振动模态多种多样,振动机理复杂。轧机振动的形式主要包括轧机机架和辊系的垂直振动、传动系统的扭转振动和辊系的水平振动等[1-2]。轧机的自激振动机理有轧制过程和轧机结构之间的相互作用,由轧制张力波动所造成的负阻尼效应,轧机不同振动模态之间的耦合,以及相邻机架之间的耦合作用所导致的再生颤振等[2]。其中轧机的再生颤振机理最复杂。轧机的再生颤振是指上一时段本机架轧机的振动再次引起该轧机的振动。轧机振动会在机架之间扩散,1个机架振动会带动整个连轧机产生振动。在对宝钢2030冷连轧机组的振动测试中,曾发现第四机架最先开始振动而后带动其他机架一起振动的现象[1]。HU等[3-5]建立了连轧机再生颤振模型,对连轧机的再生颤振机理进行了解释,表明机架间的张力耦合和轧件厚度波动在机架间的有时滞传递是导致连轧机再生颤振的重要原因。KIMURA等[6]建立了仅考虑垂直方向振动的五自由度的五机架冷连轧机再生颤振模型,其研究结果表明第五机架存在1个最优的摩擦因数使得连轧机系统稳定性达到最佳。NIROOMAND等[7]引入波的传播理论对张力波动在机架间的传递进行了表征,通过仿真和实验证明该方法更能准确地描述张力波动在机架间的传递。但是,HU等[8]在建立连轧机再生颤振模型时所用的动态轧制过程模型忽略了轧制过程中轧件的加工硬化和轧辊的弹性压扁效应,而ZHAO等[4]建立的连轧机再生颤振模型只考虑了轧机在垂直方向的振动,没有考虑轧机在水平和扭转方向的振动。在冷轧过程中轧件的加工硬化和轧辊的弹性压扁效应不可忽略,轧机不同方向振动之间也存在明显的耦合作用[9]。为此,本文作者首先综合考虑轧件的加工硬化和轧辊的弹性以及轧辊振动引起的轧制辊缝在垂直和水平方向的变化,建立了1个新的动态轧制过程模型,然后将该动态轧制过程模型和多方向耦合振动的轧机结构模型耦合,建立单机架轧机振动模型,在单机架轧机振动模型的基础上,对机架间的耦合因素进行表征,建立新的多方向耦合振动的连轧机再生颤振模型,最后以典型冷连轧机参数为例,对模型进行验证,以便为后续对连轧机振动机理的研究提供参考。

1 动态轧制过程模型的建立

1.1 轧制变形区几何特征

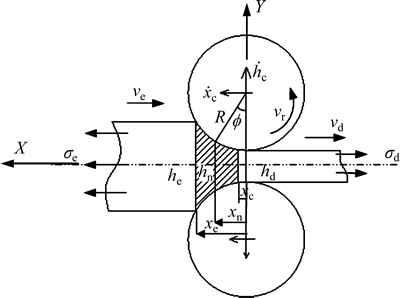

当轧辊发生垂直和水平方向的振动时,轧制变形区动态几何关系如图1所示,其中: 为轧件入口张应力;

为轧件入口张应力; 为轧件出口张应力;ve为轧件的入口速度;vr为轧辊的线速度;vd为轧件的出口速度;he为入口轧件厚度;hn为中性点处轧件厚度;hd为出口轧件厚度;hc为出口辊缝高度;xc为轧件水平出口位置,以轧件中心线为X轴,上下轧辊的中心连线为Y轴;

为轧件出口张应力;ve为轧件的入口速度;vr为轧辊的线速度;vd为轧件的出口速度;he为入口轧件厚度;hn为中性点处轧件厚度;hd为出口轧件厚度;hc为出口辊缝高度;xc为轧件水平出口位置,以轧件中心线为X轴,上下轧辊的中心连线为Y轴; 为轧制接触弧上任意一点与轧辊中心的连线和Y轴的夹角。

