文章编号:1004-0609(2008)11-1971-06

Ag对Al-Cu-Mg合金拉伸延性的影响

宋 旼,吴正刚,贺跃辉,黄伯云

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:通过实验和理论计算研究Al-Cu-Mg-(Ag)合金的拉伸延性。研究表明:Al-Cu-Mg-(Ag)合金的拉伸延性与析出相的体积分数和尺寸有重要关系;析出相体积分数的增加将减小位错的有效滑移距离,从而降低合金的拉伸延性;在时效过程中,合金的拉伸延性首先随着时效时间的延长而降低,达到时效峰值后,拉伸延性随着时效时间的进一步延长而增大;Ag的加入可以提高Al-Cu-Mg合金中析出相的体积分数和强度,但降低合金的拉伸延性;通过控制时效时间虽然可以提高合金的拉伸延性,但同时将降低合金的屈服强度。

关键词:Al-Cu-Mg-(Ag)合金;拉伸延性;时效;几何滑移距离

中图分类号:TG 249.9 文献标识码:A

Effects of Ag on tensile ductility of Al-Cu-Mg alloy

SONG Min, WU Zheng-gang, HE Yue-hui, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The tensile ductility of Al-Cu-Mg-(Ag) alloys was studied through both experiments and theoretical calculations. The results show that the tensile ductility of Al-Cu-Mg-(Ag) alloys has important relationship with the volume fraction and size of the precipitates. The increase of volume fraction of precipitates decreases the effective geometric slip distance, and thus degrades the tensile ductility. During aging, the tensile ductility of Al-Cu-Mg-(Ag) alloys decreases with aging time at the beginning, but increases with increasing aging time after the alloy reaches the peak-aged stage. The Ag addition can improve the volume fraction of the precipitates and thus the tensile ductility, but it will degrade the strength of Al-Cu-Mg-(Ag) alloys. Although the controlling of the aging time can improve the tensile ductility, it will inevitably decrease the yield strength of the alloy.

Key words: Al-Cu-Mg-(Ag) alloy; tensile ductility; aging; geometric slip distance

由于Al-Cu-Mg合金具有高比强度和低密度,已被广泛应用于航天航空领域[1]。微合金化作为提高力学性能的一种重要手段,被广泛应用于Al合金中,例如在Al-Cu-Mg合金中加入少量的Ag可以同时提高合金的室温和高温强度[2?4]。这是因为Ag的加入改变了合金的时效序列,传统Al-Cu-Mg合金的时效序列可表示为:GP区(沿{100}面偏聚)→θ′′→θ′→θ,而Ag的加入使得合金的时效序列改变为:GPB区(沿{111}面偏聚)→Ω→θ。由于Ω相比θ′相有更高的密度和更好的抗粗化性能,含Ag的Al-Cu-Mg合金具有更高的强度。宋旼等[5]的研究表明,当合金中同时存在Mg和Ag元素时,Mg和Ag元素将强烈地相互吸引形成原子簇,使得Mg原子沿基体的{111}面偏聚(Mg原子簇)。Mg原子簇在Al基体中将会产生负畸变区,从而促进Cu原子沿基体{111}面上偏聚,以减低给基体带来的晶格畸变,从而使得Mg原子簇成为Ω相的优先形核区域,抑制θ′相的形核。然而,尽管Ag的加入可以提高合金的强度,但却不可避免地降低合金的拉伸延性[6?7]。早期的实验研究可以描述由于Ag的加入造成的合金拉伸延性降低的现象,但是不能给出拉伸延性随合金化学成分、时效规程演变规律的物理本质,不具备普适性。因此,发展相关的力学模型描述Al-Cu-Mg-(Ag)合金拉伸延性和断裂韧性的演变规律,对于指导设计同时具有高强度和高延性的Al-Cu-Mg-(Ag)合金有着重要的意义。

HAHN和ROSENFIELD[8]、THOMPSON[9]和ASHBY[10]的研究指出:结晶相、弥散相和析出相对铝合金的拉伸延性有着重要的影响。粗大的脆性结晶相的断裂强度低,在变形过程中由于应力集中将断裂形成微裂纹,从而降低合金的拉伸延性。而弥散相和析出相可以通过改变位错的几何滑移距离(即相邻强化相之间的间距),在提高强度的同时降低合金的拉伸延性。最近,宋旼等发展了Al-Cu-Mg合金[11?12]和SiC增强铝基复合材料拉伸延性和断裂韧性的力学模 型[13?15],用以预测合金及复合材料拉伸延性和断裂韧性随合金化学成分、时效时间和温度的演变规律。本文作者采用上述模型研究Ag对Al-Cu-Mg合金拉伸延性的影响规律,为合理设计Al-Cu-Mg-(Ag)合金提供理论参考。

