DOI:10.19476/j.ysxb.1004.0609.2019.10.07

热处理温度对含纳米SiC的快冷镁合金固溶组织影响

张丽攀,杨 伟,刘 亮,余 欢

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:采用铜模喷铸与等温热处理相结合,制备出纳米SiC参与下快冷镁合金细晶组织,研究热处理温度对非平衡凝固镁合金固溶组织转变的影响及其高温晶粒长大行为。结果表明:提高冷速与添加纳米SiC可实现镁合金的复合细化,有利于形成细小花瓣状组织。经320、370和400 ℃等温处理2 h后,快冷AZ91+2%纳米SiC合金从不完全固溶向完全固溶发生转变,溶质偏析程度降低,同时,晶界β-Mg17Al12相不断消失,最终获得多边形等轴晶组织。由于纳米SiC对晶界迁移起到良好的抑制作用,亚稳细晶组织的高温晶粒长大行为得到有效控制,其中经400 ℃固溶8 h后的平均晶粒尺寸仅为13 μm,快冷合金的热稳定性得到显著提高。

关键词:镁合金;非平衡凝固;固溶处理;组织细化;晶粒长大

文章编号:1004-0609(2019)-10-2277-08 中图分类号:TG146.2 文献标志码:A

镁合金具有良好的比强度和比刚度、优异的阻尼减震及尺寸稳定性能,在汽车交通、电子通讯及航空航天等国防领域得到广泛应用[1]。AZ91作为目前使用最广的商用镁合金,铸态组织由α-Mg 基体和β-Mg17Al12相所组成,其中晶界处溶质偏析引起的β相具有硬脆特征,易产生裂纹,严重降低合金的变形能力[2-4]。此外该相熔点低,导致合金高温力学性能差。因此,控制并消除β相,提高材料组织均匀性,对于改善镁合金力学性能具有重要意义[5]。

随着喷射沉积、熔体旋铸及激光熔凝等技术的开发,快速凝固引起的溶质截留及晶粒细化结果可以显著降低镁合金中的溶质偏析,β相的形成受到有效抑制,合金组织均匀性得到极大改善[6-10]。因此,非平衡凝固及其影响下的组织调控已成为高性能镁合金研发的重要领域[11]。

通过高温条件下将第二相溶入基体,固溶处理有利于提高基体组织的成分均匀性,消除镁合金晶界处的脆性β相[12-15]。合金凝固阶段所经历的相变路径不仅影响到材料的铸态组织及其力学性能,也是热处理工艺规范制定的重要依据[16]。由于快速凝固过程中所形成的细晶组织是一种特殊的非平衡亚稳相,多余的能量作为晶界能被储存在晶界上。经高温固溶或退火处理后,细晶组织受晶界能降低的驱动会发生粗化现象[17-19]。因此,理想的快冷镁合金固溶工艺不仅要保证β相完全溶入基体,同时要避免细晶组织发生过分长大而破坏原始非平衡凝固组织特征。

本文采用铜模喷铸与高温固溶处理相结合,系统研究纳米SiC对快冷镁合金晶粒细化及高温组织的影响,重点探讨不同热处理温度下固溶组织的转变和纳米SiC对镁合金高温晶粒长大的抑制效应,从而为亚稳细晶组织的制备及其热稳定性改善提供参考。

1 实验

试验材料为AZ91合金,其化学成分为(质量分数,下同):Al 8.5%~9.5%,Zn 0.45%~0.9%,Mn 0.17%,Si 0.05%,Fe 0.004%,Cu 0.015%,Ni 0.001%,杂质 0.001%,其余为Mg。SiC颗粒尺寸为40~60 nm。采用搅拌摩擦加工技术实现纳米SiC均匀分散。首先在厚度为12 mm的AZ91合金薄板上钻出间距为6 mm系列盲孔,填入SiC粒子并压实后置于旋转搅拌摩擦机中进行挤压加工,从而制备出颗粒含量为6%的中间合金。然后利用混合称量方式配比出AZ91+2%SiC目标合金[20]。

