Mg-4Zn-xY-1Ca (x=1.0, 1.5, 2.0, 3.0)镁合金的铸态显微组织和力学性能

来源期刊:中国有色金属学报(英文版)2015年第3期

论文作者:杨明波 吴德勇 候梦丹 潘复生

文章页码:721 - 731

关键词:镁合金;Mg-Zn-Y合金;Mg-Zn-Y-Ca合金;显微组织;力学性能

Key words:magnesium alloy; Mg-Zn-Y alloy; Mg-Zn-Y-Ca alloy; microstructure; mechanical properties

摘 要:研究和比较了Mg-4Zn-xY-1Ca (x=1.0, 1.5, 2.0和3.0,质量分数%) 镁合金的铸态显微组织和力学性能。结果表明:所有铸态合金均主要由a-Mg、Mg2Ca、Ca2Mg6Zn3、I (Mg3YZn6)和W (Mg3Y2Zn3)相组成。然而,随着Y含量从0.86% 增加到2.68%,合金中Ca2Mg6Zn3相的数量逐渐减少,而I (Mg3YZn6)和W(Mg3Y2Zn3)相的数量却逐渐增加。当Y含量从0.86%增加到2.68%时,合金的铸态晶粒尺寸逐渐减小。此外,铸态合金的抗拉性能和蠕变性能也随着Y含量的变化而变化,当Y含量从0.86%增加到2.68%时,合金的蠕变性能逐渐增加,而抗拉性能也先增加并在1.77%Y 时达到最大,但当Y含量超过1.77%后抗拉性能开始下降。在Y含量为0.86%、1.19%、1.77%和2.68%的合金中,Y含量为1.77%的合金具有较好的抗拉性能和蠕变性能。

Abstract: The as-cast microstructures and mechanical properties of Mg-4Zn-xY-1Ca (x=1.0, 1.5, 2.0 and 3.0, mass fraction, %) alloys were investigated and compared. The results indicate that all the as-cast alloys are mainly composed of α-Mg, Mg2Ca, Ca2Mg6Zn3, I (Mg3YZn6) and W (Mg3Y2Zn3) phases. However, with Y content increasing from 0.86% to 2.68%, the amount of the Ca2Mg6Zn3 phase gradually decreases but that of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases gradually increases. Furthermore, an increase in Y content from 0.86% to 2.68% also causes the grain size of the as-cast alloys to gradually decrease. In addition, the tensile and creep properties of the as-cast alloys vary with Y content. Namely, with Y content increasing from 0.86% to 2.68%, the creep properties gradually increase, whereas the tensile properties firstly increase and attain the maximum at 1.77% Y, beyond that they decrease. Amongst the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y, the alloy with 1.77% Y exhibits the relatively optimal tensile and creep properties.

Trans. Nonferrous Met. Soc. China 25(2015) 721-731

Ming-bo YANG1,2,3, De-yong WU2, Meng-dan HOU2, Fu-sheng PAN3

1. Chongqing Mold and Die Engineering Technology Research Center, Chongqing University of Technology, Chongqing 400054, China;

2. College of Materials Science and Engineering, Chongqing University of Technology, Chongqing 400054, China;

3. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400030, China

Received 21 March 2014; accepted 24 July 2014

Abstract: The as-cast microstructures and mechanical properties of Mg-4Zn-xY-1Ca (x=1.0, 1.5, 2.0 and 3.0, mass fraction, %) alloys were investigated and compared. The results indicate that all the as-cast alloys are mainly composed of α-Mg, Mg2Ca, Ca2Mg6Zn3, I (Mg3YZn6) and W (Mg3Y2Zn3) phases. However, with Y content increasing from 0.86% to 2.68%, the amount of the Ca2Mg6Zn3 phase gradually decreases but that of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases gradually increases. Furthermore, an increase in Y content from 0.86% to 2.68% also causes the grain size of the as-cast alloys to gradually decrease. In addition, the tensile and creep properties of the as-cast alloys vary with Y content. Namely, with Y content increasing from 0.86% to 2.68%, the creep properties gradually increase, whereas the tensile properties firstly increase and attain the maximum at 1.77% Y, beyond that they decrease. Amongst the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y, the alloy with 1.77% Y exhibits the relatively optimal tensile and creep properties.

Key words: magnesium alloy; Mg-Zn-Y alloy; Mg-Zn-Y-Ca alloy; microstructure; mechanical properties

1 Introduction

Magnesium alloys are the lightest structural alloys commercially available and have great potential for applications in automotive, aerospace and other industries. In recent years, the development of new magnesium alloys has become increasingly important due to the potential saving in mass compared with aluminum-based alloys. Previous investigations indicated that Mg-Zn-Y based alloys containing icosahedral phase as a secondary solidification phase exhibit good mechanical properties at elevated temperatures as well as room temperature [1], and then significant interest has been attracted to these alloys [2-4]. At present, the Mg-Zn-Y based alloys such as Mg-Zn-Y-(Zr) and Mg-Zn-Y-Nd-Zr have received much global attention [5-9], Mg-Zn-Y-Ca alloys are also thought to be one of the potential Mg-Zn-Y based alloys due to the following reasons: 1) Ca in magnesium alloys not only behave as a grain refiner but also can improve the corrosion resistance and heighten the oxidizing combustion temperature [10]; 2) Zn and Ca together with Mg may form the stable intermetallic compound Ca2Mg6Zn3, and Ca can solely form a stable Mg2Ca compound with Mg [11]; 3) simultaneously adding Y and Ca into Mg can obtain Mg-Y-Ca alloys with high ductility [12]; 4) Ca addition to Mg-Zn-Y ternary alloys can play a beneficial role in microstructural refinement and texture evolution [13], and Ca addition to Mg-Y-Mn-Zn alloys can increase the thermal stability of eutectic X (Mg12YZn) phase [14]. To date, some positive results about the microstructures of Mg-Zn-Y-Ca alloys have been reported [10,13]. For example, KYONG et al [13] found that the as-rolled Mg-5Zn-0.8Y-0.3Ca (mass fraction, %) alloy exhibits very fine grains, and both dynamic and static recystallization kinetics of the as-rolled alloy are also accelerated. In addition, ZHANG et al [10] reported that the addition of 0.025%-0.5% Ca to Mg-(41-45)Zn- 2.5Y (mass fraction, %) alloys can modify and refine the primary I (Mg3YZn6) phase in the alloys.

