文章编号:1004-0609(2007)01-0068-07

Cu-Ag合金原位纤维复合材料的应变强化效应

宁远涛,张晓辉,吴跃军

(昆明贵金属研究所,昆明 650221)

摘 要:制备Cu-10Ag和Cu-10Ag-Ce合金原位纤维复合材料,研究结构变化与应变强化的关系。随着真应变增大,复合材料中的Ag纤维平均尺寸呈真应变的负指数函数减小,而极限强度呈真应变的指数函数增大。按其结构变化,原位复合材料显示两种强化机制:低应变阶段主要为加工硬化机制,高应变阶段主要为超细Ag纤维及界面强化机制。增大凝固速率和添加微量Ce明显细化合金的初始Ag相和Ag纤维尺寸,增高原位纤维复合材料的应变强化速率。在真应变为10.4时,缓慢、快速凝固Cu-10Ag合金和Cu-10Ag-Ce合金原位纤维复合材料的Ag纤维平均直径分别为140、90和80 nm,极限拉伸强度分别为1 250、1 370和1 430 MPa。

关键词:Cu-Ag合金;复合材料;强化效应;Ce添加剂

中图分类号:TG 146.1; TG 146.3 文献标识码:A

Strain strengthening of Cu-Ag alloy in situ filamentary composites

NING Yuan-tao, ZHANG Xiao-hui, WU Yue-jun

(Kunming Institute of Precious Metals, Kunming 650221, China)

Abstract: Cu-10Ag and Cu-10Ag-Ce alloys in situ filamentary composites were prepared. The relationships of the ultimate tensile strengths (UTS) and microstructure evolution of the filamentary composites were studied. With increasing true strain, the sizes of Ag filaments in the composites decrease according to a negative exponential function of the true strain. The UTS of the composites increase also according to a exponential function of the true strain. The two-stage strengthening mechanisms were discussed on the evolution of microstructure during deformation process: at low true strain stage, the strengthening mechanism is mainly one caused by the working hardening controlled by dislocation increasing; at high true strain stage, the strengthening mechanism is mainly one caused by the super-fine Ag filaments and large coherent interfaces between Ag filaments and Cu matrix. The rapid solidification and trace Ce addition in the alloys obviously refine the sizes of original Ag precipitate in cast alloys and Ag filaments in the in situ composites, and therefore obviously increase the strain strengthening rate of the Cu-10Ag alloy in situ filamentary composites. As the true strain is 10.4, the average size of Ag filaments are about 140, 90 and 80 nm, and the ultimate tensile strengths are 1 250, 1 370 and 1 430 MPa in the Cu-10Ag alloys solidified slowly or rapidly, as well as in Cu-10Ag-0.05Ce alloy, respectively.

Key words: Cu-Ag alloy; composite; strengthening effect; Ce addition

近年来通过原位复合技术已将Cu-Ag共晶合金发展为高强度和高导电率原位复合材料,并对其结构和性能已作了许多研究,尤其对其高的强度性质显示了特别地关注。这类复合材料的力学和电学性能处决于合金成分、变形程度和中间热处理[1-8]。大变形复合材料的强度一般超过1 GPa(是硬化Cu的3~5倍)并保持60%~70%IACS电导率。

关于Cu-Ag合金原位纤维复合材料的强化机 制,有学者提出了位错模型[9]。Hong等[10-12]提出Ag纤维和界面无热障碍模型并认为优于位错模型。基于合金形变组织和初始凝固组织的尺度与两相材料的体积分量的相似性,根据Hall-Petch关系和混合定律,Han等[13-14]提出一个简单模型用于解释和预测共变形两相复合材料的强度。虽然该模型也可以较为合理的解释Cu-Ag合金原位复合材料的强化,但在大变形条件下,这类复合材料的强度往往偏离Hall-Petch关系和混合定律。事实上,Cu-Ag合金原位复合材料的强化涉及固溶强化、组织细化强化、沉淀强化、加工硬化及两相组织的协调变形等因素,单一的机制难以解释和预测其强化效应,因而仍有必要对其强化规律和机制作更多的研究。

