预变形2219铝合金应力松弛时效成形统一本构建模及回弹预测

来源期刊:中国有色金属学报(英文版)2019年第6期

论文作者:汪凯 湛利华 杨有良 马子尧 李喜财 刘健

文章页码:1152 - 1160

关键词:2219铝合金;应力松弛时效;统一本构模型;回弹

Key words:2219 aluminum alloy; stress relaxation ageing; unified constitutive model; springback

摘 要:通过应力松弛时效实验和有限元仿真研究预变形2219铝合金应力松弛行为。结果表明:应力能促进时效析出进程,缩短到达峰值强度的时间。且初始应力越大,时效后的剩余应力越高,合金的屈服强度越大。基于显微组织演变和时效强化理论建立统一本构模型,并通过子程序开发将其嵌入有限元仿真模型中。发现仿真回弹后的半径与实验值间的相对误差为3.6%,回弹为16.8%。从而可知,所建立的应力松弛时效本构模型能较好预测带筋壁板时效过程中的回弹行为。

Abstract: Stress relaxation ageing behavior of pre-deformed AA2219 is studied through stress relaxation age experiments and finite element (FE) simulation. The results show that the stress can promote the process of ageing precipitation, and shorten the time to reach the peak strength. Meanwhile, the residual stress and yield strength increase along with the increase in the initial stress. Based on microstructure evolution and ageing strengthening theory, a unified constitutive model is established and incorporated into the FE simulation model through a user subroutine. It is found that the relative error of the radius is 3.6% compared with the experimental result and the springback is 16.8%. This indicates that the proposed stress relaxation ageing constitutive model provides a good prediction on the springback of such stiffened panel during its ageing process.

Trans. Nonferrous Met. Soc. China 29(2019) 1152-1160

Kai WANG1,2, Li-hua ZHAN1,2, You-liang YANG1,2, Zi-yao MA1,2, Xi-cai LI1,2, Jian LIU1,2

1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of High-Performance Complex Manufacturing, Central South University, Changsha 410083, China

Received 21 July 2018; accepted 27 February 2019

Abstract: Stress relaxation ageing behavior of pre-deformed AA2219 is studied through stress relaxation age experiments and finite element (FE) simulation. The results show that the stress can promote the process of ageing precipitation, and shorten the time to reach the peak strength. Meanwhile, the residual stress and yield strength increase along with the increase in the initial stress. Based on microstructure evolution and ageing strengthening theory, a unified constitutive model is established and incorporated into the FE simulation model through a user subroutine. It is found that the relative error of the radius is 3.6% compared with the experimental result and the springback is 16.8%. This indicates that the proposed stress relaxation ageing constitutive model provides a good prediction on the springback of such stiffened panel during its ageing process.

Key words: 2219 aluminum alloy; stress relaxation ageing; unified constitutive model; springback

1 Introduction

As the aero-space industry develops rapidly, large integral panel components featuring good integrity, high strength and outstanding performance have seen increasingly extensive utilization in vital parts of civil and military air crafts as well as the new generation of launch vehicles [1,2]. Creep age forming (CAF) technology, as a new sheet metal forming method, is designated exactly for coordinated manufacturing of large integral panel component with high performance and accurate shape forming [3-5].

CAF utilizes the creep and stress relaxation behavior of ageing-strengthened aluminum alloy under the stress field and temperature field to make the integral panel meet the shape requirements. In this process, ageing precipitation makes the alloy achieve good microstructure and mechanical property, realizing control over both shape and property [6-9]. Creep is slow but continuous plastic deformation of alloy under constant stress. Stress relaxation is a process in which the deformation of the alloy remains unchanged while the stress decreases spontaneously. The essence of it is that the internal elastic strain of the material gradually transforms into inelastic strain [10-13]. Hence, how to accurately characterize the deformation behavior and mechanical properties of materials during the ageing forming process is the primary challenge for the extensive utilization of this technique. To address this challenge, the most effective solution is the constitutive modeling technique based on experiment and forming mechanism. As creep and stress relaxation occur simultaneously, the springback of component ageing formation is predicted through establishing either creep ageing constitutive model or stress relaxation ageing constitutive model. YANG et al [6] established the creep ageing constitutive model of 2524 aluminum alloy with both tensile and compressive stresses considered. LI et al [7,8] proposed an implicit integral algorithm, and developed FE model of asymmetric creep-ageing behavior of AA2050 in CAF. MA et al [9] established a unified constitutive model to predict the stress-level dependency of creep ageing behaviors, which can simulate the CAF of complex components. HO et al [10] proposed a unified creep ageing constitutive model, which can describe the precipitated phase evolution and the creep ageing behavior of 7070 aluminum alloy at 150 °C. IDEM and PEDDIESON [11] simulated the thermal viscoplastic behavior and stress relaxation effect, and found that nonlinear stress relaxation was the main reason for the decrease of springback. ZHAN et al [12] established the stress relaxation constitutive model under the electric pulse, which took into account the effect of electric pulse on dislocation motion. ZHENG et al [13] developed a set of unified constitutive equation, which can predict the stress relaxation, age hardening response and their interactions at different temperatures. Essentially similar to traditional creep, the stress relaxation of panel component is special compared with constant stress creep ageing in that its precipitation strengthening is influenced by continuous stress change, which causes differences in property and springback. Therefore, it is necessary to study the evolution law of the shape in the stress relaxation ageing process, and establish a model to predict the springback behavior of the components accurately.

