DOI:10.19476/j.ysxb.1004.0609.2017.05.009

W-(Ni-Cr-Fe-Si-B)混合粉末中间层真空扩散钎焊连接钨与钢

杨宗辉1, 2,沈以赴3,初雅杰1, 2,李晓泉1, 2

(1. 南京工程学院 材料工程学院,南京 211167;

2. 南京工程学院 江苏省先进结构材料与应用技术重点实验室,南京 211167;

3. 南京航空航天大学 材料科学与技术学院,南京 211067)

摘 要:以高能球磨态90W-10(Ni-Cr-Fe-Si-B)(质量分数,%)混合粉末为钎料中间层,分别采用1000、1050和1100 ℃,均保温60 min并加压5 MPa的工艺参数,对纯钨(W)和0Cr13Al钢进行真空扩散钎焊连接。利用激光粒度分析仪、SEM、EDS和电子万能试验机等研究混合粉末形态、接头的微观组织、成分、力学性能及断口特征。结果表明:接头中的混合粉末中间层通过液相烧结过程,实现钨与钢的扩散钎焊连接,并在接头中生成均匀致密的钨基高密度合金层。高能球磨制备混合粉末对钨基高密度合金层压力下的均匀化与致密化生成具有关键作用。连接温度越高,钨基高密度合金层的液相烧结组织特征越明显。钨/钢接头剪切强度在125~130 MPa之间,断裂均发生在钨基高密度合金层/钨母材的结合区,断口主要呈现为钨母材的脆性沿晶断裂和钨基高密度合金层粘结相与钨颗粒相的韧性脱离断裂。

关键词:钨;中间层;钎焊;钨基高密度合金

文章编号:1004-0609(2017)-05-0941-06 中图分类号:TG457.1 文献标志码:A

核聚变托卡马克装置中偏滤器的面向等离子体材料直接和反应堆高能粒子交互作用,经受强烈的热冲击和物理、化学冲刷作用。钨及其合金,由于具有高熔点、高原子序数及低氘滞留等显著优点,被选定为重要的面向等离子体材料[1-2]。在制造氦冷型钨偏滤器时,需要实现面向等离子体材料钨与支撑结构材料钢的连接[3-4]。

钨与钢的熔点、线膨胀系数相差非常大,常规熔化焊难以焊接,目前常用固相扩散焊[5-9]与钎焊连接钨与钢。钨/钢钎焊的关键在于钎料的选择与设计。采用55Ni-45Ti[10]、纯Ti[11]等高温钎料有利于接头的耐热性能,但需要采用激光或电子束作为热源,工艺难度很大。为了适用炉中钎焊,在Ni基、Ti基或Fe基钎料中加入Si、B元素降低钎料的熔点是一个可行的办法[12-14]。可钨与钎料界面的大线膨胀系数差导致热应力的问题仍然存在,KALIN等[12]和OONO等[13]在钎料中加入片状的小线膨胀系数材料作为缓释层来缓解接头热应力。但是,置入缓释层后增加的两个异质界面加大了接头的结合难度,并降低了接头的结合质量。为此,本文作者以添加降熔点元素Si、B的Ni-Cr-Fe-Si-B镍基合金粉末与钨粉为原料,通过高能球磨制成混合粉末钎料中间层对钨/钢进行真空扩散钎焊连接(以下简称为连接),一方面可在较低温度下进行炉中钎焊,另一方面可利用钎料层本身的低线膨胀系数来缓解接头热应力,改善接头连接质量。

1 实验

试验所用母材为纯钨(W)和0Cr13Al铁素体不锈钢。中间层材料为钨粉、Ni-Cr-Fe-Si-B粉及镍箔,其中镍箔中间层加入有利于钢侧界面的结合,并进一步降低接头残余应力。试验用各材料成分如表1所示。钨和钢母材均线切割加工成d 8 mm×6 mm的圆柱体。厚300 μm的镍箔也剪成d 8 mm的圆片。连接前,所有连接端面均打磨至1200号金相砂纸,然后在丙酮中超声清洗15 min。质量比为9:1的钨粉与Ni-Cr-Fe-Si-B粉在Pulverisette 6高能球磨机中以300 r/min球磨10 h后冷压成厚约300 μm的d 8 mm混合粉末箔片。从上至下按钨/混合粉末箔片/镍箔/钢顺序组装好的连接试样放入ZRYS1500真空热压炉中进行真空扩散钎焊。