本文作者采用原位复合技术制备了Cu-10Ag和Cu-10Ag-Ce合金原位纤维复合材料,研究了复合材料在形变过程中的结构变化以及强化效应的规律,讨论了复合材料的强化机制。

1 实验

采用纯度99.99%Ag、99.9%Cu和Ce,在高频感应炉Ar气氛中熔炼合金并将熔体浇入水冷铜模和预热石墨模,得到Cu-10%和Cu-10%Ag-Ce (质量分数,简写Cu-10Ag 或Cu-10Ag-Ce)合金铸锭。水冷铜模和预热石墨模制备的Cu-10Ag合金分别编号为CA1和CA2合金,石墨模制备的Cu-10Ag-Ce合金编号为CA3合金。经化学分析,合金中Ag含量分别为10.05%、10.09%和9.95%;定量光谱(ICP-AES)分析CA3合金含0.05%Ce。

合金铸锭经冷锻和冷拉拔至直径0.08 mm细丝材,在相应的真实应变阶段取试样测定力学性能。直径0.3 mm以上和以下丝材分别在FM250和FM3拉伸试验机上测量极限拉伸强度。采用 扫描电镜和透射电镜观察了丝材试样的显微结构。

2 实验结果

2.1 Cu-10Ag铸态合金及其原位纤维复合材料的结构

Cu-10Ag合金的铸态组织呈树枝晶体结构(图1)。CA2合金的树枝晶较CA1粗大,而CA1和CA3合金的树枝晶细小。合金的铸态组织均由Cu基体、(Cu+Ag) 共晶和Ag沉淀相组成(图1(d))。由电子探针面分析测定,各相的比例分别为69.1%、30.2%、0.7%(CA1合金),81.0%、16.5%、2.5%(CA2合金)和77.7%、21%、1.3%(CA3合金)。Ag沉淀相是由初生Cu晶体在冷却时析出并形成围绕Cu晶体的Ag膜。SEM测定得Ag膜的尺寸约为0.5~1.0 μm(CA1和CA3合金)和1.5~2.0 μm(CA2合金)。已测定CA1和CA2合金在凝固过程中的冷却速率分别为5.8×103和57 K/s[6]。由此可见,慢速凝固的CA2合金有粗大的晶体尺寸和更高的Ag沉淀比例,而快速凝固的CA1和含微量Ce添加剂的CA3合金有细小的晶体尺寸和更高的(Cu+Ag)共晶比例。

图1 铸态CA1、CA2和CA3合金的显微组织

Fig.1 Microstructures of as cast CA1(a), CA2(b) and CA3((c), (d)) alloys

在冷变形过程中,Ag沉淀和(Cu+Ag)共晶中Ag层随着Cu基体变形。Ag相沿拉拔方向伸长形成纤维并沿轴向排列。随着变形量增大,银纤维尺寸逐渐减小,形成以Ag纤维为增强相的Cu基原位纤维复合材料。Ag沉淀形成相对粗的Ag纤维,(Cu+Ag)共晶中的Ag层形成相对细的Ag纤维。图2所示为在不同真实应变时合金中Ag纤维形貌。采用扫描电镜观测Ag纤维直径,其平均直径d随真应变ε增大呈负指数关系减小(图3):

图2 在不同真应变阶段Cu-10Ag合金中Ag纤维形貌

Fig.2 SEM images of Ag filaments in Cu-10Ag alloys at different true strain stages: (a) CA1 alloy, ε=2.95; (b) CA2 alloy, ε=2.95; (c) CA3 alloy, ε=2.3; (d) CA2 alloy, ε=7.1

