文章编号:1004-0609(2007)04-0518-07

稀土Er对Sn-3.0Ag-0.5Cu无铅焊料合金组织与性能的影响

卢 斌,栗 慧,王娟辉,朱华伟,焦羡贺

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:研究稀土Er含量对Sn-3.0Ag-0.5Cu无铅焊料合金显微组织以及性能的影响。结果表明:当Er含量为0.05%~0.50%(质量分数)时,对该无铅焊料合金的导电性和腐蚀性影响不大,但使熔化区间温度降低;当Er含量为0.05%时,焊点剪切强度最高;当Er含量为0.10%时,焊料铺展面积最大,焊料润湿性有所改善,同时焊料的拉伸强度达到最高;当Er含量为0.25%时,伸长率最大。随着Er含量的增加,该焊料合金的组织由树枝晶向等轴晶转变,且组织逐渐细化。Er的较佳添加量为0.05%~0.25%。

关键词:无铅焊料;Sn-3.0Ag-0.5Cu;Er;组织;性能

中图分类号:TG 42 文献标识码:A

Effect of Er on microstructure and properties of Sn-3.0Ag-0.5Cu lead-free solder alloy

LU Bin, LI Hui, WANG Juan-hui, ZHU Hua-wei, JIAO Xian-he

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Trace rare earth element Er was added into Sn-3.0Ag-0.5Cu solder to investigate the effect of rare earth on the microstructure and mechanical properties of SnAgCu solder. The results show that, when Er content(mass fraction) is within 0.05%-0.50%, the Er has a slight effect on the resistivity and corrosion, and lowers the melting range. When Er content is 0.05%, the shear strength is the highest. When Er content is 0.10%, the spreading area is the biggest and the tensile strength is the highest. When Er content is 0.25%, the elongation is the highest. With the increase of Er content, the microstructure of the solder changes from fir-tree crystal to equiaxed crystal and is refined. And the suitable content of Er is within 0.05%-0.25%.

Key words: lead-free solder; Sn-3.0Ag-0.5Cu; Er; microstructure; property

锡铅焊料因其具有良好的焊接性能和使用性能而具有悠久的历史,但随着对铅毒性的认知和电子工业发展对焊点的更高要求,新型无铅焊料的开发和应用已迫在眉睫。

目前,SnAgCu系焊料因具有良好的强度、抗疲劳性能和塑性等特点而成为最重要的、最接近实用化的无铅焊料体系之一[1]。但是,与SnPb共晶焊料相比,SnAgCu系焊料熔点偏高(通常要高30~40 ℃),润湿性较差。目前,改善该系焊料合金的主要技术手段是利用多元微合金化效应[2]。Ti、Mn、Fe、Ni、Co等元素有利于细化SnAgCu系焊料微观组织以及提高力学性能,但Co易导致焊料合金的塑性明显降低[3];Bi和In元素复合添加有利于降低SnAgCu系焊料合金的熔点和熔程,改善焊料综合性能,但单独添加Bi会导致焊料熔程增大、润湿性和抗剪切性能下降[4];共同添加少量Cr、Al元素可以明显提高SnAgCu系焊料合金的高温抗氧化和润湿性[5];添加少量Sb可以细化该系焊料合金晶粒、降低熔点、提高润湿性[6]。近年来,国内外开始重视稀土元素在无铅焊料中的研究。与国外相比,国内对于轻稀土或混合稀土在SnAgCu系焊料合金中研究较多,发现微量稀土Ce在该系焊料中具有较好的效果[7-11],但鲜见有关重稀土元素Er在SnAgCu系焊料合金中的研究报道。本文作者以Sn-3.0Ag-0.5Cu系合金为研究对象,探讨了微量稀土Er对该系合金显微组织和性能的影响。

1 实验

实验选用原材料为纯度大于99.9%的单质金属Sn以及Sn-10%Cu、Sn-17.9%Ag和Sn-3.25%Er等中间合金,按Sn-3.0Ag-0.5Cu-xEr(x=0,0.05,0.10,0.25,0.50)名义成分(质量比)配料,在真空感应熔炼炉中熔炼,熔炼温度为600~650 ℃。如此反复熔炼3次,得到铸态合金试样。

