DOI: 10.11817/j.ysxb.1004.0609.2020-35812

球磨预处理强化铜冶炼烟灰中砷与有价金属高效分离

胡中求1, 2,瞿 军1, 2,郭 莉1, 2,马文博1, 2,胡 楠1, 2,占 伟1, 2,杜冬云1, 2

(1. 中南民族大学 资源与环境学院 湖北省重金属污染防治工程技术研究中心,武汉 430074;

2. 中南民族大学 催化转化与能源材料教育部重点实验室,武汉 430074)

摘 要:探究了球磨预处理铜冶炼烟灰中As与有价金属的高效分离,并对比研究球磨及碱性介质中球磨预处理对烟灰中As分离浸出效果影响。结果表明:单独采用球磨预处理会抑制烟灰中As的浸出,与未球磨烟灰相比,浸出率由56.01%降至32.85%;而碱性介质的加入可显著提高As浸出率,浸出率则由56.01%升至78.52%,最优工艺参数为:NaOH与烟灰质量比(mNaOH:mAsh)=0.5:1、球磨活化60 min(碱性介质下球磨预处理(50±5) min后,投加入一定量的乙醇研磨(10±5) min)、转速600 r/min。另外,采用该方法处理后,烟灰中Cu、Zn、Pb、Cd基本未被浸出,且浸出残余固体物中As含量由5.74%降低至0.13%。SEM和粒径分析表明:球磨可使颗粒表面产生缺陷,减小烟灰粒度,增大反应比表面积,促进界面传质,提高As浸出率。XRD和XPS结果表明:球磨过程中局域产生高温高压,诱导固-固反应,As2O3等与NaOH反应转化为可溶性的砷酸盐,部分PbSO4在局部高温下最终分解为PbO,进一步强化浸出过程中As与有价金属的高效分离,该方法为烟灰无害化及资源化的利用提供了理论依据。

关键词:铜冶炼烟灰;球磨;化学反应;活化;界面传质;选择性浸出

文章编号:1004-0609(2020)-08-1915-10 中图分类号:X756 文献标志码:A

铜冶炼过程中会产生大量富含铜、锌、铅、锡、铋等多种有价金属元素的烟尘,经济回收价值极高,但同时却伴随有As、Cd等有害金属,不利于烟灰的无害化及资源化利用[1-4]。目前,国内冶炼厂多数将其囤积储存或直接返回冶炼炉[5-8],但堆砌闲置会造成极大资源浪费,同时,雨水冲刷、微生物等作用会使重金属离子溶于水体,造成二次污染[9-10];另一方面,直接返回冶炼炉不仅降低矿物品位,且As等杂质积累会缩短冶炼炉使用寿命[10-13]。因此,开发冶炼烟灰中砷与伴随有价金属的高效分离工艺对于解决冶炼过程中砷循环累积,烟灰无害化及资源化具有极其重要的研究意义。 NaOH[14-15]与NaOH-Na2S[16-17]是常被用于实现冶炼烟灰中砷选择性脱除的碱性浸出体系,但单纯采用NaOH浸出体系浸出液成分复杂、处理难度高,NaOH消耗量大、砷浸出率较低且伴随金属浸出多,因此,引入NaOH-Na2S复合体系在获得较高砷浸出率的同时进一步使浸出液中Cu、Zn、Pb等离子形成CuS、ZnS、PbS沉淀,从而实现As的选择性浸出[18-19],但总体而言,传统体系易造成药剂反应不充分,砷的浸出率和选择性仍有待提高,且需要高温、高压辅助,对设备要求高、能耗大[7, 20-22]。因此,亟需探究节能环保且高效的预处理工艺,提高药剂利用率,强化砷浸出及其与有价金属的高效分离,进而实现烟灰的资源化利用。 近年来,机械活化法被广泛应用于强化湿法冶金矿物浸出过程[23-26]。研究表明,矿物原料经械活化后,晶格结构和物化性质会发生质的变化,表观活化能降低,因而能诱导或促进在常规条件下难发生或发生缓慢的反应,或者使需要在高温条件下进行的反应可在较低温度甚至是常温下进行[27-29]。不同的矿物原料在机械活化时有不同的反应机理,目前,对于机械活化预处理强化铜冶炼烟灰中As选择性浸出的研究未见报道。基于此,本研究尝试了一种新球磨工艺,即添加NaOH与烟灰共研磨,减小颗粒尺寸的同时彻底混合反应组分,提高药剂利用率,机械诱导固态反应,并利用Cu、Zn、Pb等金属在碱性介质下不易浸出而As在球磨过程中可转化为可溶性的砷酸盐的特性,实现As与有价金属的高效分离,进而为冶炼行业环境资源保护及可持续发展提供一定的理论基础。

