DOI: 10.11817/j.issn.1672-7207.2017.02.014

轴向柱塞泵滑靴副功率损失特性

汤何胜1,李晶2,訚耀保2

(1. 温州大学 机电工程学院,浙江 温州, 325035;

2. 同济大学 机械与能源工程学院,上海,201804)

摘要:为降低轴向柱塞泵滑靴副功率损失,考虑油液的压差和剪切流动的影响,建立滑靴副的功率损失模型,讨论泵的柱塞腔压力、主轴转速以及结构参数对滑靴的泄漏流量、摩擦力矩、泄漏功率损失以及黏性摩擦功率损失的影响。研究结果表明:滑靴副的功率损失以黏性摩擦为主,摩擦力矩比较大,而泄漏流量比较小。主轴转速对黏性摩擦功率损失的影响占据主导地位,大于柱塞腔压力的影响;当滑靴的半径比为1.5~2.0时,应尽量取较小值,有利于降低滑靴副的泄漏和黏性摩擦功率损失;当阻尼管的长度直径比为3.50~8.75时,阻尼孔直径不宜设计太小,尽管阻尼管的长度直径比变大对泄漏功率损失产生抑制作用,但是油膜厚度变薄将会增加黏性摩擦功率损失。

关键词:轴向柱塞泵;滑靴;功率损失;油膜;泄漏

中图分类号:TH137.5 文献标志码:A 文章编号:1672-7207(2017)02-0361-09

Power loss characteristics of slipper/swash plate pair in axial piston pump

TANG Hesheng1, LI Jing2, YIN Yaobao2

(1. College of Mechanical Engineering, Wenzhou University, Wenzhou 325025, China;

2. School of Mechanical and Energy Engineering, Tongji University, Shanghai 201804, China)

Abstract: Considering pressure-gradient flow and shear flow, the power loss model of slipper pair in axial piston pump was built to decrease energy dissipation of axial piston pump. The leakage, friction torque, leakage power loss and viscous friction power consumption of slipper under different pressures of piston chamber, shaft speeds and structure parameters were discussed. The results show that the power loss of slipper bearing is mainly due to the viscous friction and the leakage power loss is low, which causes the friction torque to increase. The influence of shaft speed on viscous friction power loss is more significant than pressure of piston chamber. When the radius ratio of slipper is set from 1.5 to 2.0, the lower radius ratio of slipper helps to reduce the leakage and viscous friction power loss. When the length diameter ratio of orifice is set from 3.50 to 8.75, the higher length diameter ratio of orifice due to the thin film thickness is useful to decrease leakage power loss, but the viscous friction power loss increases.

Key words: axial piston pump; slipper; power loss; oil film; leakage

轴向柱塞泵是工程机械液压操纵系统的心脏。在高速重载工况下,滑靴、斜盘、柱塞、缸体以及配流盘所组成的摩擦副是轴向柱塞泵产生泄漏和能量损失的主要来源,直接影响柱塞泵的工作效率和使用寿命。

尤其,滑靴所处的运动状态和受力情况较为复杂,导致滑靴副的泄漏流量和黏性摩擦所产生的能量损失全部转化成热能,增加油液内能,引起油液温度升高,油液黏度降低,泄漏流量增大,导致油膜厚度变薄,这是造成滑靴副润滑失效的主要原因[1]。由于柱塞泵的性能和寿命与摩擦副息息相关,所以国内外学者围绕摩擦副油膜动力学、黏性摩擦力和功率损失等关键性问题开展研究[2-3]。SCHENK等[4]考虑弹性变形对滑靴副能量耗散机理的影响,分析滑靴副的泄漏功率损失和黏性摩擦功率损失。KOC等[5]研究滑靴的阻尼孔尺寸、偏心载荷以及压紧力系数对滑靴的抗倾覆能力的影响。MANRING[6]研究摩擦副的几何结构与油膜特性之间的映射关系,并搭建相应试验台,测试滑靴的球窝结构对油膜承载能力的影响。HARRIS等[7-8]开展摩擦副油膜动态特性研究,研究表明滑靴处于泵的吸排油区过渡时,滑靴的运动稳定性较差,油膜的动态变化比较显著。KAZAMA[9-10]建立滑靴副非等温流体动力润滑模型,分析不同工况下滑靴副热流体动力润滑特性。BERGADA和KUMAR等[11-12]利用CFD技术分析滑靴底面间隙油液的运动特征和涡流效应,讨论环形沟槽对油液流动状态的影响。国内关于轴向柱塞泵摩擦副功率损失特性的研究比较少[13-14]。孙毅等[15]建立剩余压紧力状态下滑靴副油膜润滑模型,分析不同负载和转速工况下滑靴副的功率损失。徐兵等[16]分析倾覆状态下滑靴底面油膜动态特性,解释滑靴倾覆的本质。然而,上述研究大多数围绕摩擦副的油膜动力学特性和润滑机理开展研究,没有进一步分析不同工况下滑靴的结构参数与功率损失之间的映射关系。因此,本文作者建立滑靴副功率损失模型,分析不同柱塞腔压力、主轴转速以及结构参数对滑靴副功率损失特性的影响。