In this study, the stress relaxation ageing behavior of the pre-deformed AA2219 with different stress levels at 165 °C is studied, and the microstructure evolution during the ageing process is observed by transmission electron microscopy (TEM). Based on stress relaxation theory and ageing strengthening theory, a unified macro-micro coupled stress relaxation constitutive model has been established through stress relaxation ageing experiment and micro-structural statistical analysis. Meanwhile, the constitutive model is incorporated into the FE software MSC.MARC through a subroutine to make prediction about the ageing and springback of the typical stiffened and thin-walled components. By comparing with the creep constitutive model, a better method is explored to provide theoretical and practical guidance for the springback prediction of the actual components.

2 Experimental

2.1 Material

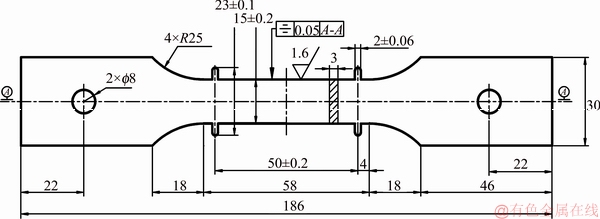

The experimental material is a 20 mm-thick pre-formed AA2219 hot-rolled plate, provided by China Academy of Space. The plate experienced a 7% pre-stretching after solution quenching, and its chemical composition is listed in Table 1. Stress relaxation samples were machined out of the plate in parallel with the rolling direction, as illustrated in Fig. 1.

2.2 Stress relaxation ageing tests

The stress relaxation ageing tests were carried out on the RMT-D10 electronic creep/relaxation testing machine. The temperature error and the stress error are controlled within 2 °C and 3 N, respectively. Through preliminary exploration [9,12,14], the test temperature was set as 165 °C, and the initial stress was set as 120, 150 and 180 MPa. In order to probe into the theory of hardening precipitates and mechanical property evolution, the ageing duration for stress relaxation test was set as 1, 3, 5, 8 and 11 h.

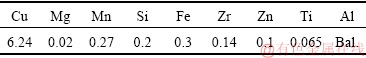

Table 1 Chemical composition of 2219 aluminum alloy (wt.%)

Fig. 1 Specimen geometry and size (unit: mm)

2.3 Mechanical property tests and microstructure characterization

After the stress relaxation ageing experiment, room temperature tensile tests were conducted on a CMT-5504 machine, with the operation speed being 2 mm/min. The experiment data were the average values of three tests. Since material property is determined by microstructure, TEM observation on JEM-2100F (JEOL, Japan) was adopted to illustrate the precipitation evolution during the stress relaxation ageing process, with the operating voltage being 200 kV. The TEM specimens were prepared by cutting 10 mm × 10 mm × 0.5 mm (L×W×T) blocks from the gauge section of samples along the stress direction. Then, they were thinned to 80 μm and punched into discs of 3 mm in diameter with a punching machine. At last, they were twin-jet-electro-polished with a mixture of 30% nitric acid and 70% methanol at temperature between -35 °C and -25 °C, with the voltage being 15 V.

2.4 Statistics of precipitates

The profile of precipitate varied constantly during the ageing process of AA2219. The precipitate was simplified into a single θ′ phase in previous studies [15], which is plate-shaped. The geometrical shape of the θ′ phase is expressed by the diameter l and the thickness h [16]. In other words, l is the length (diameter) of the precipitated phase, and h is the thickness of the precipitated phase. With digital micrograph software, the TEM images under different ageing conditions were analyzed. The average length and thickness of the precipitated phases were calculated.