采用差分扫描热量计(DSC)测定焊料合金的液、固相线温度,氩气保护,升温速率为2 ℃/min。采用开尔文直流双臂电桥法测试并计算样品的电阻率,样品尺寸为200 mm×10 mm×0.8 mm,测试温度为25 ℃。采用铺展法来评价焊料的润湿性,利用照相面积法测出试样铺展面积,并通过专门图像处理软件计算铺展面积,实验结果均为3次实验的平均值。通过在SI1287电化学综合测试仪测量焊料合金的极化曲线来计算腐蚀电位和腐蚀速率,并采用塔费尔直线外推法,以此评估其抗腐蚀性能的好坏,电解液为3.5%NaCl水溶液。在CSS4100型电子万能拉伸机进行拉伸以及钎焊接头剪切实验,实验温度为室温,拉伸速率为1mm/min。拉伸样品尺寸为d10 mm×50 mm,焊点剪切试样制备按GB11363—89进行,在270 ℃下恒温60 s,实现无铅焊料对铜件的钎焊。在Olympus光学显微镜(OM)和KYKY-2800型扫描电子显微镜(SEM)及能谱仪(EDS)上进行焊料样品的微观组织观察及成分分析,腐蚀液为20 mL HCl+10 g FeCl3+100 mL H2O。在日本Rigaka D/Max 2500型X射线衍射仪上进行焊料样品的物相分析。

2 结果与讨论

2.1 显微组织

图1所示为Sn-3.0Ag-0.5Cu-xEr(x=0~0.50)焊料合金的显微组织。从图中可以看出,Sn-3.0Ag-0.5Cu焊料合金典型的组织特征为树枝状初晶和分布其间的共晶组织,如图1(a)和(b)所示,初晶为β-Sn相,共晶组织包含Cu6Sn5+β-Sn和Ag3Sn+β-Sn 2种二元共晶组织以及β-Sn+Ag3Sn+Cu6Sn5三元共晶组织[12]。其中,二元共晶组织中的Ag3Sn具有相当长的纤维组织特征,二元共晶组织中的Cu6Sn5具有片状组织特征,三元共晶组织中的Cu6Sn5和Ag3Sn相混在一起,很难区分,但可以通过EDS分析予以区别。当添加稀土Er后,随着Er含量的增加,β-Sn初晶由树枝状晶逐渐向等轴状晶转变,且焊料的组织逐渐细化,如图1(a)和(c)~(f)所示。初晶形态对合金流动性有很大影响,添加稀土Er可明显细化β-Sn初晶,晶粒越细,凝固界面越光滑,合金流动阻力越小,流动性越好[13]。由于晶粒越细越难形成裂纹形核所需的应力集中,同时裂纹在不同位向上的各个晶粒内传播也更加困难,因此,稀土Er细化焊料组织可提高合金力学性能。

图1 Sn-3.0Ag-0.5Cu-xEr焊料合金的显微组织

Fig.1 Microstructures of Sn-3.0Ag-0.5Cu-xEr solders: (a) x=0(OM); (b) x=0(SEM); (c) x=0.05(OM); (d) x=0.1(OM); (e) x=0.25(OM); (f) x=0.50(OM)

图2所示为Sn-3.0Ag-0.5Cu-xEr(x=0, 0.25, 0.50)焊料合金典型的XRD谱。由图2可见,当稀土Er含量为0~0.50%时,焊料合金主要由β-Sn相、Ag3Sn和Cu6Sn5相组成;未发现富稀土Er中间化合物的存在,这很可能与其含量极少导致XRD未分辨出有关。当Er含量少时,在β-Sn初晶生长过程中,由于Sn与Er相互吸引倾向大,导致Er主要富集于相界面或晶界处,从而影响着初晶或共晶组织的生长形态。金相观察显示,随着Er含量从0增加至0.5%时,初晶形态由树枝晶向等轴晶演变,这一现象与Er富集于β-Sn相界面或晶界处有关。

图2 Sn-3.0Ag-0.5Cu-xEr焊料合金典型的X射线衍射谱

Fig.2 XRD patterns of Sn-3.0Ag-0.5Cu-xEr solders: (a) x=0; (b) x=0.25; (c) x= 0.50