1 滑靴副功率损失分析

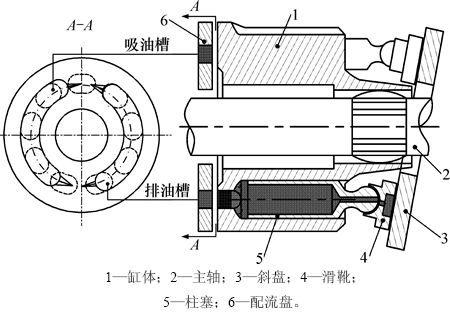

1.1 滑靴的工作原理

图1所示为轴向柱塞泵结构图。轴向柱塞泵主要包括滑靴、配流盘、主轴、斜盘、柱塞以及缸体。当缸体随主轴旋转时,在0°~180°范围内,柱塞沿缸体向左运动时,缸体的工作腔容积减小,促使液压油从配流盘的排油槽流出,为柱塞腔的排油区,如图1中A-A视图所示。同时,在180°~360°范围内,柱塞沿缸体向右运动时,将油液从配流盘的吸油槽引入缸体的柱塞腔,为柱塞腔的吸油区。其中,滑靴底面通入柱塞腔的高压油,产生液压反推力,平衡柱塞对斜盘的压紧力,并在滑靴副间形成边界油膜,从而减轻磨损。

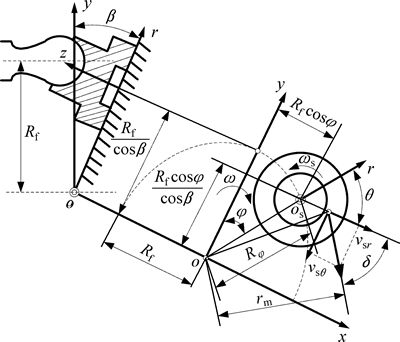

1.2 滑靴的运动轨迹

图2所示为滑靴的运动轨迹。在高速高压工况下,滑靴在斜盘表面相对运动,受到离心力矩和摩擦力矩的影响,促使滑靴与斜盘之间形成楔形油膜。滑靴底面油液受到压力差和黏性剪切的影响,造成间隙油液流动,产生压差功率损失和剪切功率损失,并将该部分的功率损失全部转换成油液内能,表现为油膜温度升高,油液黏度下降,引起油膜厚度变薄,甚至降低油膜的承载能力。当滑靴底面油膜过薄时,滑靴与斜盘配合面间的间隙过小,导致摩擦阻力过大,造成滑靴运动不灵活。

滑靴表面任意一点处(r,θ)的径向和周向速度分别为[17]

(1)

(1)

图1 轴向柱塞泵结构图

Fig. 1 Structure scheme of axial piston pump

图2 滑靴的运动轨迹

Fig. 2 Motion trajectory of slipper

式中:vsr为滑靴的径向速度;vsθ为滑靴的切向速度, ω为滑靴公转角速度, ω=2πnT/60;n为主轴转速;T为主轴旋转周期;ωs为滑靴自转角速度; δ为滑靴径向和切向速度之间的夹角;rm为滑靴底面上的任意一点与缸体中心的距离;r为滑靴半径。

rm可表示为

(2)

(2)

(3)

(3)

式中:φ为缸体转角;θ为滑靴油膜支承面上任意点的角度;β为斜盘倾角;Rφ为任意缸体转角下滑靴中心到缸体中心之间的距离;Rf为柱塞的分布圆半径。

1.3 滑靴的功率损失特性

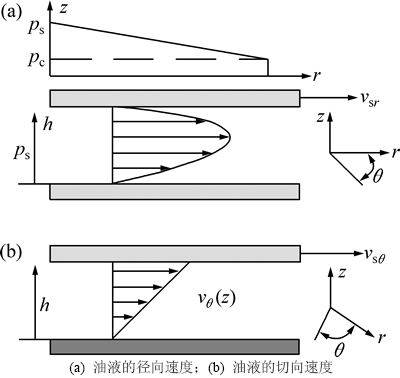

图3所示为油液的径向和切向速度。滑靴在斜盘表面相对滑动摩擦过程中,间隙油液从滑靴的油室向边缘流动,产生径向和切向的流动速度。因此,采用圆柱坐标系N-S方程对油液的径向和切向流速进行求解,其简化形式为

