文章编号:1004-0609(2011)06-1373-07

La0.7Mg0.3Ni2.8Co0.5-xFex系列合金的制备及其储氢性能

唐成颖,潘文超,覃钺迪,周怀营

(桂林电子科技大学 材料科学与工程学院,桂林541004)

摘 要:在制备La-Ni-Co-Fe中间合金的基础上,采用机械合金化方法制备La0.7Mg0.3Ni2.8Co0.5-xFex (x=0, 0.1, 0.2, 0.3, 0.4, 0.5)系列储氢合金,研究在不同球磨时间下储氢合金的物相、微观形貌和电化学性能及元素置换对其储氢性能的影响。结果表明:La0.7Mg0.3Ni2.8Co0.5合金的主相为LaNi5相,La0.7Mg0.3Ni2.8Co0.5-xFex系列储氢合金球磨40 h和80 h后,主相为LaNi5相和少量LaMg2Ni9相;且随着球磨时间的增加,合金晶粒变细小,La0.7Mg0.3Ni2.8Co0.5合金的最大放电容量呈变大的趋势,从142.4 mA?h/g 增加到157.5 mA?h/g,La0.7Mg0.3Ni2.8Co0.2Fe0.3合金的最大放电容量从150.7mA?h/g增加到162.1mA?h/g,合金具有较好的循环稳定性能。

关键词:储氢合金;元素置换;XRD相分析;电化学性能

中图分类号:TG139.7 文献标志码:A

Preparation and hydrogen storage properties of La0.7Mg0.3Ni2.8Co0.5-xFex series alloys

TANG Cheng-ying, PAN Wen-chao, QIN Yue-di, ZHOU Huai-ying

(School of Materials Science and Engineering, Guilin University of Electronic Technology, Guilin 541004, China)

Abstract: The La0.7Mg0.3Ni2.8Co0.5-xFex (x=0, 0.1, 0.2, 0.3, 0.4, 0.5) series alloys were prepared by mechanical alloying (MA) based on the preparation of intermediate alloy. The phases, microstructures and electrochemical properties of the alloys were investigated. The results indicate that LaNi5 is the dominant phase in the alloy La0.7Mg0.3Ni2.8Co0.5, LaNi5 and small amount of LaMg2Ni9 phase exist in the alloys La0.7Mg0.3Ni2.8Co0.5-xFex after ball milling for 40 h and 80 h. The grains size decrease with increasing the ball milling time. The largest discharge capacity of the alloy La0.7Mg0.3Ni2.8Co0.5 increases to 157.5 mA?h/g from 142.4 mA?h/g with increasing the ball milling time. The largest discharge capacity of La0.7Mg0.3Ni2.8Co0.2Fe0.3 alloy increases to 162.1 mA?h/g from 150.7 mA?h/g, as well as the improved cycling stability.

Key words: hydrogen storage alloys; element substitution; XRD phase identification; electrochemical properties

稀土镍系AB5型储氢合金由于具有能量密度高、高倍率放电能力强、循环寿命长、无记忆效应、无环境污染以及价格适中等诸多优点被广泛用做镍氢电池负极活性材料[1]。当前储氢合金研究热点之一是采用元素取代、材料复合、机械合金化法制备微细纳米晶等多种措施,提高储氢合金放电容量,改善合金循环性能,开发有应用前景的新型储氢合金材料[2-7]。La-Mg-Ni系AB3型合金是一种具有PuNi3型结构的新型稀土系储氢合金[8]。CHEN等[9-10]研究发现具有PuNi3结构的LaCaMgNi9合金的电化学容量可达360 mA?h/g,但其高倍率放电能力较差,循环容量衰退比较快。KOHNO等[11]用感应熔炼法制备La2MgNi9、La5Mg2Ni23和La3MgNi14型La-Mg(Ni-Co)x(x=3.0~3.5)合金研究发现,上述合金的放电容量高达390~410 mA?h/g。其中,La5Mg2Ni23型合金La0.7Mg0.3Ni2.8Co0.5的放电容量最高达到410 mA?h/g,但循环性能较差。