铜模喷铸实验在高真空高频感应炉内进行,该装置主要包括真空获得系统、感应加热熔炼系统、红外/热偶温度采集系统和惰性气体喷铸系统。首先将合金原料装入尺寸为直径15 mm×150 mm的石英坩埚中,移动支架位置并调整坩埚与铜模间相对高度,确保坩埚底部小孔正对铜模内腔中心。启动机械泵预抽真空至5 Pa后返充99.999%高纯Ar到0.03 MPa,避免熔炼过程中镁元素氧化挥发。合金完全熔化并均匀混合后,坩埚上方通入绝对压力为0.12 MPa的Ar,金属液被垂直喷射入内径8 mm的紫铜模具内,从而制备出快冷合金试棒。为对比研究纳米SiC及铜模激冷的复合细化效果,采用该装置还分别制备出未进行喷铸操作而随炉自然冷却的原位熔炼AZ91及AZ91+2%SiC铸态合金。

快冷合金试棒经线切割加工成厚度3 mm的圆片后,放入箱式坩埚电阻炉内进行等温固溶处理,其控温精度为±2 ℃。热处理温度分别设置为320、370和400 ℃,保温时间为2~8 h。固溶处理结束后试样被迅速快淬到冷水中,以保存其高温显微组织。

试样经镶嵌、打磨、抛光及5%柠檬酸腐蚀后,采用VHX-600E型三维超景深显微镜进行光学显微组织分析,并利用Image-Pro Plus 6.0软件分析快冷合金及其固溶组织中共晶相体积分数。为确保数据准确,分别在试样不同区域测量5次,然后取平均值作为最终结果。采用FEI-Nova NanoSEM450场发射高分辨扫描电镜进行高倍组织分析,并利用INCA Energy 250型能谱仪对微区成分进行表征。采用丹麦DuraScan维氏显微硬度计测量不同条件下合金显微硬度,每个试样至少测试5个结果,并取平均值作为最终硬度值。硬度测试中所加载荷2 N,作用时间15 s。

2 结果与分析

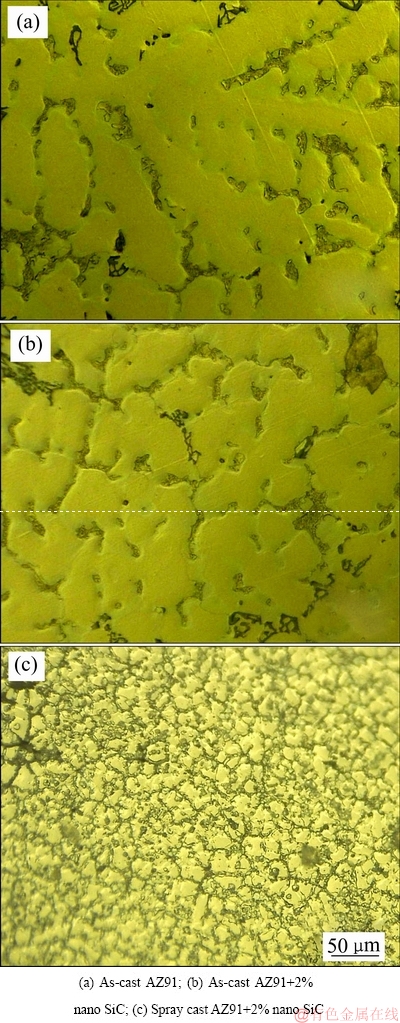

2.1 不同冷速条件下镁合金显微组织

图1所示为不同制备条件下镁合金光学显微组织。在常规冷速条件下,AZ91合金铸态组织为具有发达枝晶主干的粗大枝晶形貌,其中最大晶粒尺寸可达400 μm(见图1(a))。当加入纳米SiC后,异质形核数目增多,晶粒尺寸有所细化。由于α-Mg为HCP结构,具有平行于密排面的六重对称特征,因此,形成花瓣状形貌(见图1(b))。铜模喷铸条件下,冷速的提高有利于增加过冷度,同时SiC的存在进一步提供更多形核质点,二者共同促进镁合金凝固过程中的形核,有利于实现组织的复合细化,从而形成细小的等轴晶组织(见图1(c))。

