DOI: 10.11817/j.issn.1672-7207.2015.04.034

胎体耐损性弱化孕镶金刚石钻头的试验及碎岩机理分析

王佳亮,张绍和

(中南大学 地球科学与信息物理学院,有色金属成矿预测教育部重点实验室,湖南 长沙,410083)

摘要:为了提高孕镶金刚石钻头在坚硬致密弱研磨性地层的钻进效率,将胎体耐磨损性弱化理论引入钻头设计中,对胎体耐磨损性弱化孕镶金刚石钻头碎岩机理进行探讨并对胎体进行扫描电镜分析。研究结果表明:与普通孕镶金刚石钻头相比,胎体耐磨损性弱化孕镶金刚石钻头的机械钻速提高了64%;经弱化处理的钻头在钻进过程中,弱化颗粒易于从胎体表面脱落,使其表面形成非光滑形态,减少了钻头唇面与孔底岩石面之间的接触面积,提高了钻头唇面与岩石的单位面积压力,改善了金刚石颗粒的冷却效果,降低了金刚石颗粒的热损耗;脱落的弱化颗粒在孔底参与磨损钻头胎体,增加了孔底岩粉的研磨能力,促进了胎体中新颗粒金刚石的出刃。

关键词:胎体弱化;孕镶金刚石钻头;非光滑表面;胎体弱化颗粒;碎岩机理

中图分类号:TG115 文献标志码:A 文章编号:1672-7207(2015)04-1436-06

Experiment and rock fragmentation mechanism of impregnated diamond bit with weakening matrix

WANG Jialiang, ZHANG Shaohe

(Key Laboratory of Non-ferrous Metal Ore Forecast of Ministry of Education,

School of Geosciences and Info-Physics, Central South University, Changsha 410083, China)

Abstract: Weakening matrix theory was applied to design of the drilling bit to improve the drilling efficiency of impregnated diamond bit in hard compact rock formation. The rock fragmentation mechanism was studied and the matrix was analyzed by SEM. The results show that drilling efficiency increases by 64% compared with that of the conventional impregnated diamond bit. Under the process of drilling, the weakening particle can easily drop from matrix developing non-smooth surface, the working surface area in contact with the rock is reduced, the pressure between surface and rock increases, and the cooling effect of diamond is improved. The weakening particle participates in wearing matrix, which increases the abrasive power of rock powder, and promotes the speed of diamond metabolism.

Key words: weakening matrix; impregnated diamond bit; non-smooth surface; particle of weakening matrix; rock fragmentation mechanism

近年来,我国加大了矿产资源的勘探力度。在大规模的矿产勘探中,坚硬致密弱研磨性岩层非常普遍。由于该岩层岩石致密,抗压强度高,岩粉少且细,对胎体研磨性弱,孕镶金刚石钻头在该地层钻进时,新颗粒金刚石不易出刃,钻头易出现打滑不进尺等现象[1-2],为此,科研人员采用不同方法如降低胎体硬度、优化切削齿唇面结构、选用高品级金刚石等,取得了一定成效。在金刚石切割工具中,为提高工具的切割效率,在保证胎体强度能够满足使用要求的前提下,利用适当方法降低胎体的耐磨损性能,将这种工艺过程称为胎体耐磨损性弱化[3-4]。本文作者将金刚石切割工具中的胎体耐磨损性弱化理论与孕镶金刚石钻头设计结合起来,以便为提高孕镶金刚石钻头在坚硬致密弱研磨性岩层钻进效率提供一种新思路。

1 钻头胎体耐磨损性弱化设计

1.1 胎体耐磨损性弱化方式设计

研究表明,不同类型金刚石工具因其设计需求不同,采用不同的胎体耐磨损性弱化方式,大体上可以分为工艺控制法、添加剂法、表面非光滑形态法、粗化晶粒法等。添加剂法是通过在胎体中添加硅、硼、稀土元素镧等降低胎体韧性的元素,使胎体耐磨性能下降[5]。表面非光滑形态法是指在胎体中添加石墨树脂合成材料,使其表面形成非光滑形态,从而降低了胎体耐磨性能。孕镶金刚石钻头在坚硬致密弱研磨性地层钻进时,产生岩粉少且细,研磨能力弱,新颗粒金刚石不易出刃,要求钻头具有较高的自锐能力[6]。于是,将添加剂法和表面非光滑形态法复合设计钻头,将胎体弱化元素以硬质颗粒形式添加至胎体中,其颗粒与胎体包镶力较弱,在钻进过程中易于从胎体表面脱落,使其表面形成非光滑形态,残留孔底的颗粒与岩粉共同研磨胎体,增加岩粉的研磨能力,以达到提高金刚石新陈代谢速度的目的。