为了改善La-Mg-Ni系AB3型合金的循环性能,唐睿等[12]研究稀土元素Sm和Dy取代La0.8-xRExMg0.2- Ni3.2Co0.6合金中的La,LI等[13]和刘丽琴等[14]分别研究稀土元素Ce、Pr、Nd置换La0.8R0.2Mg0.2-(NiCo- MnAl)3.5(R=La, Ce, Pr, Nd)和La0.8-xRExMg0.2Ni2.8Co0.6合金中的La对储氢合金结构和储氢性能的影响。结果表明:稀土元素的置换都在一定程度上降低了合金的放电容量, 但却都改善或显著改善合金的循环稳定性能,提高了合金电极的循环寿命。LIAO等[15]研究La2Mg(Ni0.8-xCo0.2Alx)9合金中Al置换Ni对其结构和电化学性能的影响,发现Al含量的增加导致放电容量和高倍率放电能力降低,但却显著改善合金循环稳定性能。LIAO等[16]对Co部分置换La2Mg(Ni1-xCox)9 (x=0.1~0.5)中Ni对合金结构和电化学性能影响的研究表明:随着Co含量的增加,合金放电容量有一定程度的增加,循环稳定性大为改善,100次循环容量保持率从60.2%达到87.9%。但Fe置换Co对La-Mg-Ni系AB3型合金储氢性能的影响研究尚未见报道。为此,本研究在电弧熔炼法制备中间合金的基础上,用机械合金化方法制备La-Mg-Ni系La0.7Mg0.3Ni2.8C0.5-xFex (x=0, 0.1, 0.2, 0.3, 0.4, 0.5)合金,研究球磨时间及元素Fe部分取代Co对合金结构和电化学性能的影响规律。

1 实验

1.1 合金试样的制备

用电弧熔炼法制备La-Ni-Co-Fe中间合金。首先,打磨和清洗合金组元La的表面氧化物,放入高纯酒精或丙酮中。然后,按合金La0.7Mg0.3Ni2.8C0.5-xFex (x=0, 0.1, 0.2, 0.3, 0.4, 0.5)摩尔比计算、称量合金除Mg以外各组元质量。最后,将各中间合金组元放入国产WK-II型非自耗真空电弧炉、在高纯氩气气氛下熔炼3次,得到成分均匀的中间合金。

用机械合金化方法制备La-Mg-Ni-Co-Fe储氢合金。将电弧熔炼制备的中间合金表面打磨、清洗干净后,在研钵中捣碎磨细,按计算结果称取适量合金粉末和Mg粉混合装入不锈钢罐中,在QM-1SP行星式球磨机中球磨。为了防止球磨过程中样品的氧化,将球罐抽真空后再充入氩气保护。先采用200 r/min的转速球磨1 h,使样品均匀混合,然后采用400 r/min分别球磨20,40,80 h制得所需合金粉末,球料比为40:1。

1.2 合金试样的表征

采用X射线粉末衍射方法(XRD)对合金的相结构进行分析,衍射仪的型号为德国Bruker公司D8-Advance型衍射仪(Cu Kα,电压30 kV,电流30 mA)。采用扫描电子显微镜(SEM)对合金样品的表面形貌进行观察,扫描电子显微镜型号为日本JEOL公司JSM-5600LV。

1.3 合金电化学性能测试

贮氢合金的电化学性能采用武汉兰电电子有限公司生产的LAND系列电池测试系统CT2001A电池测试仪进行测试。采用三电极系统即储氢合金为工作电极、NiOOH/Ni(OH)2 为辅助电极,Hg/HgO 为参比电极,电解液为6 mol/L 的KOH 溶液。先将适量的合金粉末与导电剂Ni粉以1?2(质量比)比例充分混合均匀,加入适量的聚乙烯醇(PVA)水溶液(4.0%,质量分数)和羧甲基纤维素钠(CMC)水溶液(3.0%,质量分数)等作为粘结剂,混合均匀制成糊状混合物,涂覆于点焊有镍导线的泡沫镍集流体上,烘干、压制、修整后得到储氢电极。充放电条件如下:充电电流Ic=150 mA/g,充电时间τc=4.5 h,放电电流Id=30 mA/g,放电截止电压Ud=0.9 V。在每次充、放电间隔,电池开路搁置10 min。