为轧制接触弧上任意一点与轧辊中心的连线和Y轴的夹角。

图1 动态轧制辊缝

Fig. 1 Dynamic roll gap

将轧制接触弧看作抛物线,沿接触弧任意水平位置的轧件高度如下:

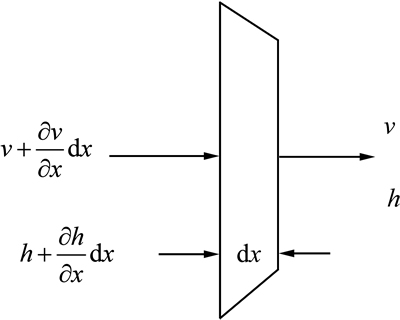

稳态金属轧制过程遵循秒流量相等原则,即 。但是,在轧机振动的情况下,进入轧制区的金属体积处于不断变动之中,需要对秒流量方程进行修正。轧制变形区单位轧件宽度的体积微元如图2所示,其中:v为任意位置轧件的水平金属流动速度;h为任意位置的轧件截面高度。单位时间单位轧件宽度体积微元内金属体积的变化为

。但是,在轧机振动的情况下,进入轧制区的金属体积处于不断变动之中,需要对秒流量方程进行修正。轧制变形区单位轧件宽度的体积微元如图2所示,其中:v为任意位置轧件的水平金属流动速度;h为任意位置的轧件截面高度。单位时间单位轧件宽度体积微元内金属体积的变化为

图2 轧制变形区内的体积微元

Fig. 2 Volume element in roll gap

将该体积微元截面视为梯形,其体积为

体积V对时间求偏导,忽略二阶项,可得

将式(4)代入式(2),忽略二阶项,可得

对式(1)两边求关于t的偏导,可得

对式(1)两边求关于x的偏导,可得

将式(6)和(7)代入式(5),以入口位置的轧件速度ve和入口位置轧件厚度he为初始条件,求解得到沿轧制区任意水平位置x的水平轧制速度:

将式(1)代入式(8),即得修正后的秒流量相等方程:

此外,由于轧制压力的作用,轧制过程中存在轧辊的弹性压扁,引入Hitchcock的轧辊弹性压扁模型,变形后的轧辊等效半径可以表示为

式中:Rw为轧辊原始半径; 为轧辊材料泊松比;p为接触区单位轧件宽度的轧制压力;r为压下量;Ew为轧辊材料的弹性模量。根据轧辊半径和轧制压力之间的关系,进行收敛运算,就可以得到动态轧制力下的轧辊压扁等效半径。

为轧辊材料泊松比;p为接触区单位轧件宽度的轧制压力;r为压下量;Ew为轧辊材料的弹性模量。根据轧辊半径和轧制压力之间的关系,进行收敛运算,就可以得到动态轧制力下的轧辊压扁等效半径。

1.2 轧件的出入口位置和速度

在中性点xn处,轧辊线速度近似等于轧制水平速度,根据式(8)得

对上式进行整理,得到轧件的入口速度ve:

同样,可以得到轧件出口速度vd:

根据式(1),得到轧件的入口位置xe:

为轧件出口位置和轧辊中心的连线与Y轴的夹角,因为该角度较小,满足以下关系:

为轧件出口位置和轧辊中心的连线与Y轴的夹角,因为该角度较小,满足以下关系:

对式(15)进行整理,得到vd并将其代入式(13),化简可得:

因为 远大于

远大于 ,对式(16)进行化简可得出口位置为

,对式(16)进行化简可得出口位置为

1.3 轧制力和轧制扭矩计算

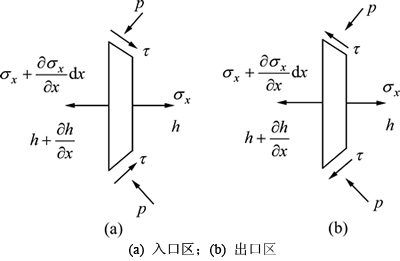

在均匀变形假设条件下,在变形区取任意微元段,轧制入口区和出口区的应力关系如图3所示,变形区轧制力平衡方程如式(18)所示,其中出口区用下侧的正号,入口区用上侧的负号。