2.2 物理性能

2.2.1 熔化特性

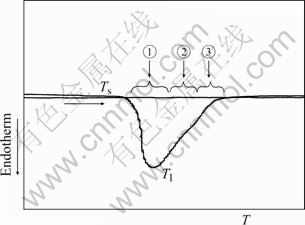

作为无铅焊料,熔点是非常重要的一个特性,SnAgCu焊料的熔化特征最好与Sn37Pb焊料相似,以免使基体母材晶粒长大、过烧或局部熔化,这样就可以沿袭现有的焊接工艺和焊接设备。焊料作为合金,它通常从固态熔化转变为液态经过一个温度区间。在此温度区间,固液相并存,焊料的粘度增大,流动性减小,因而在钎焊过程中,当焊料熔化时可造成基体母材溶蚀现象,使焊料的润湿性降低或者造成反润湿[2]。该温度区间越大,凝固过程中越容易在晶内和晶间产生偏析,同时形成热裂缝的可能性越大[14]。采用热分析法分析了稀土Er对Sn-3.0Ag-0.5Cu焊料合金的液固相线温度的影响,图3所示为典型的Sn-3.0Ag-0.5Cu-0.25Er焊料合金的DSC曲线。从图3中可以看出,焊料在熔点附近发生吸热反应,Sn-3.0Ag-0.5Cu-0.25Er合金的吸热峰不是由单一吸热反应引起的,其中可能包含着3个吸热反应。这意味着升温过程中在熔点附近存在3个吸热熔化反应:①Sn+Ag3Sn+Cu6Sn5→液体;②Sn+Ag3Sn共晶→液体;③Sn→液体。需指出②和③吸热熔化反应有重合的趋势,这与文献[15] (Sn-3.0Ag-0.5Cu合金的DSC曲线上存在明显的三个阶段)有所差别。

图3 Sn-3.0Ag-0.5Cu-0.25Er焊料合金典型的升温DSC曲线

Fig.3 DSC curve of Sn-3.0Ag-0.5Cu-0.25Er solder

图4所示为Sn-3.0Ag-0.5Cu-xEr(x=0~0.50)焊料合金的熔化特征。与Sn-3.0Ag-0.5Cu合金相比,随着稀土Er含量的增加,固相线温度Ts和液相线温度Tl均略微上升,固相线温度增加幅度要略大于液相线温度,而熔化区间ΔT(即Tl-Ts)均呈现先降低然后回升的趋势,当Er含量在0.05%,熔化区间ΔT最小。从目前对熔点的研究情况来看,SnAgCu焊料的熔点(液相线和固相线)偏高,固液相温差较大。研究表明,稀土Er略微提高焊料的熔点,但可缩小熔化温度范围,提高焊料的流动性,减小形成焊接裂缝的可能性,改善钎焊工艺性。

图4 Sn-3.0Ag-0.5Cu-xEr焊料合金的熔化特征

Fig.4 Melting properties of Sn-3.0Ag-0.5Cu-xEr solders

2.2.2 电阻率

现代微电子产业正向高性能和微型化方向发展,电子器件所承受的体积和焊点可靠性尺寸越来越小,要求焊料具有低的电阻率[16-17]。焊料电阻率过高会导致这些微小钎焊接头局部电阻过大,造成电路局部高温,甚至可能导致钎焊接头重熔失效,引起电路短路。由于以上原因,电阻率成为了一项受人们密切关心的焊料物理性能。图5中曲线1所示为稀土Er对Sn-3.0Ag-0.5Cu焊料合金电阻率的影响。从图中可知,随着Er含量增加,除Er为0.05%时焊料的电阻率略微上升外,其余焊料的电阻率均低于未添加Er的焊料,并且以Er含量为0.25%时焊料的电阻率最小。由此可见,稀土Er的添加(w(Er)≥0.10%)可略微降低焊料的电阻率,表现出良好的导电性,在同等功率载荷下,焊料发热减少,局部温度降低,同时,产生的热量可及时传导出去,使温度更趋于均匀化,从而减少钎焊结构的热应力。