图1 不同制备工艺下镁合金光学显微组织

Fig. 1 Optical microstructures of AZ91 alloy fabricated by different conditions

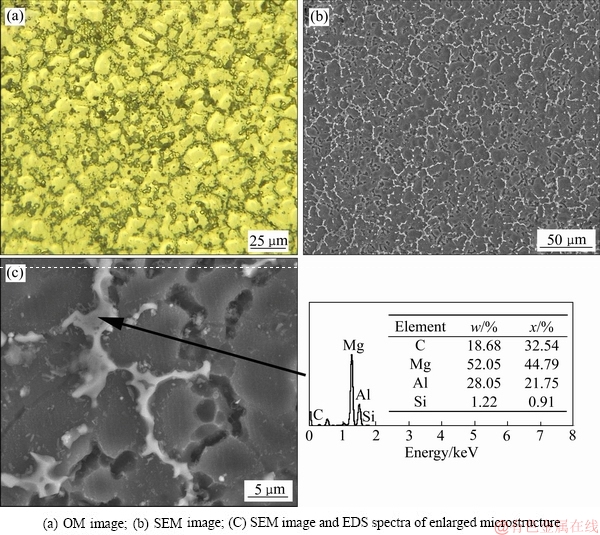

图2所示为铜模喷铸AZ91+2%纳米SiC合金的扫描电镜组织及元素分析结果,其中晶界处含有较高Al元素,局部存在少量Si元素。这是由于随凝固过程进行,具有较低Al含量的α-Mg相在合金液中不断形成并长大,导致残余液相、尤其凝固界面前沿受溶质再分配影响而发生Al元素富集,从而在初生枝晶间发生共晶反应。由于该共晶组织中的α-Mg相依附于初生α-Mg相形核并生长,最终在晶界处形成离异共晶β-Mg17Al12相。

图2 铜模喷铸AZ91+2%纳米SiC合金扫描电镜组织及元素分布结果

Fig. 2 SEM images and element distributions of spray cast AZ91+2% nano SiC alloy

2.2 固溶温度对快冷镁合金晶界组织的影响

由于晶界处β相熔点低且具有硬脆特征,严重降低镁合金高温力学性能及室温塑性变形能力,因此,需通过固溶处理进行有效控制。图3所示为铜模喷铸AZ91+2%纳米SiC合金经320 ℃、2 h等温处理后的显微组织。由于高温条件下晶界处低熔点共晶相发生熔解,晶粒形貌逐渐清晰(见图3(a))。然而扫描组织中可看到该条件下晶界处β相含量并未发生明显变化,仍以不连续网状形式分布(见图3(b)),高倍组织可进一步观察到晶界处存在较多体积分数的β相,并且其所对应的Al元素含量高达28.05%(见图3(c))。因此,可推断由于该温度条件下热激活效应不足导致原子扩散速率较慢,晶界相的消失不彻底,快冷镁合金处于不完全固溶状态。

通过高温原子扩散实现成分均匀,固溶处理可以有效消除第二相,其中温度是决定原子扩散快慢的关键因素。温度越高,用于克服扩散能垒的激活能越大,原子越易迁移,扩散速度越快[21]。图4所示为快冷AZ91+2%纳米SiC合金经370 ℃、2 h等温处理后的显微组织。随固溶温度升高,原始晶界处不连续粗大β相逐渐消失,组织形貌由花瓣状向多边形等轴晶发生转变(见图4(a))。结合扫描组织分析可知,该固溶温度下,快冷合金中β相体积分数明显下降,但仍存在少量晶界相。能谱分析结果表明该基体组织中Al含量为5.68%。此外晶界处还发现富集少量C、Si元素,可推断为纳米颗粒的存在(见图4(b))。

图5所示为铜模喷铸AZ91+2%纳米SiC合金经400 ℃、2 h等温处理后的显微组织。随固溶温度进一步提高,未发生明显晶粒长大现象,原始细晶组织仍然保存,平均晶粒尺寸仅为8 μm(见图5(a))。扫描组织分析可知,该条件下β相几乎完全溶入基体,仅局部残存微量第二相,基本可获得均匀单相固溶体组织(见图5(b)),表明该温度下快冷合金发生完全固溶现象。能谱分析结果表明,基体中溶质Al含量持续增加,达到7.24%,接近于合金原始成分,说明经快冷和高温固溶处理后,受溶质截留及高温扩散综合影响,溶质偏析得到有效控制。随着第二相的消失,纳米SiC被不断推移,最终富集于晶界交汇处。