1 模型简述

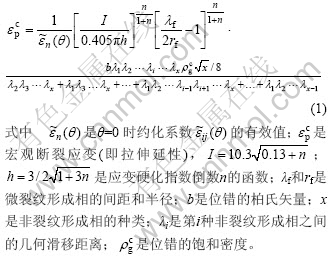

将本文作者发展的模型[11?15]一般化,则任意一种多相材料的拉伸延性可表示为

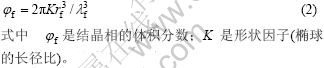

对于Al-Cu-Mg-(Ag)合金来说,微裂纹形成相为结晶相,而非裂纹形成相则为析出强化相。粗大的脆性结晶相来源于凝固过程中合金中的Fe和Si杂质与过量的合金元素或Al基体的结合物,通常尺寸为1~30 μm,体积分数为1%~5%[8?9]。由于结晶相多为椭球形,其间距、半径和体积分数之间的关系可表示为

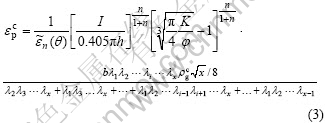

(椭球的长径比)。将式(2)代入式(1)可得:

Al-Cu-Mg-(Ag)中的析出相包括几种:含Ag合金中的析出相为Ω亚稳相,不含Ag合金中的析出相包括欠时效阶段的θ′亚稳相和过时效阶段的θ稳定相。θ′和Ω亚稳相均为片状,而θ稳定相为球形。ASHBY[10]指出:对于球形析出相,几何滑移距离可表示为

假定在某一个特定的时效时间合金中只存在一种析出相,则式(3)可简化为

如果定义 为参考的拉伸延性,则用

为参考的拉伸延性,则用 除以

除以 可以得到约化的断裂应变比,或约化的拉伸延性比:

可以得到约化的断裂应变比,或约化的拉伸延性比:

2 实验

合金的名义化学成分列于表1。其中合金1不含Ag,而合金2含0.6%Ag。合金在充氩气的感应炉中熔炼而成,经500 ℃均匀化退火10 h后,空冷至室温。在450 ℃下采用挤压比为18的工艺,热挤压成棒材,挤压棒在450 ℃下固溶处理1 h,随即水淬,经轻微预拉伸(约1%)后棒材在185 ℃下时效不同的时间。

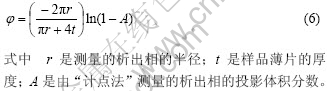

测量时效后样品的维氏硬度。采用单轴拉伸测量合金的拉伸延性,拉伸实验标样尺寸为d 5 mm×25 mm,在岛津AG?100KNA实验机上进行,所有的试样均沿挤压方向,拉伸应变速率为10?4 /s。采用透射电子显微镜由“计点法”测量合金时效至不同时间后析出相的尺寸和体积分数。透射电子显微镜为JEM-100XII型,操作电压为100 kV。样品在?35 ℃下由电解双喷制成,电解液为30%硝酸和70%的甲醇。在测量析出相的尺寸和体积分数时,至少测量100个随机的析出相的尺寸,然后取平均值。由于析出相的尺寸与电镜薄片的厚度相当[16],析出相的体积分数( )需要进行修正[17]:

)需要进行修正[17]:

表1 合金的名义化学成分

Table 1 Chemical composition of present alloys

3 实验结果

3.1 合金的时效硬化

图1所示为两种合金的维氏硬度曲线。从图1可以看出,两种合金的维氏硬度随时效时间的变化趋势类似。在时效早期,合金的维氏硬度随时效时间的增加而增大,时效13 h后合金的维氏硬度达到峰值,然后下降,表明进入过时效阶段。在同样的时效时间下,合金2的维氏硬度总是高于合金1的维氏硬度,这表明Ag的加入提高了合金的时效硬化能力,即提高了合金的强度。

