复杂空区群露天开采境界三维可视化及其应用

刘科伟,李夕兵,刘希灵,宫凤强,杜坤

(中南大学 资源与安全工程学院,深部金属矿产开发与灾害控制湖南省重点实验室,

湖南 长沙,410083)

摘要:为了预防露天开采境界下复杂空区群对矿山生产造成重大安全事故,研究以不规则三角网(TIN)为基础的复杂地质体三维可视化建模技术,并以Surpac软件为平台制定出相应的复杂空区群露天开采境界三维可视化实施方案。将该方案应用于某矿区,建立该矿区内露天开采境界地表、地下矿体以及复杂空区群的三维可视化模型,重点对空区群内部错综复杂的通透关系进行三维描述。研究结果表明:复合模型的建立明确了地表、地下矿体及各水平采空区之间的空间位置关系,可利用其分析空区群的安全隐患及空区间的连带破坏作用,为露天境界内复杂空区群的灾害控制、安全性评判及矿区地表开采的施工设计提供了参考依据,从而解决了多空区矿山的盲目开采问题,有效预防了重大安全事故的发生。

关键词:复杂空区群;三维可视化;不规则三角网(TIN);Surpac软件;通透关系

中图分类号:TD325 文献标志码:A 文章编号:1672-7207(2011)10-3118-07

3D visualization of complicated cavity group under open-pit limit and its application

LIU Ke-wei, LI Xi-bing, LIU Xi-ling, GONG Feng-qiang, DU Kun

(Hunan Key Laboratory of Resources Exploitation and Hazard Control for Deep Metal Mines,

School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: Because of the existence of complicated cavity group with open-pit limit constitutes a potential hazard for mine safety production, and of the necessity to accurately analyze cavity group and then create conditions for choosing proper prevention and treatment countermeasures so as to plan exploitation of mineral resources reasonably, 3D visualization modeling technology of complicated geological bodies based on triangular irregular network (TIN) was studied, and corresponding implementing scheme of 3D visualization of complicated cavity group with open-pit limit on platform of Surpac software was made, then, a case study was discussed. On the foundation of massive field survey, collecting and sorting data, the 3D visualization models of digital terrain models (DTM) of open-pit surface, occurrence state of ore body and complicated gravity group of the mine were built, especially. The results show that transfixion relationship in cavity group is emphatically described in 3D which can be used to logically analyze jointly destructive effect. The spatial relationships among the DTM, ore body and gravity group are made explicit which can be used to analyze the potential hazards of complicated cavity group with open-pit limit and associated destructive effect of cavities, besides, the references for hazard control, safety judgment and designing for open-pit mining can also be obtained by using the model built, the problem of blind mining can be solved and the major safety accidents can be prevented successfully.

Key words: complicated cavity group; 3D visualization; triangulated irregular network (TIN); Surpac software; transfixion relationship

20世纪70年代至90年代初矿山普遍采用留矿采矿法、空场采矿法对地下资源进行开采,遗留下大量的地下采空区,特别是在20世纪80年代,我国矿业开采秩序较为混乱,在此期间民采情况极其严重,导致在很多矿区形成了错综复杂的地下空区群。其后,随着对矿产资源开发中混乱局面的整顿和资源的逐渐枯竭,多数矿山由原来的地采转为露天开采。随着时间的推移,由于受到地压、风化和爆破震动的影响,矿岩发生了变形、破坏,其位置、大小、形状均发生了改变,因而,这些存在于露天开采境界下的复杂空区群便形成了目前矿山生产的重大安全隐患[1]。空区群的破坏有着明显不同于单个空区破坏的特点,在破坏过程中多伴随着连带破坏效应,破坏范围大,频度高,严重威胁着矿山的人员和设备安全并阻滞了生产进度[2]。因此,如何正确规划存在下覆复杂空区群的露天开采已经成为矿产资源开采过程中亟待解决的问题[3]。对此,国内外许多学者对空区灾害的预防和治理从理论分析、数值模拟、实地勘测以及相似材料实验等方面开展了大量的研究[4~9]。但大多局限于单个空区,对于多空区系统尤其是处于露天开采境界下的复杂空区群,由于问题难度极大提高,相应的研究很少。对于空区群灾害的预防和治理,首先应详细调查统计空区空间分布情况,为制定出空区的合理处理方案提供数据基础;其次,岩体的构造特征是决定岩土工程稳定性的重要因素,随着现代计算机技术的发展,计算机构模技术能够综合复杂地质体的海量信息,实现工程岩体三维可视化,为复杂地质体的稳定性分析与防治对策的选择提供帮助[10]。为此,本文作者针对地下空区群的形成和分布特点,介绍基于剖面轮廓线法以及Delaunay三角化的不规则三角网((Triangulated irregular network,简称TIN)复杂地质体空间描述方法,以实地勘测、AutoCAD数据、地质钻探数据等为基础,以Surpac软件为平台的矿山三维建模技术,并结合工程实例具体说明三维可视化技术在露天开采境界复杂空区群分析中的实际应用。