图3 铜模喷铸AZ91+2%纳米SiC合金经320 ℃、2 h等温处理后的显微组织

Fig. 3 Microstructures of spray cast AZ91+2% nano SiC alloy after being annealed at 320 ℃ for 2 h

图4 铜模喷铸AZ91+2%纳米SiC合金经370 ℃、2 h等温处理后的显微组织

Fig. 4 Microstructures of spray cast AZ91+2% nano SiC alloy after being annealed at 370 ℃ for 2 h

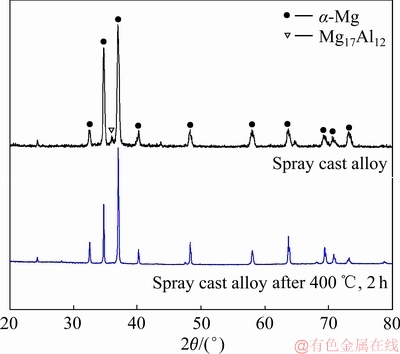

图6所示为铜模喷铸AZ91+2%纳米SiC合金及其经400 ℃、2 h固溶处理后的XRD谱。对比分析可知,原始快冷镁合金的微观组织主要由α-Mg所组成,同时存在少量的β-Mg17Al12相,这与图2中扫描电镜组织及能谱分析结果相一致。经400 ℃、2 h固溶处理后,快冷合金中β相衍射峰消失,基本呈现为单相α-Mg固溶体,从而进一步表明该固溶处理条件下,晶界处的离异共晶β-Mg17Al12相已完全溶入基体中。

图5 铜模喷铸AZ91+2%纳米SiC合金经400 ℃、2 h等温处理后显微组织

Fig. 5 Microstructures of spray cast AZ91+2% nano SiC alloy after being annealed at 400 ℃ for 2 h

图6 快冷AZ91+2%纳米SiC合金及其400 ℃、2 h固溶处理后的XRD谱

Fig. 6 XRD patterns of rapidly cooled AZ91+2% nano SiC alloy after being annealed with 400 ℃ for 2 h

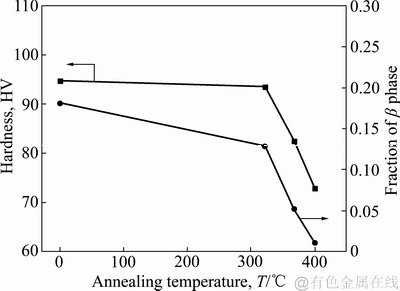

图7所示为不同固溶温度下铜模喷铸AZ91+2%纳米SiC合金晶界处β相体积分数及显微硬度的变化结果。随固溶温度的升高,β相消失速率加快,并且其含量持续下降,分别由原始快冷组织中的18.2%降低到400 ℃固溶处理后的1.156%。材料的硬度主要取决于基体的过饱和程度、第二相数量、形态及尺寸。经固溶处理后,大量Al原子溶入α-Mg基体中,由于二者原子半径不同,从而在所获得的过饱和置换固溶体中引起晶格畸变,阻碍位错运动,这种固溶强化效果理论上有利于提高硬度[22],然而分析图7可知,随热处理温度提高,快冷AZ91+2%纳米SiC合金的显微硬度不升反降。这是由于随着合金从不完全固溶向完全固溶发生转变,具有硬脆特征的β相基本消失,显著降低其对晶界迁移的抑制作用,甚至超过固溶强化效果,最终导致材料硬度不断下降。

图7 不同固溶温度下快冷AZ91+2%纳米SiC合金的硬度及晶界共晶相体积分数

Fig. 7 Micro-hardness and volume fraction of eutectic phase at grain boundary in spray cast AZ91+2% nano SiC alloy at different heat treatment temperatures

2.3 快冷镁合金亚稳细晶组织的热稳定性

快冷条件下所形成的细晶组织属于非平衡亚稳相,其中过剩的能量作为晶界能被储存在晶界上。在高温热激活作用下,该亚稳细晶组织将不可避免地发生晶粒长大现象,其驱动力来自于晶界间存储的能量,而保温时间则决定了相同温度下晶粒长大的动力学过程[23]。图8所示为铜模喷铸AZ91合金经400 ℃等温固溶处理后的光学显微组织。分析可知,随保温时间的延长,快冷AZ91合金中发生了明显的晶粒长大现象,其中平均晶粒尺寸由保温2 h时的26 μm急剧增加到保温8 h时的78 μm(见图8),说明非平衡凝固阶段所形成的原始细晶组织在高温下易发生长大。