(4)

(4)

其边界条件为: vr(0)=0, vr(h)=vsr, vθ(0)=0, vθ(h)=vsθ。

对式(4)进行积分,可求得油液的径向和切向流速为

(5)

(5)

式中:vr为径向流速;vθ为切向流速;μ为油液黏度;h为油膜厚度。

为了计算滑靴副黏性摩擦功率损失,对间隙油液的径向和切向应力进行求解,即为

(6)

(6)

式中:τr为油膜的径向应力;τθ为油膜的切向应力。

滑靴的摩擦力矩为

(7)

(7)

式中:Ms为摩擦力矩;r0为滑靴内径;R为滑靴外径。

黏性摩擦功率损失为

(8)

(8)

式中:Ws1为黏性摩擦功率损失。

滑靴与斜盘之间的泄漏流量为

(9)

(9)

式中:Qs为泄漏流量。

泄漏流量功率损失为

(10)

(10)

式中:Ws2为泄漏流量功率损失;ps为滑靴的油室压力;pc为壳体油腔压力。

图3 油液的径向和切向速度

Fig. 3 Tangential and radial velocities of oil

轴向柱塞泵在工作过程中,柱塞腔的高压油经过滑靴的阻尼管进入滑靴油室,从而形成滑靴副的支承反力。因此,考虑油液在阻尼管中的压力损失,滑靴油室压力的计算公式[4]为

(11)

(11)

式中:pp为柱塞腔压力;l为阻尼管长度;d为阻尼管直径;λ为沿程阻力系数;ρ为油液密度。

滑靴油室压力决定滑靴密封带的油膜压力边界条件。根据雷诺方程,推导出滑靴底面的油膜压力控制方程为

(12)

(12)

式(12)中,油膜压力的边界条件为:

由式(12)可知:油膜压力梯度与油膜厚度的映射关系,将结果代入式(5),求解油液的径向和切向流速。

2 计算结果与分析

本文选择单个柱塞组件作为研究对象,分析不同柱塞腔压力、转速以及结构参数对单个滑靴副功率损失的影响。计算所选用工况条件和滑靴的结构参数如下:柱塞腔压力为21 MPa,主轴转速为1 500 r/min,壳体内腔油液压力为1.5 MPa,斜盘倾角为16°,沿程阻力系数为0.018;柱塞的分布圆半径为46.8 mm,滑靴内径为6.4 mm,滑靴外径为12 mm,阻尼管直径为1 mm,阻尼管长度为3.5 mm;油液密度为860 kg/m3,油液黏度为0.038 Pa·s。

2.1 柱塞腔压力的影响

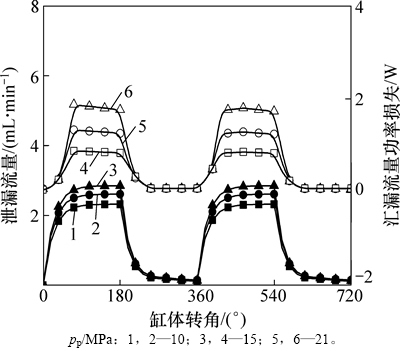

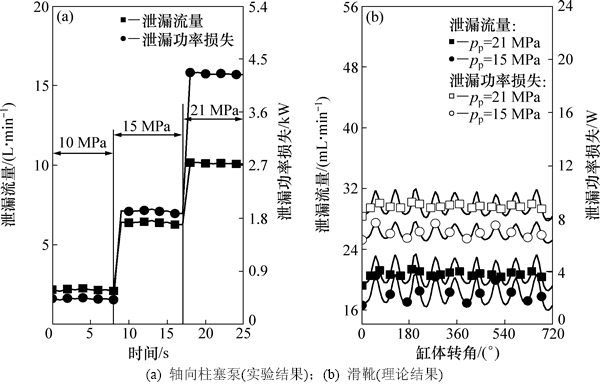

图4所示为不同柱塞腔压力对滑靴副泄漏流量和泄漏功率损失的影响。泄漏流量随缸体转角呈周期性变化,随柱塞腔压力增大而增大,最大泄漏流量为0.002~0.003 L/min,主要集中在泵的排油区,这是因为泄漏流量与油液的径向流速有关。油液的径向流速为压力流和剪切流的合成流速,与油膜压力梯度呈正相关,与油膜厚度呈负相关。其中,滑靴的油室压力决定油膜压力梯度,随柱塞腔压力增大而增大,促使式(5)中的油膜厚度项减小,引起油液的径向流速增大,增加泄漏流量。其次,由于泄漏功率损失与油室压力呈正相关,所以,泄漏功率损失随油室压力和径向流速增大而增大,泄漏功率损失为0.9~1.7 W,引起油液内能增加,表现为油液温度升高。