1 矿山地质体的三维可视化

三维地质模型的数据模型是研究三维地质模型可视化的基础和核心。目前所使用的三维数据模型若不区分准3D和真3D,那么,可主要分为面元数据模型、体元模型和混合元数据三大类[11],而在与之相对应的三维可视化建模方法方面,同样存在着块段(block)构模法、实体(solid)构模法、线框(wire frame)构模法、断面(section)构模法及表面(surface)构模法等一系列方法。这些构模方法在矿山地质体的三维可视化中应用广泛,每种方法各有利弊,如:块段构模技术的优点是可以采用隐含定位技术来节省存储空间和运算时间,但在精确模拟矿体边界与分割粒度(存储量)上存在着尖锐的矛盾等[12-13]。因此,应结合所提供的数据特点、分析目的[14]及工程需求选择合适的可视化构模方法。

在通常情况下,矿山三维地质体建模所提供的地质资料主要有:钻孔数据,表面离散点数据和剖面图数据。一般钻孔数据和表面离散点数据是以表格形式给出,而剖面图是以AutoCAD的格式给出,这就要求在建模过程中合理地运用这些资料并对这些数据进行预先处理。同时,为了能够获得高真实度的可视化模型,必须对地质体模型绘制的基本技术方法进行研究。根据已处理的数据及研究决定的三维模型绘制方法对地质体绘制三维模型,从而最终得出地质体的高真实度三维实体模型。本文根据空区群露天开采境界三维可视化建模中所涉及的地表模型、矿体模型以及空区群模型的原始数据特点,决定采用表面模型中不规则三角网(Triangulated irregular network,简称TIN)绘制的线框数据模型来建立地质体三维可视化模型。

表面模型有时也称为数字地面模型(Digital terrain models,简称DTM),多用于层状矿体构模。一般先生成各岩层的接触界面或厚度在模型域上的表面模型,然后,根据岩层间的截割和切错关系通过“修剪”、“优先级次序覆盖”等逻辑运算来对各模拟面进行精确修饰。有很多方法可以用来表达表面,如等高线模型、网格模型等,而最常用的模型是不规则三角网(TIN)[15]。

1.1 不规则三角网(TIN)介绍

不规则三角网(TIN)是按地质特征采集的点根据一定规则连接成覆盖整个区域且互不重叠的许多三角形构成的1个不规则三角网。目前,TIN模型应用十分广泛,如空间对象的三维可视化、任意剖面的切割、坡度和坡向的计算等。与正方形网格结构(Grid)相比,TIN能较好地顾及地貌特征点和线,逼真地表示复杂地形起伏特征,克服地形起伏变化不大的地区产生冗余数据问题,并且具有可变的分辨率,即当表面粗糙或急剧变化时,TIN能包括大量的数据点;而当表面单一时,在同样的区域,TIN只需要最少的数据点。

1.2 基于不规则三角网的三维可视化构模技术

三维可视化要研究的主要问题之一是如何在计算机中数字化地重塑实体边界,运用三角网近似表示实体边界是一种通过轮廓线尺寸建立数字化模型的较好方案。这种方法主要是把相临轮廓线上的点连接成三角形,通过这种方式得到的三角形平面单元界定1个多面体,该多面体的表面便可近似为要模拟的实体 表面。

对于这种构模技术,其难点在于如何解决在确定数目的轮廓点间三角形的结合问题。例如,在2条分别由m和n个点组成的轮廓线间可以形成的不同三角形排列方式可用下式表示:

(1)

(1)

式(1)表明:即使是对于比较少的轮廓点,可能的三角形排列方式的数目也是相当大的。为了找出最佳的三角形排列方式,长期以来,许多学者[16-17]提出了各自的解决方案和相应的运算法则。其思路主要有2种:一是从宏观入手,通过假设一种比较简单的目标方程并结合图解推理技术(即图论)等来解决该问题中的最佳化问题;二是将需要建模的数据点利用Delaunay三角化的方法来生成模拟物体表面的TIN。