2.5 Validation of stress relaxation ageing constitutive model

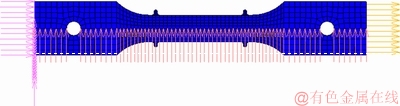

In order to validate the accuracy of the constitutive model and the feasibility to incorporate it into FE software for simulation, a commercial FE software MSC.MARC was employed on uniaxial tensile samples for stress relaxation ageing FE analysis. The FE model, illustrated in Fig. 2, adopted No. 7 solid element. Elastic modulus is 67552 MPa. Poisson ratio is 0.3 and yield strength is 306 MPa, while other parameters were set the same as the experiment, namely, 165 °C/11 h/120, 150 and 180 MPa. Left end nodes displacement along the X axis and the symmetric center nodes displacement along the Y axis were fixed, while tensile stress was applied on the right end. When the stress is increased to the target stress, the constant strain is maintained. In order to simulate the stress relaxation ageing behavior of the sample, the constitutive model is programmed by FORTRAN language and embedded in the FE software by a subroutine, CRPLAW.

Fig. 2 Uniaxial tensile stress relaxation FE model

3 Results and discussion

3.1 Stress relaxation ageing behavior

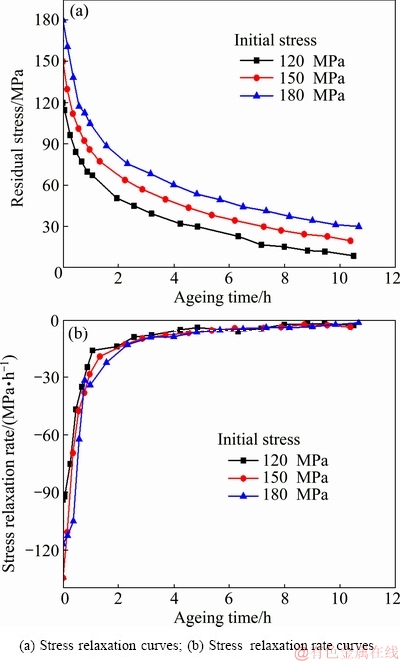

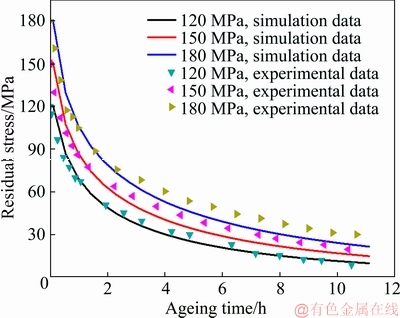

Figure 3 demonstrates stress relaxation ageing curves and corresponding relaxation rate curves of pre-deformed AA2219 at 165 °C under initial stress of 120, 150, and 180 MPa for 11 h. According to Fig. 3(a), stress relaxation increases while residual stress decreases with prolonging the ageing time. And the residual stress positively correlates with the initial stress. For example, after 11 h, residual stresses under stress levels of 120, 150, and 180 MPa are 8.7, 19.6 and 30.1 MPa, respectively.

Generally, stress relaxation curves can be divided into three stages of rapid relaxation stage, transition relaxation stage with reduced relaxation rate and stable relaxation stage [13]. From the stress relaxation rate curve of Fig. 3(b), it can be found that the stress decreases rapidly at the initial stage, but this process is generally as short as 1-2 h. Then, it enters the transition stage and further moves to the stable relaxation stage after 3 h. As the experiment material is pre-stretched aluminum alloy, a lot of movable dislocations were introduced via early pre-stretch treatment. At the initial stress relaxation stage, the effective stress is great and there are many movable dislocations, vacancies and relatively low short-range resistance, making stress decrease rapidly; with the activation by temperature and stress, dislocations slipped or climbed, transforming elastic deformation into plastic deformation and reducing the effective stress. In the ageing process, many second- phase particles precipitate, which impede dislocation slipping and climbing, thus reducing the relaxation rate and advancing it to the stable relaxation stage [12].