Though the above mentioned investigations have been carried out to develop Mg-Zn-Y-Ca alloys, these investigations about the microstructures and mechanical properties of Mg-Zn-Y-Ca alloys are very limited as compared with Mg-Zn-Y-(Zr) alloys. At the same time, the investigations about the as-cast microstructures and mechanical properties of Mg-Zn-Y-Ca alloys are very scarce in the literatures. In addition, the effects of main alloying element of Y on the as-cast microstructures and mechanical properties of Mg-Zn-Y-Ca alloys are not also reported. It is well known that the as-cast microstructures and mechanical properties of engineering alloys are very important to their application regardless of whether the alloys are developed as wrought or casting alloys. Therefore, in order to provide a theoretical guidence for the development and application of Mg-Zn-Y-Ca alloys, the as-cast microstructures and mechanical properties of the Mg-4Zn-xY-1Ca (x=1.0, 1.5, 2.0 and 3.0, mass fraction, %) alloys were studied, in which a moderate Zn content and a relatively high Ca content were selected due to the following reasons: 1) high Zn levels (≥5%) possibly increase the densities of Mg-Zn-Y-Ca alloys; 2) Ca content of ~1% and above can substantially improve the resistance of molten magnesium to oxidation and ignition [15]. In addition, the creep mechanism of the experimental alloys was also simply discussed in the present work.

2 Experimental

The Mg-Zn-Y-Ca experimental alloys were prepared from pure Mg and Zn (>99.9%), and Mg-17%Y and Mg-19%Ca master alloys were made by Hunan Rare Earth Metal & Material Institute in China. The experimental alloys were melted in a resistance furnace and protected by 2% RJ-2 flux additions. The pure Mg and Zn were first melted, and then when the melt temperature reached 740 °C approximately, the Mg-Y and Mg-Ca master alloys were added to the melt. After being homogenized by mechanical stirring at 740 °C and mixed completely, the melt was held at 740 °C for 20 min and then poured into a permanent mould which was coated and preheated to 150 °C in order to obtain a casting. The non-standard specimens as reported in Ref. [11] were fabricated by spark cutting from the casting for tensile and creep tests. Table 1 lists the actual chemical compositions of the experimental alloys, which were inspected by inductively coupled plasma spectroscopy.

Table 1 Actual compositions of experimental alloys

In order to analyze the solidification behavior of the experimental alloys, differential scanning calorimetry (DSC) was carried out with a NETZSCH STA 449C system. Samples weighting approximately 30 mg, were heated in a flowing argon atmosphere from 30 to 700 °C for 5 min before being cooled down to 100 °C. The heating and cooling curves were recorded at a speed of 15 °C /min.

The as-cast samples were etched with 8% nitric acid distilled water solution, and then examined with an Olympus optical microscope and JEOL/JSM-6460LV scanning electron microscope (SEM) operated at 20 kV. The phases in the experimental alloys were analyzed by D/Max-1200X type X-ray diffraction (XRD) operated at 40 kV and 30 mA. The tensile properties at room temperature and 150 °C for the as-cast experimental alloys were determined from stress-strain curves. The ultimate tensile strength (UTS), 0.2 % yield strength (YS) and elongation to failure were obtained based on the average of three tests. The constant-load tensile creep tests of the as-cast experimental alloys were carried out at a constant temperature between 150 and 200 °C and a constant applied stress between 50 and 80 MPa. The tests were performed until the specimen broke or the minimum creep rate was reached. The total creep strain and minimum creep rates were respectively measured from elongation-time curves and averaged over three tests.