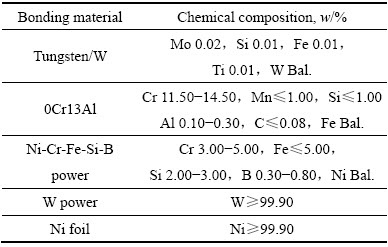

表1 试验材料的化学成分

Table 1 Chemical compositions of bonding materials

利用DTA404PC高温差示量热扫描仪测试Ni-Cr-Fe-Si-B粉末的熔点为970 ℃左右。为了使连接温度下Ni-Cr-Fe-Si-B粉末液化,论文选择的连接温度为1000、1050和1100 ℃,均保温60 min。以10 ℃/min的加热速率升至连接温度,保温结束后随炉冷却。连接压力为5 MPa,真空度小于2×10-3 Pa。

球磨后的混合粉末采用BT9300H激光粒度分析仪测试粒径分布,采用JSM-6360LV扫描电镜(SEM)观察粉末形貌。连接后,截取钨/钢试样。用扫描电镜对结合区进行显微组织观察,用扫描电镜附带的能谱仪(EDS)对结合区进行成分分析。用线切割加工出5 mm×5 mm×12 mm的剪切试样,利用自制模具在CMT-5105电子万能实验机上进行静载拉剪试验,剪切速度为1 mm/min。抗剪强度取相同工艺下3个试样剪切强度的平均值。剪断后,用扫描电镜观察断口形貌。

2 结果与分析

2.1 结合区显微组织与成分

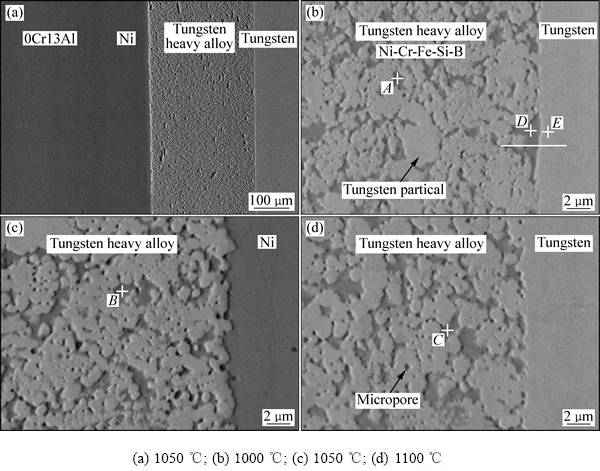

试验所形成接头结构如图1(a)所示,由钢母材/镍层/钨基高密度合金层/钨母材4部分组成。其中钨基高密度合金层由90W-10(Ni-Cr-Fe-Si-B)高能球磨态混合粉末在连接温度下液相烧结生成,厚度均为280 μm左右。接头中钢母材/镍界面不存在连接难度,而钨基高密度合金层的均匀化、致密化生成及其与钨母材的高强结合是决定接头连接质量的关键。

由图1(b)、(c)、(d)可知,3种连接温度下,钨基高密度合金层均由占大部分体积的钨颗粒相和均布在钨颗粒相之间的Ni-Cr-Fe-Si-B粘结相(以下简称粘结相)构成,整体组织均匀。钨颗粒长度多小于5 μm,在钨颗粒的中间存在很多微孔隙,但大部分孔隙直径不超过0.2 μm,没有发现直径超过1μm的孔隙,其致密性良好。图1中A、B、C点对应粘结相中W元素含量(摩尔分数,下同)分别为10.21%、15.42%和18.09%,说明钨基高密度合金层的粘结相处于液态时溶解了大量W原子,并且连接温度越高,粘结相溶解的W原子越多。随着连接温度的升高,钨基高密度合金层的液相烧结组织特征变得更加明显,相对于连接温度1000 ℃,1100 ℃对应的钨颗粒相轮廓更加圆滑,高能球磨形成的微小黏聚团中的钨颗粒通过粘结相烧结成整体钨颗粒相,只在钨颗粒相中留下微小的近圆形微空隙。