Fig. 3 Stress relaxation behavior of pre-deformed AA2219 at different tested stresses

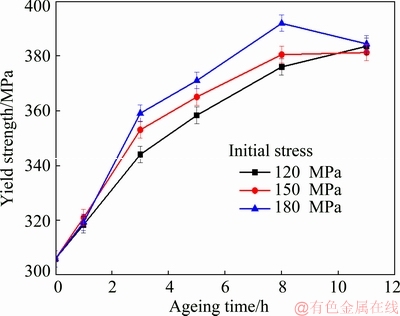

3.2 Stress relaxation ageing property

Figure 4 demonstrates AA2219 yield strength evolution at 165 °C under different stress levels. It can be found out that, with time passing by, the yield strength undergoes initial increase before approaching to the peak and then it shows a tendency of gradual decrease. For instance, when the initial stress is 180 MPa, the yield strength reaches the peak value of 391.9 MPa at the ageing time of 8 h. Then, it goes down. Under the same ageing condition, the yield strength after the stress relaxation ageing increases along with the initial stress. For example, under different stress levels of 180, 150 and 120 MPa, yield strengths at the ageing time of 8 h are 391.88, 380.45 and 375.99 MPa, accordingly.

Fig. 4 Yield strengths of pre-deformed AA2219 under various stresses at 165 °C

Within the ageing duration of 11 h, the yield strength under the initial stress of 120 MPa does not seem to reach its peak; under the initial stress of 150 MPa, the yield strength peak comes at around 8 h and with further ageing, the yield strength maintains at the peak level; under the initial stress of 180 MPa, the yield strength reaches its peak before 8 h, indicating that higher stress can promote the precipitation process and shorten the time to reach the peak strength. Furthermore, the yield strength increases rapidly during the first 3 h and slows down thereafter. By taking an example of the initial stress of 150 MPa, the stress increases to 353 MPa from 306 MPa in the first 3 h, and then it reaches the peak strength of 380.5 MPa at 8 h. This is mainly due to the fact that the yield strength increases quickly under the influence of high stress field and temperature field in initial stress relaxation ageing period. With further ageing, the initial stress drops quickly, rendering the alloy ageing under low stress. If the ageing stress diminishes below the threshold stress, it would not be able to promote the precipitation in the GP zone and then the strength increases slowly in the later period.

3.3 Microstructure evolution

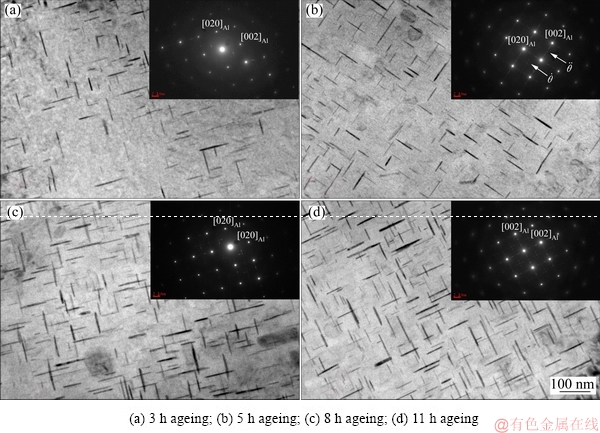

Fig. 5 Micrograph images showing microstructures of pre-deformed AA2219 after stress relaxation under stress of 150 MPa ([001]Al electron beam)

Figure 5 presents TEM images and corresponding SAD patterns, showing the microstructure evolution of AA2219 after stress relaxation ageing at 165 °C under the stress of 150 MPa. The electron beam is from [001]Al direction. Figure 5(a) shows a few perpendicular precipitates in the aluminum matrix after 3 h of stress relaxation ageing. It can be seen from the upper right corner diffraction pattern that, there are some dim lines indicating the presence of θ′ and absence of θ′ [17]. Figure 5(b) depicts the microstructure under the stress of 150 MPa after 5 h of stress relaxation ageing. Compared with the microstructure of 3 h ageing, more θ′ phases can be seen with a more even distribution. The SAD pattern shows that there are traces of diffraction spots at the center. They are diffraction spots of θ′ phases, revealing a little presence of θ′ phases in the aluminum matrix and the yield strength is increased by 12 MPa. Figure 5(c) displays the microstructure under the stress level of 150 MPa for 8 h in which there are more diffraction spots of θ′ phase while the θ′ phases becomes relatively weak, indicating that part of θ′ phases convert into θ′. At that point, yield strength reaches its maximum of 380.5 MPa. With the extension of ageing time, the TEM image at 11 h ageing, as depicted in Fig. 5(d), shows similar grain interior with that at 8 h, which matches the property depicted in Fig. 4.