1 实验

1.1 研究对象

本研究所用铜冶炼烟灰(以下简称“烟灰”)收集于某铜冶炼厂电除尘系统,准确称取0.2 g 105 ℃下烘干至质量恒定后的烟灰于聚四氟乙烯罐中,加入6 mL HNO3和1 mL HF进行消解实验,稀释后测得其中重金属含量,经计算结果如表1所示。

表1 铜冶炼烟灰中主要金属含量

Table 1 Main metal composition of copper smelting soot (mass fraction, %)

1.2 实验仪器及试剂

所用仪器主要为:BSA124S-CW型精密电子天平,北京赛多利斯天平有限公司;PM100型球磨机,德国Retsch公司;524G恒温磁力搅拌器,广州瑞丰实验设备有限公司;SHB-IIIA循环水式多用真空泵,上海卫凯仪器设备有限公司;HC-3518 高速离心机,郑州南北仪器设备有限公司;101-2AB型电热鼓风干燥箱,天津市泰斯特仪器有限公司;DZG-6050D 型真空干燥箱,上海森信实验仪器有限公司;ICE 3500原子吸收光谱仪,美国赛默飞有限公司;Avio 200 电感耦合等离子体发射光谱仪(ICP-OES),美国Perkin-Elmer 公司;MULT1AB 2000 X 射线光电子能谱仪(XPS),美国 VG 公司;LS-609激光粒度分析仪,珠海欧美克仪器有限公司;XD-3 自动 X 射线粉末衍射仪(XRD),北京普析通用仪器有限责任公司;FEI-Quanta 200 扫描电镜(SEM),荷兰 FEI 公司;UPW-30S超纯水器,北京历元仪器有限公司。 本实验所用试剂除另有注明外,均为符合国家标准的分析纯化学试剂;实验用水为新制备的去离子水。

1.3 实验方法

球磨活化烟灰:称取一定质量比的烟灰与NaOH一起放入50 mL容量的球磨罐中,以一定的转速、时间进行球磨活化预处理,收集活化后的样品并保存以供进一步使用。 浸出实验:称取2 g活化后的烟灰,按照液固比为25:1(mL/g),以一定转速和时间在NaOH-Na2S体系下浸出,保证最终NaOH最终用量为mNaOH:mAsh= 0.5:1(g/g),mNaOH:mAsh=0.4:1(g/g);反应完成后抽滤,浸出液过0.45 μm滤膜后测定As及其他重金属浓度。

1.4 分析方法

用原子吸收光谱仪测定溶液中As、Cu、Pb、Zn、Cd含量;取少许105 ℃下烘干至恒重后的球磨前和碱性介质中经球磨预处理后的烟灰,用激光粒度衍射仪分析粒径和比表面积变化情况;通过扫描电子显微镜(SEM)分析颗粒表面形貌特征;通过X射线衍射仪(XRD)分析球磨前后物相组成变化;通过X 射线光电子能谱(XPS)分析表面元素的化学组成和化学形态。

2 实验结果与讨论

2.1 碱性介质下球磨预处理最佳工艺探究

2.1.1 NaOH用量对砷浸出效率的影响

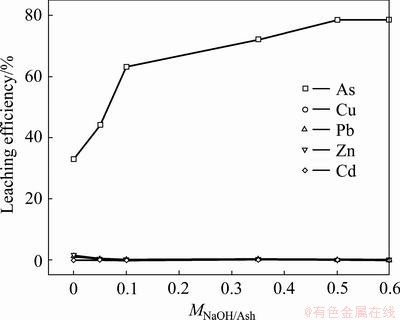

在球磨机转速为600 r/min,探究不同NaOH用量(mNaOH:mAsh为0:1、0.05:1、0.1:1、0.35:1、0.5:1、0.6:1)对球磨60 min后烟灰中As、Cu、Zn、Pb、Cd浸出率的影响,浸出过程中NaOH最终用量均为mNaOH:mAsh=0.5:1,其他条件为:L:S=25:1 (mL/g),mNa2S:mAsh=0.4:1,反应时间60 min,温度55 ℃,搅拌转速250 r/min,结果如图1所示。

由图1可知,烟灰中Pb、Zn在未添加NaOH条件下仍有部分浸出,而且球磨后烟灰中As浸出率较低,仅为32.85%;添加NaOH球磨后烟灰As浸出效果显著提高,当mNaOH:mAsh=0.05:1,As浸出率可提升11.4%,随着NaOH用量的继续增加,As浸出率依次升高至63.15%、71.94%、78.52%、78.54%( mNaOH:mAsh为0.1:1、0.35:1、0.5:1、0.6:1时),同时,烟灰中Cu、Zn、Pb、Cd基本未被浸出;综上所述,在碱性介质中球磨预处理可强化烟灰中As与有价金属元素(Cu、Zn、Pb、Cd)分离浸出效果,且一定范围内,As浸出率随球磨过程中NaOH用量的增加逐渐增强,综合考虑药剂成本,最终选择NaOH与烟灰最佳质量比为0.5:1。