图1 185 ℃时时效不同时间后两种合金的维氏硬度

Fig.1 Hardness curves of present alloys aged at 185 ℃ for different times

3.2 合金的显微组织

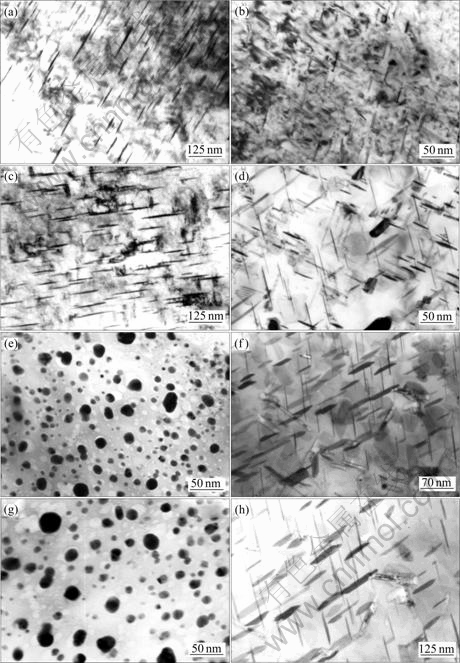

图2所示为两种合金分别时效4、13、16及20 h后的显微组织。由图2可知,不含Ag的合金在时效的早期(4 h)析出片状的θ′相,长度约为80 nm。这种片状相分布在基体的{001}面上并沿<001>方向分布,与基体相连的界面为共格或半共格。当达到峰值时效(13 h)时,θ′片状相长大到约125 nm,片与片之间的间距减小。当时效时间达到16 h后,θ′相发生共格失稳而演化成与基体不共格的球状θ相。进一步延长时效时间(20 h),球状的θ相尺寸粗化,并且间距加大。

图2 时效温度为185 ℃时两种合金在不同时效时间下的析出相

Fig.2 Precipitates after different aging times for two types of alloys at 185 ℃: (a) Alloy without Ag, 4 h; (b) Alloy with Ag, 4 h; (c) Alloy without Ag, 13 h; (d) Alloy with Ag, 13 h; (e) Alloy without Ag, 16 h; (f) Alloy with Ag, 16 h; (g) Alloy without Ag, 20 h; (h) Alloy with Ag, 20 h

含Ag的合金在时效的早期(4 h)也析出片状相,长度约为40 nm。这些片状相可以分为两种:1种为θ′相;另1种为Ω相。两种相与基体相连的界面均为共格或半共格。Ω相和θ′相析出在基体的同一位置并有着1个特殊的方向关系:1个θ′片析出在基体的{001}面上并沿<001>方向,同时2个Ω片分别析出在基体的{111}面上并沿<111>方向分布。当达到峰值时效(13 h)时,θ′和Ω相均有一定程度的长大,与基体的界面更加明显。进一步延长时效时间(16和20 h),θ′和Ω相均发生明显长大,其长度增加,片层变厚。然而,这两种析出相仍然保持片状,与基体没有发生共格失稳,θ′和Ω相也没有演化成θ相。

为表征析出相尺寸的整体变化(沿不同方向的尺寸变化),定义 为析出相的标准尺寸,其中ds和dl分别为析出相沿最小和最大方向的尺寸。对于片状析出相来说,ds和dl分别为析出相的厚度和直径,对于球形析出相来说,ds=dl为析出相的直径。图3所示为两种合金中析出相的标准尺寸和体积分数随时效时间的演变规律。由图3可知,两种合金中析出相的尺寸和体积分数在时效的早期随着时效时间的增加而增加(欠时效阶段),当时效时间达到13 h(峰值时效)时,析出相的体积分数达到最大值;随着时效时间的进一步延长,体积分数不再增加,但析出相尺寸继续增大。在相同时效时间下,含Ag合金中析出相的体积分数总是比不含Ag的合金大,而析出相的尺寸则小很多。

为析出相的标准尺寸,其中ds和dl分别为析出相沿最小和最大方向的尺寸。对于片状析出相来说,ds和dl分别为析出相的厚度和直径,对于球形析出相来说,ds=dl为析出相的直径。图3所示为两种合金中析出相的标准尺寸和体积分数随时效时间的演变规律。由图3可知,两种合金中析出相的尺寸和体积分数在时效的早期随着时效时间的增加而增加(欠时效阶段),当时效时间达到13 h(峰值时效)时,析出相的体积分数达到最大值;随着时效时间的进一步延长,体积分数不再增加,但析出相尺寸继续增大。在相同时效时间下,含Ag合金中析出相的体积分数总是比不含Ag的合金大,而析出相的尺寸则小很多。