Fig. 1 XRD patterns of as-cast alloys

3 Results and discussion

3.1 Microstructures

Figure 1 shows the XRD results of the as-cast alloys. It is observed that all the as-cast alloys are mainly composed of α-Mg, Mg2Ca, Ca2Mg6Zn3, I (Mg3YZn6) and W (Mg3Y2Zn3) phases. Furthermore, it is found from Fig. 1 that the peak intensities of the Ca2Mg6Zn3, I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloys vary with Y content. The difference in the peak intensities of these phases indicates that with Y content increasing from 0.86% to 2.68%, the amount of the Ca2Mg6Zn3 phase decreases but that of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases increases. Previous investigations indicate that the formation of I (Mg3YZn6) and W (Mg3Y2Zn3) phases in Mg-Zn-Y-(Zr) alloys firmly depends on Zn/Y mass ratio [2,6,7]. When Zn/Y mass ratio exceeds 4.38, it will meet the requirement to completely form I (Mg3YZn6) phase; when Zn/Y mass ratio is between 1.10 and 4.38, the amount of Zn could not meet the requirement to completely form I (Mg3YZn6) phase and then some W (Mg3Y2Zn3) phases will be formed, and with the decrease of Zn/Y mass ratio, more W (Mg3Y2Zn3) phases will be formed. Obviously, through checking the Zn/Y mass ratios of the as-cast alloys (Table 1), the XRD results about the I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloys can be easily understood. In addition, the XRD results may be also further confirmed by the DSC results of the as-cast alloys. Figure 2 shows the DSC cooling curves of the as-cast alloys. It is found from Fig. 2 that the DSC cooling curves of the as-cast alloys are similar, with five main peaks of A, B, C, D and E in the cooling curves, indicating that the types of the phase transformation for the as-cast alloys basically do not vary with Y content. Based on Mg-Zn, Mg-Y and Mg-Zn-Y phase diagrams and combined with the previous investigations [5,16-18], it is inferred that during the solidification of the experimental alloys the primary α-Mg phase firstly nucleates and grows until the temperature falls to about 515 °C, where the binary eutectic reaction (L→α-Mg+ Mg3Y2Zn3) occurs [5], and then at about 480 °C and 430 °C, the ternary peritectic reaction (L+Mg3Y2Zn3→ α-Mg+Mg3YZn6) [5,18] and the binary eutectic reaction (L→α-Mg+Mg2Ca) occur [11], respectively. Finally, at about 400 °C the binary eutectic reaction (L→α-Mg+ Ca2Mg6Zn3) takes place [11]. Accordingly, the final microstructures of the as-cast alloys mainly consist of α-Mg, Mg2Ca, Ca2Mg6Zn3, I (Mg3YZn6) and W (Mg3Y2Zn3) phases. Furthermore, based on the above analyses, the possible reason for the difference in the amount of the Ca2Mg6Zn3 phases in the as-cast alloys with different Y contents is given as follows: Zn would be consumed during the reactions L→α-Mg+Mg3Y2Zn3 and L+Mg3Y2Zn3→α-Mg+ Mg3YZn6, and then the increase in the amount of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases, which is resulted from Y content increasing, inevitably causes the amount of the Ca2Mg6Zn3 phase formed by the eutectic reaction (L→α-Mg+Ca2Mg6Zn3) to decrease. As for the reason why there is no obvious peak B corresponding to the binary eutectic reaction (L→α-Mg+Mg3Y2Zn3) for the alloy with 0.86% Y, it is possibly related to the relatively small amount of the W (Mg3Y2Zn3) phase in the alloy.

Fig. 2 DSC cooling curves for as-cast alloys

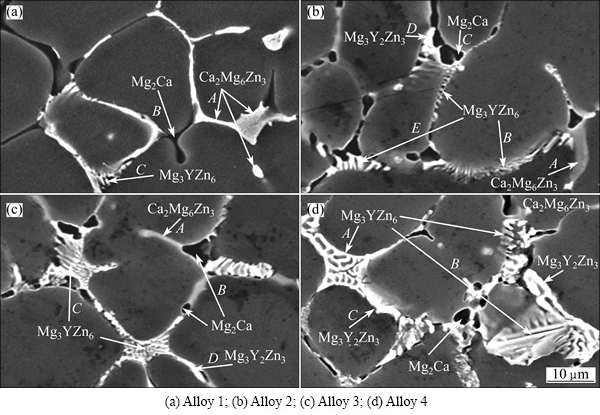

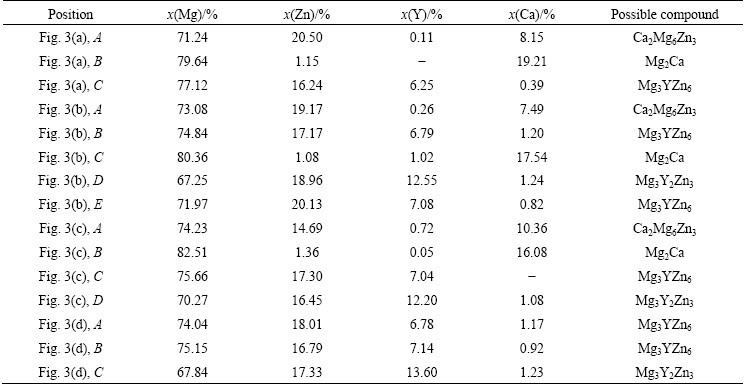

Figure 3 shows the SEM images of the as-cast alloys. Previous investigations indicate that I (Mg3YZn6) and W (Mg3Y2Zn3) phases in Mg-Zn-Y-(Zr) alloys can be easily distinguished by different particular morphologies of the two phases [8]. Based on the XRD and EDS results (Fig. 1 and Table 2) and combined with the previous investigations [8], the intermetallic compounds in Fig. 3 are identified as Ca2Mg6Zn3, Mg2Ca, I (Mg3YZn6) and W (Mg3Y2Zn3) phases mainly distributed at the grain boundaries. As shown in Fig. 3, the Ca2Mg6Zn3 phases in the alloy with 0.86% Y mainly exhibit the continuous and/or quasi-continuous distribution, whereas the Ca2Mg6Zn3 phases in other alloys mainly exhibit rod-like shapes. At the same time, with Y content increasing from 0.86% to 2.68%, the amount of the Ca2Mg6Zn3 phase gradually decreases. Furthermore, it is found from Fig. 3 that, similar to the previous investigations about microstructures of Mg-Zn-Y-(Zr) alloys [7-9], in all the as-cast alloys the I (Mg3YZn6) phases are of skeleton, granules and/or lamellar features, whereas the W (Mg3Y2Zn3) phases mainly exhibit rod-like shapes. Moreover, it is observed from Fig. 3 that parts of the Ca2Mg6Zn3 and I (Mg3YZn6) phases are interrupted by the Mg2Ca phases. In addition, simple visual comparison of these images in Fig. 3 further confirms that an increase in Y content from 0.86% to 2.68% causes the amount of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloys to increase. However, with Y content increasing from 0.86% to 2.68%, the grain boundaries of the as-cast alloys are gradually coarsened by the I (Mg3YZn6) and W (Mg3Y2Zn3) phases. The effect of Y content on the amount of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloys may be indirectly confirmed from Fig. 4, which shows the SEM images of the experimental alloys solutionized at 300 °C for 12 h and 450 °C for 12 h, and followed by water quenching. Based on the EDS results of the solutionized alloys (Table 3), the intermetallic compounds in Fig. 4 are identified as Ca2Mg6Zn3, Mg2Ca, I (Mg3YZn6) and W (Mg3Y2Zn3) phases. As shown in Fig. 4, under the same heat-treated conditions, with Y content increasing from 0.86% to 2.68% the amount of the remnant I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the solutionized alloys gradually increases.