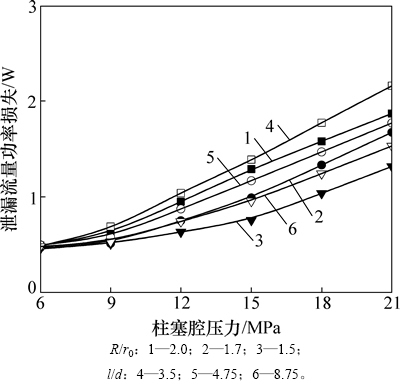

滑靴的半径比和阻尼管的长度直径比是影响滑靴副泄漏功率损失的主要参数。图5所示为不同结构参数下柱塞腔压力与泄漏功率损失的关系。当压力为15 MPa,滑靴的半径比从1.5增大到2.0时,泄漏功率损失增加幅度为0.6 W,且随着柱塞腔压力增加而显著增大,这说明泄漏流量因半径比所引起的过流面积增大而明显增加,但对不同压力条件下所增加的幅度不尽相同。再者,泄漏功率损失与阻尼管的长度直径比成反比,随阻尼管的长度直径比增大而减小,其原因是泄漏流量来自于柱塞腔内高压油,所以,阻尼管对泄漏油液起到节流作用。当阻尼管的长度恒定时,泄漏流量随阻尼管直径减小而减小。因此,阻尼管的长度直径比变大有利于降低滑靴副的泄漏功率损失。

图4 不同柱塞腔压力对泄漏流量和泄漏功率损失的影响

Fig. 4 Effects of different pressure of piston chamber on leakage and power consumption of slipper

图5 不同滑靴结构参数下柱塞腔压力与泄漏功率损失的关系

Fig. 5 Relationships between pressure of piston chamber and leakage power loss under different structure parameters of slipper

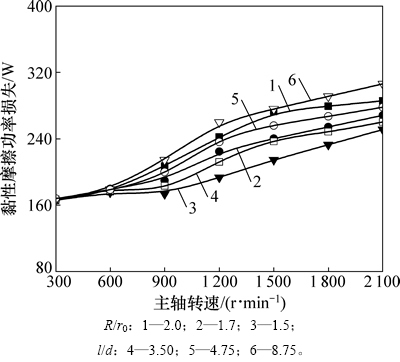

图6所示为不同柱塞腔压力对滑靴副摩擦力矩和黏性摩擦功率损失的影响。摩擦力矩主要是克服滑靴和斜盘之间的黏性摩擦力,而黏性摩擦力与柱塞腔压力和油膜厚度有关。由图6可知:当滑靴处于泵的排油区时,摩擦力矩损失为0.8~1.5 N·m,并随柱塞腔压力增大而增大,这是因为滑靴所受的压紧力较大,降低油膜厚度,油膜剪切应力增大,导致黏性摩擦功率损失随之增大。与图5相比,当柱塞腔压力为21 MPa时,黏性摩擦功率损失为245 W,滑靴因油膜剪切造成的功率损失要远大于滑靴因压差泄漏造成的功率损失,这说明滑靴的功率损失以黏性摩擦为主,泄漏流量损失比较小。

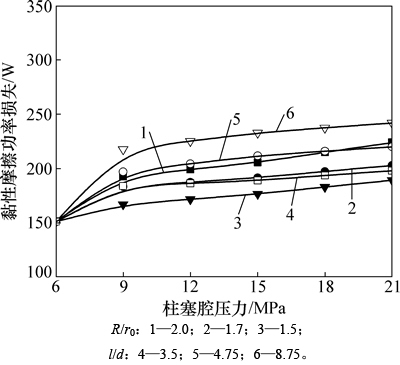

图7所示为不同结构参数下柱塞腔压力与黏性摩擦功率损失的关系。当柱塞腔压力恒定时,黏性摩擦功率损失与滑靴的半径比成正比,且柱塞腔压力越大所对应的黏性摩擦功率损失也越大。由式(8)可知:黏性摩擦功率损失与滑靴的过流面积以及油液流速成正比,滑靴的半径比增大,引起滑靴的密封带面积增大,不仅增加泄漏流量,同时还增加黏性摩擦功率损失;其次,当柱塞腔压力为15 MPa时,阻尼管的长度直径比从3.50增加到8.75,黏性摩擦功率损失从175 W增加到235 W,增加幅度为25.5%,这是因为滑靴的剪切应力与滑靴油室压力有关,决定油膜压力梯度,而油室压力与阻尼管长度直径比成反比,在某种程度上抑制泄漏功率损失,但是增大黏性摩擦功率损失。