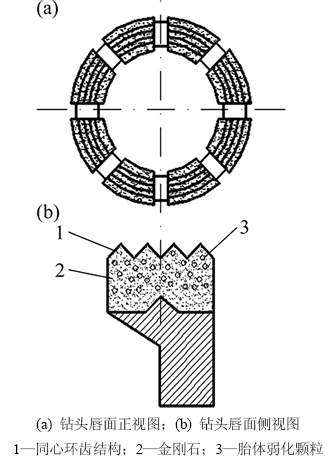

1.2 胎体耐磨损性弱化表面结构设计

常规孕镶金刚石钻头切削齿唇面常设计成同心环齿型宏观非光滑结构,或在制作过程中向模具底部填充适当比例的石墨颗粒,烧结完毕后切削齿经喷砂工艺处理,使其唇面形成微观非光滑形态,以达到弱化胎体耐磨性的目的。但在钻头唇面上仅设计一层胎体耐磨损性弱化表面意义不大,因为钻头磨损后,胎体耐磨损性弱化表面消失,钻头唇面与岩石接触面积增大,钻头比压下降,钻速下降,为此,将胎体弱化结构分为宏观不可再生结构和微观可再生结构。宏观不可再生结构是指在钻头唇面磨损后无法再自动形成胎体耐磨损性弱化结构,微观可再生结构是指当胎体表面非光滑形态磨损后还会继续产生非光滑形态。本设计将这2种胎体耐磨损性弱化结构复合,如图1所示。其中微观可再生胎体耐磨损性弱化结构由胎体弱化颗粒来实现,宏观不可再生胎体耐磨损性弱化结构设计为径向同心环齿型。

1.3 胎体材料设计

钻头切削齿胎体成分如表1所示。其中:WC为骨架材料,具有良好的冲击韧性、高耐磨性特点且对金刚石腐蚀较小;Ni,Mn,Co和663青铜粉等黏结金属在适当温度下熔化,湿润WC颗粒,并使WC颗粒表面熔融,促进了制品的收缩致密化过程[7]。WC基胎体较Fe基和Cu基胎体具有更高的胎体硬度,有利于保证钻头的使用寿命。

图1 胎体表面弱化结构图

Fig. 1 Weakening matrix structure of bit

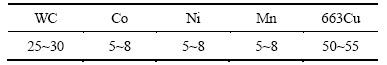

表1 钻头胎体成分(质量分数)

Table 1 Composition of matrix material %

在钻进坚硬致密弱研磨性地层时,金刚石极易被磨平,因此,选用品级较高的SMD40型金刚石,粒度为355~450 μm,抗压强度为350 N,抗冲击韧性指标为75%。金刚石颗粒的抗压强度和冲击韧性越高,其工作时破碎断裂的可能性越小,金刚石工具的磨削性越好[8]。胎体弱化颗粒选用具有较强研磨能力且与胎体包镶力较弱的SiC颗粒,颗粒形状不规则,粒度为550~680 μm。

2 胎体耐磨损性弱化钻头加工及试验

2.1 钻头参数设计

钻头参数设计主要包括尺寸参数设计、金刚石参数设计、胎体性能参数设计、水路系统参数设计等。胎体耐磨损性弱化孕镶金刚石钻头还包括胎体弱化颗粒浓度设计。胎体弱化颗粒浓度是指胎体弱化颗粒体积占胎体体积的比例。大量前期试验结果证明,弱化颗粒浓度设计不当的胎体存在以下几个问题:若弱化颗粒浓度过高,则金刚石与胎体弱化颗粒易发生黏结现象,削弱了胎体对金刚石的把持力,导致金刚石提前脱落造成钻头寿命下降;若弱化颗粒浓度过低,则胎体力学性能改变不明显,金刚石不易出刃。可见胎体弱化的设计原则是在胎体强度少受损害的前提下适当降低胎体的耐磨损性能。在试验中,加工的常规钻头与胎体弱化钻头的设计参数均一样。根据标准和经验,确定钻头设计参数如下:钻头尺寸外径为77 mm,内径为49 mm;胎体硬度HRC为20;金刚石体积分数为100%,粒径为355~450 μm,水口数为8个,胎体弱化颗粒体积分数设计为35%。