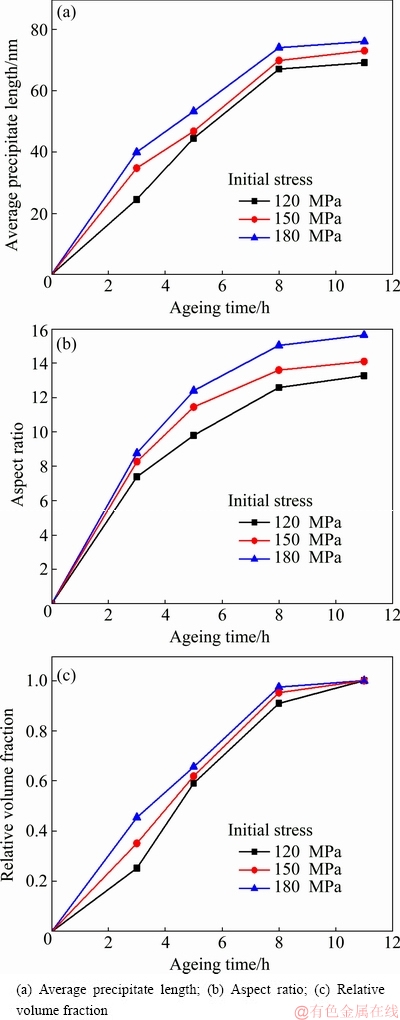

3.4 Quantitative characterization of precipitation

Average length l and relative volume fraction fv of the precipitate are adopted to depict the profile character. And aspect ratio q is employed to describe the precipitates:

(1)

(1)

(2)

(2)

q=l/h (3)

where N denotes precipitate numbers in the TEM image, a and b are length and width of the whole zone in the TEM image and  is the peak relative volume fraction of the precipitates in the image.

is the peak relative volume fraction of the precipitates in the image.

With Eqs. (1), (2) and (3), the outcome is depicted in Fig. 6. According to the result, average length of AA2219 precipitates increases along with the extension of ageing duration while the increasing rate decreases gradually, which is due to the fact that the grain provides relatively large space in the initial stage and the resistance against the increase is relatively small. But, with ageing preceding, increased precipitates influence each other directly and the space gets smaller. Some may even merge with each other. For such reason, the precipitate increasing slows down and shows a tendency towards stabilization. As the relative volume fraction and aspect ratio are both correlative of precipitate length, they follow the same evolution law according to Eqs. (1)-(3).

4 Unified constitutive modeling of stress relaxation ageing

4.1 Establishment of model

Fig. 6 Micro-statistical results of 2219 aluminum alloy

Based on the microstructural evolution law and ageing strengthening theory [18-21], the macro-micro coupled constitutive equation of stress relaxation ageing is established by integrating the discussion above on stress relaxation ageing behavior. The equations are as follows:

(4)

(4)

(5)

(5)

σy=σ0+σss+σppt+σdis (6)

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

(11)

(11)

(12)

(12)

(13)

(13)

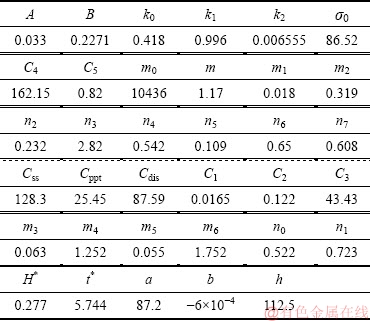

where  is stress relaxation rate, E is elastic modulus, σ is external stress, and H is intermediate variable related to stress and stress relaxation rate. A, B, k0, k1, k2, σ0, C1, C2, C3, C4, C5, m0, m, m1, m2, m3, m4, m5, m6, n0, n1, n2, n3, n4, n5, n6, n7, Css, Cppt, Cdis, t* and H* are material constants.

is stress relaxation rate, E is elastic modulus, σ is external stress, and H is intermediate variable related to stress and stress relaxation rate. A, B, k0, k1, k2, σ0, C1, C2, C3, C4, C5, m0, m, m1, m2, m3, m4, m5, m6, n0, n1, n2, n3, n4, n5, n6, n7, Css, Cppt, Cdis, t* and H* are material constants.