图3 Cu-10Ag合金原位纤维复合材料中Ag纤维直径与真应变的关系

Fig.3 Relationships of Ag filament diameters vs true strain in Cu-10Ag in situ filamentary composites

由不同真应变下实验测定的d值通过式(1)推导得d0CA1=930 nm(CA1合金)、d0CA2=1 500 nm (CA2合金)和d0CA3=800 nm(CA3合金),这与SEM测定的初始Ag相的平均尺寸基本吻合。真应变ε=ln(A0/Ad), A0和Ad 为初始和变形试样的截面积。可以看出,CA1和CA3合金中Ag纤维尺寸比CA2合金中的Ag纤维细小。增大合金凝固速率和添加微量Ce添加剂细化了Cu-10Ag铸态合金的初始Ag相尺寸d0,从而明显细化了由这些合金制备的原位纤维复合材料中的Ag纤维直径。

随着冷变形程度增大,Cu-Ag合金原位纤维复合材料的组织也发生变化。在低应变阶段,合金中形成大量位错与位错胞结构,其位错胞尺寸大约为150~200 nm(图4(a)[3]),因而使合金的位错密度迅速提高,可达到1012~1014/cm2[15]。在高应变阶段,如当真应变ε≥9时,复合材料中Ag纤维尺寸已达到或小于位错胞结构尺寸,位错胞迁移到界面而Ag纤维变成无位错状态(图4(b)),Cu晶体中的位错迁移到晶界而使位错明显减少,菊池线(图4(c))的出现是Cu基体内部缺陷减少的明证。图4(d)显示了图4(b)中Cu基体与Ag纤维界面间的电子衍射花样。可以看出Ag纤维的弱斑点与具有相同位相Cu基体的明亮斑点完全对应,表明大变形Cu-10Ag原位纤维复合材料中Ag纤维与Cu基体具有明显的织构并取 ∥

∥ , (220)Cu∥(220)Ag, [110]Cu∥[110]Ag等共格界面位相关系。

, (220)Cu∥(220)Ag, [110]Cu∥[110]Ag等共格界面位相关系。

图4 Cu-Ag合金原位纤维复合材料的透射电镜像

Fig.4 TEM images and Kikuchi line in Cu-10Ag in situ filamentary composites: (a) Dislocation cells at ε=4.2[3]; (b) Ag filament (A) and Cu matrix (B) at ε=9.8; (c) Kikuchi line in Cu matrix at ε=9.8; (d) Electronic diffraction pattern between Ag filament (A) and Cu matrix (B) at ε=9.8

2.2 Cu-10Ag合金原位纤维复合材料的应变强化

图5所示为Cu-10Ag合金原位纤维复合材料的极限抗拉强度(UTS)与真应变(ε)的关系。随着真实应变增大,合金的强度呈指数函数增大,并且CA1和CA3合金比CA2合金显示了更高的应变强化速率。在低应变阶段, CA2合金的强度高于CA1和CA3合金;在高应变阶段,CA1和CA3合金的强度明显高于CA2合金。对图5中强度曲线在低应变阶段和高应变阶段作切线,两切线的交点可视为强度曲线上的拐点εp。可以确定CA1和CA3合金的εp =8.5,CA2合金的εp=9.0。

图5 冷变形Cu-10Ag合金原位纤维复合材料的极限拉伸强度与真应变的关系

Fig.5 Dependences of σb on ε for cold deformed Cu-10Ag alloy in situ filamentary composites