图1 NaOH与烟灰质量比对不同金属浸出率的影响

Fig. 1 Effect of mass ratio of NaOH to ash on different metals leaching efficiency

2.1.2 不同球磨时间对砷浸出率的影响

在球磨机转速为600 r/min,mNaOH:mAsh=0.5:1条件下,探究不同球磨时间(10 min、30 min、50 min、60 min、70 min)对As及其他金属浸出率的影响,其结果见图2。

图2 球磨时间对不同金属浸出率的影响

Fig. 2 Effect of milling time on different metals leaching efficiency

由图2可知,未施加球磨时烟灰中As浸出率仅为56.01%,而经球磨预处理(碱性介质)后烟灰中As浸出率显著提高,且随着球磨时间逐渐增加,当球磨时间为60 min,As浸出率可升高至78.52%,与未施加球磨时烟灰As浸出率相比提高了22.51%;然而,进一步延长球磨时间,As浸出效果基本保持不变,因此,选择60 min为球磨活化最佳时间。上述结果再次验证了球磨预处理(碱性介质)对烟灰中As分离浸出效果的强化作用。

2.1.3 不同转速对砷浸出效率的影响

研究表明,转速是影响机械活化反应性能的重要参数,转速越大,产生的能量越大,且球磨时颗粒进一步细化,固体表面积增加,更易于化学物质与表面组分相互作用[31-33]。因此,探究了在mNaOH:mAsh=0.5:1,球磨时间60 min条件下,球磨机转速(200 r/min、400 r/min、600 r/min)对As及其他金属浸出率的影响,结果见图3。 由图3可知,As浸出率随着转速的增加而增加,当球磨机转速从200 r/min增加到600 r/min,As浸出率也从61.9%升高至75.65%。这可能是因为在机械活化过程中,转速增加,研磨介质间的冲击、摩擦等作用增强,颗粒细化,晶体结构被破坏,反应产物的比表面能降低,同时,局域产生的高温促进了As与碱性介质间反应,因而As浸出效率提高。

图3 转速对不同金属浸出率的影响

Fig. 3 Effect of rotation speed on different metals leaching efficiency

2.1.4 乙醇对烟灰中砷浸出促进作用

烟灰与碱性介质共磨时易团聚(见图4(a))、较难收集,不利于工业应用;而乙醇是一种绿色的极性溶剂,具有极好的分散性能[34-35]。因此,探究了未添加及添加乙醇在碱性介质球磨过程中对烟灰颗粒分散性能及As浸出率的影响,如图4和5所示。可以发现,加入乙醇后烟灰颗粒分散性能较好(见图4(b)),但与未加乙醇时相比,球磨后烟灰中As浸出率由78.52%降至70.22%(见图5中A及B),这是因为烟灰中砷主要以极性物质氧化物存在,而乙醇属于极性物质,球磨初期乙醇溶液的加入使烟灰颗粒在其表面富集并降低体系表面张力,烟灰颗粒与碱性介质之间传质几率降低,进而影响NaOH与含As物质的结合。为此,进一步探究了乙醇投加时间段对As浸出率影响,即对比了在碱性介质下球磨预处理后期((50±5) min)投加一定量的乙醇研磨(10±5) min后烟灰中As浸出效果(见图5中C)。综上可知,在预处理后期投加乙醇不仅可维持烟灰中砷浸出效果(浸出率为78.92%),而且可以防止球磨过程中颗粒团聚(见图5中C)。