忽略二阶量 ,并据

,并据 ,可得:

,可得:

在冷轧过程中轧件的加工硬化不可忽略,轧件变形抗力随轧件应变的变化如下:

图3 入口区和出口区的轧制压力分布切片法分析

Fig. 3 Slab analysis on a volume element of entry region and exit region

其中: ,A和n为与材料相关的系数,可以通过实验测定,对于连轧机h 0是指第1机架的入口轧件厚度。将塑性变形条件式

,A和n为与材料相关的系数,可以通过实验测定,对于连轧机h 0是指第1机架的入口轧件厚度。将塑性变形条件式 及库仑摩擦模型

及库仑摩擦模型 代入式(19),可得

代入式(19),可得

引入轧件的加工硬化后,增加了式(21)的求解难度。从入口区到出口区,h持续减小,kf持续增加。因此假设hkf是一个常数,忽略第3项。但若直接将第3项忽略,则无法考虑到加工硬化对轧制力的影响,因此,在忽略第3项后,方程两端同时除以hkf,得到式(22)。根据文献[10],忽略第3项后,轧件厚度越小,根据式(22)得到的单位轧制压力分布与根据卡尔曼方程得到的轧制压力分布越接近。因此,对于冷轧薄板带材时,该假设成立。

方程(22)的边界条件为

可以得到入口区单位轧制压力pe和出口区单位轧制压力pd为:

式中:

在中性点处, ,由此得到轧制区中性点位置:

,由此得到轧制区中性点位置:

沿轧件和轧辊的接触弧积分,得到垂直方向的轧制力F v、轧制扭矩M和水平方向的轧制力Fh:

因为 ,对式(30)进行化简得到:

,对式(30)进行化简得到:

1.4 轧制力能参数增量模型

轧制过程中的各种参数波动或者外界扰动会造成轧制力波动,轧制力的波动是造成轧机振动的直接原因。为了简化计算,对轧制力能参数的变化量做线性化处理。将轧制力能参数对轧制工艺参数进行泰勒级数展开,并取其一阶小量。轧件的入口速度ve、出口速度vd、垂直方向轧制力Fv、水平方向轧制力Fh以及轧制扭矩M随辊缝波动量的一阶泰勒展开式可表示为

式中: 为yi对rj偏导的稳态值;rj为

为yi对rj偏导的稳态值;rj为 中的元素。

中的元素。

综上得到动态轧制过程模型如下:

2 连轧机再生颤振模型的建立

2.1 单机架轧机振动模型的建立

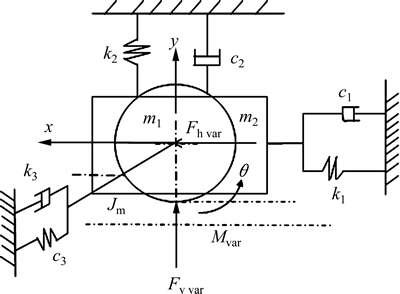

轧机振动是轧制过程和轧机结构相互作用的结果,选择合适的轧机结构模型与动态轧制过程模型相互耦合才能建立合理的轧机振动系统模型。将轧机机架简化为如图4所示的弹簧质量块模型。其中:m1为上工作辊的等效质量;k1为由工作辊偏移距产生的上支承辊系对上工作辊的水平等效刚度;c1为由工作辊偏移距产生的上支承辊系对上工作辊的水平阻尼;m2为集中于上工作辊中心的上部机架和上部辊系的等效质量;k2为机架上立柱和横梁的等效刚度;c2为机架立柱及上横梁的阻尼;Jm为上工作辊的等效转动惯量;k3为上工作辊及其传动系统的等效扭转刚度;c3为上主传动系统的阻尼系数[9]。

单机架轧机的振动模型如下:

图4 轧机结构模型

Fig. 4 Mill stand model

式中:w为轧件宽度。忽略轧件宽展,在轧制过程中轧件宽度不变。

2.2 多机架轧机再生颤振模型的建立

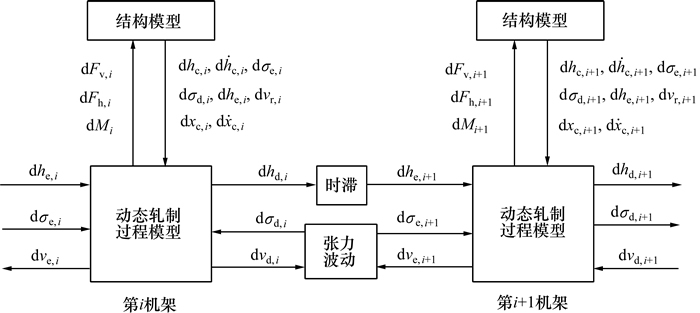

连轧机相邻机架间的关系表征如图5所示,相邻机架通过轧件张力和厚度波动在机架间有时滞传递耦合。机架间的张力波动与速度波动满足以下关系[4]:

图5 连轧机相邻机架间的关系表征

Fig. 5 Relationship between adjacent stands

其中:E为轧件材料的弹性模量;i为机架号; 为第

为第 机架与第i机架之间的距离;

机架与第i机架之间的距离; 为第i机架与第i+1机架之间的距离。

为第i机架与第i+1机架之间的距离。

在连轧过程中,上游机架振动所产生的轧件厚度波动在机架之间传播,经历过一个时间滞后传入下游机架,即第i+1机架轧件入口厚度和第i机架出口厚度之间满足以下关系:

其中: 为第i机架和第i+1机架之间的时滞时间,

为第i机架和第i+1机架之间的时滞时间,

为第i+1机架的轧件入口速度。

为第i+1机架的轧件入口速度。

以单机架轧机振动模型为基础,根据相邻机架间的关系,可以得到相邻的第i机架和第i+1机架再生颤振模型如下:

根据式(38)可知:每增架1个机架,系统增加7个自由度,据此可以建立任意机架耦合在一起的多方向耦合振动连轧机再生颤振模型。

3 连轧机再生颤振系统模型的验证

3.1 单机架轧机振动系统稳定性分析

以某钢厂五机架冷连轧机为例,对所建立的轧制过程模型、单机架轧机振动模型以及连轧机再生颤振模型进行验证。该五机架冷连轧机每个机架的轧制工艺参数如表1所示。每个机架结构相似,因此,每个机架的结构参数设置相同,m1=4 800 kg,m2=117 900 kg,Jm=138 kg,k1=2.9×108 N/m,k2=1.8×1010 N/m,k3=24 MN/m,c1=3.9×105,c2=2.4×107,c3=5.9×103,w=1 m, L=4.5 m。

表1 五机架冷连轧机轧制工艺参数

Table 1 Process parameters of the five stand tandem cold rolling mills

根据前面所建立的轧制过程模型,对每一机架的轧制力进行计算,将其与实测轧制力进行对比,并进行误差分析,结果如表2所示。从表2可见:计算轧制力和实测轧制力之间的误差较小,证明了本文所建立的轧制过程模型的正确性。根据劳斯判据,分别对每一个单机架进行稳定性分析,求解每一个单机架的临界速度。对比分析5个机架的临界速度,由于第1和第2机架的压下量较大,轧件变形抗力较小,其临界速度明显比后续3个机架的小;后续3个机架的临界速度比较接近,但是第4和第机架的轧制工作速度比较大,因此,第4和第5机架稳定性较差,在实际生产中,也是第4和第5机架振动较剧烈。根据秒流量相等原则,当第5机架的轧制速度为29.36 m/s时,第4机架的轧制速度为21.58 m/s,这表明在第5机架达到其临界速度时,第4机架还远未达到其临界速度,因此,第5机架稳定性最差。