当真实应变大于相应的εp值时,复合材料的强度急剧增高。

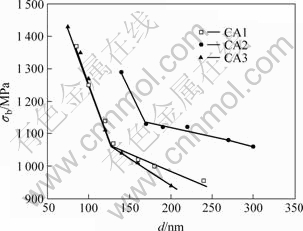

图6所示为合金的极限抗拉强度与Ag纤维直径d的关系。随着Ag纤维直径减小,合金的强度增大。在曲线上也存在一个拐点dp,它们的尺寸分别约为 130 nm(CA1、CA3合金)和160 nm(CA2合 金),这与强度曲线上拐点εp所对应的Ag纤维尺寸相当。可以看出,极限拉伸强度转折点所对应的Ag纤维尺寸恰好相当于或低于位错胞的尺寸(150~200 nm)。当d<dp,即当Ag纤维直径低于位错胞尺寸时,合金的强度急剧增高。Ag纤维尺寸相同时,CA2合金具有更高的强度,但要达到与CA1和CA3合金相同或相当的Ag纤维直径,CA2合金需要有更大的真应变。这也是在极限抗拉强度对真应变的关系曲线(图5)上CA2合金的εp(εp=9.0)值高于CA1和CA3合金εp(εp=8.5)值的原因。

图6 冷变形Cu-10Ag合金原位纤维复合材料的极限拉伸强度与Ag纤维直径的关系

Fig.6 Dependences of σb on diameter of Ag filament for cold deformed Cu-10Ag alloy in situ filamentary composites

3 讨论

3.1 Cu-10Ag合金原位纤维复合材料应变强化规律

根据Hall-Petch关系和混合定律,Han等[13-14]导出Cu-Ag合金原位复合材料的强度σ(Cu/Ag)为应变的指数函数:

将本工作测定的Cu-10Ag合金原位纤维复合材料极限拉伸强度值对exp(ε/3)作图,由图7可见极限拉伸强度与exp(ε/3)呈较好的线性关系。

图7 Cu-10Ag合金原位纤维复合材料极限拉伸强度与exp(ε/3)的关系

Fig.7 Dependences of σb on exp(ε/3) for cold deformed Cu-10Ag alloy in situ filamentary composites

式(4)中[k(Cu/Ag)d0-1/2]为图7中强化曲线的斜率,其中Hall-Petch系数k(Cu/Ag)近似地等于0.3 MN/m3/2 [10],因此,d0-1/2就成为决定强化曲线斜率的主要因素。前文已指出d0CA1 =930 nm(CA1合金)、d0CA2=1 500 nm(CA2合金)和d0CA3=800 nm(CA3合金),快速凝固和微量Ce添加剂明显减小Cu-10Ag合金的d0值,由d0-1/2值则显示图7中CA1和CA3合金有更高的斜率,即有更高的应变强化速率,致使在高应变条件下,CA1和CA3合金的强度远高于CA2合金。虽然CA2合金有较高的初始强度,但初始Ag沉淀尺寸相对粗大,在形变过程中其Ag纤维细化速率较低,从而其应变强化速率也低于CA1和CA3合金,如图3和图7所示。这表明在形变过程中组织细化,尤其Ag纤维的细化,是Cu-Ag合金原位纤维复合材料强化的主要因素。

4.2 Cu-10Ag合金原位纤维复合材料应变强化机制

在图5和6中εp和dp拐点的存在表明Cu-10Ag原位纤维复合材料呈现由不同机制控制的两阶段应变强化效应,这与合金在形变过程中的结构变化有关。Cu-10Ag和Cu-10Ag-Ce合金实质上由Cu基体和Ag相组成,Cu-10Ag原位纤维复合材料的应变强度应由Cu相和Ag相的加工硬化项(σwhs)以及Ag纤维和Cu晶体细化引起的强化项(σfs)组成,即