2 结果与分析

2.1 XRD物相分析

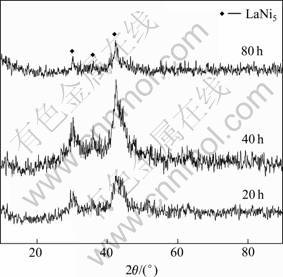

图1所示为采用机械合金化法制备的La0.7Mg0.3Ni2.8Co0.5储氢合金球磨不同时间的XRD谱。由图1可知,La0.7Mg0.3Ni2.8Co0.5合金样品的主相为LaNi5相。球磨20 h后,合金粉末样品中不再含有单质相,说明所有合金组元都已经参与合金化过程。当球磨时间延长到40 h后,样品的XRD谱中LaNi5相出现加强的趋势,说明样品合金化效果更明显。球磨80 h后,样品XRD谱中的一些衍射强峰消失,衍射峰强度的降低,且衍射峰出现明显的宽化,表明合金粉末已变得很细,合金向着晶粒细化和非晶态的方向发展。

图1 La0.7Mg0.3Ni2.8Co0.5合金粉末的XRD谱

Fig.1 XRD patterns of La0.7Mg0.3Ni2.8Co0.5 alloy powders

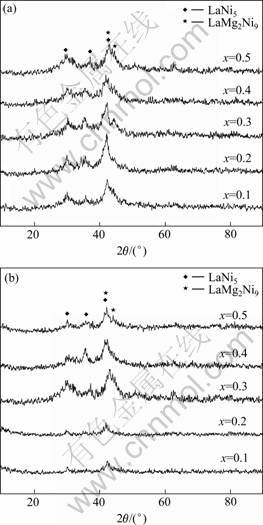

图2所示为La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.2, 0.3, 0.4, 0.5)储氢合金分别球磨40 h和80 h得到的XRD谱。由图2可知,La0.7Mg0.3Ni2.8Co0.5-xFex系列合金的主相为LaNi5相,球磨40 h和80 h后,合金还存在少量的LaMg2Ni9相。随着替代元素Fe含量的增加,个别衍射峰加强,表示生成了少量的第二相。与此同时,衍射峰峰形变宽,合金粉末颗粒呈现晶粒细化和非晶化的特征。通过比较图2(a)和(b)中La0.7Mg0.3Ni2.8Co0.2Fe0.3合金球磨不同时间的XRD谱发现,球磨80 h的衍射峰比球磨40 h的更宽化,表明随着球磨时间的增加,合金化效应越来越明显,合金颗粒越来越细。

图2 La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.2, 0.3, 0.4, 0.5)合金球磨40 h和80 h的XRD谱

Fig.2 XRD patterns of La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.2, 0.3, 0.4, 0.5) alloys milled for 40 h (a) and 80 h (b)