图6 柱塞腔压力对摩擦力矩和黏性摩擦功率损失的影响

Fig. 6 Effects of input pressure on friction torque and viscous friction power consumption of slipper

图7 不同滑靴结构参数下柱塞腔压力与黏性摩擦功率损失的关系

Fig. 7 Relationships between pressure of piston chamber and viscous friction power loss under different structure parameters of slipper

2.2 主轴转速的影响

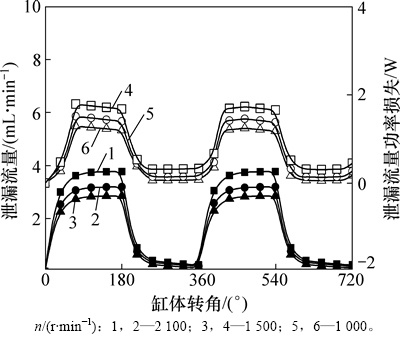

图8所示为不同主轴转速对泄漏流量和泄漏功率损失的影响。由图8可见:同一柱塞腔压力下,主轴转速从1 000 r/min升高到2 100 r/min,泄漏流量从2.5 mL/min增加到4.0 mL/min,增加幅度为37.5%,其原因是主轴转速升高会造成滑靴的径向和周向运动速度升高,油液的径向流速增加,使得泄漏流量增大。泄漏功率损失与泄漏流量呈正相关,且泄漏流量与油液的径向流速和油膜厚度有关,导致泄漏功率损失随因主轴转速所引起的油液流速增大而增大。

图8 不同主轴转速对泄漏流量和泄漏功率损失的影响

Fig. 8 Effects of different shaft speeds on leakage and power consumption of slipper

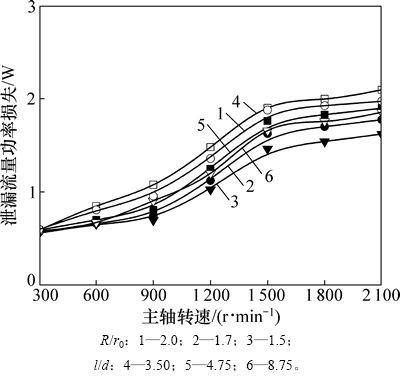

图9所示为不同滑靴结构参数下主轴转速与泄漏功率损失的关系。由图9可见:主轴转速与泄漏功率损失并非单调递增关系,这说明泄漏功率损失受到油液流动的影响比较大。当主轴转速为1 200 r/min,滑靴的半径比为2.0时,泄漏功率损失为1.3 W,与半径比为1.5时的泄漏功率损失相比,增加0.4 W,这是因为滑靴的过流面积随半径比增大而增大,且油液流速随转速升高而增加,增加泄漏功率损失。当阻尼管的长度直径比为3.5,主轴转速为1 200 r/min和2 100 r/min时,对应的泄漏功率损失为1.5 W和2.0 W,与阻尼管的长度直径比为8.75时的泄漏功率损失相比,增加幅度分别为0.3 W和0.4 W,这说明阻尼管的长度直径比对泄漏功率损失的影响比较小。

