文章编号:1004-0609(2010)01-0055-07

铝管连轧过程孔型参数优化及数值模拟

于 辉,杜凤山,许志强,徐海亮

(燕山大学 机械工程学院,秦皇岛 066004)

摘 要:为了研究孔型参数对铝管连轧过程的影响,采用正交试验优化设计方法设计数值模拟方案,在Marc有限元平台上,研究轧辊孔型参数(侧壁角、侧壁半径比、过渡圆角半径、辊缝大小、轧辊和管坯之间的摩擦因数)分别对轧制力、轧制力距、外径椭圆度和壁厚不均的影响,并分析各参数的影响显著性顺序。结果表明:侧壁角是最重要的影响因素,管坯和轧辊间的摩擦因数对外径椭圆度和壁厚不均的影响居于次位,侧壁半径比对轧制力和壁厚不均的影响最小。根据影响规律获得最优孔型参数组合,并对5机架铝管连轧过程进行有限元模拟分析。

关键词:孔型优化;连轧;数值模拟;正交试验

中图分类号:TG 335.7 文献标识码:A

Pass parameter optimization and numerical simulation for

tandem rolling process of aluminum tube

YU Hui, DU Feng-shan, XU Zhi-qiang, XU Hai-liang

(College of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, China)

Abstract: In order to investigate the influence of the pass parameters on the tandem rolling process of aluminum tube, a numerical simulation project was designed by orthogonal experiment optimization design method. On the FEM software platform of Marc, the influence of roller pass parameters including the side wall angle, the ratio of side wall radius, the fillet radius, the roll gap size and the friction coefficient between the roller and tube billet on the rolling force, rolling torque, the external diameter ovality and the wall thickness unevenness was investigated. Moreover, the effect order of the parameters was analyzed. The results show that the side wall angle is the major factor, the influence of the friction coefficient between the roller and the tube billet on the external diameter ovality and the wall thickness unevenness is secondary, and the influence of the ratio of side wall radius on the rolling force and the wall thickness unevenness is the least. The optimum pass parameters are obtained based on the influence law. Furthermore, the FEM analysis on the 5-stand aluminum tube random rolling process is carried out.

Key words: pass optimum; tandem rolling process; numerical simulation; orthogonal experiment

MPM限动芯棒连轧管机在轧制过程中控制芯棒的运行速度,促使金属变形均匀,克服传统连轧方法带来的“竹节”状缺陷,提高终轧温度,轧出成品管的壁厚偏差和内外表面质量得到改善,将连轧管机生产成品管的最大外径由168 mm扩大到426 mm,在世界各钢管企业得到广泛应用[1?2]。

毛管经过由轧辊、芯棒所组成的孔型中完成连轧,实现减壁和延伸,因此,孔型设计是MPM连轧管机的技术核心,直接影响到轧制过程的建立和产品的几何尺寸精度、表面质量及轧制力能参数的变化[3?5],郭海明等[6]通过在SMS Meer公司的相关数学模型的基础上,对d159 mm MPM限动芯棒连轧管机组进行系列孔型的开发设计。王鹏飞等[7]提出5机架MPM限动芯棒连轧管机组孔型设计方法,部分机架的计算结果与原始资料十分接近。由于MPM连轧过程的金属变形比较复杂,国内外学者对限动芯棒连轧过程的金属流动和轧后形状进行一些研究工作,特别是随着有限元技术的发展,为定量分析钢管连轧过程的变形提供了有效方法[8]。李胜祗等[9]对T91钢管内表面裂纹进行了有限元建模分析,根据分析结果对孔型进行修改。VACANCE等[10]用粘塑性有限元法研究了不同孔型轧制对轧件横向壁厚分布的影响。YAMAMOTO等[11]用刚塑性有限元法,研究了孔型对出口处横截面的形状、轧件表面压力分布的影响,BAINES[12]用铅做为模型材料,利用能量法分析孔型参数对平均轧制压力的影响。

