DOI:10.19476/j.ysxb.1004.0609.2019.02.14

铸态和退火态Al0.5CoCrFeNiTi0.5 高熵合金的组织与性能

蒋淑英,林志峰,许红明

(中国石油大学(华东) 机电工程学院,青岛 266580)

摘 要:采用真空电弧熔炼法熔炼出Al0.5CoCrFeNiTi0.5高熵合金,并在600、800和1000 ℃下进行真空退火热处理。利用X射线衍射仪(XRD)、光学显微镜(OM)、电子探针(EPMA)、硬度计、万能试验机以及电化学工作站对合金铸态和不同温度退火态的微观组织、硬度、压缩力学性能以及在3.5% NaCl溶液中的耐蚀性进行研究。组织分析表明:铸态和退火态的Al0.5CoCrFeNiTi0.5合金均由富(Cr,Fe)的FCC、富(Al,Ni,Ti)的BCC和σ三相组成,但退火处理使合金的组织形貌和各相的相对含量发生了改变,铸态下的粗大白色FCC柱状晶转变为细小的FCC+BCC+σ的混合组织;随着退火温度的升高,BCC和σ相含量增加。800 ℃退火态合金成分均匀性最好,1000 ℃退火态合金由于退火温度过高,组织粗大,元素偏析重新加剧。硬度试验和压缩试验结果表明:合金在铸态和3种温度退火态下的硬度都较高,表现出良好的抗回火软化能力;800 ℃退火态合金中由于BCC和σ相的增加,其硬度和屈服强度最高,但塑性最差。1000 ℃退火态合金由于大量σ相的析出以及组织粗大,其屈服强度、断裂强度和压缩形变率都急剧降低。600 ℃退火态合金具有理想的FCC、BCC和σ相的组成含量,其综合力学性能最好。电化学腐蚀试验表明:铸态和3种温度退火态的合金在3.5% NaCl溶液中都表现出良好的耐蚀性,800 ℃退火态合金由于其成分均匀性最好,耐蚀性最好。

关键词:高熵合金;退火;组织结构;力学性能;耐蚀性

文章编号:1004-0609(2019)-02-0326-08 中图分类号:TG113 文献标志码:A

传统合金以一种或两种元素为主组元,而后加入其他少量元素来改善其组织和性能。2004年,台湾学者叶均蔚等[1]正式提出多主元高熵合金的概念,所谓多主元高熵合金即合金中主要元素种类大于5种但不超过13种,每种元素的摩尔分数在5%~35%之间。由于在高熵合金中混合熵占主导地位,且熵值远高于传统合金的,所以通常情况下容易形成固溶体,其组织更容易产生纳米晶体,甚至于形成非晶体[2-3]。因此,通过成分优化设计可使高熵合金在性能上比传统合金具有更大的优势[4],例如高硬度、高强度和高韧性[5-9]、优良的热稳定性[10-11]、耐高温氧化性[12-17]、耐磨损性[18-19]和耐腐蚀性[20-22],可以很好地弥补块体非晶合金应用中的室温脆性大和无法高温使用的缺点。

在元素周期表中,Co、Cr、Fe、Ni同属第四周期过渡族元素,具有相近的原子半径和电负性,容易形成简单固溶体结构。Al、Ti同属轻金属元素,都具有较大的原子半径,固溶后可以起到很好的固溶强化效应,此外,Al容易使合金表面生成致密的氧化膜,而Ti在海水中有很好的耐蚀性。因此,AlxCoCrFeNiTiy系列高熵合金受到了广泛研究[10-11, 18, 21, 23-25]。WANG等[10]发现,在AlxCoCrFeNi中Al含量太高会导致BCC和B2结构形成,使合金的延性极大地降低。ZHOU等[24]发现在AlCoCrFeNiTix中Ti含量太高会导致Laves相形成,将使合金的脆性增大。本文作者为了减少AlxCoCrFeNiTiy合金中B2相和Laves相的生成,获得具有良好力学性能和耐蚀性能的合金,选择了Al0.5CoCrFeNiTi0.5的合金配方,用非自耗真空电弧熔炼法制备出Al0.5CoCrFeNiTi0.5高熵合金,并在不同的退火温度下对其进行真空退火处理,研究退火温度对合金的组织结构、力学性能和耐腐蚀性能的影响。