图5 Er对Sn-3.0Ag-0.5Cu焊料合金电阻率和铺展面积的影响

Fig.5 Influence of Er on resistivity and spread area of Sn-3.0Ag-0.5Cu solder

2.3 铺展性能

润湿性是指一种液态金属在一个固体表面铺展的能力。对于焊料来说,能否与基板形成良好的浸润是完成钎焊的关键。为了保证钎焊牢固,焊料必须很好地润湿基板材料。影响焊料润湿性的主要因素[18]有:焊料和母材的成分、温度、金属表面氧化物、助焊剂、母材表面的状态、表面活性物质等。焊料的可焊性检验主要包括铺展面积、铺展率、浸润角、浸润时间和附着力等指标。本实验通过测试焊料与Cu基板的铺展面积来评价Sn-3.0Ag-0.5Cu-xEr(x=0~0.50)焊料合金的可焊性。

图5中曲线2所示为稀土Er含量对Sn-3.0Ag-0.5Cu-xEr焊料合金钎焊铺展面积的影响。从图中可以看出,随着Er含量增加,焊料铺展面积增加,但是当Er含量超过0.10%后,焊料的铺展面积又呈现逐渐下降趋势。实验表明,当稀土Er的添加量为0.10%时可更好的改善Sn-3.0Ag-0.5Cu焊料的润 湿性。

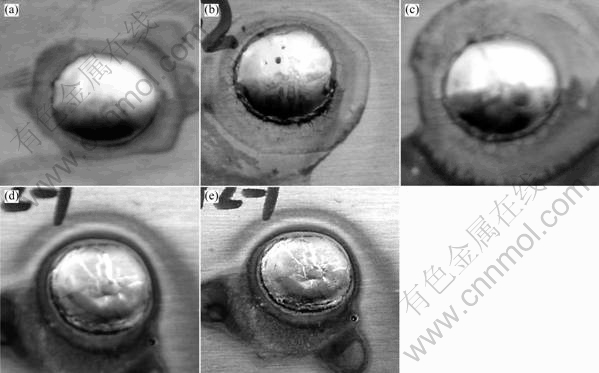

图6所示为稀土Er含量对Sn-3.0Ag-0.5Cu焊料合金在Cu基板上铺展后表面状态的影响。从图中可以看出,随着Er含量增加,焊料表面光亮度增加,但是当Er含量超过0.10%后,焊料表面开始呈现暗灰色,表面光亮程度呈现逐渐下降趋势。结果表明,在Sn-3.0Ag-0.5Cu焊料合金中添加微量的稀土Er可以改善钎焊焊点表面质量,获得光亮的焊点;但当稀土Er含量超过0.10%后,反而由于稀土Er氧化加剧导致焊点表面残留氧化物量增加而降低了焊点表面质量。

图6 Sn-3.0Ag-0.5Cu-xEr焊料合金在铜基板上铺展后表面状态的实物照片

Fig.6 Surface morphologies of Sn-3.0Ag-0.5Cu-xEr solders after spreading on copper substrate: x=0; (b) x=0.05; (c) x=0.10; (d) x=0.25; (e) x=0.50

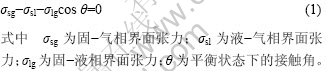

对于体系铺展后的最终形状可由杨氏(Young)方程[19]来描述:

由式(1)可以推导出接触角与各界面张力的关系:

cos θ=(σsg-σsl)/ σlg (2)

接触角的大小表征了体系润湿与铺展能力的强弱。钎焊时,一般希望液态焊料在母材上的接触角要小于20?。根据式(2)可知,为改善液态焊料对母材的润湿性,要使θ角减小,cos θ增大,即增大σsg,减小σsl或σlg。从物理概念上说,σlg减小意味着液体内部原子对表面原子的吸引力减弱,液体原子容易克服本身的引力趋向液体表面,使表面积扩大,焊料容易铺展。σsl减小,表示固体对液体原子的吸引力增大,使液体内层的原子容易被拉向固-液界面,也容易使焊料铺展。由此可知,凡是能使σsl和σlg减小的因素都可提高其润湿性能。稀土元素Er可以改善钎料合金润湿性,主要是基于以下两个方面的原因:一是稀土Er的表面张力小[20-21],可以降低液态焊料的表面张力σlg,使得焊料流动性提高;另一方面就是稀土元素本身为表面活性物质,浸润性好,有利于焊料合金流动,充型能力好,从而使焊料的润湿性得到明显改善。但同时由于稀土元素化学性质活泼,在钎焊过程中,易于生成稀土化合物,将妨碍液态焊料在母材表面上的铺展,降低焊料合金的润湿性。正是由于稀土元素Er对于液态焊料在基板母材的润湿铺展过程中存在上述两个相反作用,导致稀土Er添加量存在一个临界值,小于此临界值时,有利于改善焊料的润湿性能和表面光亮程度。