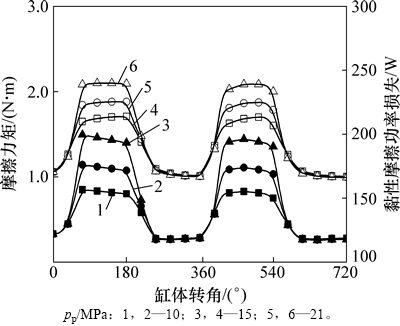

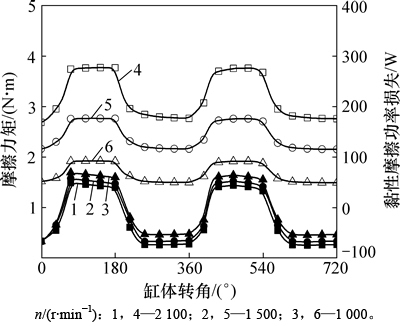

图10所示为不同主轴转速对摩擦力矩和黏性摩擦功率损失的影响。摩擦力矩随主轴转速升高而减小,其原因是主轴转速增大造成油膜厚度因动压效应增强而变厚,减小油液剪切应力,降低摩擦力矩。与图6相比,柱塞腔压力对黏性功率损失的影响远小于转速对黏性功率损失的影响,这是因为黏性摩擦功率损失与油膜厚度成反比,与滑靴的运动速度成正比,且滑靴的运动速度与角速度呈正相关,导致主轴转速升高对黏性摩擦的影响要大于油膜厚度的影响。因此,当柱塞腔压力不变而主轴转速提高时,转速增大不仅造成泄漏流量功率损失增大,同时也增加黏性摩擦功率损失。尤其当主轴转速为2 100 r/min时,黏性摩擦功率损失为285 W,与转速为1 500 r/min时的黏性摩擦功率损失相比,其增加幅度为38.6%,这说明转速对黏性摩擦功率损失的影响占据主导地位。

图9 主轴转速对泄漏流量和泄漏功率损失的影响

Fig. 9 Effects of shaft speeds on leakage and power consumption of slipper

图10 不同主轴转速对摩擦力矩和黏性摩擦功率损失的影响

Fig. 10 Effects of shaft speeds on friction torque and viscous friction power consumption of slipper

图11所示为不同滑靴结构参数下主轴转速与黏性摩擦功率损失的关系。在相同转速工况下,随着半径比增大,黏性摩擦功率损失也增大,并随着转速升高而增加。当滑靴的半径比为1.5~2.0时,应尽量取较小值,降低黏性摩擦功率损失。当阻尼管的长度与直径比为8.75,主轴转速为1 200 r/min和2 100 r/min时,对应的黏性摩擦功率损失分别为275 W和305 W,与阻尼管的长度直径比为3.50时的黏性摩擦功率损失相比,增加幅度分别为14.2%和15.1%,这些特征说明因转速升高引起的油膜厚度变大带来的黏性摩擦功率损失的减小远小于油液流速提高带来的黏性剪切功率损失的增加,且阻尼管的长度直径比与滑靴的剪切应力呈正相关,造成黏性摩擦功率损失显著增加。

图11 不同滑靴结构参数下主轴转速与黏性摩擦功率损失的关系

Fig. 11 Relationships between shaft speed and leakage power loss under different structure parameters of slipper

3 理论与实验结果对比分析

3.1 滑靴副的泄漏功率损失对比

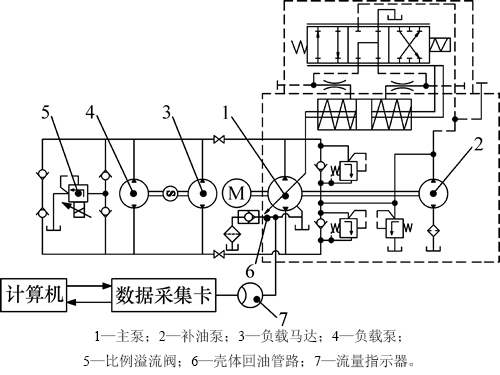

由于柱塞泵内部空间紧凑,且滑靴底面的油液流动状态比较复杂,试验测试比较困难,所以本文采用某型轴向柱塞泵作为研究对象,通过综合液压试验台测试液压泵的泄漏流量,对比研究滑靴副泄漏流量在泵的泄漏流量中所占的比例。设定轴向柱塞泵的转速为1 500 r/min,出口压力为10,15和21 MPa,油液温度控制在40~50 ℃,分别测量泵的泄漏流量。

图12所示为液压泵的闭式回路测试系统。负载泵和负载溢流阀组成溢流加载闭式回路。负载泵及其负载回路模拟负载马达的双向负载,通过调节比例溢流阀实现负载压力变化。主泵和负载马达组成的闭式系统,补油泵为闭式系统提供补油和换油冷却,保证液压泵的正常工作。在泵的壳体回油管路上,安装流量指示器,采用有线数据传输的方式,记录柱塞泵泄漏流量的实验数据。

图12 A4VTG90泵闭式回路测试系统

Fig. 12 Closed loop testing system of A4VTG90 bump

图13所示为滑靴与液压泵的泄漏流量和泄漏功率损失比较。从图13可见:当泵的转速为1 500 r/min,压力为15 MPa和21 MPa时,泵的实际泄漏流量分别为6.39 L/min和10.12 L/min,而9个滑靴的平均理论泄漏流量分别为0.02 L/min和0.018 L/min,所占泵的泄漏流量损失率分别为0.031%和0.178%,这说明同等工况下滑靴副产生的泄漏流量在液压泵的泄漏流量所占比例较小;当压力从15 MPa上升到21 MPa时,滑靴的平均理论泄漏功率损失从7.6 W增加到9.8 W,所占泵的泄漏功率损失率从0.039%下降到0.023%,这表明随着压力增大,滑靴副对轴向柱塞泵泄漏功率损失的影响较小。