前一种方法的主要解决过程如下:

(1) 首先通过反复交替的方式把轮廓线上的点分解成若干个独立的凹或凸状点子集,并在点子集之间给出一个试用的三角网;

(2) 制定最佳化目标函数并求出目标函数表达式及相应准则;

(3) 结合图论方法找出最佳三角网;

(4) 以上述过程为依据求出通用的三角网运算 法则。

该种方法的关键在于如何处理轮廓线任意弯曲而导致的曲率符号交替变换问题。

第2种方法也是目前比较流行的方法,是对离散分布的数据点进行Delaunay三角化,进而形成目标TIN。所谓Delaunay三角化是指由3点形成1个三角形,且在这3个点的外接圆内不包含其他数据点,这样的三角形称为Delaunay三角形。

利用Delaunay三角化生成TIN的方法很多,常用的一种生成方式如下:

(1) 通过创建Thiessen多边形来划分图形表面;

(2) 对具有公共边的Thiessen多边形内部控制点连接,进而形成TIN;

利用Delaunay三角化生成TIN的方法被广泛地应用于地理信息系统,并处于不断改进和完善之中[18]。

1.3 可视化实施流程

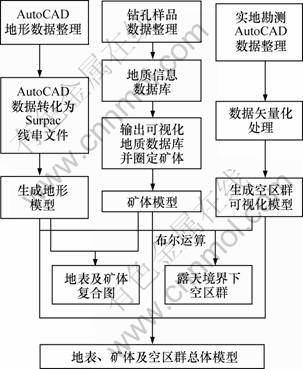

根据本次建模的数据特点,决定以Surpac软件为平台,综合运用剖面轮廓线法和Delaunay三角化,建立了某矿区的地表、矿体和空区群的可视化三维模型,主要技术流程如图1所示。

图1 可视化实施流程图

Fig.1 Flow chart of visualization of actualization

对于地表模型,采用剖面轮廓线法和Delaunay三角化结合的方式进行。而矿体表面及空区群表面在模拟过程中主要采用优化的交互式剖面轮廓线法,即利用一系列相邻地质勘探剖面或地质中段平面上交互式矢量化地质体的表面轮廓线(或包络线),两两间完成三角联网,最终实现矿体及空区群表面的模拟 绘制。

2 复杂空区群露天开采境界三维可视化应用实例

2.1 多空区矿区概况

某露天矿为一钼、钨、铼多金属共生矿床。自20世纪80年代后,矿区出现了集体、个人进入矿区大肆掠夺矿产资源的现象。矿区内采矿单位达到96个,开拓的坑口达200多个。乱采乱挖形成大量形态千奇百怪、上下重叠且空间位置不详的空区。其后,各级政府对钼矿资源开发中发现的混乱局面进行了整治,民采现象得到遏制。2002年调查空区总容积达 1 017.2×104 m3,矿区范围内年新增矿区量为77.8×104 m3,空区主要分布在高程为1 293~1 469 m的范围内。1991年该矿区开始建设5 000 t/d露天矿,2003年根据市场需要,决定停止矿区的地下开采。随着露天坑底临近采空区,其露天坑底与空区的隔离层厚度越来越薄,露天矿作业人员与大型设备受到空区的直接威胁,随时有可能因地表塌陷而引发重大安全事故。

2.2 矿山三维模型的建立

2.2.1 地表模型

针对矿区的实际情况,其地表台阶复杂,地下空区分布不规则,因而在三维建模时必须考虑地表模型的存在。只有考虑地表模型的界面,才能清楚地反映出采空区所在空间位置并预测其可能的灾变情况与范围。

根据矿区内保留的MapGIS原始地形图及实时的AutoCAD露天采场现状图,提取出地形等高线和台阶、道路、边坡等特征边界点线。对台阶开挖部分、道路变更部分等进行GPS更新测量,以批处理文件的方式进行导入,以提高数据的生成和更新速度(见 图2)。