4.2 Material constants

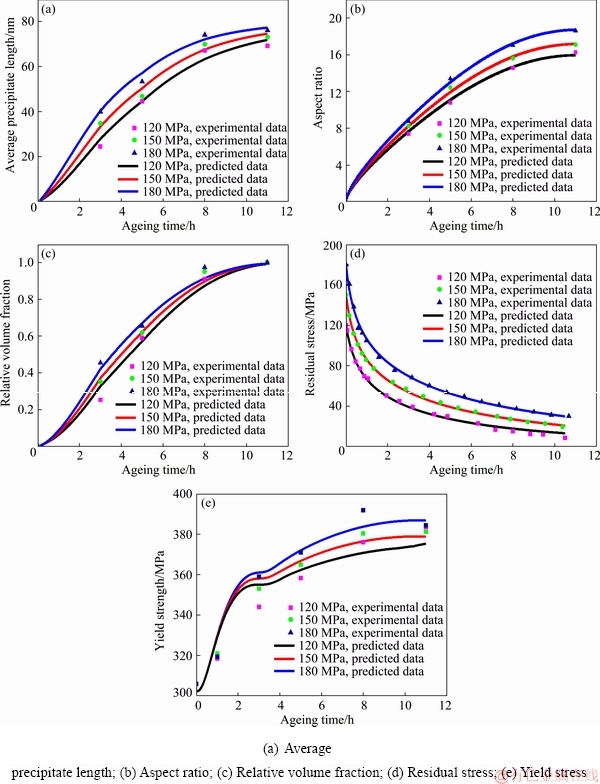

Particle swarm optimization (PSO) [22] was adopted to fit the experiment result obtained at 165 °C. Firstly, the statistical variation of aspect ratio, average length and relative volume fraction are worked out to determine related material constants. Then, the stress relaxation ageing curves of AA2219 under corresponding stress and at corresponding temperature are fitted to obtain the material constants. Figure 7 shows the fitting curve and Table 2 gives the material constants.

4.3 Validation of stress relaxation ageing constitutive model

Figure 8 shows the result of introducing the constitutive model to the FE simulation. It can be seen that FE simulation excels in predicting experimental data with a sound agreement, indicating that this model is well capable of predicting stress relaxation ageing behavior and the compiled constitutive subroutine is correct, which lays a good foundation for further FE simulation.

Fig. 7 Comparison of experimental data and fitted results of 2219 aluminum alloy under various stresses at 165 °C

Table 2 Material constants in constitutive equations for 2219 Aluminum alloy

Fig. 8 Comparisons between experimental results and uniaxial tensile stress relaxation simulation

5 Springback prediction and validation of grid panel component

5.1 Simulation of grid panel component

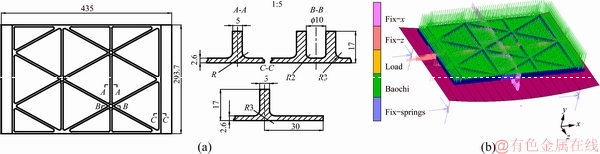

A 20 mm-thick panel was milled into the grid panel, as depicted in Fig. 9(a). The size of it was 435 mm × 294 mm × 17 mm. The skin was 2.6 mm thick, and the rib was 17 mm high and 5 mm wide.

Firstly, a 3D geometrical model was established according to size of the grid panel component. Then, shell element type was selected. Fillet, rib and hole features were simplified, as demonstrated in Fig. 9(b). The rigid mould was set with a radius of 1160 mm. The tensile stress-strain curve of the material was imported to the material property to simulate the elastoplastic nonlinear process during the loading process. To ensure full contact between the panel and the mould, the creep ageing time and pressure were set as 8 h and 0.45 MPa, respectively. For the purpose to study the influence of different constitutive models on panel ageing behavior, a constitutive model based on creep ageing experiment [14] and the stress relaxation constitutive model proposed in this work were incorporated into the age forming simulation model established by MSC.MARC through a user subroutine. In this way, ageing process of such stiffened panel could be simulated.

5.2 Ageing forming of grid panel component

The age forming experiment was conducted in an YT-13-03 autoclave. The temperature in the autoclave was set as 165 °C with a controlling accuracy of ±1.5 °C. Pressure of 0.45 MPa, ageing time of 8 h, mould material of Q235 and radius of 1160 mm were adopted. The experiment was divided into 3 stages: initial vacuum loading, ageing forming and springback. The specific operation is shown in Fig. 10.

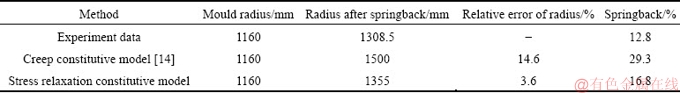

5.3 Springback prediction

For quantitative representation of component formation accuracy, radius method is adopted for calculating the springback:

S=(Rf-Ro)/Ro (14)

where Ro and Rf are outer surface radius after loading and after springback, accordingly. The smaller the springback is, the more accurate the formed plate is. After the experiment, grid panel radius after springback was measured by ATOS Compact Scan to compare with the simulated value. Comparisons are listed in Table 3.