Fig. 3 SEM images of as-cast alloys

Table 2 EDS results of as-cast alloys

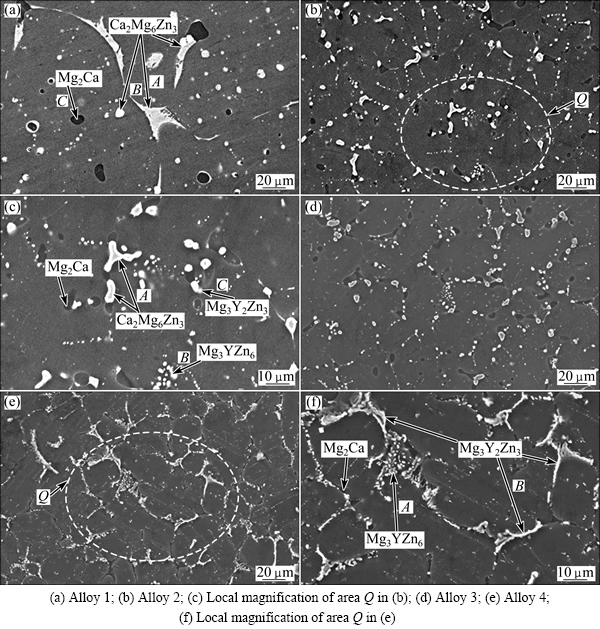

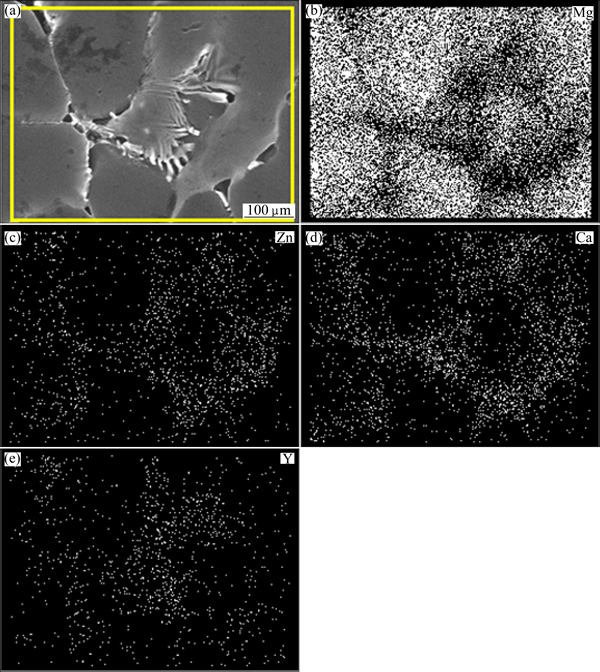

Figure 5 shows the optical images of the as-cast alloys. It is observed from Fig. 5 that all the as-cast alloys mainly display a dendrite configuration, and with Y content increasing from 0.86% to 2.68% there is a trend towards a more equiaxed structure. Simple visual comparison of these images in Fig. 5 shows that the dendrite arm spacing and grain size of the alloy with 0.86% Y are relatively large. However, with Y content increasing from 0.86% to 2.68%, the dendrite arm spacing and grain size of the as-cast alloys gradually decrease. Obviously, the increase of Y content has positive effect on the grain refinement of the as-cast alloys. Previous investigations indicate that the grain refinement effect of Y content on as-cast Mg-Zn-Y-Zr alloys is mainly ascribed to the following factors [7]: Y can change solution degree of Zn, which decreases the solidus temperature and shortens the time for nucleation, and then reduces the grain size. However, as shown in Fig. 2, except that the as-cast alloy with 2.68% Y has the relatively low onset crystallizing temperature (solidus temperature), the onset crystallizing temperatures of other as-cast alloys are basically similar, indicating that under the present experimental conditions the effect of Y content on the onset crystallizing temperature (solidus temperature) of the as-cast alloys is not very obvious. Obviously, the above mentioned mechanism cannot completely explain the effect of Y content on grain refinement of the as-cast alloys. Figure 6 shows the X-ray mapping results of the alloy with 1.77% Y. It is observed that the Y element mainly distributes at the grain boundary. Since Y is a surface active element and it can easily segregate at the liquid-solid interface or be absorbed onto the growth front [19], it is inferred that the above observed effect of Y content on grain refinement of the as-cast alloys is possibly related to the strong growth restriction effect of Y atoms. However, this needs to be further confirmed. Of course, the difference in the amount of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases, which is resulted from the change of Y content, is also one of the possible reasons because the I (Mg3YZn6) and W (Mg3Y2Zn3) phases possibly restrain the growth of the a-Mg phase during the solidification due to their relatively high melting point and heat resistance.