钨基高密度合金层与钨母材结合非常紧密,从图1(b)、(d)可知,两者界面由钨颗粒相/钨母材结合区和粘结相/钨母材结合区组成,两种结合区间隔分布。对于连接温度1000 ℃对应的粘结相/钨母材结合区,近界面的粘结相中W元素含量为11.31%(见图1中D点),而近界面的钨母材中Ni、Fe、Cr元素含量分别为3.77%、1.81%和1.23%(见图1中E点)。粘结相/钨结合区界面通过钨母材表面大量的W原子溶入粘结相及粘结相中少量的Ni、Fe、Cr原子扩散进入钨母材表层而实现两者之间的冶金结合。图2所示为连接温度1000 ℃对应的粘结相/钨母材结合区成分线扫描,扫描途径如图1(b)中所示。从图2可知,粘结相在靠近钨母材表面的很窄范围内,Ni、Fe、Cr元素的含量明显降低,而W元素明显增加。这是由于保温过程中钨母材界面向液态粘结相溶解的W原子来不及扩散及降温过程中钨母材界面W原子持续向粘结相固相扩散的结果。对于钨颗粒相/钨母材结合区,其界面结合机理也属于钎焊连接,钎料来自高能球磨过程中黏附在钨颗粒表面的Ni-Cr-Fe-Si-B和连接过程中通过毛细作用润湿过来的液态Ni-Cr-Fe-Si-B。由于钎料很少,经过相互扩散,钨颗粒相/钨母材界面观察不到Ni-Cr-Fe-Si-B钎缝。

镍/钨基高密度合金层界面形状不规则(见图1(c)),相对于采用常规中间层所形成的平直界面结合,该结合区成为两种材质之间的过渡带,有利于提高界面强度和降低界面热应力。该界面主要以瞬间液相扩散连接机制结合。Ni-Cr-Fe-Si-B液化后,与镍中间层发生原子互扩散,Ni原子扩散进入Ni-Cr-Fe-Si-B液中,而Si、B等元素扩散进入镍中间层,导致Ni-Cr-Fe-Si-B液相因Si、B含量逐渐降低而等温凝固,实现界面的瞬间液相扩散连接。钢母材和镍中间层通过固相扩散形成连接,从图1(a)中难以分辨两者的结合界面,结合非常好。

图1 不同连接温度对应的钨/钢接头显微组织

Fig. 1 Microstructures of tungsten/steel brazing joint at different bonding temperatures

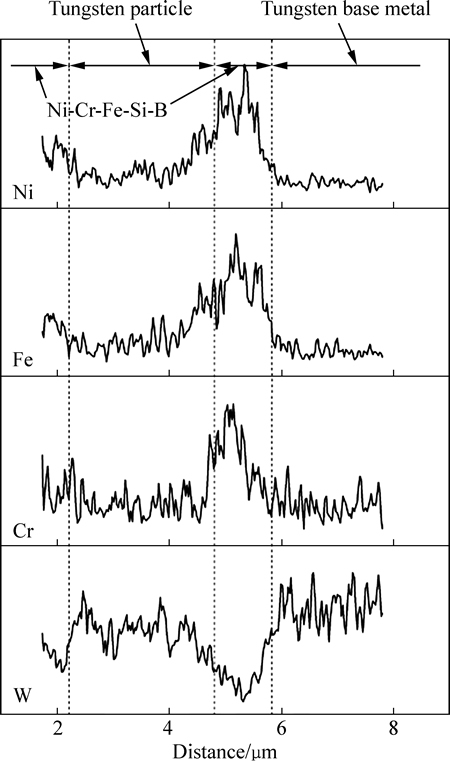

图2 连接温度1000 ℃时对应的钨基高密度合金层/钨母材界面中粘结相/钨母材结合区成分线扫描

Fig. 2 Element line scanning of tungsten heavy alloy/tungsten interface at bonding temperature of 1000 ℃