2.2 钻头制作工艺

为降低金刚石颗粒与胎体弱化颗粒发生黏结导致金刚石提前脱落的概率,首先将润湿的金刚石颗粒、胎体弱化颗粒分别按设计要求与胎体粉末混合均匀,再将2种粉料充分混合并填入组装完毕的石墨模具中,然后填入非工作层粉量并按设计要求摆放保径金刚石聚晶,最后将钻头钢体置于组装完毕的石墨模具之上进行热压烧结。热压烧结工艺如下:烧结压力为5.5 MPa,烧结温度为1 000 ℃,保温时间为5 min。烧结完毕后自然冷却至室温,退出模芯对钻头半成品进行机加工,按设计尺寸要求加工钻头水路系统和螺纹。

2.3 野外试验

试验地点位于江西省某矿区,主要地层为:1) 石英岩,坚硬,致密研磨性差,平均厚度为5~7 m;2) 透辉石矽卡岩,较完整,致密,研磨性差,平均厚度为25 m左右;3) 二长花岗岩,较完整,夹有磁铁矿,弱研磨性,平均厚度为70 m左右,不连续。岩石硬度可钻性级别为9~11级,研磨性为中等至较强。钻进参数如下:钻压为9~13 kN;转速为750~850 r/min;泵量为34 L/min。钻头试验参数如表2所示。

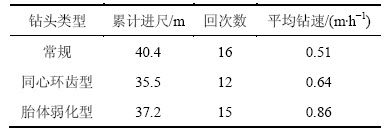

从表2可看出:3种钻头的参数设计方案均与该地层岩性特征相适应,体现出其本来的寿命和机械钻速;胎体弱化钻头的平均寿命较普通钻头略有降低,但平均机械钻速较普通钻头提高64%,较同心环齿型钻头提高45%。