3.3 合金的拉伸延性

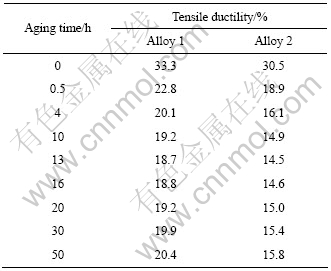

表2所列为实验测得合金的拉伸延性与时效时间的关系。由表可知:拉伸延性在时效的早期随着时效时间的增加而降低,当时效达到峰值后,拉伸延性开始增加。这种拉伸延性随时效时间的演变规律与合金在时效过程中的显微组织演变密切相关。如图3所示,在欠时效阶段,析出相的体积分数和尺寸增大,不可避免地减小相邻析出相之间的间距,从而减小位错的有效滑移距离,因此,合金的拉伸延性降低。当合金时效至峰值时,析出相达到饱和,基体的过饱和状态消失,析出相的体积分数保持不变。由于析出相与基体存在界面能,较大的析出相继续长大,而较小的析出相则消失,因此相邻析出相的间距和位错的有效滑移距离增加,合金的拉伸延性也相应增加。这种拉伸延性随时效时间的变化规律与合金屈服强度随时效时间的变化规律基本相反。一般来说,对于时效可硬化铝合金,屈服强度随着时效时间的增加先增加,达到峰值后开始下降,进入过时效阶段。从表3同时可以看出,在相同的时效时间下,含Ag合金的拉伸延性要低于不含Ag的合金的拉伸延性。

图3 析出相的标准尺寸和体积分数随时效时间的演变规律

Fig.3 Relation between standard size(a) and volume fraction(b) of precipitates and aging time

表2 时效不同时间后合金的拉伸延性

Table 2 Tensile ductilities of alloys after aging treatment

4 模型计算与实验结果的比较

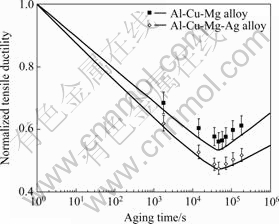

图4所示为模型计算以及实验测得的约化拉伸延性随时效时间的变化趋势,计算所用的析出相的体积分数和析出相的尺寸采用图3的数据。由图4可知,计算的约化拉伸延性随时效时间的演变规律和实验结果吻合很好。在时效的早期,约化拉伸延性随着时效时间的增加而下降。当时效至峰值后,约化拉伸延性达到最小值。随着时效时间的继续增加,约化拉伸延性开始增加。这种变化趋势与大多数时效可硬化铝合金类似,即在欠时效阶段铝合金的拉伸延性随时效时间的增加而下降,在过时效阶段铝合金的拉伸延性随时效时间的增加而增加。这种现象已在前面进行讨论,即在欠时效阶段,析出相的体积分数和尺寸增大,减小相邻析出相之间的间距和位错的有效滑移距离,从而降低合金的拉伸延性;在过时效阶段,析出相的体积分数保持不变,而平均尺寸增加,这增加相邻析出相的间距和位错的有效滑移距离,从而提高合金的拉伸延性。 从力学角度来说,变形过程中当位错密度在材料中的某一处达到饱和时,材料开始出现失稳变形,即合金已不能容纳更多的位错,此时材料在饱和位错密度区(一般是在强化相与基体相连的界面)形成裂纹以释放能量。当位错的几何滑移间距减小时,位错在小的滑移区内更容易达到饱和位错密度,即在变形量较小时就会开始出现失稳变形(对于单轴拉伸即出现缩颈),从而有较小的拉伸延性。因此,对于时效可强化的铝合金而言,在时效过程中拉伸延性的变化趋势直接取决于析出相的体积分数和尺寸。

图4 实验测定以及模型计算的约化拉伸延性随时效时间的变化趋势

Fig.4 Measured and predicted normalized tensile ductilities of Al-Cu-Mg-Ag alloy with aging time

由图4可知,早期发展的多相材料的多尺度延性模型适用于Al-Cu-Mg-(Ag)合金。这种模型可以用来量化材料延性与显微组织的关系(析出相的含量和尺寸)。从模型的解析和实验结果可知,时效过程中屈服强度和拉伸延性是相互矛盾的,控制合金在欠时效阶段或过时效阶段虽然可以提高合金的拉伸延性,但是将不可避免地降低合金的屈服强度。因此,通过增加合金元素来提高强度的手段同时将伴随着伸长率下降的现象。

5 结论

1) 模型的计算结果与实验数据吻合很好。Al-Cu- Mg-(Ag)合金的拉伸延性与时效过程中析出相的体积分数和尺寸有重要关系,析出相主要通过改变位错的几何滑移距离来影响合金的拉伸延性。Ag的加入可以提高Al-Cu-Mg合金中析出相的体积分数,从而提高合金的强度,但将不可避免地减小位错的几何滑移距离,从而降低合金的拉伸延性。

2) 在时效过程中,合金的拉伸延性首先随着时效时间的延长而降低,达到时效峰值后,拉伸延性随着时效时间的进一步延长而增大。在欠时效阶段,析出相的体积分数和尺寸增大,减小相邻析出相之间的间距和位错的有效滑移距离,从而降低合金的拉伸延性;在过时效阶段,析出相的体积分数保持不变,而平均尺寸增加,增加相邻析出相的间距和位错的有效滑移距离,从而提高合金的拉伸延性。

REFERENCES

[1] HATCH J E. Aluminum: properties and physical metallurgy[M]. Metals Park, OH: ASM Press, 1983: 90.