图8 不同保温时间下铜模喷铸AZ91合金经400 ℃等温处理后光学显微组织

Fig. 8 Optical microstructures of AZ91 alloy after being annealed at 400 ℃ for different holding time

图9所示为铜模喷铸AZ91+2%纳米SiC合金经400 ℃等温处理后的光学显微组织。分析可知,随着纳米SiC的加入,细晶组织的高温晶粒长大能够得到有效控制,其中固溶4和8 h后所对应的晶粒尺寸分别为10和13 μm。相比固溶2 h时的平均尺寸8 μm(见图5(a)),均未发生明显长大,表明纳米SiC颗粒可以显著提高快冷镁合金细晶组织的热稳定性。

由Zener晶粒生长理论[24],晶粒长大时的阻力PZ可表示为

(1)

(1)

式中:r和fV分别为第二相颗粒的尺寸及体积分数;σ为晶界能。由于纳米SiC对晶界的迁移起到强烈的阻碍作用,因此当小晶粒被大晶粒吞噬时,晶界滑移到SiC质点时会降低甚至停止其迁移速度,表现出良好的高温组织稳定性。根据式(1),抑制生长的阻力PZ随颗粒尺寸r的下降而升高,因此当添加相同含量的SiC时,纳米颗粒对细晶组织的热稳定性要优于微米颗粒[20]。

图9 不同保温时间下铜模喷铸AZ91+2%纳米SiC合金经400 ℃等温处理后光学显微组织

Fig. 9 Optical microstructures of AZ91+2% nano SiC alloy after being annealed at 400 ℃ for different holding time

3 结论

1) 经320 ℃、2 h等温处理后,AZ91+2%纳米SiC快冷合金发生不完全固溶,其中晶界处β相仍以不连续网状形式分布,晶粒形貌与快冷合金中花瓣状组织保持一致。

2) 随热处理温度提高,原子扩散速度加快。经400 ℃、2 h等温热处理后,AZ91+2%纳米SiC快冷合金中形成完全固溶组织,晶界处β相基本溶入α-Mg基体中,溶质偏析得到有效控制,同时,材料硬度不断下降。

3) 纳米SiC可显著提高快冷镁合金细晶组织的热稳定性,其中400 ℃固溶4和8 h后的晶粒尺寸分别为10和13 μm,高温晶粒长大得到有效控制。

REFERENCES

[1] LUO A. Processing, microstructure, and mechanical behavior of cast magnesium metal matrix composites[J]. Metallurgical and Materials Transactions A, 1995, 26(9): 2445-2455.

[2] 王文礼, 张 薇, 雷宁宁, 王 杰. 稀土元素Sm、Ce对Mg-Y系合金组织和性能的影响[J]. 稀有金属材料与工程, 2016, 45(6): 1473-1476.

WANG Wen-li, ZHANG Wei, LEI Ning-ning, WANG Jie. Effect of Sm and Ce addition on microstructures and mechanical properties of Mg-Y series magnesium alloy[J]. Rare Metal Materials and Engineering, 2016, 45(6): 1473-1476.

[3] 孟帅举, 余 晖, 崔红卫, 张 静, 赵维民, 王志峰, 秦春玲. 新型Mg-Bi-Al-Zn变形镁合金的微观组织与力学性能[J]. 中国有色金属学报, 2017, 27(5): 894-901.

MENG Shuai-ju, YU Hui, CUI Hong-wei, ZHANG Jing, ZHAO Wei-min, WANG Zhi-feng, QIN Chun-ling. Microstructure and mechanical properties of new Mg-Bi-Al-Zn wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(5): 894-901.

[4] 王长义. AZ91HP镁合金疲劳裂纹扩展行为与断裂机理[J]. 失效分析与预防, 2015, 10(2): 87-91.

WANG Chang-yi. Fatigue crack propagation behavior and mechanism of AZ91HP magnesium alloy[J]. Failure Analysis and Prevention, 2015, 10(2): 87-91.