表2 钻头试验参数

Table 2 Experimental data of both bits

3 胎体耐磨损性弱化孕镶金刚石钻头碎岩机理

胎体耐磨损性弱化孕镶金刚石钻头的碎岩机理是以普通孕镶金刚石钻头碎岩机理为基础,在荷载、胎体表面形态、胎体的磨粒磨损等方面对碎岩机理进行了补充。

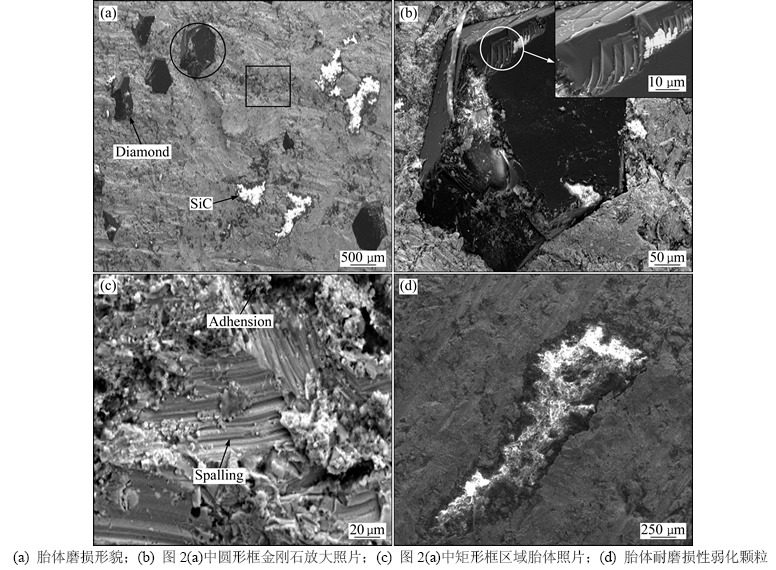

3.1 胎体显微分析

采用SIRION200场发射扫描电镜及GENSIS60能谱仪对胎体表面进行表面形貌观察和微区成分分析。图2所示为胎体耐磨损性弱化孕镶金刚石钻头的胎体磨损形貌,图2(b)所示为图2(a)中圆形框区域金刚石放大照片,图2(c)所示为图2(a)中白色矩形框区域胎体放大照片。由图2(a)可知:胎体存在宽且深的犁沟,具有明显的磨粒磨损特征,金刚石出刃高度良好;胎体中存在粒径约为650 μm的大颗粒;与添加SiC颗粒粒度相当,颗粒形状不规则,结合扫描电镜能谱分析,判断该颗粒为SiC颗粒;金刚石颗粒与SiC颗粒分布较均匀,未出现相互黏结现象,证明本次胎体弱化颗粒浓度设计参数合理。由图2(b)和图2(c)可知:胎体表面存在剥落和黏着现象。对黏着物能谱进行分析可知:其主要含有Si,Ca,K和O元素,确定为岩屑,证明胎体发生了黏着磨损;金刚石和胎体结合紧密,棱角处发生解离断裂。由图2(d)可知:SiC颗粒与胎体界面有较大缝隙,与胎体把持力较弱,出刃高度较低且无明显棱角。

3.2 胎体弱化钻头高效碎岩定性分析

3.2.1 钻头底唇面上的金刚石压力

胎体耐磨损性弱化孕镶金刚石钻头在钻进过程中,胎体弱化颗粒易于从胎体中脱落形成凹坑型非光滑表面,使得钻头唇面与岩石的接触面积减小,增大了底唇面的比压。钻头比压的增加会产生2方面影响:一方面,增大了岩石破碎穴的直径,有利于岩石破碎穴周围微裂纹的纵向扩展,使金刚石颗粒切入岩石的深度有所增加;另一方面,提高了钻头的自锐性能,有利于提高胎体中金刚石的新陈代谢速度[9-10]。此外,非光滑表面的存在有利于存储冲洗液,提高金刚石颗粒的冷却效果,降低其热损耗,增加单颗粒金刚石的工作时间。这些都对钻进效率的提高产生了积极的影响。

以往的钻进试验结果也证明减少唇面与岩石的接触面积能有效提高钻进效率,故钻头唇面常设计成径向同心环齿型、锯齿型等宏观非光滑结构。但钻进一段时间后,宏观非光滑形态磨平,唇面与岩石接触面积增大,钻进比压下降,钻进效率降低。由于胎体弱化孕镶金刚石钻头唇面的微观非光滑形态设计为可再生结构,在胎体表面非光滑形态磨损后继续产生非光滑形态,故其钻进效率比普通钻头的钻进效率高。

图2 胎体表面磨损形貌

Fig. 2 Wear morphologies of matrix

3.2.2 弱化颗粒存在时钻头对岩石摩擦阻力的影响

孕镶金刚石钻头在坚硬致密弱研磨性地层钻进时,孔底产生的岩粉少且细,在回转钻进时钻头唇面对岩石的摩擦因数低,作用于钻头唇面上的摩擦力小,胎体不易磨损,金刚石颗粒易磨平,胎体中金刚石新陈代谢速度降低[11]。胎体耐磨性弱化孕镶金刚石钻头中的胎体弱化颗粒与胎体包镶力较弱,易于从胎体表面脱落。残留于孔底的胎体弱化颗粒本身还具有研磨胎体的作用,由于非光滑表面的存在,增加了胎体唇面的粗糙度。脱落的胎体弱化颗粒不会即时随冲洗液冲离孔底,而是与岩粉一起挤夹在钻头唇面间隙中,以滚动和滑动方式凿削胎体,提高了孔底岩粉对胎体的研磨能力,增加了钻头与岩石的摩擦阻力,提高胎体中金刚石的新陈代谢速度[12-13]。

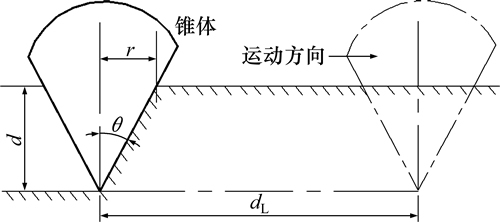

3.3 胎体耐磨损性弱化钻头碎岩机理定量计算

胎体耐磨损性弱化孕镶金刚石钻头在坚硬致密弱研磨性地层钻进时的效率与钻头唇面与孔底岩石摩擦力有直接关系。从摩擦机理出发,总的摩擦力由剪切力和凿削力2部分组成[14]。当硬颗粒如脱落的胎体弱化颗粒、岩粉、脱落的金刚石对胎体表面进行高应力碰撞时,在胎体表面形成犁沟,产生凿削式磨料磨损。为求得磨料磨损的数学表达式,将磨粒看作1个顶角为2θ的锥体,当荷载PN作用在锥体上时,它刺入胎体表面,深度为d,锥体在材料表面处的直径为2r。锥体移动dL排出的体积为dW。如图2所示。