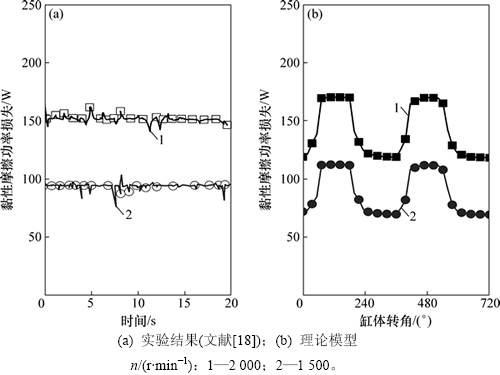

3.2 滑靴副的黏性摩擦功率损失对比

图14所示为不同主轴转速条件下滑靴的黏性摩擦功率损失与文献[18]中实验结果比较,计算中采用文献[18]中给出的实验工况和滑靴的初始参数。结果表明当泵的转速为2 000 r/min时,滑靴的黏性摩擦功率损失从100 W增加到150 W,增加幅度为33%,与文献[18]变化趋势较为一致,但平均值相差5.8~9.7 W,其原因是文献[18]采用剩余压紧力法设计了一个轴向柱塞泵滑靴副的功率损失装置,但没有考虑油膜动压效应的影响,而本文则修正了油膜控制方程,有利于滑靴结构参数的优化设计。这些特征说明转速的变化对滑靴副的黏性摩擦功率损失的影响显著。

图13 滑靴和轴向柱塞泵的泄漏流量和泄漏功率损失比较

Fig. 13 Comparison of leakage and leakage power loss of slipper and axial piston pump

图14 滑靴副的实际黏性摩擦功率损失

Fig. 14 Practice viscous friction power consumption of slipper pair

4 结论

1) 在相同工况条件下,滑靴因油膜剪切造成的黏性功率损失要远大于滑靴因压差泄漏造成的泄漏功率损失,这说明滑靴的功率损失以摩擦为主,导致滑靴的摩擦力矩较大,而泄漏流量比较小。主轴转速对黏性摩擦功率损失的影响占据主导地位,大于柱塞腔压力的影响,应该予以重视。

2) 滑靴的半径比与滑靴的过流面积有关。滑靴的半径比变大会造成滑靴密封带的面积增大,增加泄漏流量,导致滑靴的黏性摩擦功率损失增加。因此,当滑靴的半径比为1.5~2.0时,应尽量取较小值,有利于降低滑靴的泄漏和黏性摩擦功率损失。

3) 阻尼管的长度直径比与滑靴的泄漏流量呈负相关。当阻尼管的长度恒定时,泄漏流量随阻尼管直径减小而减小,这些特征说明阻尼管的长度直径比变大对压差流的泄漏功率损失有一定的抑制作用,但是油膜厚度变薄将会增大黏性摩擦功率损失。因此,当阻尼管的长度直径比为3.50~8.75时,阻尼孔直径不宜设计太小,否则不利于降低滑靴的功率损失,增加油液内能,表现为油液温度升高。

参考文献:

[1] WIECZOREK U, IVANTYSYNOVA M. Computer aided optimization of bearing and sealing gaps in hydrostatic machines: the simulation tool CASPAR[J]. International Journal of Fluid Power, 2002, 3(1): 7-20.

[2] 刘桓龙, 柯坚, 王国志, 等. 水压滑靴副的润滑特性[J]. 机械工程学报, 2006, 42(3): 35-39.

LU Huanlong, KE Jian, WANG Zhiguo, et al. Lubrication characteristics of the water hydraulic sliding shoe pairs[J]. Journal of Mechanical Engineering, 2006, 42(3): 35-39.

[3] WANG X, YAMAGUCHI A. Characteristics of hydrostatic bearing/seal parts for water hydraulic pumps and motors (part 2): on eccentric loading and power loses[J]. Tribology International, 2002, 35(7): 435-442.

[4] SCHENK A, IVANTYSYNOVA M. An investigation of the impact of elastohydrodynamic deformation on power loss in the slipper swash plate interface[C]//Proceedings of 8th JFPS International Symposium on Fluid Power. Okinawa, Japan, 2011: 228-234.