According to Table 3, the relative error of radius simulated by the stress relaxation constitutive model is 3.6% as compared with the experimental result of panel grid after springback, with the springback being 16.8%. The relative error of radius simulated by the creep constitutive model is 14.6%, with the springback being 29.3%. Through the analysis of the simulation process, it is found that different parts of the component are under different stresses and node stress keeps decreasing during the ageing process, which is similar to the ageing process in the experiment. In the early stage, the pressure is applied to the component, and after entering the ageing stage, the panel is closely attached to the mould under the pressure. The total deformation of the component is invariable, and the internal part of the elastic deformation is transformed into permanent plastic deformation leading to continuous reduction of the initial stress. This process is closer to the stress relaxation ageing, implying that stress relaxation constitutive model predicts more accurately than creep constitutive model. However, since the simulation does not consider external factors of the actual experiment (variation of friction between the component and the mould, thermal expansion effect, temperature field distribution, etc), there is some deviation between the simulation and the experiment result. Nevertheless, the stress relaxation constitutive model is better in predicting the deformation quality of the panel component as compared with the creep ageing constitutive model.

Fig. 9 Grid panel size (a) and simulation model of grid panel component (b)

Fig. 10 Autoclave ageing forming procedure

Table 3 Comparison of different constitutive model simulation and experiments

6 Conclusions

(1) During the stress relaxation ageing process, the residual stress after the stress relaxation ageing increases along with the initial stress and the stress relaxation mainly takes place in the first 2 h.

(2) Before the alloy reaches the peak ageing state, the greater the initial stress is, the greater the yield strength is after the same ageing time. With the increase of initial stress, ageing time for the alloy to reach the peak strength would be shortened, which means that stress can promote ageing strengthening.

(3) Based on stress relaxation ageing experiment and microstructure observation, a micro-macro coupled stress relaxation ageing unified constitutive model is established to reflect shape and property evolution, and the accuracy of the model is verified by experiments and simulations.

(4) By comparing the simulated result with experiment data, simulation based on stress relaxation ageing constitutive model works out springback of 16.8%, post-formation radius of 1355 mm and the relative error of radius of 3.6%. Hence, the stress relaxation ageing constitutive model can provide an accurate estimate of the springback behavior of such stiffened panel during the ageing forming process.

References

[1] ZHAN Li-hua, YANG You-liang. Research on creep forming technology for large integrated component [J]. International Journal of Machine Tools & Manufacture, 2016, 59(13): 16-23. (in Chinese)

[2] XU Fu-shun, ZHANG Jin, DENG Yun-lai, ZHANG Xin-ming. Effect of pre-stretching on synchronization of shape and property in creep age forming of 2124 aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 1-7. (in Chinese)

[3] ZHANG Jin, DENG Yun-lai, LI Si-yu, CHEN Ze-yu, ZHANG Xin-ming. Creep age forming of 2124 aluminum alloy with single/double curvature [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 1922-1929.

[4] ZHAN Li-hua, ZHANG Jiao, JIA Shu-feng. Strength evolution rule and its model for stress ageing of 2219 aluminum alloy [J]. Journal of Central South University (Science and Technology), 2016, 47(7): 2235-2241. (in Chinese)

[5] QUAN Li-wei, ZHAO Gang, TIAN Ni, HUANG Ming-li. Effect of stress on microstructures of creep-aged 2524 alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2209-2214.

[6] YANG You-liang, ZHAN Li-hua, LI Jie. Constitutive modeling and springback simulation for 2524 aluminum alloy in creep age forming [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3048-3055.

[7] LI Yong, SHI Zhu-sheng, LIN Jian-guo, YANG Y L, RONG Qi, HUANG B M, CHUNG T F, TSAO C S, YANG J R, BALINT D S. A unified constitutive model for asymmetric tension and compression creep-ageing behaviour of naturally aged Al-Cu-Li alloy [J]. International Journal of Plasticity, 2017, 89: 130-149.

[8] LI Yong, SHI Zhu-sheng, LIN Jian-guo, YANG Y L, SAILLARD P, SAID R. FE simulation of asymmetric creep-ageing behaviour of AA2050 and its application to creep age forming [J]. International Journal of Mechanical Sciences, 2018, 140: 228-240.

[9] MA Zi-yao, ZHAN Li-hua, LIU Chun-hui, XU Ling-zhi, XU Yong-qian, MA Pei-pei, Li Jian-jun. Stress-level-dependency and bimodal precipitation behaviors during creep ageing of Al-Cu alloy: Experiments and modeling [J]. International Journal of Plasticity, 2018, 110: 183-201.

[10] HO K C, LIN J, DEAN T A. Constitutive modelling of primary creep for age forming an aluminium alloy [J]. Journal of Materials Processing Tech, 2004, 153-154(1): 122-127.