图4 乙醇添加前后颗粒分散情况

Fig. 4 Particle dispersion before and after ethanol addition

图5 乙醇添加前后As浸出率变化

Fig. 5 Effect of ethanol addition on arsenic leaching rate

2.2 球磨预处理对砷浸出强化作用及浸出残余固体物中As含量分析

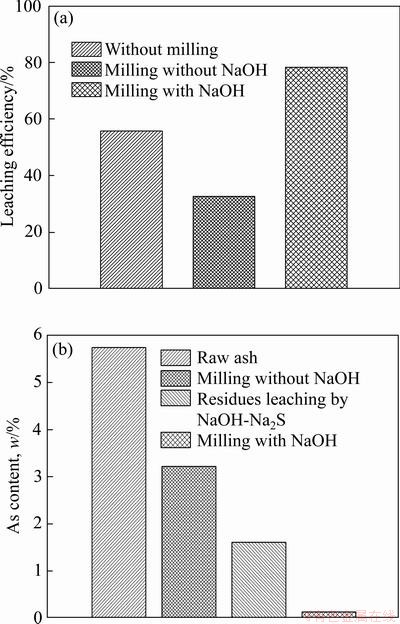

碱性介质中球磨预处理烟灰最佳工艺条件为:mNaOH:mAsh=0.5:1,球磨机转速600 r/min、球磨时间60 min(碱性介质中球磨预处理(50±5) min后投加入一定量的乙醇研磨(10±5) min)。保证预处理及浸出条件一致,对比研究了球磨及碱性介质球磨预处理对烟灰中As浸出率的影响。如图6(a)所示,未施加球磨时烟灰中As浸出率为56.01%,碱性介质下共磨烟灰As浸出率可达78.52%,而无碱性介质球磨预处理条件下As浸出率仅为32.85%,与原烟灰相比降低了23.16%。 图6(b)展示了不同条件下处理后浸出残余固体物中As的含量。可以发现,无碱性介质添加时,球磨直接预处理后浸出残余固体物中As含量为3.22%,高于未球磨时浸出残余固体物中As的含量(1.61%),而在碱性介质中经球磨预处理后,浸出残余固体物中As含量为仅为0.13%,与原烟灰相比降低了5.61%。球磨过程常包含一系列复杂晶体结构转化过程,无碱性介质时球磨单独作用可能促使砷嵌入二次结晶产物中,从而抑制砷浸出,而NaOH的加入可改变As的浸出行为,这可能是因为球磨过程中局域会产生高温和高压,促使As与NaOH结合生成可溶性的砷酸盐,而其他金属在碱性条件下不易浸出,减弱了其与As的结合,从而进一步提高As浸出率,该工艺为烟灰无害化及资源化创造了有利条件;后续将探究机理以进一步验证这一猜想。

图6 碱性介质下球磨预处理对烟灰中As浸出强化作用及As含量分析

Fig. 6 Effect of ball milling with addition of NaOH on arsenic leaching efficiency(a) and As content in leaching residues(b)

2.3 碱性介质下球磨预处理强化As浸出机理

2.3.1 球磨预处理前后铜冶炼烟灰表面形貌的变化

图7所示为球磨前(即原烟灰)和碱性介质中球磨预处理后的烟灰SEM像。由图7(a)可知,原烟灰由许多块状的大颗粒组成,颗粒表面光滑,而在碱性介质中经球磨预处理后颗粒表面粗糙多孔(见图7(b)),出现明显缺陷。由此可知,球磨过程中的高能碰撞和摩擦作用会促使晶体表面产生缺陷,从而改变颗粒表面形貌和内部结构。

2.3.2 球磨预处理前后烟灰粒度分布图

在球磨过程中,球和研磨罐之间的速度差异可产生摩擦力和冲击力,力与力之间相互作用,从而释放出高动态能量,减小颗粒尺寸[25, 36]。表2和图8所示分别对比了球磨前和球磨后烟灰粒度分布和BET比表面积SBET的变化情况。未球磨时,D10、D50、D90(D10、D50、D90分别表示粒径小于(或大于)它的颗粒占10%、50%、90%)及Dave(指平均粒径)分别对应为6.642、29.67、77.39和36.77 μm,而球磨后粒径均有所减小且颗粒比表面积增大(由385.22增加至665.19 m2/kg),结果表明,球磨挤压和研磨作用可使烟灰粒度减小,比表面积增大,反应活性位点增多[37],从而强化铜冶炼烟灰中As 的浸出效率。

图7 球磨前后颗粒表面形貌

Fig. 7 Surface morphologies of particles before(a) and after(b) ball milling

2.3.3 球磨预处理前后晶体结构的变化

表2 球磨前后铜冶炼烟灰粒径及比表面积变化

Table 2 Variation of particle size and specific surface area of soot before and after ball milling

图8 球磨对铜冶炼烟灰粒度分布的影响

Fig. 8 Effect of ball milling on particle size distribution of copper smelting soot