2.2 高能球磨与钨基高密度合金层的均匀致密化

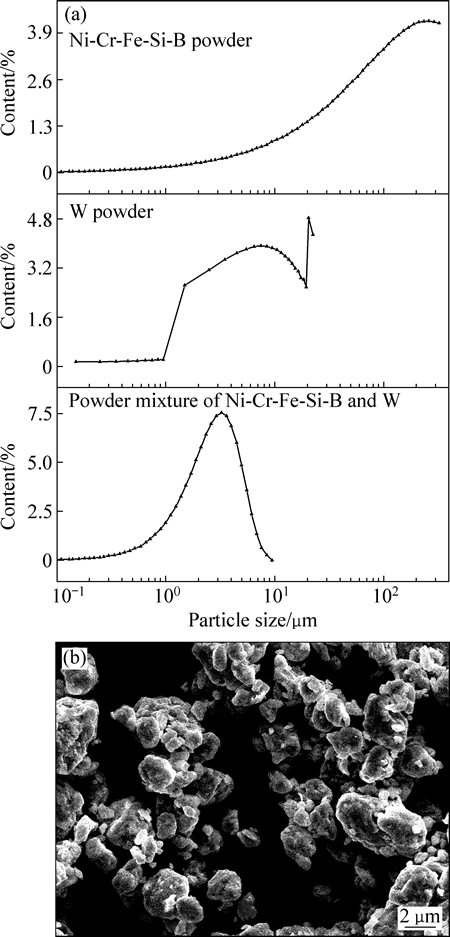

普通液相烧结条件下,固相颗粒随着液相的流动,发生滑动、旋转、重排而实现组织的均匀化与致密化,是一种自发过程[15]。如果液相烧结在较大压力下进行,则均匀化与致密化难以顺利进行,烧结组织中会形成较多的大孔隙和粘结相聚集区[16]。其原因在于粘结相液化后,固相颗粒在压力下迅速靠近并接触,形成阻碍组织均匀化与致密化自发进行的固相颗粒骨架。接头中钨基高密度合金层在5 MPa的连接压力下液相烧结生成,如何避免其组织中出现大孔隙和粘结相聚集区,从而保证钨/钢接头的物理、力学性能均匀性与气密性是很重要的问题。本实验中采用高能球磨制备钨粉与Ni-Cr-Fe-Si-B粉的混合粉末解决了该问题。由图1可知,钨基高密度合金层组织中没有出现大孔隙,也没有出现粘结相聚集区,实现了钨基高密度合金组织的均匀化与致密化。首先,高能球磨使混合粉末大大细化,如图3(a)可知,Ni-Cr-Fe-Si-B粉末中粒径大于100 μm的颗粒占很大比例,其中位径为107 μm,并且粒径分布很不均匀。钨粉的粒径分布也不均匀,且中位径也达到14 μm。经过10 h高能球磨后,混合粉末大大细化,中位径只有2.7 μm,并且粒径分布均匀化,呈正态分布。混合粉末的细化与均匀化为钨基高密度合金层形成均匀化组织打下了基础。其次,高能球磨使混合粉末由分离态变成黏附态。混合粉末细化的同时,硬质钨颗粒被反复地砸入软质Ni-Cr-Fe-Si-B颗粒中并又被反复地挤出,逐渐使钨颗粒表面黏附一层Ni-Cr-Fe-Si-B,并在钨粉表面层发生机械合金化。图3(b)所示为球磨后的混合粉末微观形貌,球磨后的混合粉末细小、形状复杂,部分粉末颗粒黏结成团。连接过程中,Ni-Cr-Fe-Si-B液化后,钨颗粒表面便包覆一层薄薄的液膜。在压力作用下,虽很快形成钨骨架,但由于液态粘结相一开始便分布非常均匀,从而很少会存在缺少液相的空洞区,保证了液相烧结形成钨基高密度合金层的致密化与均匀化。当然,即使制备出完美的高能球磨态混合粉末,也不能使液相烧结生成的钨基高密度合金层完全致密化,因为液相被钨骨架分割成一个个封闭或半封闭的小液区而不能自由流动,冷却过程中,由于液态收缩和凝固收缩,原封闭的液相区域便会形成分散的微缩孔(见图1(d))。