2.4 抗腐蚀性能

现代电子产品正向高性能、高可靠性的方向发展,由于新型无铅焊料的组成元素的过电位较低,因而采用无铅焊料的焊接接头在潮湿的环境中,容易发生电极极化反应,降低电路的可靠性,这对无铅焊料的研究和使用是至关重要的。在室温3%NaCl水溶液环境下,采用动电位测定焊料合金的阳极极化曲线,考察Sn-3.0Ag-0.5Cu-xEr焊料合金的抗腐蚀性能。

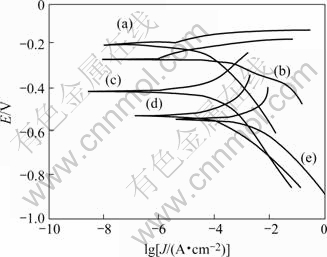

图7所示为Sn-3.0Ag-0.5Cu-xEr(x=0~0.50)焊料合金的极化曲线。从图中可以看出,随着稀土Er含量的增加,Sn-3.0Ag-0.5Cu-xEr(x=0~0.50)焊料合金的腐蚀电位降低,腐蚀电流密度(J)增大,电极反应容易发生,使得合金的耐蚀性能降低。利用塔菲尔直线外推法,计算出各焊料合金的腐蚀电位和腐蚀速率,图8所示为稀土Er含量对Sn-3.0Ag-0.5Cu焊料合金腐蚀电位和腐蚀速率的影响。从图中可以看出,随着稀土Er含量的添加,腐蚀速率呈现出增大的趋势。这说明该系焊料合金中加入稀土元素Er会略微降低焊料合金的抗腐蚀性能。

图7 Sn-3.0Ag-0.5Cu-xEr焊料合金的极化曲线

Fig.7 Polarization curves of Sn-3.0Ag-0.5Cu-xEr solders: (a) x=0; (b) x=0.05; (c) x=0.10; (d) x=0.25; (e) x=0.50

图8 Sn-3.0Ag-0.5Cu-xEr焊料合金的腐蚀电位和腐蚀速率

Fig.8 Corrosion potential and corrosion rate of Sn-3.0Ag-0.5Cu-xEr solders

2.5 力学性能

焊点的剪切强度和抗拉强度是焊料最为重要的2个力学性能指标。图9所示为稀土Er含量对Sn-3.0Ag-0.5Cu焊料合金力学性能的影响。从图中可知,随着稀土Er含量的增加,焊料合金的抗拉强度和伸长率均随之增加。当Er含量为0.10%时,抗拉强度达到最大值;当Er含量为0.25%时,抗拉强度降到未添加稀土Er焊料的水平,但焊料伸长率却达到最大值,随后又逐渐降低。剪切强度在稀土Er含量为0.05%达到最大值,随着含量增加,也明显地呈现下降趋势。由前面的分析可知,一方面在SnAgCu焊料合金中加入稀土Er后,可以细化β-Sn初晶,缩小共晶区域和富Sn相区域的间距,使组织分布均匀;另一方面从生成金属间化合物角度来考虑,由于稀土Er几乎不固溶于Sn基体中,而是富集于相界面或晶界处,因此在凝固过程中,适量的稀土Er有利于阻碍焊料中Ag3Sn和Cu6Sn5脆性IMC(金属间化合物)的生成,并细化这些IMC粒子,从而提高焊料合金的抗拉强度和剪切强度。但稀土Er含量超过某一临界值后,会导致焊料合金的晶界变宽、晶内富稀土Er析出相质点分布不均匀以及富稀土Er的IMC量增多,结果使焊料合金的强度和塑性呈现下降趋势。另外,从钎焊接头样品的断面来看,随着稀土Er含量的增加,在钎焊界面附近出现的气孔数量增多,这与文献报道的现象相一致[8],说明加入Er元素会使焊料的填缝能力显著下降,明显降低焊料的剪切强度。