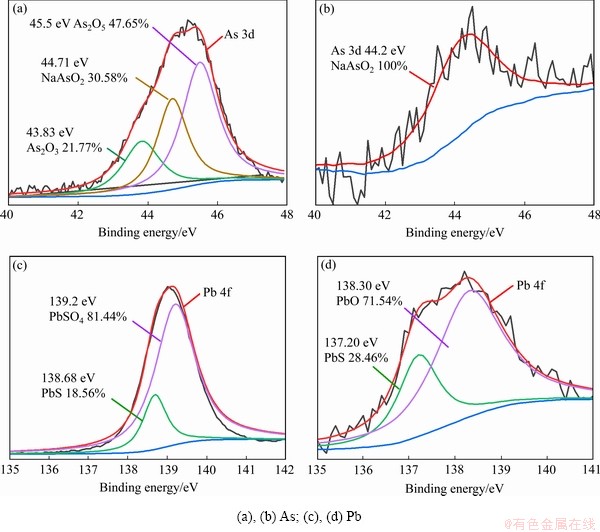

研究表明,球磨过程中可在局域提供高温、高压的环境,诱导常温下不能进行的固-固反应或者造成一些特殊物质部分晶格缺陷,使反应组分之间的活性界面面积增加,化学活性位点增多,进而提供快速扩散路径[38-40]。为进一步解释球磨高效选择性浸出砷的机理,采用X射线衍射(XRD)对球磨前后烟灰物相组成变化情况进行分析,如图9所示。球磨前(见图9(a))衍射峰强度较高,且烟灰物相组成复杂,主要成分为PbSO4和PbS,部分As主要以As2O3和NaAsO2的形式存在,而球磨后(见图9(b))衍射峰强度明显下降,As转化为Na2HAsO3和Na2HAsO4,且PbSO4的衍射峰消失,部分转化为PbO,这可能是球磨过程中由于巨大冲击能量产生的界面温度促使了中间产物Pb(OH)2的分解,因而进一步提高了后续浸出体系下Pb的回收效率,反应式如(1)~(12)所示。该过程中利用Cu、Zn、Pb等金属在碱性条件下不易浸出,而As在球磨过程中会与NaOH反应最终转化为可溶性的砷酸盐的特性,进而促进了As的选择性浸出,同时,球磨过程中发生的高能碰撞和摩擦作用,造成晶格缺陷,使颗粒粒径减小,比表面积增大,反应活性位点增多,As浸出率进一步提高。

PbSO4+2NaOH→Pb(OH)2+Na2SO4 (1)

Pb(OH)2 PbO+H2O (2)

PbO+H2O (2)

PbO+Na2S+H2O→PbS↓+2NaOH (3)

As2O3+2NaOH→2NaAsO2+H2O (4)

NaAsO2+NaOH→Na2HAsO3 (5)

As2O5+6NaOH→2Na3AsO4+3H2O (6)

Na3AsO4+H2O→Na2HAsO4+NaOH (7)

2.3.4 球磨预处理前后XPS谱分析

图10所示为球磨前和后烟灰的XPS谱。由图10可知,球磨前,As主要以As2O3、As2O5和NaAsO2 存在(见图10(a));而球磨后,氧化态的As消失,均转化为NaAsO2 (见图10(b)),进一步证明在加入NaOH与烟灰球磨的过程中会促进可溶性砷酸盐的生成。在碱性介质中经球磨预处理后PbSO4的衍射峰消失,部分转化为PbO,这与XRD谱的结果一致(见图10(c)和(d))。

图9 球磨对铜冶炼烟灰物相组成的影响

Fig. 9 Effect of ball milling on phase composition of copper smelting soot

图10 球磨前与球磨后烟灰中金属XPS谱分析

Fig. 10 XPS spectra analysis of metals in soot before((a), (c)) and after((b), (d)) ball milling

图11 球磨预处理机理

Fig. 11 Pretreatment mechanism diagram of ball milling

2.3.5 球磨预处理强化As浸出机理图

碱性介质下球磨预处理可强化烟灰中As与有价金属高效分离,其机理示意图如图11所示。整个球磨系统中由于高速碰撞产生巨大摩擦力和一定冲击能量,磨球与介质间相互挤压,颗粒尺寸减小、比表面积增大,化学活性位点增多,同时,局域产生高温高压,一定程度上诱导了固-固反应[41-42]:部分PbSO4与NaOH反应生成Pb(OH)2,并最终分解为PbO,部分PbO在浸出体系下与Na2S作用生成不溶性硫化物,一定程度上可提高Pb的回收效率;氧化态砷在碱性介质中经球磨预处理后可转化为可溶性砷酸盐,进而最终实现了铜冶炼烟灰中As与有价金属的高效分离。

3 结论

1) 碱性介质中球磨预处理可强化铜冶炼烟灰中砷的选择性浸出,最佳预处理工艺为mNaOH:mAsh= 0.5:1,球磨机转速为600 r/min,球磨时间为60 min(碱性介质下球磨预处理(50±5) min后投加入一定量的乙醇研磨(10±5) min),一定量乙醇的加入可防止球磨过程中烟灰颗粒团聚。 2) 无碱性介质时球磨单独预处理烟灰会抑制As的浸出,而加入碱性介质的加入可显著提高As浸出率(78.52%),与球磨单独作用以及原烟灰相比分别提高了45.67%和22.51%;浸出残余固体物中As含量可从5.74%降低至0.13%,为烟灰的无害化及资源化利用创造了有利条件。 3) SEM和粒径分析表明:球磨会促使颗粒表面产生缺陷,使烟灰粒径减小,比表面积增大,化学活性位点增多,从而强化As浸出传质过程。XRD和XPS表征表明:加入NaOH球磨As可转化为Na2HAsO3和Na2HAsO4,同时,原烟灰中的部分PbSO4可通过球磨最终反应生成PbO;整个过程利用Cu、Pb、Zn等金属在碱性条件下不溶解,而砷氧化物可在碱性条件下易生成可溶性砷酸盐的特性,进而促进了砷与有价金属的选择性分离。

REFERENCES

[1] GUO Xue-yi, SHI Jing, YI Yu, TIAN Qing-hua, LI Dong. Separation and recovery of arsenic from arsenic-bearing dust[J]. Journal of Environmental Chemical Engineering, 2015, 3(3): 2236-2242.