2.2 SEM扫描电镜形貌分析

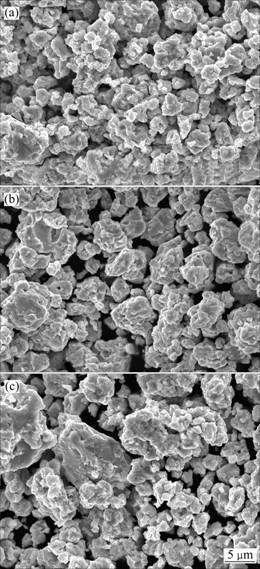

图3所示为合金La0.7Mg0.3Ni2.8Co0.5分别球磨20 h、40 h和80 h的SEM像。由图2可知,合金经过20 h球磨后,粉末颗粒呈多角形碎石状,尺寸分布较均匀;球磨40 h后,样品出现较多的粘结团状大颗粒,整体尺寸分布趋向不均匀;球磨80 h后,合金颗粒变小,呈现出严重的塑性变形,甚至出现多层次的粘结态。机械合金化法直接合成合金的本质是颗粒在球磨过程中不断冷焊和受磨球撞击破坏粉碎的过程。图 3(b)和(c)中SEM像出现粘结团状大颗粒或多层次的粘结态是由于随着球磨时间的延长,粉末粒度不断变小,达到一定的粒径后,粉末获得较大的比表面 积,粉末体系内部产生更多的畸变从而具有更高的能量,产生较大的有效相互吸附作用力,将周围的颗粒吸住并在磨球的撞击作用下粉碎或粘结得更好形成团状甚至层状大颗粒。因此,合金在球磨过程中粉末粒度大小、粒度分布变化及颗粒显微形貌变化符合机械合金化法[17]的本质变化过程。此外,与XRD结果相一致,图3中除了主要的多角形碎石状晶粒外,还存在极少部分平面状晶粒,表明除了主相LaNi5外,还存在少量其他合金相。

图3 合金La0.7Mg0.3Ni2.8Co0.5球磨20 h、40 h和80 h的 SEM像

Fig.3 SEM images of La0.7Mg0.3Ni2.8Co0.5 alloy powders milled for 20 h (a), 40 h (b) and 80 h (c)

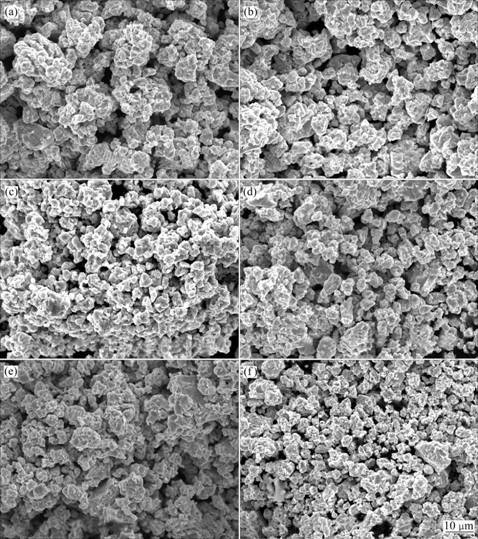

图4所示为La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.3, 0.5)分别球磨40 h和80 h后的SEM像。对比图4(a)、(c)、(e)可知,随着Fe元素部分替代La0.7Mg0.3Ni2.8Co0.5合金中Co元素含量增多,样品的表面形貌特征并没有太大的变化,呈多边形碎石状。随着替代元素Fe含量的增加,样品的颗粒分布趋向不均匀,原因可能是由于Fe元素的加入,样品内部出现少量新相;另一方面,由于球磨时间的延长,合金粉末反复的破裂及冷焊过程产生微细粒子,不断细化绕卷成螺旋状,单个的粒子逐步转变成混合体系,样品内部发生粘结所致。比较图4(a)、(c)、(e)和(b)、(d)、(f)发现,相同成分的合金粉末球磨80 h后的晶粒比球磨40 h后的更小,这与XRD谱中的衍射峰变宽、颗粒变小的结论相一致。

2.3 合金的电化学性能分析

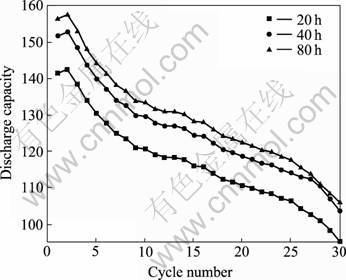

图5所示为经过不同球磨时间制得的La0.7Mg0.3- Ni2.8Co0.5合金样品充分活化后测定的放电曲线。从图5中看出,随着球磨时间的增加,La0.7Mg0.3Ni2.8Co0.5合金的最大放电容量有所提高,这是由于随着球磨时间的增加,晶粒细化,合金体系内部的表面能增大,内部缺陷和畸变增多,使其活性增大,合金的表面具有更高的电催化活性,合金的微结构因晶粒细化和缺陷密度增加而有利于合金的吸放氢,从而提高了合金的放电容量[7]。从图5中放电曲线的峰值可知,本研究的合金电极虽然活化性能良好,但最大放电容量值较低,低于文献[11]报道的最大放电容量,其原因可能是与现实的实验条件和样品制备方法不同有关,或者是因为从样品制样到性能测试,中间放置时间过长导致其内部发生各种复杂的物理化学变化。此外,不同球磨时间的合金电极的放电曲线升降变化规律具有相似性,其放电容量先略微升高,然后随着充放周期增多,容量衰减较快。后期合金电极容量衰变的较快的原因可能是由于合金粉末在电解液中腐蚀、脱落所致。