图9 Er 含量对Sn-3.0Ag-0.5Cu-xEr焊料合金力学性能的影响

Fig.9 Effect of Er content on mechanical properties of Sn-3.0Ag-0.5Cu-xEr solders

3 结论

1) Sn-3.0Ag-0.5Cu-xEr(x=0~0.50)焊料合金中,微量稀土Er可以减小焊料的熔化区间,改善焊接工艺性。Er含量为0.05%时,熔化区间最小。随着Er含量增加,焊料熔化温度有所上升,但变化不大。Er的添加对焊料的电阻率影响比较小,表现出良好的导电性,略微降低焊料的抗腐蚀性能。

2) 随着稀土Er含量的增加,焊料铺展面积增加。当Er含量为0.10%时,钎料铺展面积最大;当Er含量超过0.10%时,焊料铺展面积则逐渐下降。

3) 微量稀土Er可以显著地改善SnAgCu焊料的力学性能。当Er含量为0.05%时,剪切强度为最大值,当Er含量超过0.05%后,剪切强度呈下降趋势。当Er含量增加到0.10%时,抗拉强度最大。当Er含量达到0.25%时,伸长率最大。

4) 随着Er含量的增加,焊料组织由树枝晶向等轴晶转变,且组织逐渐细化。稀土Er在SnAgCu焊料合金中的最佳添加量为0.05%~0.25%。

REFERENCES

[1] 娄浩涣. 无铅BGA封装可靠性的力学试验与分析[J]. 半导体技术, 2005, 30(3): 36-40.

LOU Hao-huan. Mechanical test and analysis on the reliability of lead-free BGA packaging[J]. Semiconductor Technology, 2005, 30(3): 36-40.

[2] 张富文,刘 静,杨福宝,胡 强,贺会军,徐 骏. Sn-Ag-Cu无铅焊料的发展现状与展望[J]. 稀有金属, 2005, 29(5): 619-624.

ZHANG Fu-wen, LIU Jing, YANG Fu-bao, HU Qiang, HE Hui-jun, XU Jun. Developing tendency and current situation of Sn-Ag-Cu lead-free solder[J]. Chinese Journal of Rare Metals, 2005, 29(5): 619-624.

[3] Kim K S, Huh S H, Suganuma K. Effects of fourth alloying additive on microstructures and tensile properties of Sn-Ag-Cu alloy and joints with Cu[J]. Microelectronics Reliability, 2003, 43: 259-267.

[4] 陈国海,耿志挺,马莒生,张 岳. 新型无铅焊料合金Sn-Ag-Cu-In-Bi的研究[J].电子元件与材料, 2003, 22(4): 36-38.

CHEN Guo-hai, GENG Zhi-ting, MA Ju-sheng, ZHANG Yue. A new type lead-free solder Sn-Ag-Cu-In-Bi[J]. Electronic Components & Materials, 2003, 22(4): 36-38.

[5] 刘 静,张富文,徐 骏,杨福宝,朱学新. 合金元素Cr、Al元素对SnAgCu基无铅焊料高温抗氧化和润湿性的影响[J]. 稀有金属, 2006, 30(1): 16-20.

LIU Jing, ZHANG FU-wen, XU Jun, YANG Fu-bao, ZHU Xue-xin. Effect of alloying elements Cr, Al on high-temperature oxidation resistance and wettability of SnAgCu based lead-free solder[J]. Chinese Journal of Rare Metals, 2006, 30(1): 16-20.

[6] 张曙光,何礼君,张少明,石力开. 绿色无铅电子焊料的研究与应用进展[J]. 材料导报, 2004, 18(6): 72-75.

ZHANG Shu-guang, HE Li-jun, ZHANG Shao-ming, SHI Li-kai. Progress of research and application of lead-free solder [J]. Materials Review, 2004, 18(6): 72-75.