[2] GUO Xue-yi, YI Yu, SHI Jing, TIAN Qing-hua. Leaching behavior of metals from high-arsenic dust by NaOH–Na2S alkaline leaching[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 575-580.

[3] BASHA C A, SELVI S J, RAMASAMY E, CHELLAMMALAS. Removal of arsenic and sulphate from the copper smelting industrial effluent[J]. Chemical Engineering Journal, 2008, 141(1): 89-98.

[4] 姚瑛瑛, 郭 莉, 胡中求, 全 瞿, 杜冬云. 超声辅助碱浸铜冶炼烟灰中铜砷分离[J]. 化工学报, 2018, 69(9): 3983-3992.

YAO Ying-ying, GUO Li, HU Zhong-qiu, QUAN Qu, DU Dong-yun. Separation of copper and arsenic in copper smelting dust by Na2S-NaOH leaching assisted with ultrasound method[J]. The Chemical Industry and Engineering Society of China, 2018, 69(9): 3983-3992.

[5] 刘海浪, 和 森, 宋向荣, 罗中秋, 夏举佩, 周新涛. 铜冶炼高砷烟尘浸出特性研究[J]. 安全与环境学报, 2017, 17(3): 1124-1128.

LIU Hai-lang, HE Sen, SONG Xiang-rong, LUO Zhong-qiu, XIA Ju-pei, ZHOU Xin-tao. On the leaching ability of high arsenic smoke-dust from the copper smelting processing[J]. Journal of Safety and Environment, 2017, 17(3): 1124-1128.

[6] LI Yu-hu, LIU Zhi-hong, ZHAO Zhong-wei, LI Qi-hou, LIU Zhi-yong, ZENG Li. Determination of arsenic speciation in secondary zinc oxide and arsenic leachability[J]. Transactions of the Nonferrous Metals Society of China, 2012, 22(5): 1209-1216.

[7] XU Zhi-feng, LI Qiang, NIE Huang-ping. Pressure leaching technique of smelter dust with high-copper and high-arsenic[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 176-181.

[8] SHIBAYAMA A, TAKASAKI Y, WILLIAM T, YAMATODANI A, HIGUCHI Y, SUNAGAWA S, ONO E. Treatment of smelting residue for arsenic removal and recovery of copper using pyro-hydrometallurgical process[J]. Journal of Hazardous Materials, 2010, 181(1/3): 1016-1023.

[9] CUI Ri-cheng, YANG Hong-ying, CHEN Sen, ZHANG Shuo, LI Ke-feng. Valence variation of arsenic in bioleaching process of arsenic-bearing gold ore[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 1171-1176.

[10] RUIZ M C, GRANDON L, PADILLA R. Selective arsenic removal from enargite by alkaline digestion and water leaching[J]. Hydrometallurgy, 2014, 150: 20-26.

[11] MONTENEGRO V, SANO H, FUJISAWA T. Recirculation of high arsenic content copper smelting dust to smelting and converting processes[J]. Minerals Engineering, 2013, 49(1): 184-189.

[12] CHEN Ya, LIAO Ting, LI Gai-bian, CHEN Bai-zhen, SHI Xi-chang. Recovery of bismuth and arsenic from copper smelter flue dusts after copper and zinc extraction[J]. Minerals Engineering, 2012, 39(1): 23-28.

[13] YIN Zhou-lan, LU Wei-hong, XIAO Hui. Arsenic removal from copper–silver ore by roasting in vacuum[J]. vacuum, 2014, 101(1): 350-353.

[14] REYNOLDS J E, COLTRINARI E L. Process for recovering arsenic compounds by sodium hydroxide leaching: US patent 4244927 A[P]. 1981-06-13.

[15] LI Yu-hu, LIU Zhi-hong, LI Qi-hou, LIU Fu-peng, LIU Zhi-yong. Alkaline oxidative pressure leaching of arsenic and antimony bearing dusts[J]. Hydrometallurgy, 2016, 166(1): 41-47.

[16] LEWIS A E. Review of metal sulphide precipitation[J]. Hydrometallurgy, 2010, 104(2): 222-234.

[17] LI Yu-hu, LIU Zhi-hong, LI Qi-hou, ZHAO Zhong-wei, LIU Zhi-yong, ZENG Li. Removal of arsenic from Waelz zinc oxide using a mixed NaOH-Na2S leach[J]. Hydrometallurgy, 2011, 108(3): 165-170.

[18] GUO Xue-yi, SHI Jing, YI Yu, TIAN Qing-hua, LI Dong. Separation and recovery of arsenic from arsenic-bearing dust[J]. Journal of Environmental Chemical Engineering, 2015, 3(3): 2236-2242.

[19] 吴玉林, 徐志峰, 郝士涛. 炼铜烟灰碱浸脱砷的热力学及动力学[J]. 有色金属 (冶炼部分), 2013(4): 3-7.