本文作者以影响MPM限动芯棒连轧管机产品质量的关键因素-轧辊孔型为研究对象,采取数值模拟和正交试验相结合的方法,在Marc有限元平台上,研究孔型参数对连轧过程的影响,分析侧壁角、侧壁半径比、过渡圆角半径、辊缝大小、轧辊和管坯之间的摩擦因数分别对轧制力、轧制力距、外径椭圆度和壁厚不均的影响显著性及其影响规律,并对5机架MPM限动芯棒连轧过程进行模拟分析。

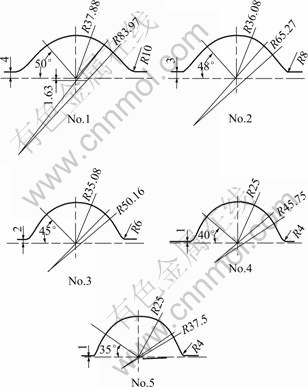

1 MPM连轧管机的孔型设计

MPM连轧管机组的机架数目一般为5~7架,由于第1机架的压下量较大,且毛管壁较厚,一般采用有利于咬入的椭圆孔型,其余采用圆弧侧壁圆孔型或者直侧壁圆孔型,最后两架精轧机架采用的孔型相同,相邻机架孔型错开90?交错布置形成多机架连轧。本实验中研究的MPM连轧管孔型采用椭圆?圆孔型组合,共5个机架,各机架孔型配置示意图如图1所示。

图1 5机架MPM孔型配置示意图

Fig.1 Schematic diagram of MPM pass arrangement with 5 stands (mm)

毛管规格为d 70.12 mm×11 mm,荒管规格为d 50 mm×5 mm,芯棒直径为d 38.6 mm,机架间距为500 mm,管子出口速度为3 m/s,芯棒限动速度为1.35 m/s。

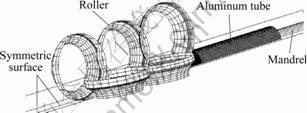

2 有限元模型的建立

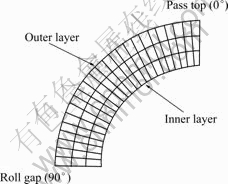

随着计算机技术的飞速发展和有限元理论的日趋成熟,有限元模型在轧制领域得到广泛应用[13]。MPM连轧管机的轧辊孔型曲面是相对于轧辊轴线的旋转面,且沿孔型底部左右对称。根据这一几何特点,在进行有限元建模时,取半个轧辊曲面作为研究对象建立轧辊曲面模型,与此相对应把管坯的计算模型减少到整个截面的1/4,建立90?圆弧(孔型底部至辊缝间)的计算模型,有限元模型如图2所示。

图2 连轧有限元模型示意图

Fig.2 Schematic diagram of finite element model of tandem rolling

由于MPM连轧管机的机架刚度较大,建模时可把轧辊和芯棒皆视为刚性体,芯棒在不影响轧制过程准确建立的条件下,对其位置和长度不做要求。初始管坯视为变形体,假定其横向壁厚和纵向壁厚均匀,采用八节点等参元来建立描述管坯的有限元网格,网格划分时沿管坯半径方向分为3层,圆周方向(横向)分为25份。轧辊与管坯之间以及芯棒与管坯之间都采用剪切摩擦模型。

模拟计算时先给轧件一个与轧制方向相同的速度,待第一架轧辊咬入后,施加在轧件上的速度变为零,然后轧件在轧辊摩擦力的带动下进行稳定轧制。除了管坯头部和尾部,轧件在整个连轧过程的变形可看作是一个稳态变形,于是取轧件中间某断面作为分析对象。

3 机架孔型正交优化

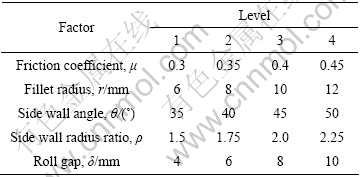

3.1 研究方案的确定

正交试验设计根据正交性从全面试验中挑选出部分有代表性的点进行试验,是一种高效率的实验设计方法,大大减少工作量,在诸多领域的研究中已经得到广泛应用[14]。MPM连轧管机孔型优化主要考虑侧壁角、侧壁半径比、过渡圆角半径、辊缝大小、轧辊和管坯之间的外摩擦因数,共5个参数,每个参数分4个水平,选择L16(45)正交表。这里仅列出第3架的正交试验工艺参数,如表1所列。