1 实验

试验中所用的原料是纯度为99.9%~99.99%的Co、Cr、Fe、Ni、Al、Ti金属粉末,按配方精确称量后充分搅拌均匀,利用769YP-40型粉末压片机加压到20 MPa压制成短柱状待熔炼。将试样放入WK-Ⅱ型非自耗真空电弧熔炼炉内,抽真空至5.0×10-3 Pa后通入高纯氩气点弧熔炼,熔炼电流130 A,熔炼时间约1 min,熔炼过程中通冷却水冷却。每个试样反复熔炼5次,以使合金内部成分均匀。

熔炼后的试样分为4组,一组为铸态,其余3组分别在NBD-T系列管式高温真空烧结炉内进行600、800和1000 ℃真空退火处理,保温时间为10 h,随炉冷却。

采用X’Pert PRO MPD 型X射线衍射仪(XRD)、LJ-JX2030型金相显微镜和JXA-8230型电子探针对铸态和不同温度退火态的试样的相结构、微观组织形貌和成分分布进行分析,XRD扫描范围为10°~100°,每个试样扫描所需时间为10 min。

采用HV-1000A型维氏硬度计对铸态和不同温度退火态的合金室温硬度进行测试,载荷为9.8 N,负载时间为15 s,每个试样取5个点测试,求取平均值。因本次试验样品为钮扣锭,因此,采用压缩试验测试合金试样的室温力学性能。在压缩试验中为了防止试样失稳,试样的宽度和高度的比例应在1.5~2之间,所以将试样切割为5 mm×5 mm×10 mm的长方体。在WDW-300E万能试验机上完成室温压缩试验,加载速率为0.2 mm/s。

利用CS310电化学工作站,采用三电极体系,在室温下测试合金在3.5% NaCl溶液中的动电位极化曲线。参比电极为甘汞电极,工作电极是合金试样,同时采用较大面积的辅助电极(Pt片制成),以减少溶液欧姆阻抗对实验结果的干扰。将试样、参比电极、辅助电极连接好导线后,用保鲜膜将烧杯瓶口与塞子连接处密封,然后开始进行电化学腐蚀实验,在开路电位稳定后开始测量极化曲线。

2 结果与讨论

2.1 铸态和退火态Al0.5CoCrFeNiTi0.5组织结构分析

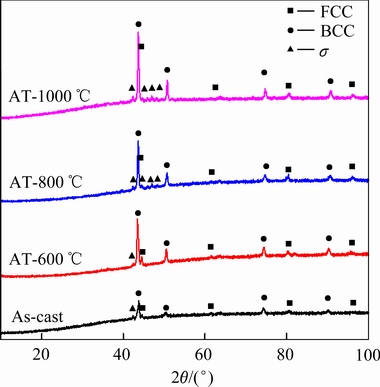

图1所示为Al0.5CoCrFeNiTi0.5合金在铸态和3种温度退火态的的XRD谱,通过XRD谱与标准PDF数据库对比后发现,铸态和3种温度退火态下的Al0.5CoCrFeNiTi0.5合金均由FCC相、BCC相和σ相三相组成,FCC相的衍射峰强度最高,其次是BCC相,σ相衍射峰强度最弱,说明在铸态和3种温度退火态下FCC相均为主相。

图1 铸态和退火态Al0.5CoCrFeNiTi0.5合金的XRD谱

Fig. 1 XRD patterns of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy (AT: Annealing treatment)

于源等[26]、王毅飞等[27]在对AlCoxCrFeMo0.5Ni和AlCoCrFeNiTi0.5高熵合金的研究中也发现了与图1具有相同衍射峰分布的σ相,对比XRD标准卡片,发现σ相与Cr0.99Fe1.01相衍射峰对应。从图1的XRD谱可以看出,随着退火温度的升高,BCC相和σ相衍射峰的相对强度增加,尤其是800 ℃和1000 ℃退火态下BCC相和σ相衍射峰的相对强度增幅明显。这说明在800 ℃和1000 ℃退火态合金中BCC相和σ相的含量增加明显,同时FCC相的含量减少。随着退火温度的升高,FCC相衍射峰的相对强度虽然减少,但绝对强度增加,这是由于铸态合金在水冷铜坩埚的快速冷凝导致合金产生大量的位错、空位以及过饱和,晶格畸变严重, 使得漫反射效应增强,衍射峰强度低,而合金退火过程为元素扩散提供了足够能量,使元素之间的扩散和置换加强。随着BCC相和σ相的进一步析出,FCC固溶体过饱和度和缺陷减少,晶格畸变减轻,漫反射效应减弱,从而衍射峰的绝对强度增加。