Fig. 4 SEM images of solutionized alloys

Table 3 EDS results of solutionized alloys

Fig. 5 Optical images of as-cast alloys

Fig. 6 X-ray mapping results for as-cast alloy 3

3.2 Tensile properties

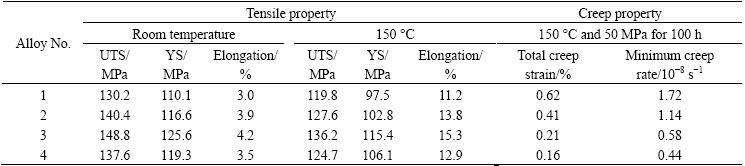

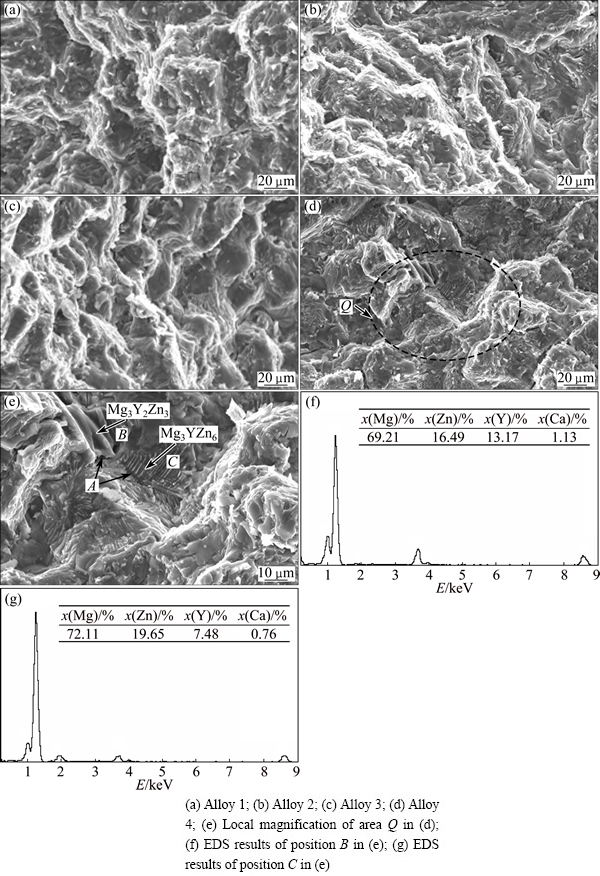

The tensile properties at room temperature and 150 °C for the as-cast experimental alloys, including ultimate tensile strength (UTS), 0.2% yield strength (YS) and elongation, are listed in Table 4. It is observed from Table 4 that the increase in Y content from 0.86% to 1.77% causes the tensile properties to gradually increase. However, the tensile properties do not further increase when Y content is 2.68%. It is known that fine grains are commonly beneficial to the tensile properties of engineering alloys. Apparently, the difference in the tensile properties for the as-cast alloys with 0.86% Y, 1.19% Y and 1.77% Y can be easily explained by the different grain sizes of these alloys. In addition, previous investigations indicate that the mechanical properties of the as-cast Mg-Zn-Y-(Zr) alloy are closely related to the variation of the main secondary phases such as I (Mg3YZn6) and W (Mg3Y2Zn3) phases [7,8]. The above results indicate that the main secondary phases in the as-cast alloy with 0.86% Y are the Ca2Mg6Zn3 phases, and the amount of I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloy is very small. At the same time, the Ca2Mg6Zn3 phases in the as-cast alloy mainly exhibit continuous and/or quasi-continuous net, which would give a detrimental effect on the tensile properties [11]. Therefore, the as-cast alloy with 0.86% Y exhibits relatively poor tensile properties. As for the as-cast alloys with 1.19% Y and 1.77% Y, the main secondary phases in the two as-cast alloys are I (Mg3YZn6) and W (Mg3Y2Zn3) whose amount and size are relatively large and small (Figs. 3(b)-(c)), respectively, which are beneficial to the tensile properties. Accordingly, the as-cast alloys with 1.19% Y and 1.77% Y, especially the as-cast alloy with 1.77% Y, exhibit better tensile properties than the as-cast alloy with 0.86% Y. However, after Y content in the as-cast alloys changes to 2.68%, the amount and size for the I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the alloy simultaneously increase, and then the grain boundaries are coarsened (Fig. 3(d)), which is not beneficial to the tensile properties. As a result, with Y content increasing from 0.86% to 2.68%, the tensile properties of the as-cast alloys first increase and attain the maximum at 1.77% Y content, beyond that they decrease. Actually, the above results may be further confirmed from Fig. 7 which shows the SEM images of tensile fractographs for the as-cast alloys tested at room temperature. As shown in Fig. 7, a number of cleavage planes and steps are present, and some minute lacerated ridges can also be observed in the localized areas of the tensile fracture surfaces, indicating that all the tensile fracture surfaces have mixed characteristics of cleavage and quasi-cleavage fractures. However, it is observed from Fig. 7 that the fracture surface of the as-cast alloy with 2.68% Y contains some small cracks possibly associated with the I (Mg3YZn6) and W (Mg3Y2Zn3) phases (arrow A in Fig. 7(e)). It is known that the initiation of microcracks can be greatly influenced by the presence and nature of the secondary phases. A common situation is for the particle to be cracked during deformation. In general, small and spherical particles are more resistant to cracking [20]. Obviously, the coarse I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloy with 2.68% Y are easily fractured, thus resulting in the relatively poor tensile properties as compared with the as-cast alloys with 1.19% Y and 1.77% Y. In addition, as shown in Fig. 8, although the tensile ruptures of the as-cast alloys with 1.19% Y, 1.77% Y and 2.68% Y occur along the inter-granular boundaries, the cracks seem to easily extend along the interface between the coarse I (Mg3YZn6) and W (Mg3Y2Zn3) phases and α-Mg matrix of the alloy with 2.68% Y (arrow A in Fig. 8(e)), thus resulting in the relatively poor tensile properties of the alloy.