图3 Ni-Cr-Fe-Si-B粉、W粉及两者高能球磨态混合粉体的粒径分布与混合粉体的微观形貌

Fig. 3 Particle size distribution of Ni-Cr-Fe-Si-B power , W powder and powder mixture of Ni-Cr-Fe-Si-B and W prepared by high energy ball milling (a) and microstructures of powders mixture (b)

2.3 接头的力学性能及断口形貌

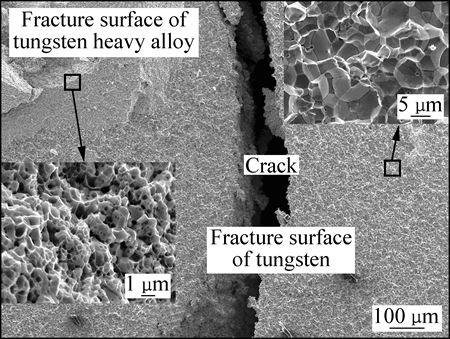

连接温度1000、1050和1100 ℃对应的接头抗剪强度分别为(126+4) MPa、(125+5) MPa和(130+3) MPa,连接温度对接头强度没有明显影响。分析3种温度下的断口形貌,发现接头试样均断在钨母材/钨基高密度合金层界面,大部分断面发生在钨母材中,小部分断面发生在钨基高密度合金层中,没有发现钨母材与钨基高密度合金层界面分离断面,这不但说明接头的钨母材/钨基高密度合金层形成了高强界面结合,并且说明接头断裂模式属于一种较低残余应力状态下的异种材料断裂模式[17]。图4所示为试样典型断口形貌,由图4可知,钨母材断裂面较为平坦,绝大部分属于钨晶粒沿晶断裂,在断裂瞬间,还诱发裂纹向钨母材纵深扩展。而发生在钨基高密度合金层中的断口形貌呈现为钨颗粒相与粘结相的韧性脱离断裂特征,粘结相在断裂过程发生较大的塑性变形,形成了类似韧窝断裂的形貌特征,高能球磨形成的细小均匀钨颗粒及均匀分布的粘结相显然加大了钨颗粒与粘结相的脱离断裂难度,从而提高了钨基高密度合金层的强度,即提高了钨/钢接头的强度。

图4 接头剪切断口形貌

Fig. 4 Fracture surface of tungsten/steel joint

3 结论

1) 以90W-10(Ni-Cr-Fe-Si-B)混合粉末为钎料中间层,实现了钨与钢的真空扩散钎焊连接。接头由钨母材/钨基高密度合金层/镍层/钢母材4部分组成。

2) 钨基高密度合金层由90W-10(Ni-Cr-Fe-Si-B)混合粉末压力下液相烧结生成。钨基高密度合金层与钨母材以钎焊机制实现连接,与镍中间层以瞬间液相扩散焊机制实现连接。

3) 高能球磨制备90W-10(Ni-Cr-Fe-Si-B)混合粉末实现了接头中钨基高密度合金层的均匀化、致密化生成。

4) 试验采用的扩散钎焊连接温度对接头剪切强度影响不大,剪切强度最低值125 MPa,最高值130 MPa。断裂均发生在钨基高密度合金层/钨母材结合区域,断口形貌主要呈现为钨母材的脆性沿晶断裂和钨基高密度合金层粘结相与钨颗粒相的韧性脱离断裂。

REFERENCES

[1] EZATO K, SUZUKI S, SEKI Y, MOHRI K, YOKOYAMA K, ESCOURBIAC F. Progress of ITER full tungsten divertor technology qualification in Japan[J]. Fusion Engineering & Design, 2015, 98/99: 1281-1284.

[2] JAKSIC N, GREUNER H, HERRMANN A,  B, VORBRUGG S. Results of high heat flux tests and structural analysis of the new solid tungsten divertor tile for ASDEX upgrade[J]. Fusion Engineering & Design, 2015, 98/99: 1333-1336.

B, VORBRUGG S. Results of high heat flux tests and structural analysis of the new solid tungsten divertor tile for ASDEX upgrade[J]. Fusion Engineering & Design, 2015, 98/99: 1333-1336.