在形变复合材料中存在的两阶段应变强化效应与σwhs和σfs项的演变有关。在ε<εp低应变阶段,合金中各相的尺寸相对粗大,即d(Cu)、d(Ag)和df(Ag)值相对大,由式(10)和(11)则σg(Cu)、σf(Ag)从而σfs项非常小。则有σ(Cu/Ag)≈σwhs。形变Cu-Ag合金纤维复合材料的强度主要由Cu基体与Ag相加工硬化项制约并正比于位错密度γd(Cu)1/2和γd(Ag)1/2。随着应变增大,合金中位错不断增生并形成位错胞,位错密度不断增高,复合材料的强度不断增高。由于CA2合金的平均晶体尺寸大于CA1和CA3合金,前者可以比后二合金容纳更多的位错胞即更高的位错密度,即γd(CA2)>γd(CA1)(或γd(CA3))。另一方面,本文已测定CA2合金比CA1和CA3合金含有更高的Ag沉淀比例,即其铸态组织就含有更高的Ag沉淀强化效应,因此,CA2合金比CA1和CA3合金有更高的初始强度,致使在低应变条件下CA2合金的强度高于CA1和CA3合金。在真应变ε=εp,复合材料中Ag纤维尺寸分别达到约130 nm(CA1和CA3合金)和约160 nm(CA2合金,见图6),即达到位错胞尺寸。在ε>εp高应变阶段,Ag纤维直径低于位错胞尺寸而不能容纳稳定的位错胞结构,位错和位错胞迁移出Ag纤维而移向界面,Ag纤维处于无位错状态。同时,Cu晶粒也高度细化使其位错和其它缺陷密度降低,菊池线(图4(c))的出现证明了Cu晶体处于低密度缺陷状态[7]。这表明大变形Cu-Ag合金原位纤维复合材料含有超细而致密Ag纤维和非常低的位错密度,且Ag纤维与Cu基体之间呈共格界面位相关系。由式(8)和(9)可知加工硬化项σwh(Cu)和σwh(Ag)很小,则有σ(Cu/Ag)≈σfs。因此,对大变形复合材料的强化机制主要是由超细Ag纤维及其共格界面所产生的强化,使大变形Cu-Ag合金原位纤维复合材料呈现超高强度。由式(10)和(11)可知,df(Ag)、δ(Cu)和δ(Ag)值越小,σg(Cu)和σf(Ag)值越大。在CA1和CA3合金中df(Ag)、δ(Cu)和δ(Ag)值远小于CA2合金,前二合金比CA2具有更高的强度。这进一步证明了组织细化是Cu-Ag合金原位纤维复合材料高应变强化效应的主要因素。

4 结论

1) 采用原位复合技术制备了Cu-10Ag亚共晶合金原位纤维复合材料,其Ag纤维尺寸随真实应变增大呈负指数函数关系减小:d=d0 exp(-0.228ε)。在低应变条件下,复合材料含位错结构和高位错密度;在高应变条件下,复合材料中Ag纤维达到纳米尺度,Ag纤维和Cu基体处于无位错或低密度缺陷状态,超细Ag纤维与Cu基体之间形成共格界面位相关系。

2) 随着真应变ε增大,Cu-10Ag合金原位纤维复合材料的应变强度呈ε的指数函数增大:σ(Cu/Ag) = σ0(Cu)+[k(Cu/Ag)d0-1/2]exp(ε/3),这里,d0是铸态合金中初始Ag相的尺寸。按合金在形变过程中的结构变化,原位纤维复合材料呈现两阶段应变强化效应:低应变阶段具有较低强度,其主要强化机制为加工硬化或位错强化;高应变阶段具有超高强度,其主要强化机制为超细Ag纤维及Ag纤维与Cu基体之间共格界面强化。

3) 增大凝固速率和添加微量Ce溶质对Cu-10Ag合金的应变强化效应呈现双重影响:一方面,它们降低铸态合金中初始Ag沉淀比例,致使初始和低应变阶段的强化效应较低;另一方面,它们明显细化铸态合金初始Ag沉淀和形变合金中Ag纤维尺寸,致使合金有更高的应变强化速率,表明组织细化,尤其是Ag纤维细化,是Cu-Ag合金原位纤维复合材料高应变强化效应的主要因素。

REFERENCES

[1] Sakai Y, Inoue K, Maeda H. New high strength, high conductivity Cu-Ag alloy sheetss [J]. Acta Metall Mater, 1995, 43(4): 1517-1522.