Table 4 Tensile and creep properties for as-cast alloys

Fig. 7 SEM images of tensile fractographs for as-cast alloys tested at room temperature

Fig. 8 Optical images of longitudinal sections for as-cast alloys failed in tensile test at room temperature

3.3 Creep properties

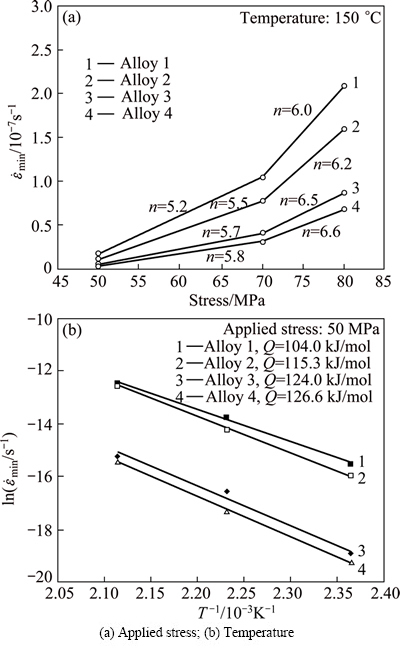

The creep properties at 150 °C and 50 MPa for 100 h for the as-cast experimental alloys, including total creep strain and minimum creep rate, are also listed in Table 4. As seen in Table 4, all the as-cast alloys exhibit the relatively high creep properties tested at 150 °C and 50 MPa for 100 h. It is well known that the steady-state creep rate ( ) can be explained by the power-law relationship reported in Ref. [21]. At the same time, both the stress exponent (n) and activation energy (Q) might be determined from the creep data collected at various temperatures and stresses, and might be used together to identify the dominant creep mechanism of a material [21]. In order to determine the stress exponents (n) and activation energies (Q) of the as-cast alloys, the slopes of a plot of

) can be explained by the power-law relationship reported in Ref. [21]. At the same time, both the stress exponent (n) and activation energy (Q) might be determined from the creep data collected at various temperatures and stresses, and might be used together to identify the dominant creep mechanism of a material [21]. In order to determine the stress exponents (n) and activation energies (Q) of the as-cast alloys, the slopes of a plot of  vs lg σ and

vs lg σ and  as a function of 1/T (in K) were evaluated. Figure 9 shows the slopes of the stress exponents and activation energies of the as-cast alloys. It is found from Fig. 9(a) that the stress exponents at low stress for the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y are 5.2, 5.5, 5.7 and 5.8, respectively, but at high stress which are 6.0, 6.2, 6.5 and 6.6, respectively. In addition, as shown in Fig. 9(b), the estimated activation energies at 50 MPa for the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y are 104.0, 115.3, 124.0 and 126.6 kJ/mol, respectively. These values indicate that under the present test conditions the creep deformation of all the as-cast alloys mainly occurs through the dislocation climb due to the following reasons [22-24]: 1) the stress exponent n=4-6 is thought to be mainly related to the dislocation climb controlled creep; 2) the activation energies of all the as-cast alloys are higher than those of the grain boundary diffusion (92 kJ/mol) and cross slip (100 kJ/mol) for magnesium alloys deformed by grain boundary diffusion but are lower than those of the lattice self-diffusion (135 kJ/mol) for magnesium alloys deformed by dislocation climb. Since the creep properties of magnesium alloys are mainly related to the structure stability at high temperatures, the high creep properties of the as-cast alloys are possibly ascribed to the presence of the thermally stable Ca2Mg6Zn3, Mg2Ca, I (Mg3YZn6) and W (Mg3Y2Zn3) phases because these thermally stable secondary phases can pin the grain boundaries and hinder both grain boundary migration and sliding during high temperature deformation. In addition, based on the above analyses and according to the stress exponents and activation energies of the as-cast alloys with different Y contents, it is concluded that under the present test conditions an increase in Y content from 0.86% to 2.68% does not cause the creep mechanism to change. However, it is observed from Table 4 that, with Y content increasing from 0.86% to 2.68%, the creep properties of the as-cast alloys gradually increase, which is possibly related to the effect of Y content on the amount of the thermally stable I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloys.