[3] NORAJITRA P, GERVASH A, GINIYATULIN R, HIRAI T, JANESCHITZ G, KRAUSS W. Helium-cooled divertor for DEMO: Manufacture and high heat flux tests of tungsten-based mock-ups[J]. Journal of Nuclear Materials, 2009, 386(2): 813-816.

[4] 刘文胜, 刘书华, 马运柱, 蔡青山, 刘昊阳, 余 强, 伍 镭. 基于镍基微晶钎料的钨/钢真空焊接接头的组织及性能[J]. 中国有色金属学报, 2014, 24(12): 3051-3058.

LIU Wen-sheng, LIU Shu-hua, MA Yun-zhu, CAI Qing-shan, LIU Hao-yang, YU Qiang, WU Lei. Microstructure and properties of tungsten/steel joint brazed with Ni-based foil-type filler[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3051-3058.

[5] ZHONG Z H, HINOKI T, NOZAWA T, PARK Y H, KOHYAMA A. Microstructure and mechanical properties of diffusion bonded joints between tungsten and F82H steel using a titanium interlayer[J]. Journal of Alloys and Compounds, 2010, 489(2): 545-551.

[6] BASUKI WW, AKTAA J. Investigationoftungsten/EU- UROFER97 diffusion bondingusing Nb interlayer[J]. Fusion Engineering and Design, 2011, 86(9/11): 2585-2588.

[7] 马运柱, 王艳艳, 刘文胜, 蔡青山. 扩散焊接钨/钒/钢体系的界面结构及力学性能[J]. 焊接学报, 2013, 34(12): 17-20.

MA Yun-zhu, WANG Yan-yan, LIU Wen-sheng, CAI Qing-shan. Interface microstructure and mechanical properties of diffusion bonded joints between tungsten and ferritic steel with vanadium interlayer[J]. Transactions of the China Welding Institution, 2013, 34(12): 17-20.

[8] 马运柱, 刘昊阳, 刘文胜, 蔡青山, 余 强, 刘书华, 伍 镭. 扩散焊接钨/钢接头残余应力的数值模拟[J]. 中国有色金属学报, 2014, 24(9): 2280-2285.

MA Yun-zhu, LIU Hao-yang, LIU Wen-sheng, CAI Qing-shan, Yu Qiang, LIU Shu-hua, WU Lei. Numerical simulation of residual stress in tungsten/steel diffusion bonded joints[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2280-2285.

[9] BASUKI W W, AKTAA J. Process optimization for diffusion bonding of tungsten with EUROFER97 using a vanadium interlayer[J]. Journal of Nuclear Materials, 2015, 459: 217-224.

[10] MUNEZ C J, GARRIDO M A, RAMS J,  A. Experimental study of W-Eurofer laser brazing for divertor application[J]. Journal of Nuclear Materials, 2011, 418(1/3): 239-248.

A. Experimental study of W-Eurofer laser brazing for divertor application[J]. Journal of Nuclear Materials, 2011, 418(1/3): 239-248.

[11] 郭双全. 面向等离子体材料钨与热沉材料的连接技术[D]. 成都: 西南交通大学, 2011: 80-100.

GUO Shuang-quan. Study on joining of tungsten as plasma facing materials with heat sink materials[D]. Chengdu: Southwest Jiaotong University, 2011: 80-100.

[12] KALIN B A,FEDOTOV V T, SEVRJUKOV O N,MOESLANG A, ROHDE M. Developmentofrapidly quenched brazing foils to join tungsten alloyswithferritic steel[J]. Journal of Nuclear Materials B, 2004, 329/333: 1544-1548.

[13] OONO N, NOH S, IWATA N, NAGASAKA T, KASADA R, KIMURA A. Microstructures of brazed and solid-state diffusion bonded joints of tungsten with oxide dispersion strengthened steel[J]. Journal of Nuclear Materials, 2011, 417(1/3): 253-256.

[14] KALIN B A, FEDOTOV V T, SEVRJUKOV O N, KALASHNIKOV A N, SUCHKOV A N, MOESLANG A, ROHDE M. Development of brazing foils to join monocrystalline tungsten alloys withODS-EUROFER steel[J]. Journal of Nuclear Materials, 2007, 367(4): 1218-1222.