表2 计算轧制力和实测轧制力的对比以及每个单机架的临界速度

Table 2 Comparison of calculated rolling force with measured rolling force and critical velocity for each stand

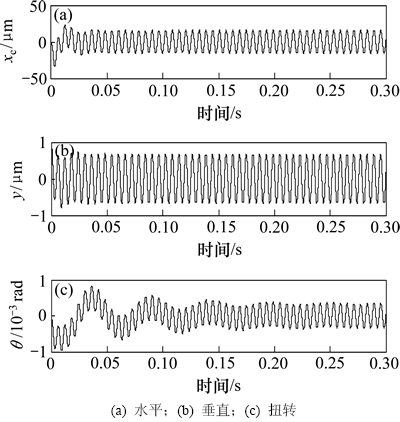

给定系统初始量yc0=1×10-6,对vr5=29.36 m/s时第5机架系统的时域和频域进行仿真分析,结果分别如图6和图7所示。从图6和图7可见:第5机架在其临界速度处做周期震荡,垂直系统的振动频率为166 Hz,扭转系统的振动频率为166 Hz和17.7 Hz,水平系统的振动频率为166 Hz和44.3 Hz,但是扭转系统和水平系统的振动以166.1 Hz为主,17.7 Hz和44.3 Hz的振动比较微弱,这表明第5机架自激振动以3倍频为主。

图6 vr5=29.36 m/s时第5机架的时域响应

Fig. 6 Time domain response for the 5th stand at vr5 of 29.36 m/s

图7 vr5=29.36 m/s时第5机架的频域响应

Fig. 7 Frequency domain response for the 5th stand at vr5 of 29.36 m/s

3.2 多机架轧机再生颤振系统稳定性分析

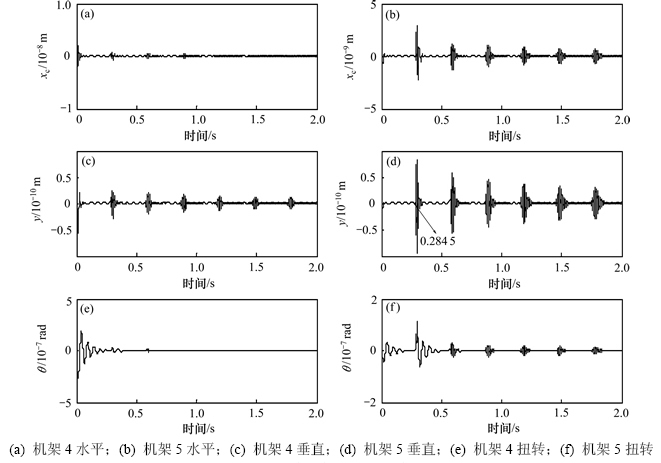

第4和第5机架稳定性较差,因此,建立第4和第5架机架耦合的2机架连轧机再生颤振模型。该模型是一个线性时滞微分系统,其特征方程是超越方程,具有无穷多个特征根,适用于无时滞系统的稳定性判定准则失效,需要采用适用于线性时滞微分系统的稳定性判定准则对其进行稳定性分析[11-13]。采用积分值检验法对连轧机再生颤振模型的稳定性进行分析,求解得到2机架轧机再生颤振模型的临界速度为20.59 m/s(这里的临界速度是指第5机架的轧辊线速度)。可见机架之间的耦合作用大幅度减小了系统的临界速度。