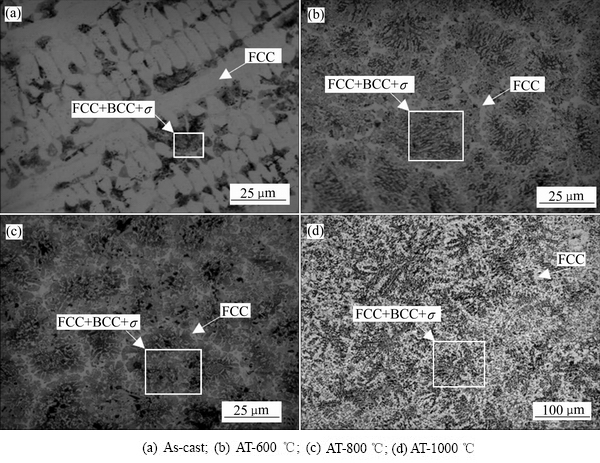

图2 Al0.5CoCrFeNiTi0.5合金在不同状态下的金相照片(王水腐蚀)

Fig. 2 Metallographs of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy (Aqua regia corrosion)

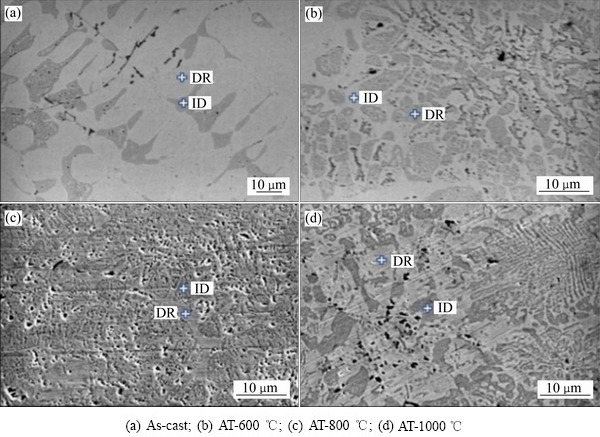

图3 不同状态下的Al0.5CoCrFeNiTi0.5合金的电子探针形貌像

Fig. 3 Electron probe images of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy

图2和3所示分别为铸态和3种温度退火态的Al0.5CoCrFeNiTi0.5合金经王水腐蚀后的光学显微金相照片和电子探针形貌像。可以看出退火处理后合金的组织发生了明显的改变。铸态下合金中大部分区域都是比较规则的白色柱状树枝晶,而枝晶间区域为短片状灰色相与白色相交替分布的层片状混合组织。此外,还分布着少量深色颗粒相。结合XRD分析结果可以推断,占据大部分区域的白色柱状晶为FCC相,灰色相为BCC相,少量深色颗粒为σ相。从图2可以看出,合金经退火处理后,铸态下的粗大白色FCC柱状晶消失,形成了白色基底上密布着短片状灰色BCC相和深色颗粒σ相的混合组织。白色相呈两种组织形态,一种呈网状独立分布,另一种在网内与灰色BCC相和深色颗粒σ相形成混合组织。退火温度越 高,网状独立FCC相越少。这说明在600 ℃及以上的退火过程中,铸态下的白色柱状FCC相分解,转变成了FCC+BCC+σ的混合组织。

在本文中,铸态合金是在水冷铜坩埚中真空熔炼而成,得到的组织相当于淬火组织,白色FCC固溶体处于过饱和状态,是非稳定相。随着退火过程的进行,不稳定的过饱和白色FCC固溶体相析出灰色BCC相和σ相,形成FCC+BCC+σ的混合组织;退火温度越高,析出转变越充分,独立自由的单相FCC越少,此过程与淬火钢在回火过程中的转变很类似。BUTLER等[28]研究了一系列Alx(NiCoCrFe)1-x合金在700 ℃和1050 ℃下的相平衡和相稳定性,发现σ相在700 ℃可以稳定存在,但在1050 ℃下σ相溶解消失。结合Fe-Cr相图也发现σ相的最高存在温度为830 ℃。因此,本文中的Al0.5CoCrFeNiTi0.5合金在1000 ℃的退火过程中,σ相先发生了溶解,在随后的随炉冷却中又由于固溶体溶解度的降低而析出,因此相比于800 ℃退火态,1000 ℃退火态中的σ相析出量并没有明显增加。