结合地貌实际情况,通过人机交互的方式快速对点、线进行核实,得到用于建立数字地形模型的理想Surpac线串文件(见图3)。在台阶线间采用通用的剖面轮廓线法,将台阶线上的节点分解成若干凹凸点子集,制定目标函数并在相应准则约束下进行三角联网;同时,在GPS测点与台阶线上节点相邻的区域以及在离散分布的测点区域划分Thiessen多边形,对具有公共边的Thiessen多边形进行控制点连接,将不同的特征点连成三角面片,即Delaunay三角化,进而生成三角网(TIN)。对该三角网按用户要求进行着色,并调整光照条件,便可得到数字地形模型。本文对地表模型按高程进行着色,结果如图4和图5所示。

图2 AutoCAD中地形等高线及GPS测点数据

Fig.2 Topographic contours and GPS measuring points data in AutoCAD

图3 核实后的Surpac线串文件

Fig.3 Verified String data in Surpac

2.2.2 矿体模型

矿体三维可视化模型的建立依赖于矿区大量细致的基础地质工作,其大量基础地质工作所得到的数据有效地控制着矿体的空间赋存规律。以矿区的地质勘探剖面图和105个地质钻孔数据为基础,通过建立可视化地质数据库可对钻孔数据进行三维显示(见图6),结合地质推断,在一系列矿体包络线进行三角联网,生成矿区钼矿体的三维实体模型。同时,对地表模型与矿体模型进行布尔运算,保留地表以下矿体,显示出地表以下未开采矿体的空间赋存状态,如图7所示。其中,Paradox地质数据库是实现矿体三维可视化的基础,对文本格式地质信息子目录的充分统计与整理,是决定矿体模型高效生成的关键。

图4 DTM俯视图

Fig.4 Plan view of DTM

图5 DTM三维显示

Fig.5 3D display of DTM

在下覆复杂空区群的条件下,对露采地表以下矿体进行合理的开采设计与施工是矿区安全生产的重中之重。在对矿体进行开采的过程中,随着露天坑底临近采空区群,露天坑底与采空区的隔离层厚度越来越小,矿区作业人员与大型设备受到采空区的直接威胁。通过对建立的地表模型、地表以下未开采矿体模型以及其后生成的复杂空区群进行复合,在对隔离层进行进一步采掘时,可以利用模型复合体在空间上准确地定位与分析空区对矿体开采区域存在的影响。

图6 地质数据库三维显示

Fig.6 3D display of geological database

图7 未开采矿体空间赋存状态

Fig.7 Spatial distribution of unmined orebody

2.2.3 空区群模型

矿区因历史原因,经历了20余年不合理的地下开采,受地压、风化和爆破震动的影响,矿岩发生了变形、破坏,其大小和形状均发生了改变。为详细了解采空区在各水平的分布情况及各水平采空区之间的通透关系,单位科研人员进行了大量的实地勘测和详尽的数据整理,在空区群实体建模过程中,对原始AutoCAD资料中的空区、巷道、空区群内部塌陷及贯通情况进行了修正和补全(见图8),并采用提取边界线并对其进行矢量化处理的方式,快速建立起各水平采空区的准确三维实体模型(见图9)。经统计,露天矿坑以下有形态各异、大小不等的采空区100多个,总容积达1×107 m3。

图8 修正后的单一水平采空区AutoCAD资料图

Fig.8 Modified data of single level cavities in AutoCAD

图9 矢量化处理后的单一水平采空区实体模型

Fig.9 Solid model of single level vectorized cavities

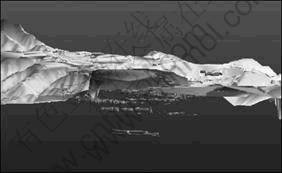

各个水平采空区经同等处理,得到矿区内空区群三维可视化总体模型,如图10所示。

结合先前建立的地表模型,空区群与露天开采境界地表的位置关系便能够在三维空间详细展现(见 图11)。

2.2.4 空区群内部通透关系

本次研究依据实地勘测,重点对空区群内部采空区之间错综复杂的通透关系进行了详尽的三维描述。本文仅以1350水平采空区为例进行说明,如图12所示。图中灰色实体区域为该水平采空区与其他水平间的通透部分。

图10 空区群三维实体模型水平投影

Fig.10 Plan view of 3D solid model of cavity group

图11 露天开采境界下空区群三维显示

Fig.11 3D display of cavity group under open-pit limit

图12 1350水平采空区与其他水平采空区间的通透关系

Fig.12 Transfixion relationship between cavities of 1350 level and others levels

为了便于对模型内部进行查看和分析,可对模型沿任意方向设计所需剖切面,利用面与实体之间的相交线切割由地表模型、矿体模型以及空区群模型构成的复合实体,在分割后的断面上运用缩放功能可详细观察复合实体内部地表、矿体和空区群之间复杂的构造关系。