as a function of 1/T (in K) were evaluated. Figure 9 shows the slopes of the stress exponents and activation energies of the as-cast alloys. It is found from Fig. 9(a) that the stress exponents at low stress for the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y are 5.2, 5.5, 5.7 and 5.8, respectively, but at high stress which are 6.0, 6.2, 6.5 and 6.6, respectively. In addition, as shown in Fig. 9(b), the estimated activation energies at 50 MPa for the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y are 104.0, 115.3, 124.0 and 126.6 kJ/mol, respectively. These values indicate that under the present test conditions the creep deformation of all the as-cast alloys mainly occurs through the dislocation climb due to the following reasons [22-24]: 1) the stress exponent n=4-6 is thought to be mainly related to the dislocation climb controlled creep; 2) the activation energies of all the as-cast alloys are higher than those of the grain boundary diffusion (92 kJ/mol) and cross slip (100 kJ/mol) for magnesium alloys deformed by grain boundary diffusion but are lower than those of the lattice self-diffusion (135 kJ/mol) for magnesium alloys deformed by dislocation climb. Since the creep properties of magnesium alloys are mainly related to the structure stability at high temperatures, the high creep properties of the as-cast alloys are possibly ascribed to the presence of the thermally stable Ca2Mg6Zn3, Mg2Ca, I (Mg3YZn6) and W (Mg3Y2Zn3) phases because these thermally stable secondary phases can pin the grain boundaries and hinder both grain boundary migration and sliding during high temperature deformation. In addition, based on the above analyses and according to the stress exponents and activation energies of the as-cast alloys with different Y contents, it is concluded that under the present test conditions an increase in Y content from 0.86% to 2.68% does not cause the creep mechanism to change. However, it is observed from Table 4 that, with Y content increasing from 0.86% to 2.68%, the creep properties of the as-cast alloys gradually increase, which is possibly related to the effect of Y content on the amount of the thermally stable I (Mg3YZn6) and W (Mg3Y2Zn3) phases in the as-cast alloys.

Fig. 9 Applied stress and temperature dependence of minimum creep rate for as-cast alloys

4 Conclusions

1) The as-cast Mg-4Zn-xY-1Ca (x=0.86, 1.19, 1.77 and 2.68, mass fraction, %) alloys are mainly composed of α-Mg, Mg2Ca, Ca2Mg6Zn3, I (Mg3YZn6) and W (Mg3Y2Zn3) phases. With Y content increasing from 0.86% to 2.68%, the amount of the Ca2Mg6Zn3 phases in the as-cast alloys gradually decreases but the amount of the I (Mg3YZn6) and W (Mg3Y2Zn3) phases gradually increases. Furthermore, an increase in Y content from 0.86% to 2.68% also causes the grain size of the as-cast alloys to gradually decrease.

2) The tensile and creep properties of the as-cast Mg-4Zn-xY-1Ca (x=0.86, 1.19, 1.77 and 2.68) alloys vary with Y content. Namely, with Y content increasing from 0.86% to 2.68%, the creep properties of the as-cast alloys gradually increase, whereas the tensile properties firstly increase and attain the maximum at 1.77% Y, beyond that they decrease. Amongst the as-cast alloys with 0.86% Y, 1.19% Y, 1.77% Y and 2.68% Y, the alloy with 1.77% Y exhibits the relatively optimal tensile and creep properties.

References

[1] BAE D H, KIM S H, KIM D H, KIM W T. Deformation behavior of Mg-Zn-Y alloys reinforced by icosahedral quasicrystalline particles [J]. Acta Materialia, 2002, 50(9): 2343-2356.

[2] LEE J Y, KIM D H, LIM H K, KIM D H. Effects of Zn/Y ratio on microstructure and mechanical properties of Mg-Zn-Y alloys [J]. Materials Letters, 2005, 59(29-30): 3801-3805.

[3] LEE J Y, LIM H K, KIM D H, KIM W T, KIM D H. Effect of volume fraction of quasicrystal on the mechanical properties of quasicrystal-reinforced Mg-Zn-Y alloys [J]. Materials Science and Engineering A, 2007, 449-451: 987-990.

[4] SINGH A, SOMEKAWA H, MUKAI T. High temperature processing of Mg-Zn-Y alloys containing quasicrystal phase for high strength [J]. Materials Science and Engineering A, 2011, 528(21): 6647-6651.

[5] HUANG Z H, LIANG S M, CHEN R S, HAN E H.Solidification pathways and constituent phases of Mg-Zn-Y-Zr alloys [J]. Journal of Alloys and Compounds, 2009, 468(1-2): 170-178.

[6] XU D K, LIU L, XU Y B, HAN E H. The influence of element Y on the mechanical properties of the as-extruded Mg-Zn-Y-Zr alloys [J]. Journal of Alloys and Compounds,2006, 426(1-2): 155-161.

[7] XU D K, TANG W N, LIU L, XU Y B, HAN E H. Effect of Y concentration on the microstructure and mechanical properties of as-cast Mg-Zn-Y-Zr alloys [J]. Journal of Alloys and Compounds, 2007, 432(1-2): 129-134.

[8] XU D K, TANG W N, LIU L, XU Y B, HAN E H. Effect of W-phase on the mechanical properties of as-cast Mg-Zn-Y-Zr alloys [J]. Journal of Alloys and Compounds, 2008, 461(1-2): 248-252.

[9] WANG J, LIU R D, DONG X G, YANG Y S. Microstructure and mechanical properties of Mg-Zn-Y-Nd-Zr alloys [J]. Journal of Rare Earths, 2013, 31(6): 616-621.

[10] ZHANG Jin-shan, DU Hong-wei, LU Bin-feng, ZHANG Yan, LIANG Wei, XU Chun-xiang, LU Feng-lei. Effect of Ca on crystallization of Mg-based master alloy containing spherical quasicrystal [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 273-279.

[11] YANG M B, CHENG L, PAN F S. Comparison about effects of Ce, Sn and Gd additions on as-cast microstructure and mechanical properties of Mg-3.8Zn-2.2Ca (wt%) magnesium alloy [J]. Journal of Materials Science, 2009, 44(17): 4577-4586.