表1 正交试验参数

Table 1 Parameters of orthogonal experiment

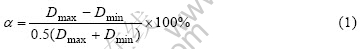

3.2 目标函数的确定

轧制力和轧制力矩是重要的轧制参数,是进行轧机设计和选用主传动电动机的主要依据,轧后产品尺寸精度主要包括外径精度和壁厚精度,外径精度反映椭圆度,壁厚精度反映壁厚不均匀度[15]。为此,轧辊孔型正交优化设计的目标函数为轧制力、轧制力矩、外径精度和壁厚精度。

外径椭圆度 为

为

式中:Dmax为管子同一截面内的最大外径;Dmin为管子同一截面内的最小外径。

精度反映壁厚不均匀的程度(壁厚不均) 为

为

式中:Smax为管子同一截面内的最大壁厚;Smin为管子同一截面内的最小壁厚;SH为管子的名义壁厚。

按照表1正交试验工艺参数进行16组模拟计算,具体模拟参数组合及结果如表2所列。

表2 参数组合及结果

Table 2 Parameter associations and simulated results

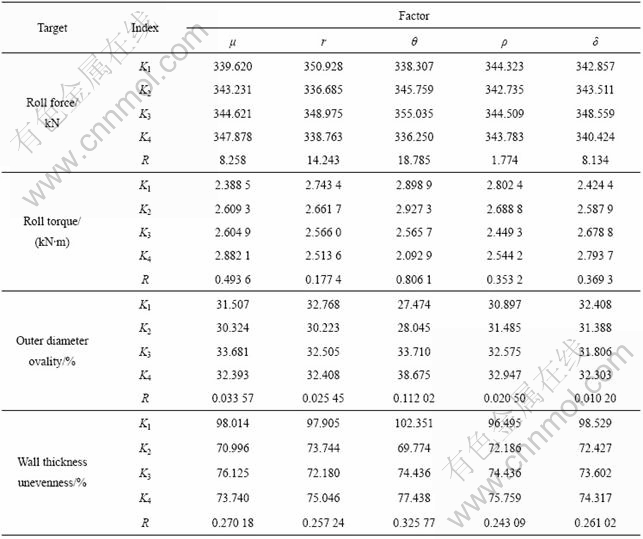

3.3 因素显著性分析

由表2中的数据得到轧制力、轧制力矩、外径精度和壁厚精度的极差分析如表3所列。其中Ki(i=1, 2, 3, 4)分别表示每个因素同一水平值之和,反映各列所排因素的不同水平对结果的影响,极差R的大小反映相应因素对目标函数作用的显著性,极差R越大,该因素对目标函数的影响越显著。分析表3中的轧制力极差可知,Rθ>Rr>Rμ>Rδ>Rρ,5个因素中侧壁角对轧制力的影响最显著,其次是过渡圆角半径,侧壁半径比的影响最小。由轧制力矩极差分析可知,Rθ>Rμ> Rδ>Rρ>Rr,其中侧壁角对轧制力矩的影响最显著,其次是管坯和轧辊之间的摩擦因数,过渡圆角半径影响最小。由外径椭圆度极差分析可知,Rθ>Rμ>Rr> Rρ>Rδ,其中侧壁角对外径椭圆度的影响最显著,其次是管坯和轧辊之间的摩擦因数,辊缝值的大小影响最小。由壁厚不均极差分析可知,Rθ>Rμ>Rδ>Rr>Rρ,其中侧壁角对壁厚不均的影响最显著,其次是管坯和轧辊之间的摩擦因数,侧壁半径比的影响最小。

表3 极差分析

Table 3 Analysis of extreme difference

3.4 轧辊孔型参数的优化

采用综合平衡法对孔型参数进行优化分析,由试验得到的各指标K1、K2、K3和K4,确定单独指标下的主次因素,忽略因素间的交互作用,进行综合平衡,找到每个因素对所有目标函数都尽可能好的组合,从而获得最优试验方案。