[5] KOC E, HOOKE C J. Investigation into the effects of orifice size, offset and overclamp ratio on the lubrication of slipper bearings[J]. Tribology International, 1996, 29(4): 299-305.

[6] MANRING N D. The relative motion between the ball guide and slipper retainer within an axial-piston swashplate type hydrostatic pump[J]. Journal of Dynamic System Measurement and Control, 1999, 121(3): 518-523.

[7] HARRIS R M, EDGE K A, TILLEY D G. Predicting the behavior of slipper pads in swashplate-type axial piston pumps[J]. Journal of Dynamic System Measurement and Control, 1993, 118(1): 21-25.

[8] HARRIS R M, EDGE K A, TILLEY D G. The suction dynamics of positive displacement axial piston pumps[J]. Journal of Dynamic System Measurement and Control, 1994, 116(2): 1-7.

[9] KAZAMA T. Thermohydrodynamic lubrication analysis of hybrid thrust bearings (modeling of a slipper used in swash plate type axial piston pumps/motors)[J]. Transactions of Japan Fluid Power System Society, 2009, 40(2): 30-35.

[10] KAZAMA T. Thermohydrodynamic lubrication model applicable to a slipper of swashplate type axial piston pumps and motors (effects of operating conditions)[J]. Tribology Online, 2010, 5(5): 250-254.

[11] BERGADA J M. Leakage and groove pressure of an axial piston pump slipper with multiple lands[J]. Tribology Transactions, 2008, 51(4): 469-481.

[12] KUMAR S, BERGADA J M, WATTON J. Axial piston pump grooved slipper analysis by CFD simulation of three-dimensional NVS equation in cylindrical coordinates[J]. Computers & Fluids, 2009, 38(6): 648-663.

[13] 汤何胜, 訚耀保, 李晶. 弹性变形对轴向柱塞泵滑靴副功率损失的影响[J]. 煤炭学报, 2016, 41(4): 1038-1044.

TANG Hesheng, YIN Yaobao, LI Jing. Influence of elastic deformation on power loss of axial piston pump slipper/swash plate pair[J]. Journal of China Coal Society, 2016, 41(4): 1038-1044.

[14] 刘洪, 苑士华, 荆崇波, 等.磨损轮廓与弹性变形对滑靴动态特性的影响[J]. 机械工程学报, 2013, 49(5): 75-82.

LIU Hong, YUAN Shihua, JING Chongbo, et al. Effects of wear profile and elastic deformation on the slipper’s dynamic characteristics[J]. Journal of Mechanical Engineering, 2013, 49(5): 75-82.

[15] 孙毅, 姜继海, 刘成强. 剩余压紧力条件下滑靴副的油膜特性及功率损失[J]. 华南理工大学学报(自然科学版), 2011, 39(1): 111-117.

SUN Yi, JIANG Jihai, LIU Chengqiang. Oil film characteristics and power consumption of slipper pair under redundant pressing Force[J]. Journal of South China University of Technology (Natural Science Edition), 2011, 39(1): 111-117.

[16] 徐兵, 李迎兵, 张斌, 等. 轴向柱塞泵滑靴副倾覆现象数值分析[J]. 机械工程学报, 2010, 46(20): 161-168.

XU Bin, LI Yingbin, ZHANG Bin, et al. Numerical simulation of overturning phenomenon of axial piston pump slipper pair[J]. Journal of Mechanical Engineering, 2010, 46(20): 161-168.

[17] HUANG Changchun. CASPAR based slipper performance prediction in axial piston pumps[C]//Proceedings of 3rd FPIN-PHD Symposium on Fluid Power. Terassa, Spain, 2004: 229-238.

[18] 孙毅. 轴向柱塞泵滑靴及其偶件的润滑与功率损失的研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院, 2013: 139-141.

SUN Yi. Research on lubrication and power loss of slipper and its matching parts within axial piston pump[D]. Harbin: Harbin Institute of Technology. School of Mechatronics Engineering, 2013: 139-141.

(编辑 陈爱华)

收稿日期:2016-04-11;修回日期:2016-06-28

基金项目(Foundation item):国家自然科学基金资助项目(51475332,51275356);浙江省自然科学青年基金资助项目(LQ17E050003)(Projects (51475332, 51275356) supported by the National Natural Science Foundation of China; Projects(LQ17E050003) supported by the Youth Natural Science Foundation of Zhejiang Province)

通信作者:李晶,博士,副教授,从事流体传动及控制基础理论研究;E-mail:Cynthia_li@tongji.edu.cn