[2] Sakai Y, Scheider-Muntau H J. Ultra-high strength, high conductivity Cu-Ag alloy wires [J]. Acta Meter, 1997, 45(3): 1017-1021.

[3] Benghalem A, Morris D C. Microstructure and strength of wire-draw Cu-Ag filamentary composites [J]. Acta Metall, 1997, 45(1): 397-406.

[4] Ohsaki S, Yamazaki K, Hono K. Alloying of immiscible phases in wire-drawn Cu-Ag filamentary composites [J]. Scr Mater, 2003, 48:1569-1574.

[5] Zhang L, Meng L. Evolution of microstructure and electrical conductivity of Cu-12wt.%Ag filamentary composite with drawing deformation [J]. Scr Mater, 2005, 52: 1187-1191.

[6] 张晓辉,宁远涛,李永年,戴 红. 大变形Cu-10Ag原位纤维复合材料的结构与性能[J].中国有色金属学报,2002, 12(1): 115-119.

ZHANG Xiao-hui, NING Yuan-tao, LI Yong-nian, DAI Hong. Structure and properties of Cu-Ag alloy in situ filamentary composites[J]. The Chinese Journal of Nonferrous Metals, 2002,12(1): 115-119.

[7] 宁远涛,张晓辉,张 婕. 大变形Cu-Ag合金原位纤维复合材料的稳定性[J]. 中国有色金属学报,2005,15(4): 506-512.

NING Yuan-tao, ZHANG Xiao-hui, ZHANG Jie. Stability of heavy deformed Cu-Ag in situ filamentary composites[J]. The Chinese Journal of Nonferrous Metals, 2005,15(4): 506-512.

[8] NING Yuan-tao, ZHANG Xiao-hui, ZHANG Jie. Influence of Thermomechanical Processing on the Structure and Properties of Cu-Ag alloy in situ Composites[A]. Proceedings of the 8th China-Russia Symposium on New Materials and Technologies[C]. Guangzhou: Guangdong Non-ferrous Metals, 2005, 15(2/3): 521-529.

[9] Funkenbusch P D, Lee J K, Courtney T H. Ductile two phase alloy: Prediction of strengthening at high strains[J]. Metall Trans, 1986, 8A: 1249-1256.

[10] Hong S I, Hill M A. Microstructure stability and mechanical response of Cu-Ag microcomposite wires [J]. Acta Metall, 1998, 46(12): 4111-4122.

[11] Hong S I, Hill M A. Mechanical stability and electrical conductivity of Cu-Ag filamentary microcomposites [J]. Mater Sci Eng A, 1999, A264: 151-158.

[12] Hong S I, Kim P H, Choi Y C. High strain rate superplasticity of deformation processed Cu-Ag filamentary composites [J]. Scr Mater, 2004, 51: 95-99.

[13] Han K, Vasquez A A, Xin Y, Kalu P N. Microstructure and tensile properties of nanostructured Cu-25wt%Ag [J]. Acta Meterialia, 2003, 51: 767-779.

[14] Han K, Embury J D, Sims J R, Campbell L J, Schneider-Muntau H J, Pantsyrnyi V I, et al. The fabrication, properties and microstructure of Cu-Ag and Cu-Nb composite conductors [J]. Mater Sci Eng, 1999(1): 99-114.

[15] Frommeyer G, Wassermann G. Microstructure and anomalous mechanical properties of in situ produced silver-copper composite wires [J]. Acta Metall, 1975, 23(4): 1353-1360.

基金项目:国家自然科学基金资助项目(50371031)

收稿日期:2006-02-16;修订日期:2006-10-26

通讯作者:宁远涛, 研究员; 电话: 0871-5138227; 传真: 0871-5151533; E-mail: ytning2002@yahoo.com.cn

(编辑 陈爱华)