图4 合金La0.7Mg0.3Ni2.8Co0.5-xFex球磨40 h和80 h后的SEM像

Fig.4 SEM images of La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.3, 0.5) alloys powders milled for 40 h and 80 h: (a) x=0.1, 40 h; (b) x=0.1, 80 h; (c) x=0.3, 40 h; (d) x=0.3, 80 h; (e) x=0.5, 40 h; (f) x=0.5, 80 h

图5 不同球磨时间的La0.7Mg0.3Ni2.8Co0.5合金粉末的放电曲线

Fig.5 Discharge curves of La0.7Mg0.3Ni2.8Co0.5 alloy powders milled for different times

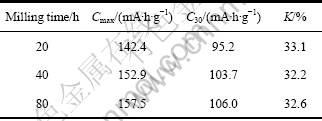

表1所列为本研究球磨不同时间制得的La0.7Mg0.3Ni2.8Co0.5合金电极的最大放电容量Cmax,经过30次充放电循环后的放电容量C30及衰变率K( )。由表1可以看出,经过 20 h、40 h和80 h球磨后,由La0.7Mg0.3Ni2.8Co0.5合金所制得电极的最大放电容量虽呈上升趋势,但是变化不大,样品经过80 h球磨后的合金电极具有最高的最大放电容量157.5 mA?h/g。经过20 h、40 h和80 h球磨后的样品内部结构本质变化不是很大,其放电衰退率K值基本一致。

)。由表1可以看出,经过 20 h、40 h和80 h球磨后,由La0.7Mg0.3Ni2.8Co0.5合金所制得电极的最大放电容量虽呈上升趋势,但是变化不大,样品经过80 h球磨后的合金电极具有最高的最大放电容量157.5 mA?h/g。经过20 h、40 h和80 h球磨后的样品内部结构本质变化不是很大,其放电衰退率K值基本一致。

表1 不同球磨时间的La0.7Mg0.3Ni2.8Co0.5合金电极的Cmax、C30、K值

Table 1 Cmax, C30 and K value of alloy electrodes of La0.7Mg0.3Ni2.8Co0.5 milled for various times

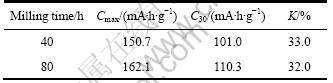

图6所示为La0.7Mg0.3Ni2.8Co0.2Fe0.3合金球磨40 h和80 h后再充分活化后的放电曲线。表2所列为其相应最大放电容量Cmax、经过30次充放电循环后的放电容量C30及衰变率K值。由图6和表2可知,随着球磨时间的延长,合金的最大放电容量也是呈上升趋势,但变化不大,球磨40 h和80 h后,两样品的最大放电容量分别为150.7 mA?h/g和162.1 mA?h/g,经过80 h球磨后,制得La0.7Mg0.3Ni2.8Co0.2Fe0.3合金的电极的循环稳定性能也略有改善。

图6 La0.7Mg0.3Ni2.8Co0.2Fe0.3合金放电曲线

Fig.6 Discharge curves of La0.7Mg0.3Ni2.8Co0.2Fe0.3 alloy milled for different times

表2 球磨40 h和80 h后La0.7Mg0.3Ni2.8Co0.2Fe0.3合金电极的Cmax、C30和K值

Table 2 Cmax, C30 and K of alloy electrodes of La0.7Mg0.3- Ni2.8Co0.5Fe0.3 milled for 40 h and 80 h

因此,合金电化学性能实验研究表明:在制备中间合金基础上,用机械合金化方法制备的La0.7Mg0.3Ni2.8Co0.5合金及La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.2, 0.3, 0.4, 0.5) 系列合金均能在第二次循环达到最大放电容量,活化性能优异,合金最大放电容量随球磨时间增加而增加,但最大放电容量较低。