为了进一步了解铸态和不同温度退火态的Al0.5CoCrFeNiTi0.5中各区域的成分分布,利用EDS分别在树枝晶晶内(DR)和树枝晶晶间(ID)做了点成分分析,分析位置如图3“+”字所示,分析结果如表1所示。

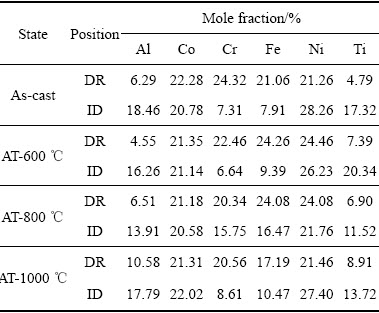

表1 铸态和退火态Al0.5CoCrFeNiTi0.5合金微区成分分布

Table 1 Component distribution of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy

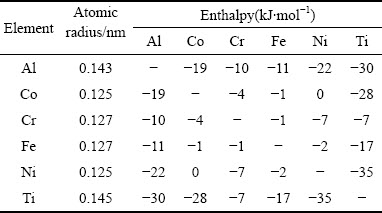

从表1中可以看出,无论铸态还是退火态合金,Co元素近乎均匀地分布在枝晶和枝晶间;而Cr、Fe、Al、Ni、Ti存在一定的偏聚,Cr、Fe元素在白色枝晶内含量较高,Al、Ni、Ti元素在灰色枝晶间处含量较高。比较Al0.5CoCrFeNiTi0.5合金中各元素之间的化学混合焓[29](见表2),由于Al-Ni、Al-Ti、Ti-Ni之间的混合焓远负于Al、Ni、Ti与Cr、Fe之间的混合焓,而元素之间的混合焓负得越多,越容易结合团聚[30]。因此,Al、Ni、Ti易于结合团聚,Al、Ni、Ti的团聚必然引起Cr、Fe被排斥,也就形成了Cr、Fe在另一区域的团聚,由此形成Al、Ni、Ti和Cr、Fe两种偏聚团,从而形成富(Cr,Fe)的FCC结构和富(Al,Ni,Ti)的BCC结构。分析Co与其他元素的混合焓可以看出,虽然Co与Al、Ti的混合焓要比Co与Cr、Fe的混合焓负,但Co与Ni的混合焓为零,不易与Ni结合,因此在Al、Ni、Ti富集区和Cr、Fe富集区Co的含量基本接近,分布较为均匀。从整体上看,800 ℃退火态成分均匀性最好,这是因为随着退火温度的升高,原子扩散能力增强,铸态下的过饱和粗大FCC固溶体析出分解越充分,成分均匀性也越好。但1000 ℃高温下由于成分不同的各相发生了聚集长大,因此成分不均匀性再一次加剧。

表2 不同元素之间的化学混合焓和原子半径[29]

Table 2 Atomic radius and mixing enthalpy of element pairs[29]

2.2 铸态和退火态Al0.5CoCrFeNiTi0.5的力学性能分析

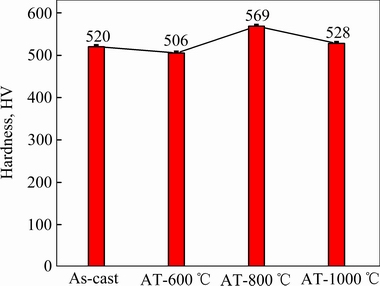

图4所示为铸态和3种温度退火态下的Al0.5CoCrFeNiTi0.5合金的室温硬度柱状图。

从图4可以看出,合金在铸态和3种温度退火态下都有较高的硬度,硬度值均在500 HV以上,说明合金有较强的抗回火软化的能力。合金经800 ℃退火处理后硬度最大,达到569 HV。这是由于800 ℃退火处理后合金中的元素分布比较均匀,组织比较细小,此外析出的σ相较多,在合金中起到析出强化的作用,也是导致合金硬度升高的原因。600 ℃退火处理后硬度最低,为506 HV,这是由于经过600 ℃退火后,铸态下的过饱和FCC相分解,饱和度降低,固溶强化效果减弱;同时合金中的空位等缺陷减少,内应力得到释放,而析出的σ相较少,析出强化作用弥补不了饱和度降低、缺陷减少等对硬度的降低。因此,600 ℃退火态的硬度略低于铸态。从图3可以看出,1000 ℃退火态由于退火温度过高,冷却后得到的室温组织比800 ℃退火态粗大,因此其硬度也比800 ℃退火态低。但1000 ℃退火温度相对于传统合金已经很高,保温时间也足够长,合金的硬度相对于铸态依然略有升高,这说明Al0.5CoCrFeNiTi0.5具有很好的热稳定性和高温使用性能。