[11] IDEM K, PEDDIESON J. Simulation of the age forming process [J]. Journal of Manufacturing Science and Engineering, 2005, 127(1): 165-172.

[12] ZHAN Li-hua, MA Zi-yao, ZHANG Jiao, TAN Jing-sheng, YANG Zhan, LI Heng. Stress relaxation ageing behaviour and constitutive modelling of a 2219 aluminium alloy under the effect of an electric pulse [J]. Journal of Alloys and Compounds, 2016, 679: 316-323.

[13] ZHENG Jing-hua, LIN Jian-guo, LEE J, PAN Ran, LI Chen, DAVIES C M. A novel constitutive model for multi-step stress relaxation ageing of a pre-strained 7xxx series alloy [J]. International Journal of Plasticity, 2018, 106: 31-47.

[14] YANG You-liang, ZHAN Li-hua, SHEN Ru-lin, LIU Jian, LI Xi-cai, HUANG Ming-hui, HE Di-qiu, CHANG Zhi-long, MA Yun-long, WAN Li. Investigation on the creep-age forming of an integrally-stiffened AA2219 alloy plate: Experiment and modeling [J]. International Journal of Advanced Manufacturing Technology, 2018, 95: 2015-2025.

[15] GRONG F, MYHR O R. Additivity and isokinetic behaviour in relation to diffusion controlled growth [J]. Acta Materialia, 2000, 48: 445-452.

[16] LIU G, ZHANG G J, DING X D, SUN J, CHEN K H. Modeling the strengthening response to aging process of heat-treatable aluminum alloys containing plate/disc- or rod/needle-shaped precipitates [J]. Materials Science and Engineering A, 2003, 344: 113-124.

[17] QUAN Li-wei, FANG Da-ran. Role of elastic stress on the precipitate in Al-Cu alloy and the corresponding modeling [J]. Rare Metal Materials and Engineering, 2016, 45(12): 3245-3249. (in Chinese)

[18] ZHANG Jin, DENG Yun-lai, ZHANG Xin-ming. Constitutive modeling for creep age forming of heat-treatable strengthening aluminum alloys containing plate or rod shaped precipitates [J]. Materials Science and Engineering A, 2013, 563: 8-15.

[19] MOORE K T, HOWE J M. Characterization of γ plate-shaped precipitates in an Al-4.2at.%Ag alloy-Growth kinetics, solute field, composition and modeling [J]. Acta Materialia, 2000, 48(16): 4083-4098.

[20] XU Fu-shun, ZHANG Jin, DEGN Yun-lai, ZHANG Xin-ming. Precipitation orientation effect of 2124 aluminum alloy in creep aging [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2067-2071.

[21] NIE J F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys [J]. Scripta Materialia, 2003, 48: 1009-1015.

[22] YE Yi, YIN Chen-bo, GONG Yue, ZHOU Jun-jing. Position control of nonlinear hydraulic system using an improved PSO based PID controller [J]. Mechanical Systems and Signal Processing, 2017, 83: 241-259.

汪 凯1,2,湛利华1,2,杨有良1,2,马子尧1,2,李喜财1,2,刘 健1,2

1. 中南大学 机电工程学院,长沙 410083;

2. 中南大学 高性能复杂制造国家重点实验室,长沙 410083

摘 要:通过应力松弛时效实验和有限元仿真研究预变形2219铝合金应力松弛行为。结果表明:应力能促进时效析出进程,缩短到达峰值强度的时间。且初始应力越大,时效后的剩余应力越高,合金的屈服强度越大。基于显微组织演变和时效强化理论建立统一本构模型,并通过子程序开发将其嵌入有限元仿真模型中。发现仿真回弹后的半径与实验值间的相对误差为3.6%,回弹为16.8%。从而可知,所建立的应力松弛时效本构模型能较好预测带筋壁板时效过程中的回弹行为。

关键词:2219铝合金;应力松弛时效;统一本构模型;回弹

(Edited by Bing YANG)

Foundation item: Project (2017YFB0306300) supported by the National Key Research and Development Program of China; Project (2014CB046602) supported by the National Basic Research Program of China; Project (20120162110003) supported by Specialized Research Fund for the Doctoral Program of Higher Education of China; Project (51235010) supported by the National Natural Science Foundation of China

Corresponding author: Li-hua ZHAN; Tel: +86-731-88830254; E-mail: yjs-cast@csu.edu.cn

DOI: 10.1016/S1003-6326(19)65023-5