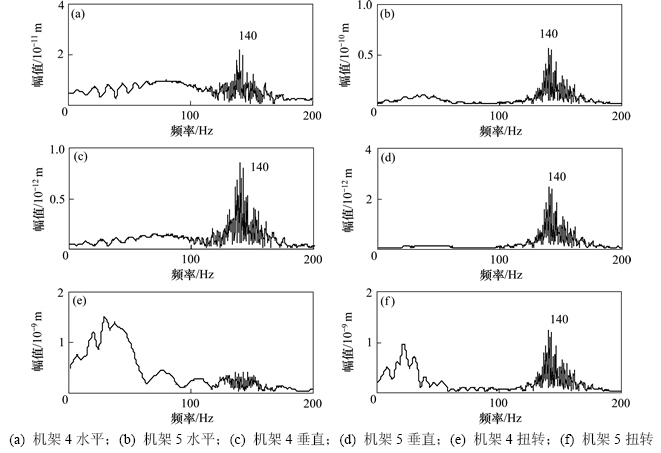

给定初始量yc04=1×10-6,对vr5=20.59 m/s时2机架轧机再生颤振模型的时域和频域特性进行仿真分析,结果如图8所示。从图8可以看出:在考虑时滞因素影响后,轧机振动波形形成了一连串的“小葫芦”波形。这种“小葫芦”波形是相邻机架之间的相互作用造成的,与文献[1]中的时域测试波形相同;由于第5机架的稳定性比第4机架的稳定性差,第5机架工作辊振动比第4机架更加剧烈;当vr5=20.59 m/s时,第4和第5机架之间的时滞时间为0.284 5 s。从图8可以看出:由于第4和第5机架之间的张力耦合,第4机架的振动会直接引起第5机架的振动,但是张力耦合所导致的第5机架振动比较小,经过0.284 5 s后,第4机架振动所导致的轧件出口厚度波动传递到第5机架,加剧第5机架的振动,使得第5机架出现第1个“小葫芦”波形,第5机架的第1个小葫芦波形恰好落后于第4机架的第1个小葫芦波形1个时滞时间。从图9可以看出:在考虑了时滞因素的影响后,系统的振动频率更复杂,但是第4和第5机架的振动仍然集中在3倍频振动频率附近,但是由于轧制速度刚达到其临界速度,扭转和水平方向的振动并不剧烈,振动频率尚未集中;随着轧机速度逐渐增大,整个机架将以4倍频振动频率发散。

以上对轧机振动模型的仿真分析和现场测试结果的比较,验证了本文所建立的动态轧制过程、单机架轧机振动模型和多机架轧机再生颤振模型的有效性,对连轧机相邻机架之间的耦合关系进行了研究,为后续深入研究连轧机再生颤振机理及其稳定性提供了理论基础。

图8 vr5=20.59 m/s多机架再生颤振模型的时域响应

Fig. 8 Time domain response for multi-stand model at vr5 of 20.59 m/s

图9 vr5=20.59 m/s多机架再生颤振模型的频域响应

Fig. 9 Frequency domain response for multi-stand model at vr5 of 20.59 m/s

4 结论

1) 建立了综合考虑轧制过程中轧件的加工硬化和轧辊弹性压扁效应以及轧制辊缝在垂直和水平方向波动的动态轧制过程模型,使用该模型对某钢厂五机架连轧机每个机架的轧制力进行了计算,将计算结果与测试结果进行误差分析,证明了该模型的有效性。

2) 将建立的动态轧制过程模型与多方向耦合振动的轧机结构模型结合,建立了多方向耦合振动的单机架轧机振动模型。基于该模型,使用劳斯判据对某五机架连轧机的每个机架稳定性进行分析,并求解了其临界轧制速度。分析结果表明,该五机架连轧机的第4和第5机架的较容易发生振动,第5机架振动最容易发散。

3) 机架间的耦合作用降低了系统的稳定性,减小了系统的临界速度。考虑机架间耦合作用的连轧机再生颤振模型时域仿真结果与轧机测试结果更接近,计算得到的临界速度也更接近轧机的实际工作状态,证明了所建立的再生颤振模型的有效性,为后续对连轧机再生颤振机理的研究奠定了基础。

参考文献:

[1] 邹家祥, 徐乐江. 冷连轧机系统振动控制[M]. 北京: 冶金工业出版社, 1998: 1-87.

ZHOU Jiaxiang, XU Lejiang. Tandem mill vibration control[M]. Beijing: Metallurgical Industry Press, 1998: 1-87.