图4 铸态和退火态Al0.5CoCrFeNiTi0.5合金室温硬度柱状图

Fig. 4 Room-temperature hardness charts of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy

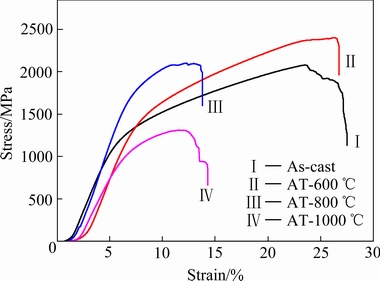

图5所示为Al0.5CoCrFeNiTi0.5合金在铸态和3种温度退火态下的室温压缩应力-应变曲线。表4列出了其室温压缩屈服强度(σy)、压缩断裂强度(σmax)和压缩形变率(εp)。可以看出,800 ℃退火态压缩屈服强度最高,达到1610 MPa,与硬度的分布一致,但塑性最低,同样也是由于800℃退火处理后合金中的BCC和σ相增加,析出强化效应显著,因此屈服强度增加,屈服强度增加的同时也会由于脆性σ相的增加而导致塑性降低。1000 ℃退火态的屈服强度和断裂强度最小,压缩形变率也很差,这是因为1000 ℃退火态由于退火温度过高,冷却后得到的室温组织粗大,加之大量脆性σ相的存在,因此其屈服强度、抗拉强度和压缩形变率都急剧降低。相对于铸态下强度较低的FCC过高,800 ℃和1000 ℃退火态下脆性较大的σ过高,600 ℃退火态由于具有较理想的FCC、BCC和σ相的组成比例,使合金具有良好的塑性变形能力和形变硬化能力,其综合力学性能最好,尤其是其压缩断裂强度在4种状态中达到最大。

图5 铸态和退火态Al0.5CoCrFeNiTi0.5合金室温压缩应力-应变曲线

Fig. 5 Room-temperature compressive stress-strain curves of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy

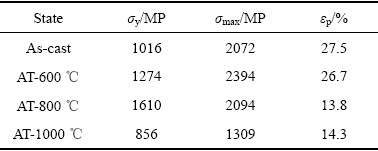

表3 铸态和退火态Al0.5CoCrFeNiTi0.5合金室温压缩性能参数

Table 3 Room-temperature compression performance parameters of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy

2.3 铸态和退火态Al0.5CoCrFeNiTi0.5的耐蚀性分析

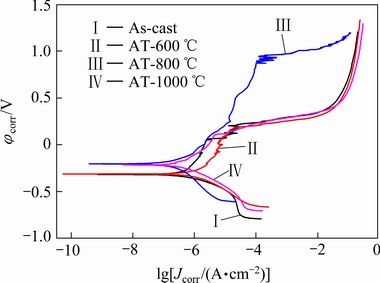

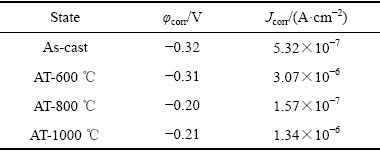

图6所示为Al0.5CoCrFeNiTi0.5铸态和3种温度退火态在3.5% NaCl溶液中的动电位极化曲线,通过塔菲尔直线外推与腐蚀电位相交可得到其自腐蚀电位(φcorr)和自腐蚀电流密度(Jcorr),如表5所示。通过曲线可以看到,无论是铸态还是退火态合金,在3.5% NaCl溶液中均没有出现钝化现象。从表5可以看出,800 ℃退火态合金自腐蚀电位最正,自腐蚀电流密度最小,比600 ℃退火态和1000 ℃退火态的自腐蚀电流密度小一个数量级。自腐蚀电位越正,说明自腐蚀倾向越小;自腐蚀电流密度越小,说明自腐蚀速率越小。因此在3.5% NaCl溶液中800 ℃退火态合金的自腐蚀倾向和腐蚀速率都最小,耐蚀性最好。从自腐蚀电流密度的大小可以看出合金的耐蚀性由高到低分别为800 ℃退火态、铸态、1000 ℃退火态、600 ℃退火态。这是由于水冷铸态下的合金虽然过饱和度大,晶格畸变严重,空位、位错等缺陷较多,但其组织大多数区域均为单相FCC柱状晶,不容易引起电位差效应,因此,有较好的耐蚀性。经过600 ℃退火后,虽然晶体饱和度降低,晶格畸变减轻,缺陷减少,内应力降低,但单相FCC柱状晶转变为了FCC、BCC和σ的混合组织,电位差效应增强,因此耐蚀性反而降低。800 ℃退火热处理后,晶体的饱和度进一步降低,晶格畸变进一步减轻,相界处的应变能得到释放,缺陷进一步减少,组织细小均匀,元素偏析降低,弥补了混合组织带来的电位差效应,耐蚀性比铸态有所提高。1000 ℃退火态由于退火温度过高,室温组织粗大,导致元素偏析再一次加剧,因此合金耐蚀性又重新降低。

图6 铸态和退火态Al0.5CoCrFeNiTi0.5合金在3.5% NaCl溶液中的室温极化曲线

Fig. 6 Room-temperature polarization curves of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy in 3.5% NaCl solution

表4 铸态和退火态Al0.5CoCrFeNiTi0.5合金在3.5% NaCl溶液中的室温腐蚀参数

Table 4 Room-temperature corrosion parameters of as-cast and annealed Al0.5CoCrFeNiTi0.5 alloy in 3.5% NaCl solution

3 结论

1) Al0.5CoCrFeNiTi0.5合金在铸态和退火态下均由富(Cr,Fe)的FCC、富(Al,Ni,Ti)的BCC和σ三相组成,但组织形貌和各相的相对含量发生了改变。随着退火过程的进行,铸态中的粗大白色过饱和FCC柱状晶发生分解,转变为FCC+BCC+σ的混合组织,退火温度越高,析出转变越充分。

2) Al0.5CoCrFeNiTi0.5合金在铸态和600 ℃、800 ℃、1000 ℃退火态下都有较高的硬度,表现出了良好的抗回火软化的能力。600 ℃退火态具有较理想的FCC、BCC和σ相的组成比例,其综合力学性能最好。

3) 800 ℃退火热处理后,晶体的饱和度降低,晶格畸变减轻,缺陷减少,元素分布最均匀,弥补了混合组织带来的电位差效应,因此在3.5 % NaCl溶液中的耐蚀性最好。

REFERENCES

[1] YEH J W, CHEN S K, LIN S J. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303.

[2] TONG C J, CHEN Y L, CHEN S K, YEH J W, LIN S J, SHUN T T, TSAU C H, CHANG S Y. Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements[J]. Metall Mater Trans A, 2005, 36(4): 881-893.

[3] LI C, LI J, ZHAO M, JIANG Q. Effect of alloying elements on microstructure and properties of multiprincipal elements high-entropy alloys[J]. J Alloy Compd, 2009, 475(1/2): 752-757.

[4] ZHANG Y, ZUO T T, TANG Z, GAO M C, DAHMEN K A, LIAW P K, LU Z P. Microstructures and properties of high- entropy alloys[J]. Prog Mater Sci, 2014, 61(4): 1-93.

[5] ZHANG K B, FU Z Y, ZHANG J Y, SHI J, WANG W M, WANG H, WANG Y C, ZHANG Q J. Annealing on the structure and properties evolution of the CoCrFeNiCuAl high-entropy alloy[J]. J Alloy Compd, 2010, 502(2): 295-299.

[6] SENKOV O N, WILKS G B, SCOTT J M, MIRACLE D B, WOODWARD C. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy[J]. J Alloy Compd, 2011, 19(5): 698-703.

[7] GLUDOVATZ B, HOHENWARTER A, CATOOR D, CHANG E H, GEORGE E P, RITCHIE R O. A fracture-resistant high-entropy alloy for cryogenic applications[J]. Science, 2014, 345(6201): 1153-1158.

[8] NG C, GUO S, LUAN J, WANG Q, LU J, SHI S, LIU C T. Phase stability and tensile properties of Co-free Al0.5CrCuFeNi2 high-entropy alloys[J]. J Alloys Compd, 2014, 584(1): 530-537.