[2] POLMEAR I J, CHESTER R J. Abnormal age hardening in an Al-Cu-Mg alloy containing silver and lithium[J]. Scripta Metall, 1989, 23(7): 1213?1217.

[3] SONG Min, CHEN Kang-hua, HUANG Lan-ping. Effects of Ag addition on mechanical properties and microstructures of Al-8Cu-0.5Mg alloy[J]. Trans Nonferrous Met Soc China, 2006, 16(4): 766?771.

[4] DESHPANDE N U, GOKHALE A M, DENZER D K, LIU J. Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: Part I. Quantitative characterization[J]. Metall Mater Trans A, 1998, 29(4): 1191?1201.

[5] SONG Min, XIAO Dai-hong. Effects of Mg and Ag elements on the aging precipitation of binary Al-Cu alloy[J]. Science in China E, 2006, 49(5): 582?589.

[6] XIAO D H, WANG J N, DING D Y, CHEN S P. Effect of Cu content on the mechanical properties of an Al-Cu-Mg-Ag alloy[J] . Journal of Alloys and Compounds, 2002, 343(1/2): 77?81.

[7] 杨海龙, 王健农, 肖代红, 丁冬雁. 新型耐热铝合金Al-Cu-Mg-Ag棒材固溶处理温度的研究[J] . 兵器材料科学与工程, 2003, 26(1): 16?18.

YANG Hai-long, WANG Jian-nong, XIAO Dai-hong, DING Dong-yan. Study on solution heat treatment temperature of new Al-Cu-Mg-Ag alloy[J]. Ordnance Material Science and Engineering, 2003, 26(1): 16?18.

[8] HAHN G T, ROSENFIELD A R. Metallurgical factors affecting fracture toughness of aluminum alloys[J]. Metall Trans A, 1975, 6: 653?668.

[9] THOMPSON D S. Metallurgical factors affecting high strength aluminum alloy production[J]. Metall Trans A, 1975, 6: 671?683.

[10] ASHBY M F. The deformation of plastically non-homogeneous materials[J]. Phil Maga, 1970, 21: 399?424.

[11] SONG M, CHEN K H, QI X W, HUANG L P. A multi-scaled model for the fracture toughness of an aluminum alloy[J]. J Mater Sci, 2007, 42(12): 4177?4282.

[12] 宋 旼, 袁铁锤, 张福勤, 黄伯云, 陈康华. Al-Cu-Mg合金的断裂韧性及拉伸延性模拟[J]. 中国有色金属学报, 2007, 17(7): 1034?1040.

SONG Min, YUAN Tie-chui, ZHANG Fu-qin, HUANG Bai-yun, CHEN Kang-hua. Modeling on fracture toughness and tensile ductility of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1034?1040.

[13] SONG M, HUANG M. Experimental and modeling of the coupled influences of variously sized particles on the tensile ductility of SiCp/Al metal matrix composites[J]. Metall Mater Trans A, 2007, 38(9): 2127?2137.

[14] SONG M, XIAO D H. Modeling the fracture toughness and tensile ductility of SiCp/Al metal matrix composites[J]. Mater Sci Eng A, 2008, 474(1/2): 371?375.

[15] SONG M, HUANG B. Effects of particle size on the fracture toughness of SiCp/Al alloy metal matrix composites[J]. 2008, 488(1/2): 601?607.

[16] EDINGTON J W. Practical electron microscopy in materials science[M]. London: Von Norstrand Reinhold Company, 1976: 207.

[17] CROMPTON J M G, WAGHORNE, R M, BROOK G B. The estimation of size distribution and density of precipitates from electron micrographs of thin foils[J]. Br J Appl Phys, 1966, 17: 1301?1305.

基金项目:湖南省自然科学基金资助项目(07JJ3117);中国博士后科学基金资助项目(20070410303)

收稿日期:2008-04-24;修订日期:2008-06-02

通讯作者:宋 旼,副研究员,博士;电话:0731-8877880;传真:0731-8710855;E-mail: msong@mail.csu.edu.cn

(编辑 龙怀中)