(1)

(1)

单位滑动距离的磨损量为

(2)

(2)

假设材料在法向荷载作用下发生了屈服,则锥体支撑荷载为

(3)

(3)

其中:σs为胎体材料的屈服点。若n个小锥体相接触,则

(4)

(4)

在单位滑动距离内排出的总体积为Q,

(5)

(5)

将式(4)代入式(5)并整理得

(6)

(6)

从式(6)可以看出:磨料磨损的磨损量与法向荷载和cotθ成正比,与胎体材料的硬度成反比。

对于胎体弱化孕镶金刚石钻头,胎体表面凹坑型非光滑结构的存在有利于加深磨粒刺入胎体表面的深度d,提高磨料磨损的cotθ,故其胎体磨损量加剧,钻头唇面与孔底岩石摩擦力提高。由锥形压头引起的磨料磨损示意图见图3。

图3 由锥形压头引起的磨料磨损

Fig. 3 Abrasive wear caused by conical heat

根据摩擦学原理,钻头唇面上金刚石的单位压力并不与轴载成正比。当金刚石颗粒与岩石接触时,其实际接触面积与轴向荷载成正比[15-16]。假设钻头唇面由等高出露的金刚石构成,每颗出露金刚石在其接近球形的顶点处具有近似的曲率半径R,可以证明其总接触面积随施加轴向荷载的2/3次方变化,即

(7)

(7)

假设钻头底唇表面上有个别出露的金刚石超出某一基准平面高度h,处于h和(h+dh)之间,数学上称这种分布为高斯分布或标准正态分布,其概率密度为

(8)

(8)

假设钻头底唇面出露的金刚石满足这种分布,且每颗出露的金刚石具有平均半径为R的球形顶部,可证明其实际接触面积与轴向荷载成正比,即

(9)

(9)

其中:K和K1为常数;A为接触面积;F为轴向荷载;h为金刚石平均出刃高度;φ(h)dh为唇面中个别金刚石出露高度处于h和(h+dh)之间的概率。综上所述,提高单颗粒金刚石破碎岩石的压力,合理措施是减小钻头底唇面积,当施加荷载一定时,金刚石上所承受的压力P将随着钻头底唇面积A的减小而增大,即

(10)

(10)

对于胎体耐磨损性弱化孕镶金刚石钻头,由于胎体表面凹坑型非光滑形态的存在,降低了底唇面积,故有利于提高作用于单颗粒金刚石上的压力。

4 结论

1) 将胎体耐磨损性弱化理论与孕镶钻头设计相结合,在胎体中添加适当浓度胎体弱化颗粒,在保证钻头寿命的前提下可提高钻头在坚硬致密弱研磨性地层的钻进时效。胎体耐磨损性弱化孕镶金刚石钻头较普通孕镶金刚石钻头时效提高64%。

2) 胎体耐磨损性弱化颗粒的存在增加了钻头胎体唇面的粗糙度,脱落的胎体弱化颗粒与岩粉一起挤夹在钻头唇面间隙中,以滚动和滑动方式凿削胎体,提高了孔底岩粉对胎体的研磨能力,增加了钻头与岩石的摩擦阻力,提高了胎体中金刚石的新陈代谢速度。

3) 胎体弱化颗粒易于从胎体表面脱落,使其表面形成非光滑形态,弱化了胎体耐磨损性能,减少了钻头唇面与孔底岩石面之间的接触面积,提高了钻头唇面对岩石的单位面积压力;改善了金刚石颗粒的冷却效果,降低了金刚石颗粒的热损耗。

参考文献:

[1] 赵尔信, 蔡家品. 浅谈国内外金刚石钻头的发展趋势[J]. 探矿工程(岩土钻掘工程), 2010, 37(10): 70-73.

ZHAO Erxin, CAI Jiapin. Discussion on development of diamond bit in both china and abroad[J]. Exploration Engineering (Rock and Soil Drilling), 2010, 37(10): 70-73.

[2] 蒋青光, 张绍和, 陈平. 新型优质孕镶金刚石钻头研制[J]. 金刚石与模具磨料工程, 2008(6): 12-16.

JIANG Qingguan, ZHANG Shaohe, CHEN Ping. Development of new type and high quality impregnated diamond bits[J]. Diamond and Abrasives Engineering, 2008(6): 12-16.