由表3可知每个因素分别对单个目标函数的最佳组合如下:

1) 轧制力:μ1r2θ4ρ2δ4;

2) 轧制力距:μ1r4θ4ρ3δ1;

3) 外径椭圆度:μ2r2θ1ρ1δ2;

4) 壁厚不均:μ2r3θ2ρ2δ2。

式中:μi表示相应Ki对应的最小μ值;ri表示相应Ki对应的最小r值;θi表示相应Ki对应最小θi值;ρi表示相应Ki对应的最小ρ值;δi表示相应Ki对应的最小δ值。

对于成品管首先要考虑尺寸精度,因此摩擦因数选2水平,过渡圆角半径叶选2水平,侧壁角选4水平,侧壁半径比选2水平,辊缝选2水平,优化孔型参数为μ2r2θ4ρ2δ2,即管坯与轧辊的摩擦因数μ为0.35,过渡圆角半径r为8 mm,侧壁角θ为50?,侧壁半径比ρ为1.75,即侧壁半径为顶部半径的1.75倍,辊缝δ为6 mm。由于该最优方案不在16组试验中,对该组合进行模拟,得到的轧制力为73.2 kN,轧制力距为2.38 kN?m,外径椭圆度为6.93%,壁厚不均为14.6%。由此可见,优化后的孔型参数不仅减小该机架的轧制力和轧制力距,还大大减小了外径椭圆度和壁厚不均。

4 孔型优化后轧制分析

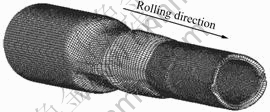

利用正交优化方法分别对MPM连轧管机的5个机架轧辊孔型参数进行优化后,进行三维有限元建模,对管坯连轧过程的金属变形进行模拟分析,管坯经过5个机架连轧的宏观变形过程模拟如图3所示。由图3可知,前几个道次孔型减径量较大,管坯变形程度较大,经过几个道次轧制后管子外形成为比较规则的圆形。

图3 管坯连轧变形示意图

Fig.3 Schematic diagram of rolling deformation of tube billet

4.1 金属流动分析

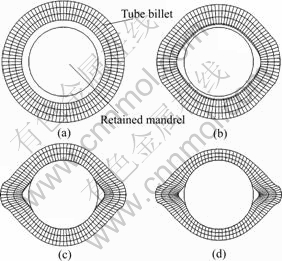

MPM连轧管机组机架数目较多,前几个机架孔型实现较大的减壁和延伸,最后机架为成品机架,受篇幅限制,本研究仅对第1架进行金属流动分析,在工件刚刚咬入时,主要发生空减径变形,工件接触芯棒后促使金属向辊缝部位流动,促使定量分析管断面变形。图4所示为横断面图形反映工件在变形区不同位置的变形。图4(a)表示工件变形前所处的状态,图4(b)反映工件进入变形区的空减径过程,图4(c)反映工件对应孔型顶部所产生的接触变形,图4(d)反映工件对应辊缝部位的空隙减小和壁厚发生变化。这样管坯经过第1机架轧辊孔型,壁厚在孔型顶部被减薄,在辊缝部位出现增厚。

图4 第1机架轧制横断面在不同状态下的变形示意图

Fig.4 Schematic diagrams of deformation of cross section for 1-stand rolling under different processes: (a) Before deformation; (b) Hollow reduction; (c) Contact deformation; (d) Wall thickness variation