[9] OTTO F, DLOUHY A, SOMSEN C, BEI H, EGGELER G, GEORGEEP. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high entropy alloy[J]. Acta Mater, 2013, 61(15): 5743-5755.

[10] WANG W R, WANG W L, YEH J W. Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures[J]. J Alloys Compd, 2014, 589(3): 143-152.

[11] BUTLER T M, WEAVER M L. Oxidation behavior of arc melted AlCoCrFeNi multicomponent high entropy alloys[J]. J Alloys Compd, 2016, 674(7): 229-244.

[12] 谢红波, 刘贵仲, 郭景杰. Mn、V、Mo、Ti、Zr元素对AlFeCrCoCu-X高熵合金组织与高温氧化性能的影响[J]. 中国有色金属学报, 2015, 25(1): 103-110.

XIE Hong-bo, LIU Gui-zhong, GUO Jing-jie. Effects of Mn, Mo, V, Ti, Zr elements on microstructure and high temperature oxidation performance of AlFeCrCoCu-X high entropy alloys[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 103-110.

[13] SENKOV O N, SENKOVA S V, WOODWARD C, MIRACLE D B. Low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system: Microstructure and phase analysis[J]. Acta Mater, 2013, 61(5):1545-1557.

[14] SENKOV O N, SENKOVA S V, MIRACLE D B, WOODWARD C. Mechanical properties of low-density, refractory multi- principal element alloys of the Cr-Nb-Ti-V-Zr system[J]. Mater Sci Eng A, 2013, 565(3): 51-62.

[15] GORR B, AZIM M, CHRIST H J, MUELLER T, SCHLIEPHAKE D. HEILMAIER M, Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high-entropy alloys[J]. J Alloys Compd, 2015, 624(3): 270-278.

[16] LILENSTEN L, COUZINIE J P, PERRIERE L, BOURGON J, EMERY N, GUILLOT I. New structure in refractory high- entropy alloys[J]. Mater Lett, 2014, 132(10): 123-125.

[17] ZOU Y, MAITI S, STEURER W, SPOLENAK R. Size- dependent plasticity in an Nb25Mo25Ta25W25 refractory high- entropy alloy[J]. Acta Mater, 2014, 65(2): 85-97.

[18] YU Y, LIU W M, ZHANG T B, LI J S, WANG J, KOU H C, LI J. Microstructure and tribological properties of AlCoCrFeNiTi0.5 high-entropy alloy in hydrogen peroxide solution[J]. Metallurgical and Materials Transactions A, 2014, 45(1): 201-208.

[19] HUANG P K, YEH J W, SHUN T T, CHEN S K, Multi- principal-element alloys with improved oxidation and wear resistance for thermal spray coating[J]. Adv Eng Mater, 2004, 6(1/2): 74-78.

[20] JI X L, DUAN H, ZHANG H, MA J J. Slurry erosion resistance of laser clad NiCoCrFeAl3 high-entropy alloy coatings[J]. Tribol Trans, 2015, 58(6): 1119-1123.

[21] 李 萍, 庞胜娇, 赵 杰, 李廷举. CoCrFeNiTi0.5高熵合金在熔融Na2SO4-25%NaCl中的腐蚀行为[J]. 中国有色金属学报, 2015, 25(2): 367-374.

LI Ping, PANG Sheng-jiao, ZHAO Jie, LI Ting-ju. Corrosion behavior of CoCrFeNiTi0.5 high entropy alloy in molten Na2SO4-25%NaCl[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 367-374.

[22] CHEN Y Y, HONG U T, SHIH H C, YEH J W, DUVAL T, Electrochemical kinetics of the high entropy alloys in aqueous environments-a comparison with type 304 stainless steel[J]. Corros Sci, 2005, 47(11): 2679-2699.

[23] LIU Y X, CHENG C Q, SHANG J L, WANG R, LI P, ZHAO J. Oxidation behavior of high-entropy alloys AlxCoCrFeNi (x=0.15, 0.4) in supercritical water and comparison with HR3C steel[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1341-1351.

[24] ZHOU Y J, ZHANG Y, WANG Y L, CHEN G L. Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties[J]. Appl Phys Lett, 2007, 90(18): 260-262.

[25] LI Bao-yu, PENG Kun, HU Ai-ping, ZHOU Ling-ping, ZHU Jia-jun, LI De-yi. Structure and properties of FeCoNiCrCu0.5Alx high-entropy alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 735-741.