3 结论

1) 合金样品的主相为LaNi5相,随着球磨时间增加,衍射峰变宽,毛刺感增强,合金样品粉末变得很细,合金向着晶粒细化和非晶态的方向发展。对Fe置换Co 的La0.7Mg0.3Ni2.8Co0.5-xFex (x=0.1, 0.2, 0.3, 0.4, 0.5)系列合金,随着替代元素Fe含量的增加,衍射峰先增强后降低,峰形变宽,颗粒变细;球磨40 h和 80 h后,主相为LaNi5相和少量的LaMg2Ni9相。

2) 样品的表面形貌呈多边形碎石状,随着球磨时间的延长和替代元素Fe含量的增加,合金颗粒变细,同时,合金颗粒分布趋向不均匀。原因可能是球磨时间延长,合金粉末反复破裂及冷焊过程产生微细粒子,不断细化绕卷成螺旋状,单个的粒子逐步转变成混合体系,样品内部发生粘结。

3) La0.7Mg0.3Ni2.8Co0.5合金及La0.7Mg0.3Ni2.8- Co0.5-xFex (x=0.1, 0.2, 0.3, 0.4, 0.5) 系列合金活化性能优异,合金的最大放电容量随球磨时间的增加而增加,但最大放电容量较低,合金的衰退率基本相同;用Fe部分替代Co元素制得的La0.7Mg0.3Ni2.8Co0.2Fe0.3合金具有较好的稳定性,最小衰退率为32.0%,但最大放电容量不高,仅为Cmax=162.1 mA?h/g。

4) 增加球磨时间,Fe部分置换Co改善La0.7Mg0.3Ni2.8Co0.5-xFex (x=0, 0.1, 0.2, 0.3, 0.4, 0.5)合金的储氢性能,提高合金的放电容量。

REFERENCES

[1] HONG K. The development of hydrogen storage alloys and the progress of nickel hydride batteries[J]. J Alloys Compd, 2001, 321(2): 307-313.

[2] 华 峰, 朱云峰, 刘燕芳, 张 伟, 李李泉. Ni 取代Al 对SrAl2 合金结构和储氢动力学性能的影响[J]. 中国有色金属学报, 2009, 19(9): 1658-1662.

HUA Feng, ZHU Yun-feng, LIU Yan-fang, ZHANG Wei, LI Li-quan. Effect of Ni substitution for Al on crystal structure and hydrogenation kinetics of SrAl2 alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1658-1662.

[3] PANDEY S K, SRIVASTAVA A, SRIVASTAVA O N. Improvement in hydrogen storage capacity in LaNi5 through substitution of Ni by Fe[J]. Inter J Hydrogen Energy, 2007, 32(13): 2461-2465.

[4] ZHU M, WANG Z M, PENG C H, ZENG M Q, GAO Y. The effect of grain refining on the discharge capacity of Mg2Ni/MmNi5-x(CoAlMn)x composite prepared by mechanical alloying[J]. J Alloys Compd, 2003, 349(1/2): 284-289.

[5] GAO M, MIAO H, ZHAO Y, LIU X, PAN H. Effects of rare earth elements substitution for Ti on the structure and electrochemical properties of a Fe-doped Ti-V based hydrogen storage alloy[J]. J Alloys Compd, 2009, 484(1/2): 249-255.

[6] 李松林, 刘 燚, VARIN R A, 刘怀菲, 崔建民, 陈仕奇. 球磨方式对纳米晶Mg2FeH6储氢材料合成与放氢性能的影响[J]. 中国有色金属学报, 2008, 18(1): 42-47.

LI Song-lin, LIU Yi, VARIN R A, LIU Huai-fei, CUI Jian-min, CHEN Shi-qi. Effect of ball milling methods on synthesis and desorption properties of nanocrystalline Mg2FeH6 hydrogen storage materials[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 42-47.