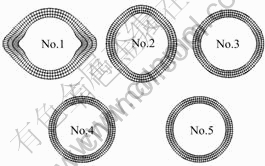

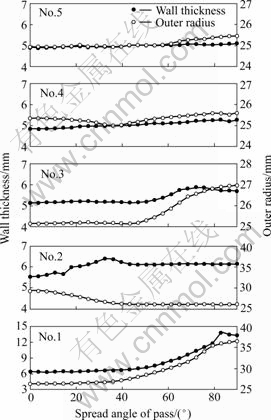

4.2 几何形状分析

外形和尺寸精度是产品质量的基本要求。图5所示为管坯经过各个轧制机架时的出口横断面形状。由图5可看出,在该轧制工艺下,由于第一道次为椭圆孔型,且延伸系数较大,孔型变形的不均匀性,以及管坯横断面各处金属沿轧制方向流动速度的差别,管子出口宽展明显且不均匀塑性变形严重。第二和第三道次为圆弧侧壁圆孔型,其侧壁角和侧壁半径都较第一机架小,使第一机架的椭圆度逐次减小,壁厚不均也到很好的改善。第四道和第五道次延伸系数进一步

图5 各机架出口截面示意图

Fig.5 Schematic diagrams of cross-section profiles of stands

减小,管子横截面形状趋于圆形,周向壁厚逐渐均匀,在第五道次精度反映壁厚不均的程度和椭圆度分别为2.11%和4.83%。

为了便于壁厚分析,规定沿着孔型的圆周方向,对于奇数机架,孔型顶部对应0?位置,辊缝对应90?位置,偶数机架各部位对应位置相反,如图6所示。图7所示为各机架出口横断面的外径和壁厚分布。由图7可知,机组减径量主要在前3机架,占总减径量

图6 孔型沿圆周方向展开的角度

Fig.6 Circular degree of pass expanded along circumferential direction

图7 出口横截面的外径和壁厚分布

Fig.7 Distributions of outer radius of cross section and wall thickness at exit

的80%以上,第一架外半径和壁厚的变化比较剧烈,在孔型顶部数值显著减小,而辊缝处明显增大;第二机架孔型交错90?布置后,外径依然是孔型顶部数值值减小,辊缝处增大,而壁厚不均得到一定改善。经过后续机架轧制后,金属横向流动使得壁厚变化趋于一致,外径椭圆度也得逐渐减小,轧件从第五机架轧出后,成品管壁厚误差为?2.1%~2.6%,外径误差为?0.2%~1.2%。

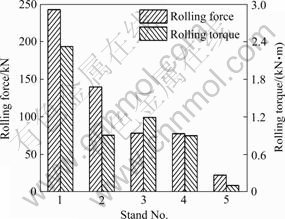

4.3 轧制力和轧制力矩分析

图8所示为5个机架的轧制力和轧制力矩,总体上随着轧制道次增加而呈递减趋势,但第2道次的轧制力矩小于第3道次的。

图8 5个机架的轧制力和轧制力矩

Fig.8 Roll force and roll torque of 5 stands

5 结论

1) 针对限动芯棒连轧管机的轧辊孔型,结合有限元模拟,利用正交试验方法,以轧制力、轧制力矩、外径椭圆度和壁厚不均为目标对孔型的5主要参数(侧壁角、管坯和轧辊之间的摩擦因数、侧壁半径比、过渡圆角半径、辊缝值)进行主次因素分析及参数水平优化,得出较优水平组合。

2) 侧壁角大小是影响研究目标的最重要因素,管坯和轧辊之间的摩擦因数对外径椭圆度和壁厚不均的影响居于次位,侧壁半径比对轧制力和壁厚不均的影响最小。得到第3机架孔型的最优参数组合为:管坯与轧辊的摩擦因数为0.35,过渡圆角半径为8 mm,侧壁角为50?,侧壁半径比为1.75,辊缝为6 mm。

3) 利用有限元分析软件Marc建立5机架MPM限动芯棒连轧过程的三维弹塑性有限元模型,分析各机架外径、壁厚、轧制力和轧制力矩分布和变化,为分析金属变形和产品尺寸精度提供依据。

REFERENCES

[1] 金如崧. 限动芯棒连轧管工艺发展简史[J]. 钢管, 2004, 33(1): 52?58.

JIN Ru-song. Developing simply history of restrained mandrel tandem tube technology[J]. Steel Pipe, 2004, 33(1): 52?58.

[2] 严泽生. 现代热连轧无缝钢管生产[M]. 北京: 冶金工业出版社, 2009: 22?27.