WU Yu-lin, XU Zhi-feng, HAO Shi-tao. Thermodynamics and kinetics of alkaline leaching of arsenic in copper smelting dust[J]. Nonferrous Metals(Extractive Metallurgy), 2013(4): 3-7.

[20] 易 宇, 石 靖, 田庆华, 郭学益. 高砷烟尘氢氧化钠-硫化钠碱性浸出脱砷[J]. 中国有色金属学报, 2015, 25(3): 806-814.

YI Yu, SHI Jing, TIAN Qing-hua, GUO Xue-yi. Arsenic removal from high-arsenic dust by NaOH-Na2S alkaline leaching[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 806-814.

[21] LI Dong, GUO Xue-yi, XU Zhi-peng, TIAN Qing-hua, FENG Qi-ming. Leaching behavior of metals from copper anode slime using an alkali fusion-leaching process[J]. Hydrometallurgy, 2015, 157: 9-12.

[22] YU Guo-ling, ZHANG Ying, ZHENG Shi-li, ZOU Xing, WANG Xiao-hui, ZHANG Yi. Extraction of arsenic from arsenic-containing cobalt and nickel slag and preparation of arsenic-bearing compounds[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1918-1927.

[23] ZHANG Zhi-yuan, ZHANG Fu-sen, YAO Tian-qi. An environmentally friendly ball milling process for recovery of valuable metals from e-waste scraps[J]. Waste Management, 2017, 68(1): 490-497.

[24] KUKURUGYA F, KIM E, NIELSEN P, HORCKMANS L, SPOOREN J, BROOS K, QUAGHEBEUR M. Effect of milling on metal leaching: Induction of galvanic effect in a secondary lead smelter matte by prolonged milling[J]. Hydrometallurgy, 2017, 171(1): 245-253.

[25] WANG Meng-meng, ZHANG Cong-cong, ZHANG Fu-sen. An environmental benign process for cobalt and lithium recovery from spent lithium-ion batteries by mechanochemical approach[J]. Waste Management, 2016, 51(1): 239-244.

[26] WELHAM N J, LLEWELLYN D J. Mechanical enhancement of the dissolution of ilmenite[J]. Minerals Engineering, 1998, 11(9): 827-841.

[27] 姚金环. 从铟铁酸锌中用机械活化方法强化浸出铟、锌的机理研究[D]. 南宁: 广西大学, 2013.

YAO Jin-huan. Investigations on the mechanism of indium and zinc leaching from indium-bearing zinc ferrite enhanced by mechanical activation[D]. Nanning: Guangxi University, 2013.

[28] NASSER A, MINGELGRIN U. Mechanochemistry: A review of surface reactions and environmental applications[J]. Cheminform, 2012, 67/68(34): 141-150.

[29] CHAI Li-yuan, LIANG Yan-jie, KE Yong, MIN Xiao-bo, TANG Chong-jian, ZHANG Hai-jing, XIE Xian-de, YUAN Cui-yu. Mechano-chemical sulfidization of zinc oxide by grinding with sulfur and reductive additives[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 1129-1138.

[30] HASEGAWA H, RAHMAN I M M, EGAWA Y,SAWAI H, BEGUM Z A, MAKI T, MIZUTANI S. Recovery of indium from end-of-life liquid-crystal display panels using aminopolycarboxylate chelants with the aid of mechanochemical treatment[J]. Microchemical Journal, 2013, 106(1): 289-294.

[31] MI G, SAITO F, HANADA M. Mechanochemical synthesis of tobermorite by wet grinding in a planetary ball mill[J]. Powder Technol, 1997, 93(1): 77-81.

[32] JAMES S L, ADAMS C J, BOLM C, BRAGA D, COLLIER P. Mechanochemistry: Opportunities for new and cleaner synthesis[J]. Chemical Society Reviews, 2011, 41(1): 413-447.

[33] FRISCIC T. New opportunities for materials synthesis using mechanochemistry[J]. Journal of Materials Chemistry, 2010, 20(36): 7599-7605.

[34] LIU T, XU Gui-ying, GONG Hou-jian, PANG Jin-yu, HE Fang. Effect of alcohols on aggregation behaviors of branched block polyether Tetronic 1107 at an air/liquid surface[J]. Langmuir, 2011, 27(15): 9253-9260.

[35] 刘 腾. X型嵌段聚醚的聚集行为及对碳纳米管的分散作用[D]. 济南: 山东大学, 2013.

LIU Teng. Aggregation behavious of X-shaped black pdgethers and the dispersing ability of carbon nanotubees[D]. Jinan: Shandong University, 2013.

[36] LOPEZ F A, LOPEZ-DELGADO A, PADILLA I, TAYIBI H, ALGUACIL F J. Formation of metacinnabar by milling of liquid mercury and elemental sulfur for long term mercury storage[J]. Science of the Total Environment, 2010, 408(20): 4341-4345.