[12] ZHOU N, ZHANG Z Y, DONG J, JIN L, DING W J. High ductility of a Mg-Y-Ca alloy via extrusion [J]. Materials Science and Engineering A, 2013, 560: 103-110.

[13] KYONG J S, KIM J K, LEE M J, PARK Y B, KIM W T, KIM D H. Texture modification by addition of Ca in Mg-Zn-Y alloy [J]. Materials Transactions, 2012, 53(5): 991-994.

[14] YANG M B, DUAN C Y, LI H L, GUO T Z, ZHANG J. Effects of minor Ca addition on as-cast microstructure and mechanical properties of Mg-4Y-1.2Mn-1Zn (wt.%) magnesium alloy [J]. Journal of Alloys and Compounds, 2013, 574: 165-173.

[15] YANG M B, CHENG L, PAN F S. Comparison about effects of Sr, Zr and Ce additions on as cast microstructure and mechanical properties of Mg-3.8Zn-2.2Ca (wt-%) magnesium alloy [J]. International Journal of Cast Metals Research, 2010, 23(2): 111-118.

[16] FARZADFAR S A, SANJARI M, JUNG I H, ESSADIQI E, YUE S. Experimental and calculated phases in two as-cast and annealed Mg-Zn-Y alloys [J]. Materials Characterization, 2012, 63: 9-16.

[17] KEVORKOV D, PEKGULERYUZ M. Experimental study of the Ce-Mg-Zn phase diagram at 350°C via diffusion couple techniques [J]. Journal of Alloys and Compounds, 2009, 478(1-2): 427-436.

[18] GROBNER J, KOZLOV A, FANG X Y, GENG J, NIE J F, SCHMID-FETZER R. Phase equilibria and transformations in ternary Mg-rich Mg-Y-Zn alloys [J]. Acta Materialia, 2012, 60(17): 5948-5962.

[19] YANG M B, PAN F S. Effects of Y addition on as-cast microstructure and mechanical properties of Mg-3Sn-2Ca (wt.%) magnesium alloy [J]. Materials Science and Engineering A, 2009, 525(1-2): 112-120.

[20] KIM B H, JEON J J, PARK K C, PARK B G, PARK Y H, PARK I M. Microstructural characterisation and mechanical properties of Mg-xSn-5Al-1Zn alloys [J]. International Journal of Cast Metals Research, 2008, 21(1-4): 186-192.

[21] SPIGARELLI S, CERRI E, EVANGELISTA E, KLOC L, CADEK J. Interpretation of constant-load and constant-stress creep behavior of a magnesium alloy produced by rapid solidification [J]. Materials Science and Engineering A, 1998, 254(1-2): 90-98.

[22] LUO A A. Recent magnesium alloy development for elevated temperature applications [J]. International Materials Reviews, 2004, 49(1): 13-30.

[23] YANG M B, GUO T Z, LI H L. Effects of Gd addition on as-cast microstructure, tensile and creep properties of Mg-3.8Zn-2.2Ca (wt%) magnesium alloy [J]. Materials Science and Engineering A, 2013, 587: 132-142.

[24] KIM B H, PARK K C, PARK Y H, PARK I M. Effect of Ca and Sr additions on high temperature and corrosion properties of Mg-4Al-2Sn based alloys [J]. Materials Science and Engineering A, 2011, 528(3): 808-814.

杨明波1,2,3,吴德勇2,候梦丹2,潘复生3

1. 重庆理工大学 重庆市模具工程技术研究中心,重庆 400054;

2. 重庆理工大学 材料科学与工程学院,重庆 400054;

3. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400030

摘 要:研究和比较了Mg-4Zn-xY-1Ca (x=1.0, 1.5, 2.0和3.0,质量分数%) 镁合金的铸态显微组织和力学性能。结果表明:所有铸态合金均主要由a-Mg、Mg2Ca、Ca2Mg6Zn3、I (Mg3YZn6)和W (Mg3Y2Zn3)相组成。然而,随着Y含量从0.86% 增加到2.68%,合金中Ca2Mg6Zn3相的数量逐渐减少,而I (Mg3YZn6)和W(Mg3Y2Zn3)相的数量却逐渐增加。当Y含量从0.86%增加到2.68%时,合金的铸态晶粒尺寸逐渐减小。此外,铸态合金的抗拉性能和蠕变性能也随着Y含量的变化而变化,当Y含量从0.86%增加到2.68%时,合金的蠕变性能逐渐增加,而抗拉性能也先增加并在1.77%Y 时达到最大,但当Y含量超过1.77%后抗拉性能开始下降。在Y含量为0.86%、1.19%、1.77%和2.68%的合金中,Y含量为1.77%的合金具有较好的抗拉性能和蠕变性能。

关键词:镁合金;Mg-Zn-Y合金;Mg-Zn-Y-Ca合金;显微组织;力学性能

(Edited by Xiang-qun LI)

Foundation item: Project (2007CB613704) supported by the National Basic Research Program of China; Project (CSTC2013jcyjC60001) supported by the Chongqing Science and Technology Commission of China; Project (CQUT1205) supported by the Open Funds from Key Laboratory of Manufacture and Test Techniques for Automobile Parts (Chongqing University of Technology), Ministry of Education, China

Corresponding author: Ming-bo YANG; Tel: +86-23-62563176; E-mail: yangmingbo@cqut.edu.cn

DOI: 10.1016/S1003-6326(15)63657-3