[2] YUN I S, WILSON W R D, EHMANN K F. Review of chatter studies in cold rolling[J]. International Journal of Machine Tools and Manufacture, 1998, 38(12): 1499-1530.

[3] HU Peihua, ZHAO Huyue, EHMANN K F. Third-octave-mode chatter in rolling, Part 3: Stability of a multi-stand mill[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2006, 220(8): 1293-1303.

[4] ZHAO Huyue, EHMANN K F. Stability analysis of chatter in tandem rolling mills, Part 1: single- and multi-stand negative damping effect Journal of Manufacturing Science and Engineering[J]. Journal of Manufacturing Science and Engineering, 2013, 135(3): 031001.

[5] ZHAO Huyue, EHMANN K F. Stability analysis of chatter in tandem rolling mills—Part 2: the regenerative effect, Journal of Manufacturing Science and Engineering[J]. Journal of Manufacturing Science and Engineering, 2013, 135(3): 031002.

[6] KIMURA Y, SODANI Y, NISHIURA N, et al. Analysis of chaffer in tandem cold rolling mills[J]. ISIJ International, 2003, 43(1): 77-84.

[7] NIROOMAND M R, FOROUZAN M R, SALIMI M. Theoretical and experimental analysis of chatter in tandem cold rolling mills based on wave propagation theory[J]. ISIJ International, 2015, 55(3): 637-646.

[8] HU PEIHUA, EHMANN K F. A dynamic model of the rolling process. Part I: homogeneous model[J]. International Journal of Machine Tools and Manufacture, 2000, 40(1): 1-19.

[9] 曾令强,臧勇,郜志英,等.轧机整体耦合建模问题研究[J].机械工程学报,2015,51(14):46-53.

ZENG Lingqiang, ZANG Yong, GAO Zhiying, et al. Study on overall coupled modeling of the rolling mill[J]. Journal of MechanicalEngineering,2015, 51(14):46-53.

[10] ZHAO Huyue. Regenerative chatter in cold rolling[D]. Evanston: Northwestern University, Department of Mechanical Engineering, 2008: 37-60.

[11] 孙健, 陈杰. 时滞系统稳定性分析与应用[M]. 北京: 科学出版社, 2012: 1-24.

SUN Jian, CHEN Jie. Stability analysis and application of time-delay systems[M]. Beijing: Science Press, 2012: 1-24.

[12] 王在华, 胡海岩. 时滞动力系统的稳定性与分岔: 从理论走向应用[J]. 力学进展, 2013, 43(1): 3-20.

WANG Zaihua, HU Haiyan. stability and bifurcation of delayed dynamic systems: from theory to application[J]. Advances in mechanics, 2013, 43(1): 3-20.

[13] 张冬梅, 俞立. 线性时滞系统稳定性分析综述[J]. 控制与决策, 2008, 23(8): 841-849.

ZHANG Dongmei, YU Li. Survey on the stability analysis of linear time delay systems[J]. Control and Decision, 2008, 23(8): 841-849.

(编辑 赵俊)

收稿日期:2016-03-25;修回日期:2016-06-28

基金项目(Foundation item):国家自然科学基金资助项目(51175035);教育部博士点基金资助项目(20100006110024);北京高校青年英才计划项目(YETP0367);中央高校基本科研业务费专项资助项目(FRF-BR-14-006A);国家高技术研究发展计划(863计划)项目(2013AA031302) (Project(51175035) supported by the National Natural Science Foundation of China; Project(20100006110024) supported by Ph.D Programs Foundation of Ministry of Education of China; Project(YETP0367) supported by Beijing Higher Education Young Elite Teacher Project; Project(FRF-BR-14-006A) supported by the Fundamental Research Funds for the Central Universities; Project(2013AA031302) supported by the National High Technology Research and Development Program (863 Program) of China)

通信作者:臧勇,教授,博士生导师,从事机械动力学和塑性加工研究;E-mail: yzang@ustb.edu