[37] XIAO Y, LYU H H, TANG J C, WANG K, SUN Hong-wen. Effects of ball milling on the photochemistry of biochar: Enrofloxacin degradation and possible mechanisms[J]. Chemical Engineering Journal, 2019, 384(1): 1-13.

[38] 蓝际荣, 孙 燕, 潘 滢, 李卓蔓, 杜冬云. 球磨与助剂强化选择性回收电解锰渣中的锰[J]. 中国有色金属学报, 2019, 29(8): 1749-1755.

LAN Ji-rong, SUN Yan, PAN Ying, LI Zhuo-man, DU Dong-yun. Ball milling and auxiliary enhancement forselective recovery of manganese in EMRs[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(8): 1749-1755.

[39] SURYANARAYANA C. Mechanical alloying and milling[J]. Progress in Materials Science, 2006, 46(1): 1-184.

[40] REZA E K,MOHAMMAD H A, ALI S. Mechanochemical effects on the molybdenite roasting kinetics[J]. Chemical Engineering Journal, 2006, 121(2): 65-71.

[41] 阳富强, 刘广宁, 刘晓霞, 黄贤煜. 机械力活化诱导硫化矿石自燃的热分析动力学[J]. 中国有色金属学报, 2016, 26(9): 1976-1981.

YANG Fu-qiang, LIU Guang-ning, LIU Xiao-xia, HUANG Xian-yu. Thermal analysis kinetics of mechanically activated sulfide ores for spontaneous combustion[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(9): 1976-1981.

[42] LI Ming-guo, SUN Chang-jung, GAU S H, CHUANG C J. Effects of wet ball milling on lead stabilization and particle size variation in municipal solid waste incinerator fly ash[J]. Journal of Hazardous Materials, 2010, 174(1): 586-591.

Selective leaching of arsenic and valuable metals in copper smelting soot strengthened by ball milling pretreatment

HU Zhong-qiu1, 2, QU Jun1, 2, GUO Li1, 2, MA Wen-bo1, 2, HU Nan1, 2, ZHAN Wei1, 2, DU Dong-yun1, 2

(1. Hubei Province Engineering Research Center for Control and Treatment of Heavy Metal Pollution, College of Resources and Environmental Science, South-Central University for Nationalities, Wuhan 430074, China;

2. Key Laboratory of Catalysis Conversion and Energy Materials Chemistry, Ministry of Education, South-Central University for Nationalities, Wuhan 430074, China)

Abstract: The high-efficiency separation of arsenic and valuable metals in copper smelting soot strengthened by the ball milling pretreatment were investigated. The results show that the ball milling pretreatment alone can inhibit the leaching of As in soot. Compared with the unmilled soot, the leaching efficiency is reduced from 56.01% to 32.85%. However, the addition of NaOH can significantly increase the As leaching efficiency from 56.01% to 78.52%. The optimal process parameters are as follows: the mass ratio of NaOH to ash (mNaOH:mAsh) of 0.5:1, activation time of ball mill of 60 min (after ball milling pretreatment for (50±5) min in alkaline medium, and then milling with ethanol in sequence), the rotation speed of 600 r/min. Besides, Cu, Zn, Pb and Cd in the soot is basically not leached after treatment by this method, and the As content in the leaching residual solid is reduced from 5.74% to 0.13%. The SEM and particle size analysis show that ball milling can create defects on the surface of the particles, reduce the particle size of the soot, increase the specific surface area of the reaction and promote the mass transfer of the interface. Therefore, the leaching efficiency of As is dramatically enhanced. The results of XRD and XPS show that high temperature and high pressure are generated in the specific area during the ball milling process, inducing the solid-solid reaction: the oxidation state of As2O3 after reacting with NaOH converges into soluble arsenate, finally. And decomposition of parts of PbSO4 into PbO in a local high temperature environment, which further enhances the efficient separation of As and valuable metals during the leaching process. This study provides a theoretical basis for the harmlessness, and the resource utilization of arsenic-containing materials is produced by copper smelting industry.

Key words: copper smelting soot; ball milling; chemical reaction; activation; interface mass transfer; selective leaching

Foundation item: Project(2015BAB01B03) supported by the National Science and Technology Pillar Program, China; Project(CZT18022) supported by Central University for South-Central University for Nationalities, China

Received date: 2019-08-02; Accepted date: 2020-01-08

Corresponding author: DU Dong-yun; Tel: +86-13871538801; E-mail: dydu666@mail.scuec.edu.cn

(编辑 李艳红)

基金项目:国家科技支撑计划项目(2015BAB01B03);中南民族大学中央高校项目(CZT18022)

收稿日期:2019-08-02;修订日期:2020-01-08

通信作者:杜冬云,教授,博士;电话:13871538801;E-mail:dydu666@mail.scuec.edu.cn