[5] YANG Ming-bo, DUAN Cheng-yu, LI Hong-liang, GUO Ting-zhang, ZHANG Jia. Effects of minor Ca addition on as-cast microstructure and mechanical properties of Mg-4Y-1.2Mn-1Zn(wt.%)magnesium alloy[J]. Journal of Alloys and Compounds, 2013, 574: 165-173.

[6] 余 琨, 黎文献, 王日初, 冯 艳, 吴志文. 快速凝固镁合金开发原理及研究进展[J]. 中国有色金属学报, 2007, 17(7): 1025-1033.

YU Kun, LI Wen-xian, WANG Ri-chu, FENG Yan, WU Zhi-wen. Research theory and development of rapidly solidified magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1025-1033.

[7] LIU F, YANG G C. Rapid solidification of highly undercooled bulk liquid superalloy: Recent developments, future directions[J]. International Materials Reviews, 2006, 3: 146-170.

[8] WANG W L, LI Z Q, WEI B. Macro segregation pattern and microstructure feature of ternary Fe-Sn-Si immiscible alloy solidified under free fall condition[J]. Acta Materialia, 2011, 59(14): 5482-5493.

[9] GUPTA M, LAI M. Synthesis, micro structure and properties characterization of disintegrated melt deposited Mg/SiC composite[J]. Journal of Materials Science, 2000, 35: 2155-2165.

[10] LIU L, LI J F, ZHOU Y H. Solidification interface morphology pattern in the undercooled Co-24.0at%Sn eutectic melt[J]. Acta Materialia, 2011, 59(14): 5558-5567.

[11] AYMAN E, JUNKO U, KATSUUOSHI K. Application of rapid solidification powder metallurgy to the fabrication of high-strength, high-ductility, Mg-Al-Zn-Ca-La alloy through hot extrusion[J]. Acta Materialia, 2011, 59: 273-282.

[12] 胡耀波, 杨生伟, 姚青山, 潘复生. 挤压比及Mn含量对Mg-10Gd-6Y-1.6Zn-XMn镁合金组织和性能的影响[J]. 稀有金属材料与工程, 2017, 46(1): 135-142.

HU Yao-bo, YANG Sheng-wei, YAO Qing-shan, PAN Fu-sheng. Effects of extrusion ratio and Mn content on microstructure and properties of Mg-10Gd-6Y-1.6Zn-XMn magnesium alloy[J]. Rare Metal Materials and Engineering, 2017, 46(1): 135-142.

[13] 王志虎, 张菊梅, 陈梓山. 固溶处理对AZ91镁合金组织与性能的影响[J]. 特种铸造及有色合金, 2015, 35(4): 341-344.

WANG Zhi-hu, ZHANG Ju-mei, CHEN Zi-shan. Effect of solution modes on microstructure and mechanical properties of AZ91 magnesium alloy after aging treatment[J]. Special Casting and Nonferrous Alloys, 2015, 35(4): 341-344.

[14] 陈 亮, 肖代红, 耿正伟, 周鹏飞. 固溶温度对挤压态Mg-13Al-6Zn-4Cu合金组织与性能的影响[J]. 粉末冶金材料科学与工程, 2016, 21(3): 463-469.

CHEN Liang, XIAO Dai-hong, GENG Zheng-wei, ZHOU Peng-fei. Effects of solid-solution temperature on micro structure and properties of as-extruded Mg-13Al-6Zn-4Cu alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2016, 21(3): 463-469.

[15] 冯 艳, 李晓庚, 王日初, 彭超群. 热处理过程中Mg-8Gd-3Y-1Nd-0.5Zr 合金的组织演变及性能[J]. 中国有色金属学报, 2017, 27(9): 1794-1802.

FENG Yan, LI Xiao-geng, WANG Ri-chu, PENG Chao-qun. Microstructure evolution and performance of Mg-8Gd- 3Y-1Nd-0.5Zr alloy during heat treatment[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1794-1802.

[16] 张 玉, 黄晓锋, 马振铎, 李 雅, 马 颖, 郝 远. 热处理工艺对Mg-6Zn-2Sm-0.4Zr 镁合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2017, 27(10): 1961-1969.

ZHANG Yu, HUANG Xiao-feng, MA Zhen-duo, LI Ya, MA Ying, HAO Yuan. Effects of heat-treatment technology on microstructure and mechanical properties of Mg-6Zn- 2Sm-0.4Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(10): 1961-1969.