YAN Ze-sheng. Modern continuous hot-rolling production of seamless steel tubes and pipes[M]. Beijing: Metallurgical Industry Press, 2009: 22?27.

[3] 张良夫. 浅谈连轧管机生产技术的发展[J]. 轧钢, 2008, 25(3): 48?49, 65.

ZHANG Liang-fu. Brief discussion on the development of MPM[J]. Steel Rolling, 2008, 25(3): 48?49, 65.

[4] 李 群, 陈洪琪, 焦 艳. 用限动芯棒连轧管机组生产厚壁无缝钢管的探讨[J]. 钢管, 2008, 37(2): 37?40.

LI Qun, CHEN Hong-qi, JIAO Yan. Discussion on producing heavy-wall seamless steel pipes with MPM plant[J]. Steel Pipe, 2008, 37(2): 37?40.

[5] AMMERLING W J, KULESSA G, VON D H J. Innovations in the seamless tube process[J]. MPT Metallurgical Plant and Technology International, 2002, 25(3): 34?39.

[6] 郭海明, 姜长华, 李道刚. φ159 mm MPM连轧管机的孔型开发与优化[J]. 钢管, 2008, 37(1): 51?56.

GUO Hai-ming, JIANG Chang-hua, LI Dao-gang. Development and optimization of passes ofφ159 mm MPM[J]. Steel Pipe, 2008, 37(1): 51?56.

[7] 王鹏飞, 连毓平, 秦建新. 少机架限动芯棒连轧管机孔型设计的探讨[J]. 钢管, 2000, 29(1): 18?21.

WANG Peng-fei, LIAN Yu-ping, QIN Jian-xin. Cursory review of groove design of fewer-stand mandrel retained MPM[J]. Steel Pipe, 2000, 29(1): 18?21.

[8] 尹元德, 李胜祗. 无缝钢管连轧技术研究进展[J]. 安徽工业大学学报, 2005, 22(3): 229?233.

YIN Yuan-de, LI Sheng-zhi. Progress of continuous rolling technology for seamless steel tube[J]. Journal of Anhui University of Technology, 2005, 22(3): 229?233.

[9] LI Sheng-zhi, XU Jie, YIN Yuan-de, XUE Jian-guo, FENG Yuan. Mechanism of internal surface crack formation of seamless modified 9Cr-1Mo steel tube rolled by mandrel mill and its application[J]. Journal of Iron and Steel Research, International, 2007, 14(5): 273?276.

[10] VACANCE M, MASSON E, CHENOT J L. Multi stand pipe mill finite element model[J]. Journal of Materials Processing Technology, 1990, 24: 421?430.

[11] YAMAMOTO S, YAMADA K, HAMAUZU S, OZAKI T. Effect of roll-groove profile on tube deformation in single-stand mandrel rolling[J]. Journal of the Japan Society for Technology of Plasticity, 1999, 466(40): 1076?1080.

[12] BAINES K. Lead as a model material to simulate mandrel rolling of hot steel tube[J]. Journal of Materials Processing Technology, 2001,118(3): 422?428.

[13] CAVALIERE M A, GOLDSCHMIT M B, DVORKIN E N. Finite element analysis of steel rolling processes[J]. Computers and Structures, 2001, 79(22/25): 2075?2089.

[14] 李云雁, 胡传荣. 试验设计与数据处理[M]. 北京: 化学工业出版社, 2005: 79?98.

LI Yun-yan, HU Chuan-rong. Experiment design and data treatment[M]. Beijing: Chemical Industry Press, 2005: 79?98.

[15] 李连诗, 韩观昌. 小型无缝钢管生产[M]. 北京: 冶金工业出版社, 1989: 3?9.

LI Lian-shi, HAN Guan-chang. Small seamless tube production[M]. Beijing: Metallurgical Industry Press, 1989: 3?9.

基金项目:国家自然科学基金资助项目(50675187)

收稿日期:2009-03-09;修订日期:2009-08-25

通信作者:于 辉,副教授,博士;电话:0335-8057040;E-mail: grayfish@ysu.edu.cn

(编辑 李艳红)