[3] 宋月清. 金刚石工具胎体性能的弱化问题研究[J]. 人工晶体学报, 1998, 27(4): 368-372.

SONG Yueqing. Study on the weakening of the diamond tool matrix performance[J]. Journal of Synthetic Crystals, 1998, 27(4): 368-372.

[4] 宋月清, 甘长炎, 夏志华, 等. 金刚石工具胎体材料的性能“弱化”问题初探[J]. 金刚石与模具磨料工程, 1997(5): 2-4.

SONG Yueqing, GAN Changyan, XIA Zhihua, et al. The discussion on weakening of the diamond tool matrix performance[J]. Diamond and Abrasives Engineering, 1997(5): 2-4.

[5] 宋月清. 割石材用金刚石工具胎体材料优化研究[D]. 北京: 北京有色金属研究总院, 1998: 42-45.

SONG Yueqing. Study on diamond tool matrix performance in cutting stone[D]. Beijing: General Research Institute for Nonferrous Metals, 1998: 42-45.

[6] 张绍和. 金刚石与金刚石工具[M]. 长沙: 中南大学出版社, 2005: 221-225.

ZHANG Shaohe. Diamond and diamond tool[M]. Changsha: Central South University Press, 2005: 221-225.

[7] 王传留, 孙友宏. 仿生耦合孕镶金刚石钻头的试验及碎岩机理分析[J]. 中南大学学报(自然科学版), 2011, 42(5): 1321-1325.

WANG Chuanliu, SUN Youhong. Experiment and rock fragmentation mechanism of bionic coupling impregnated diamond bit[J]. Journal of Central South University (Science and Technology), 2011, 42(5): 1321-1325.

[8] GAO Chao. Efficient drilling of holes in Al2O3 armor ceramic using impregnated diamond bits[J]. Journal of Materials Processing Technology, 2011, 211(11): 1719-1728.

[9] 张绍和, 王涛. 自形成同心径向环齿金刚石钻头设计与制造[J]. 金刚石与模具磨料工程, 2004(5): 59-62.

ZHANG Shaohe, WANG Tao. Research on concentrical segmented diamond bit[J]. Diamond and Abrasives Engineering, 2004(5): 59-62.

[10] 高科, 孙友宏. 仿生孕镶金刚石钻头非光滑度优化设计及试验[J]. 吉林大学学报, 2009, 39(3): 721-725.

GAO Ke, SUN Youhong. Optimization design an d test of nonsmooth ratio of bion ics impregnated diamond bit[J]. Journal of Jinlin University, 2009, 39(3): 721-725.

[11] ZHENG Lei. Hole drilling in ceramics/Kevlar fiber reinforced plastics double-plate composite armor using diamond core drill[J]. Materials and Design, 2012(4): 12-18.

[12] 张绍和. 金刚石钻头设计与制造新理论新技术[M]. 武汉: 中国地质大学出版社, 2001: 34-38.

ZHANG Shaohe. New theory of diamond bit design and manufacture[M]. Wuhan: Press of China University of Geosciences, 2001: 34-38.

[13] Zhou H, Shan H Y, Tong X, et al. The adhesion of bionicnon-smooth characteristics on sample surfaces against parts[J]. Materials Science & Engineering, 2006, 417(2): 190-196.

[14] 高彩桥. 摩擦金属学[M]. 哈尔滨: 哈尔滨工业大学出版社, 1998: 39-42.

GAO Caiqiao. Metal tribology[M]. Harbin: Press of Polytechnic University of Harbin, 1998: 39-42.

[15] TAN Songcheng, FANG Xiaohong. A new composite impregnated diamond bit for extra-hard, compact, and nonabrasive rock formation[J]. International Journal of Refractory Metals and Hard Materials, 2014, 43(3): 186-192.

[16] 徐良, 孙友宏. 仿生孕镶金刚石钻头高效碎岩机理[J]. 吉林大学学报, 2008, 38(6): 1015-1019.

XUN Liang, SUN Youhong. Efficient rock fragmentation mechanism analysis of impregnated diamond bionics bit[J]. Journal of Jinlin University, 2008, 38(6): 1015-1019.

(编辑 陈灿华)

收稿日期:2014-05-20;修回日期:2014-07-22

基金项目(Foundation item):国家自然科学基金资助项目(51074180)(Project (51074180) supported by the National Natural Science Foundation of China)

通信作者:张绍和,博士,教授,博士生导师,从事地质工程等方面研究;E-mail:zhangshaohe@163.com