[17] CHEN Z, LIU F, YANG X Q, CHEN C J, ZHAO Y M. A thermokinetic description of nano-scale grain growth under dynamic grain boundary segregation condition[J]. Journal of alloys and compounds, 2014, 608(25): 338-342.

[18] 李俊杰, 王锦程, 杨根仓. 含第二项颗粒的晶粒长大过程相场法[J]. 稀有金属材料与工程, 2008, 37(10): 1746-1750.

LI Jun-jie, WANG Jin-cheng, YANG Gen-cang. Phase-field simulation of grain growth in systems containing second phase particles[J]. Rare Metal Materials and Engineering, 2008, 37(10): 1746-1750.

[19] ZHOU Z Z, YANG W, CHEN S H, YU H, XU Z F. Combined effect of non-equilibrium solidification and thermal annealing on microstructure evolution and hardness behavior of AZ91 magnesium alloy[J]. Physica B, 2014, 443: 35-42.

[20] 杨 伟, 殷海眯, 商景利, 王 祥, 刘吕果. SiC颗粒参与下快冷镁合金异质形核与高温晶粒长大[J].中国有色金属学报, 2017, 27(2): 243-250.

YANG Wei, YIN Hai-mi, SHANG Jing-li, WANG Xiang, LIU Lü-guo. Heterogeneous nucleation and grain growth at high temperature for quenched magnesium alloy containing SiC particle[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 243-250.

[21] MABUCHI M, KUBOTA K, HIGASHI K. High strength and high strain rate super plasticity in a Mg-Mg2Si composite[J]. Scripta Metallurgica et Material, 1995, 33(2): 331-335.

[22] MEARF O, LOUZGUINE-LUZGIN D V, INOUE A. Structural investigations of rapidly solidified Mg-Cu-Y alloys[J]. Journal of Alloys and Compounds, 2010, 496(1/2): 149-154.

[23] SHENG Shao-ding, CHEN Ding, CHEN Zhen-hua. Effects of Si addition on microstructure and mechanical properties of RS/PM (rapid solidification and powder metallurgy) AZ91 alloy[J]. Journal of Alloys and Compounds, 2009, 470: L17-L20.

[24] MOELANS N, BLANPAIN B, WOLLANTS P. Pinning effect of second-phase particles on grain growth in polycrystalline films studied by 3-D phase field simulations[J]. Acta Materialia, 2007, 55(6): 2173-2182.

Effect of annealing temperature on solid solution microstructure of rapidly cooled magnesium alloy containing nano SiC particles

ZHANG Li-pan, YANG Wei, LIU Liang, YU Huan

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: With the combination of copper mould spray casting and isothermal heat treatment, rapidly cooled magnesium alloy with fine grain microstructure was prepared by adding nano SiC. The effects of annealing temperature on solid solution transition and high temperature grain growth behavior were elucidated. The results show that both the increase of cooling rate and the addition of SiC promote duplex refinement of magnesium alloy, which is beneficial to the formation of fine petal-like structure. After isothermal treatment at 320, 370 and 400 ℃ for 2 h, a transition from insufficient solid solution to complete solid solution occurs, accompanied by the reduction of solute segregation. The disappearance of β-Mg17Al12 in grain boundary generates the formation of polygon equiaxed grain structure. Due to the excellent inhibition effect of nano SiC on grain boundary migration, the grain growth at high temperature is effectively suppressed. The average grain size of rapidly cooled alloy after solid solution at 400 ℃ for 8 h is merely 13 μm, and the thermal stability of fine grain microstructure is greatly improved.

Key words: magnesium alloy; non-equilibrium solidification; solid solution treatment; microstructure refinement; grain growth

Foundation item: Project(51461032) supported by the National Natural Science Foundation of China; Project(GJJ180513) supported by the Education Department of Jiangxi Province, China

Received date: 2018-10-09; Accepted date: 2018-12-29

Corresponding author: YANG Wei; Tel: +86-791-86453167; E-mail: nchkyw@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51461032);江西省教育厅资助项目(GJJ180513)

收稿日期:2018-10-09;修订日期:2018-12-29

通信作者:杨 伟,副教授,博士;电话:0791-86453167;E-mail:nchkyw@163.com