[15] 池永恒, 张瑞杰, 方 伟, 杨诗棣, 曲选辉. W-Cu液相烧结体系致密化行为的模拟[J]. 中国有色金属学报, 2014, 24(2): 416-423.

CHI Yong-heng, ZHANG Rui-jie, FANG Wei, YANG Shi-di, QU Xuan-hui. Simulation of densification process of W-Cu system during liquid-phase sintering[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 416-423.

[16] 杨宗辉, 沈以赴, 李晓泉. 自生成钨基高密度合金中间层的钨/钢真空扩散连接[J]. 机械工程学报, 2013, 49(4): 58-63.

YANG Zong-hui, SHEN Yi-fu, LI Xiao-quan. Diffusion bonding tungsten to steel in vacuum with tungsten heavy alloy interlayer formed on tungsten surface[J]. Journal of Mechanical Engineering, 2013, 49(4): 58-63.

[17] 邹贵生, 吴爱萍, 任家烈, 杨 俊, 李晓宁, 梁陈剑. 含金属间化合物的Al基合金半固态加压连接Si3N4陶瓷[J]. 清华大学学报(自然科学版), 2002, 42(11): 1433-1435.

ZOU Gui-sheng, WU Ai-ping, REN Jia-lie, YANG Jun, LI Xiao-ning, LIANG Chen-jian. Semi-solid state pressure bonding of Si3N4 ceramics with Al-based alloys containing intermetallic compounds[J]. Journal of Tsinghua University (Science and Technology), 2002, 42(11): 1433-1435.

Vacuum diffusion brazing bonding tungsten to steel using W-(Ni-Cr-Fe-Si-B) mixed powders interlayer

YANG Zong-hui1, 2, SHEN Yi-fu 3, CHU Ya-jie1, 2, LI Xiao-quan1, 2

(1. School of Material Engineering, Nanjing Institute of Technology, Nanjing 211167, China;

2. Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology, Nanjing Institute of Technology, Nanjing 211167, China;

3. College of Material Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 211106, China)

Abstract: Vacuum diffusion brazing between tungsten (W) and 0Cr13Al steel using 90W-10(Ni-Cr-Fe-Si-B) (mass fraction, %) powder mixture interlayer prepared by high energy ball milling, was carried out with 5 MPa at 1000, 1050 and 1100 ℃ for 60 min, respectively. The morphology of powder mixture was studied by laser particle size analyzer and SEM. The microstructures, composition and fracture characteristics of the joints were studied by SEM, EDS and the shear strength of the joints were tested by electronic universal testing machine. The results show that the tungsten heavy alloy layer forms on the tungsten matrix through 90W-10(Ni-Cr-Fe-Si-B) mixed powder liquid phase sintering, and good bonding between tungsten and steel is realized based on diffusion brazing mechanism. High energy ball milling plays key role in densification and homogenization of tungsten heavy alloy layer. At higher bonding temperature, the liquid phase sintering microstructure characteristics of the tungsten heavy alloy layer is more obvious. The shear strength of joints is between 125-130 MPa. The fractures all occur near the interface of tungsten matrix and tungsten heavy alloy layer, the former fracture is brittle intergranular fracture, while the latter fracture is ductile interface debonding fracture between tungsten phase and Ni-rich phase.

Key words: tungsten; interlayer; brazing; tungsten heavy alloy

Foundation item: Project(51075205) supported by the National Natural Science Foundation of China; Project (ZKJ201502) supported by the Scientific Research Foundation of Nanjing Institute of Technology, China; Project (CKJB201303) supported by Nanjing Institute of Technology, China

Received date: 2016-03-18; Accepted date: 2016-07-19

Corresponding author: YANG Zong-hui; Tel: +86-25-86118274; E-mail: yzh@njit.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51075205);南京工程学院在职博士科研资助项目(ZKJ201502);南京工程学院创新基金面上项目(CKJB201303)

收稿日期:2016-03-18;修订日期:2016-07-19

通信作者:杨宗辉,副教授,博士;电话:025-86118274;E-mail:yzh@njit.edu.cn