[7] Wu C M L, Yu D Q, Law C M T, Wang L. Properties of lead-free solder alloys with rare earth element additions[J]. Materials Science and Engineering R, 2004, 44(1): 1-44.

[8] 陈志刚,史耀武,夏志东. 微量混合稀土对SnAgCu钎料合金性能的影响[J]. 电子工艺技术, 2003, 24(2): 53-58.

CHEN Zhi-gang, SHI Yao-wu, XIA Zhi-dong. Effect of mixed rare earth on the properties of SnAgCu lead-free solder alloy[J]. Electronics Process Technology, 2003, 24(2): 53-58.

[9] 卢 斌,张宇航,章四琪. 微量稀土Ce对SnAgCu系焊料合金性能的影响[J]. 中国材料科技与设备, 2005, 2(4): 60-63.

LU Bin, ZHANG Yu-hang, ZHANG Si-qi. Effect on the performances of SnAgCu lead-free solder with the addition of Ce[J]. Science and Technology and Equipment of Chinese Materials, 2005, 2(4): 60-63.

[10] Mavoori H, Ramirez A G, Jin S. Lead-free universal solders for optical and electronic devices[J]. Journal of Electronic Materials, 2002, 31(11) : 1160-1165.

[11] Ramirez A G, Mavoori H, Jin S. Bonding nature of rare-earth-containing lead-free solders[J]. Appl Phys Lett, 2002, 80(3): 398-400.

[12] Monn K W, Boettinger W J, Kattner U R, Biancaniello F S, Handwerker C A. Experimental and thermodynamic assessment of Sn-Ag-Cu solder alloy[J]. Journal of Electronic Materials, 2000, 29(10): 1122-1236.

[13] 孙伟成,张淑荣,侯爱芹. 稀土在铝合金中行为[M]. 北京: 兵器工业出版社, 1992: 106-110.

SUN Wei-cheng, ZHANG Shu-rong, HOU Ai-qin. The Behavior of Rare Element in the Aluminous[M]. Beijing: Weaponry Industry Press, 1992: 106-110.

[14] 虞觉奇,易文质. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1987: 58-59.

YU Jue-qi, YI Wen-zhi. State Atlas of Binary Alloy[M]. Shanghai: Shanghai Scientific and Technical Publishers, 1987: 58-59.

[15] 菅沼克昭.无铅焊接技术[M]. 宁晓山, 译. 北京: 科学出版社, 2004: 44-45.

Suganuma K. Lead-Free Welding Technique[M]. NING Xiao- shan, transl. Beijing: Science Press, 2004: 44-45.

[16] Zeng K, Tu K N. Six cases of reliability study of Pb-free solder joints in electronic packaging technology[J]. Materials Science & Engineering R , 2002, 38(2): 55-105.

[17] Amagai M. Mechanical reliability in electronic packaging[J]. Microelectronics Reliability, 2002, 42(4/5): 607-627.

[18] 陈 铮,周 飞. 材料连接原理[M]. 哈尔滨: 哈尔滨工业大学出版社, 2001: 65-99.

CHEN Zheng, ZHOU Fei. Material Joint Theory[M]. Harbin: Harbin Institute of Technology, 2001: 65-99.

[19] Young T. An essay on the cohesion of fluids[J]. Philosophical Transaction of the Royal Society of London, 1995, 1805(95): 65-87.

[20] 徐光宪. 稀土(下册)[M]. 北京: 冶金工业出版社, 1995: 473-499.

XU Guang-xian. Rare Earth(Vol.3)[M]. Beijing: Metallurgical Industry Press, 1995: 473-499.

[21] YAN Li-jun, XIE Yun-an, XING Xian-yan, QIAO Zhi-yu. Prediction of surface tension of pure liquid metals and alloys[J]. Journal of Rare Earth, 1999, 17(3): 182-188.

基金项目:湖南省科技攻关重点项目(06YKG2056)

收稿日期:2006-09-01;修订日期:2006-11-20

通讯作者:卢 斌,教授;电话:0731-8836319;E-mail:luoffice@mail.csu.edu.cn

(编辑 杨幼平)