在以上建立的地表模型、矿体模型以及空区群模型的辅助下,矿区工作人员能够在进行施工规划、矿体开采以及空区处理等决策时,不再局限于单个空区甚至是单一水平空区,而是可以从全局出发,充分、全面地考虑矿体赋存状况、空区间的相互连带关系及可能产生的效应破坏作用,从而解决了多空区矿山的盲目开采问题,有效地预防了重大安全事故的发生。

3 结论

(1) 三维地形模型的建立为空区群的模拟与分析提供了科学基础,以其为参照清晰地反映了采空区和矿体所在的空间位置及发生灾变时可能的地表波及 范围。

(2) 矿体三维模型的建立是以大量细致的基础地质工作为基础的,其大量基础地质工作所得到的数据有效地控制着矿体的空间赋存规律 (包括矿体的品味、岩性、具体方位、边界及空间形态等)。

(3) 通过多次实地勘测和详尽的数据整理,对矿区原始资料中的空区、巷道、空区群内部的塌陷及贯通情况进行了修正、补全及矢量化处理,在此基础上建立的露天开采境界下空区群三维实体模型真实再现了采空区的实际存在形态。

(4) 以上模型的建立明确了地表、地下矿体及各水平采空区的空间位置关系,矿体的准确定位及其与空区群之间复杂空间关系的精确反映为制定合理的开采设计、施工规划等提供了依据;同时,重点对采空区相互之间极其复杂的通透关系进行了三维描述,从而为分析露天境界内下覆采空区的危害现状、灾害治理范围圈定、安全性评判等提供了可视化数据资料。

(5) 针对部分盲孔区的存在,建议在台阶爆破前,采用加大台阶爆破装药孔深度的方式来探明空区是否存在。若存在,则应及时结合空区自动激光扫描系统(CALS),对不明采空区进行探测、数据处理并嵌入到空区群三维可视化模型之中,这样,一方面,有利于加强对空区群的全面综合分析,制定出合理的空区处理及露天开采计划;另一方面,能够避免在台阶爆破过程中或在台阶爆破后的生产中可能引发的重大安全事故。

参考文献:

[1] 国家安全生产监督管理总局, 国家煤矿安全监察局. 国家安全生产科技发展规划非煤矿山领域研究报告(2004—2010)[R]. 北京: 国家安全生产监督管理总局, 国家煤矿安全监察局, 2003: 1-10.

State Administration of Work Safety, State Administration of Coal Mine Safety. State technological development programming of work safety: Non-coal mine domain research bulletin(2004—2010)[R]. Beijing: State Administration of Work Safety, State Administration of Coal Mine Safety, 2003: 1-10.

[2] 周子龙, 李夕兵, 赵国彦. 民窿空区群级联失稳评价[J]. 自然灾害学报, 2007, 16(5): 91-95.

ZHOU Zi-long, LI Xi-bing, ZHAO Guo-yan. Evaluation of cascading collapse for private mined zone groups[J]. Journal of Natural Disasters, 2007, 16(5): 91-95.

[3] 李夕兵, 李地元, 赵国彦, 等. 金属矿地下采空区探测、处理与安全评判[J]. 采矿与安全工程学报, 2006, 23(1): 24-29.

LI Xi-bing, LI Di-yuan, ZHAO Guo-yan, et al. Detecting, disposal and safety evaluation of the underground goaf in metal mines[J]. Journal of Mining and Safety Engineering, 2006, 23(1): 24-29.

[4] 吴兆营, 薄景山, 杜国林, 等. 采空区对地表稳定性的影响[J]. 自然灾害学报, 2004, 13(2): 140-144.

WU Zhao-ying, BO Jing-shan, DU Guo-lin, et al. Effects of mining excavation on ground stability[J]. Journal of Natural Disasters, 2004, 13(2): 140-144.

[5] 宫凤强, 李夕兵, 董陇军, 等. 基于未确知测度理论的采空区危险性评价研究[J]. 岩石力学与工程学报, 2008, 27(2): 323-330.

GONG Feng-qiang, LI Xi-bing, DONG Long-jun, et al. Underground goaf risk evaluation based on uncertainty measurement theory[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(2): 323-330.