[26] 于 源, 谢发勤, 张铁邦, 寇宏超, 胡 锐, 李金山. AlCoCrFeNiTi0.5高熵合金的组织控制和腐蚀性能[J]. 稀有金属材料与工程, 2012, 41(5): 862-866.

YU Yuan, XIE Fa-qin, ZHANG Tie-bang, KOU Hong-chao, HU Rui, LI Jin-shan. Microstructure control and corrosion properties of AlCoCrFeNiTi0.5 high-entropy alloy[J]. Rare Metal Materials and Engineering, 2012, 41(5): 862-866.

[27] 王毅飞, 杨海彧. 凝固过程中AlCoCrFeNiTi0.5高熵合金的组织结构演变[J]. 稀有金属材料与工程, 2014, 43(10): 2459-2462.

WANG Yi-fei, YANG Hai-yu. Evolution of microstructure of AlCoCrFeNiTi0.5 high-entropy alloys in the process of solidification[J]. Rare Metal Materials and Engineering, 2014, 43(10): 2459-2462.

[28] BUTLER T M, WEAVER M L. Investigation of the phase stabilities in AlNiCoCrFe high entropy alloys[J]. J Alloys Compd, 2017, 691(1): 119-129.

[29] CANTOR B, CHANG I T H, KNIGHT P, VINCENT A J B. Microstructural development in equiatomic multicomponent alloys[J]. Mater Sci Eng A, 2004, 375/377(7): 213-218.

[30] SINGH S, WANDERKA N, MURTY B S, GLATZEL U, BANHART J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy[J]. Acta Materialia, 2011, 59(1): 182-190.

Microstructure and properties of as-cast and annealed Al0.5CoCrFeNiTi0.5 high-entropy alloys

JIANG Shu-ying, LIN Zhi-feng, XU Hong-ming

(College of Mechanical and Electronic Engineering, China University of Petroleum (Huadong), Qingdao 266580, China)

Abstract: Al0.5CoCrFeNiTi0.5 high entropy alloys were prepared by vacuum arc melting and were treated by vacuum annealing at 600, 800 and 1000 ℃ for 10 h. The microstructure, mechanical properties and corrosion resistance in the 3.5% NaCl solution of the as-cast and annealed alloys were studied by XRD, OM, EPMA, hardness tester, universal testing machine, and electrochemical workstation. The microstructure analysis shows that the as-cast and three kinds of annealed alloys are all composed of FCC rich (Cr, Fe), BCC rich (Al, Ni, Ti) and σ, but their microstructure morphologies and the relative contents of each phase are different. As the annealing process, the thick white FCC columnar crystals in the as-cast alloy shift to the mixed structures of FCC, BCC and σ, and with the increase of annealing temperature, the contents of the BCC and σ phase increase. The 800 ℃-annealed alloy has the best composition uniformity, and the 1000 ℃-annealed alloy has the increasing element segregation and the coarse microstructure due to the high annealing temperature. The hardness and compression tests show that all of the as-cast and three kinds of annealed alloys have high hardness, showing good resistance to tempering softening, the 800 ℃-annealed alloy has the highest hardness and yield strength but its plasticity is the worst due to the increase of the BCC and σ phase content, the yield strength, fracture strength and compressive deformation rate of the 1000 ℃-annealed alloy sharply decrease due to its coarse structure and a large number of σ precipitation, the 600 ℃-annealed alloy has the best comprehensive mechanical properties due to the ideal contents of FCC, BCC and σ. The electrochemical corrosion tests show that the as-cast and three kinds of annealed alloys all have good corrosion resistance in 3.5% NaCl solution and the corrosion resistance of the 800 ℃-annealed alloy is the best because of its best composition uniformity.

Key words: high-entropy alloy; annealing; microstructure; mechanical property; corrosion resistance

Foundation item: Project(ZR2016EMM22) supported by the Natural Science Foundation of Shandong Province, China

Received date: 2018-01-15; Accepted date: 2018-04-20

Corresponding author: JIANG Shu-ying; Tel: +86-13854684419; E-mail: jsyjsy1225@163.com

(编辑 龙怀中)

基金项目:山东省自然科学基金资助项目(ZR2016EMM22)

收稿日期:2018-01-15;修订日期:2018-04-20

通信作者:蒋淑英,副教授,博士;电话:13854684419;E-mail:jsyjsy1225@163.com