[7] 曹中秋, 王 婷, 边 静, 张 辉, 张国英. (Mg58Al42)0.9Ni0.1储氢合金的制备及其电化学性能[J]. 中国有色金属学报, 2009, 19(10): 1854-1859.

CAO Zhong-qiu, WANG Ting, BIAN Jing, ZHANG Hui, ZHANG Guo-ying. Preparation and electrochemical properties of (Mg58Al42)0.9Ni0.1 hydrogen storage alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1854-1859.

[8] KADIR K, SAKAI T, UEHARA I. Structural investigation and hydrogen storage capacity of LaMg2Ni9 and (La0.65Ca0.35)- (Mg1.32Ca0.68)Ni9 of the AB2C9 type structure[J]. J Alloys Compd, 2000, 302(1/2): 112-117.

[9] CHEN J, TAKESHITA H, TANAKA H, KURIYAMA N, SAKAI T, UEHARA I, HARUTA M. Hydriding properties of LaNi3 and CaNi3 and their substitutes with PuNi3-type structure[J]. J Alloys Compd, 2000, 302(1/2): 304-313.

[10] CHEN J, KURIYAMA N, TAKESHITA H, TANAKA H, SAKAI T, HANLTA M. Hydrogen storage alloys with PuNi3-type structure as metal hydride electrode[J]. Electrochemical and Solid-State Lett, 2000, 3(6): 249-252.

[11] KOHNO T, YOSHIDA H, KAWASHIMA F, INABA T, SAKAI I, YAMAMOTO M, KANDA M. Hydrogen storage properties of new ternary system alloys: La2MgNi9, La5Mg2Ni23, La3MgNil4 [J]. J Alloys Compd, 2000, 311(2): L5-L7.

[12] 唐 睿, 刘丽琴, 柳永宁, 于 光, 朱杰武, 刘晓东. La0.8-xRExMg0.2Ni3.2Co0.6储氢合金的结构及电化学性能[J]. 中国有色金属学报, 2005, 15(7): 1057-1060.

TANG Rui, LIU Li-qin, LIU Yong-ning, YU Guang, ZHU Jie-wu, LIU Xiao-dong. Structure and electrochemical properties of La0.8-xRExMg0.2Ni3.2Co0.6 hydrogen storage alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1057-1060.

[13] LI Yuan, HAN Da, HAN Shu-min, ZHU Xi-lin, HU Lin, ZHANG Zhong, LIU Yu-wen. Effect of rare earth elements on the electrochemical properties of La-Mg-Ni based hydrogen storage alloys[J]. Inter J Hydrogen Energy, 2009, 34(3): 1399-1404.

[14] 刘丽琴, 唐 睿, 柳永宁. 稀土元素对La0.8Mg0.2Ni2.8Co0.6储氢合金性能的影响[J]. 中国有色金属学报, 2003, 13(4): 871-875.

LIU Li-qin, TANG Rui, LIU Yong-ning. Effects of rare earth elements on properties of La0.8Mg0.2Ni2.8Co0.6 hydrogen storage alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 871-875.

[15] LIAO B, LEI Y Q, CHEN L X, LU G L, PAN H G, WANG Q D. The structural and electrochemical properties of La2Mg(Ni0.8-xCo0.2Alx)9 (x=0-0.03) hydrogen storage electrode alloys[J]. J Alloys Compd, 2006, 415(1/2): 239-243.

[16] LIAO B, LEI Y Q, CHEN L X, LU G L, PAN H G, WANG Q D. Effect of Co substitution for Ni on the structural and electrochemical properties of La2Mg(Ni1-xCox)9 (x=0.1-0.5) hydrogen storage electrode alloys[J]. Electrochimica Acta, 2004, 50(4): 1057-1063.

[17] 胡子龙. 贮氢材料[M]. 北京: 化学化工出版社, 2002: 211.

HU Zi-long. Hydrogen storage materials[M]. Beijing: Chemical Industry Press, 2002: 211.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50861006);广西自然科学基金资助项目(0991002Z)

收稿日期:2010-06-28;修订日期:2010-10-20

通信作者:唐成颖,教授,博士;电话:0773-2291956;E-mail: ctang@guet.edu.cn