[6] 李向阳, 李俊平, 周创兵, 等. 采空场覆岩变形数值模拟与相似模拟比较研究[J]. 岩土力学, 2005, 26(12): 1907-1912.

LI Xiang-yang, LI Jun-ping, ZHOU Chuang-bing, et al. Comparative study on numerical simulation and similarity simulation of overburden deformation in abandoned stope[J]. Rock and Soil Mechanics, 2005, 26(12): 1907-1912.

[7] 童立元, 刘松玉, 邱钰, 等. 高速公路下伏采空区问题国内外研究现状及进展[J]. 岩石力学与工程学报, 2004, 23(7): 1198-1202.

TONG Li-yuan, LIU Song-yu, QIU Yu, et al. Current research state of problems associated with mined-out regions under expressway and future development[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(7): 1198-1202.

[8] 余卫平, 汪小刚, 杨健, 等. 地下洞室群围岩稳定性分析及其结果的可视化[J]. 岩石力学与工程学报, 2005, 24(20): 3730-3736.

YU Wei-ping, WANG Xiao-gang, YANG Jian, et al. Stability analysis of surrounding rock of underground excavations and visualization of its results[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(20): 3730-3736.

[9] 朱翔鹏, 张学强, 严哲. 瑞雷波在探测地下防空洞的应用研究[J]. 工程地球物理学报, 2007, 4(1): 58-61.

ZHU Xiang-peng, ZHANG Xue-qiang, YAN Zhe. Application of rayleigh wave in inspecting underground air-raid shelter[J]. Chinese Journal of Engineering Geophysics, 2007, 4(1): 58-61.

[10] 徐能雄, 何满潮, 景海河. 非连续型非褶皱岩体三维可视化构模技术及应用[J]. 岩石力学与工程学报, 2004, 23(15): 2534-2538.

XU Neng-xiong, HE Man-chao, JING Hai-he. 3D visual modeling technique of non-continuous non-folded rock-mass and its application[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(15): 2534-2538.

[11] 洪雄. 基于似三棱柱的三维地学空间构模技术研究[D]. 武汉: 中国地质大学计算机学院, 2005: 10-30.

HONG Xiong. Research on 3D geologic modeling based on STP[D]. Wuhan: China University of Geosciences. College of Computer Science, 2005: 10-30.

[12] 吴立新, 史文中. 论三维地学空间构模[J]. 地理与地理信息科学, 2005, 21(1): 1-4.

WU Li-xin, SHI Wen-zhong. On three dimensional geosciences spatial modeling[J]. Geography and Geo-Information Science, 2005, 21(1): 1-4.

[13] 徐云和, 赵吉先, 程朋根, 等. 地矿3维GIS模型的构建及可视化[J]. 中国矿业, 2003, 12(4): 60-62.

XU Yun-he, ZHAO Ji-xian, CHENG Peng-gen, et al. Construction and visualization of 3D GIS mine model[J]. China Mining Magazine, 2003, 12(4): 60-62.

[14] ZHU Hong-lei, Eastman J R, Toledano J. Triangulated irregular network optimization form contour data using bridge and tunnel edge removal[J]. International Journal of Geographical Information Science, 2001, 15(3): 271-286.

[15] 王瑞芳. 基于空间信息的三维地学模拟理论及研究[J]. 山西建筑, 2007, 33(22): 354-355.

WANG Rui-fang. Study on three-dimension geosciences modeling theory based on spatial information[J]. Shanxi Architecture, 2007, 33(22): 354-355.

[16] Keppel E. Approximating complex surfaces by triangulation of contour lines [J]. Ibm J Res Develop, 1975, 1: 1-11.

[17] Fuchs H, Kedem Z M, Uselton S P. Reconstruction from planar contours[J]. Communications of the ACM, 1977, 20(10): 693-702.

(编辑 陈灿华)

收稿日期:2010-10-05;修回日期:2010-12-28

基金项目:“十一五”国家科技支撑计划重点项目(2007BAK24B01-4);国家重点基础研究发展计划“973”计划项目(2010CB732004);国家自然科学基金重点项目(50934006);中南大学青年教师助推计划项目(201012200232)

通信作者:刘科伟(1982-),男,河北承德人,博士研究生,从事矿山、岩土工程灾害预测、稳定性及可靠性分析的研究工作;电话:13237424600;E-mail:kewei_liu@126.com